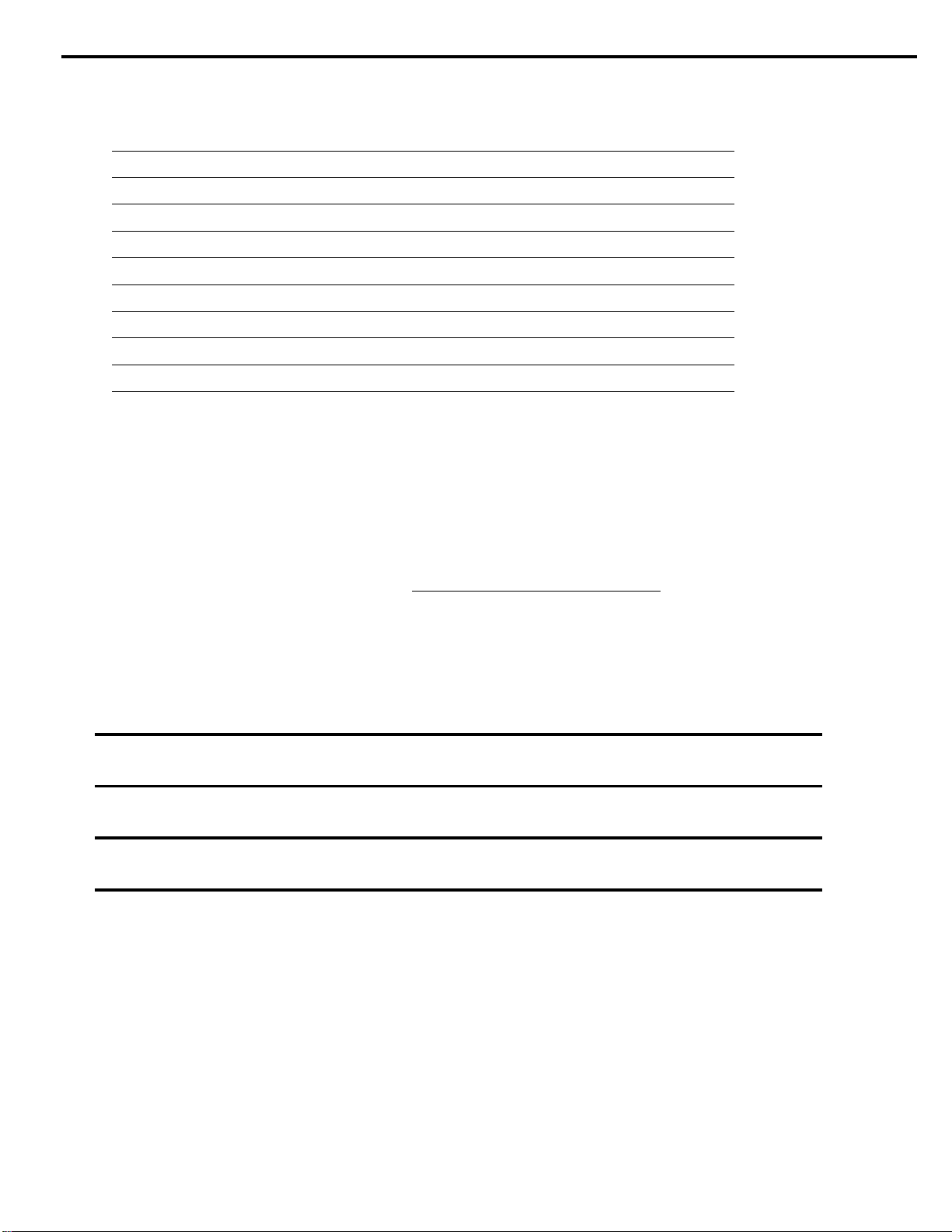

To avoid serious injury or death,

keep people away from the loader and attachment

when in use. The attachment can drop trees and

limbs in unpredictable directions. Make sure

there are no people, power lines, buildings, or

other objects that could be in the fell zone. Never

cut trees that could fall into these objects. Loader

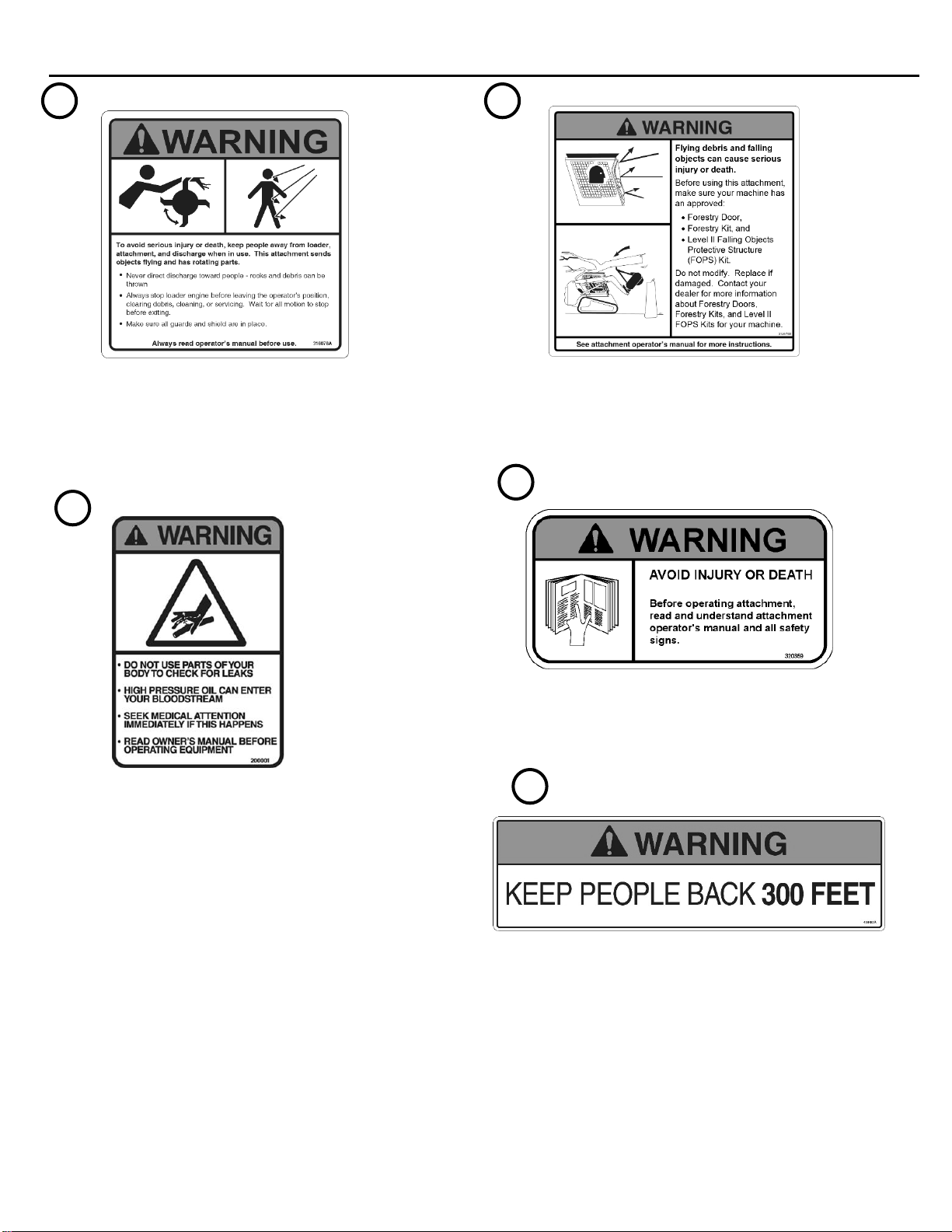

must be equipped with approved Forestry Door,

Forestry Kit, and Level II Falling Object Protective

Structure (FOPS) Kit.

IMPORTANT: Before operating the attachment,

perform the service schedule for routine maintenance.

IMPORTANT: Certain materials can wrap around

parts of the attachment or cause other damage. Avoid

contacting materials like: metal wire, hoses, ropes,

tarps, mattresses, rugs, or plastics.

IMPORTANT: Certain land features can cause

damage. Inspect the cutting area and avoid

obstructions like drop offs, holes, rocks, debris, etc.

1. With the operator in the seat of the loader, the

seat belt fastened and the seat bar lowered (if

so equipped), start the engine.

2. With the loader boom lowered completely,

mulcher deck tipped back 0 to 10 degrees and

engine at low idle, activate the auxiliary

hydraulic system to start the disc rotation. Make

sure auxiliary hydraulic circuit is operating in the

High Flow mode. It can take up to 45 seconds

for the disc to spin up to full speed if starting

from a dead stop.

IMPORTANT: The attachment is designed to

operate from 33 to 45 gpm. Operating at higher flow

rates can cause serious damage to the mulching

head and will void the warranty.

IMPORTANT: Do not operate the attachment if

excessive vibration is present. Serious damage can

occur. Check to make sure that there is not debris

lodged between the teeth.

NOTE: Certain loaders may not operate in high flow

mode without a special wire harness. Others require

the control switches to be operated in a specific way.

It may also be necessary to switch the hose couplers

around to match your loader. (See loader’s

operator’s manual)

