IMPORTANT: The mini snow blade is designed for

moving snowand lightmaterial only. It is not designed

for shaping or grading soil.

Snow Removal

1. With the operator in the seat of the loader, the seat

belt fastened, and the seat bar lowered (if so

equipped), start the engine.

2. With the loader lift arms fully lowered, tilt the

attachment forward to rest on the skid shoes.

3. Drive the loader forward to push snow.

4. Use the loader lift and tilt functions to increase

traction and adjust the pitch of the attachment.

5. On manual angling models, stop the loader, turn

off the engine, and engage the park brake. Then

remove the angle lock pin, push the blade to the

desired angle, and reinstall the pin in the nearest

pin hole location.

6. On hydraulic angling models, activate the auxiliary

hydraulics to angle the attachment left or right to

the desired position.