Mulching Trees Larger than 6”

1. First, you must decide if you can mulch the

standing tree as one piece, based on the trunk

diameter. If more than 6” diameter, use the

procedure below.

2. Cut the tree off between 0 and 3 feet above the

ground to minimize the chance of accidental

ingestion into the mulching chamber.

Always keep the attachment

low and slightly tilted back so that you are not

exposed to flying debris

3. Maintain pressure on the tree with the push bar

while you cut so the tree falls away from you.

4. Once on the tree has fallen, grind the remaining

standing portion using the teeth on the bottom of

the disc. Then proceed to mulch the limbs of the

tree either from the side or while straddling the

tree trunk.

5. For trees that are somewhat straight, you can cut

the top off and try to ingest that as one piece if it

is smaller than 6” diameter. To do this, straddle

the tree with the front of the deck angled down

slightly and drive forward while lowering the deck

onto the tree. Make sure you don’t try to ingest

such a large portion of the tree that it plugs the

mulcher. Keep the tree trunk between the 12

o’clock and 2 o’clock position on the disc for best

results.

6. For the trunk portion of the tree, use the teeth on

the bottom and edge of the disc to grind away

successive layers of material. You will need to

pause briefly after each cut to allow the disc to

speed up again. It usually works best to

approach the tree from the bottom end

NOTE: The type of wood being cut, available

horsepower and the ground conditions will determine

the best ground speed and cutting procedure.

IMPORTANT: While this attachment has been

designed to handle the extreme loads associated with

mulching whole trees, every machine has its limits.

Due to the large amount of spinning mass and high

speed of the disc, the operator must use care not to

ingest pieces of tree trunk larger than 10” diameter, as

this could overload the spindle. Any spindle damage

is considered to be the result of operator abuse, and

is not covered under warranty.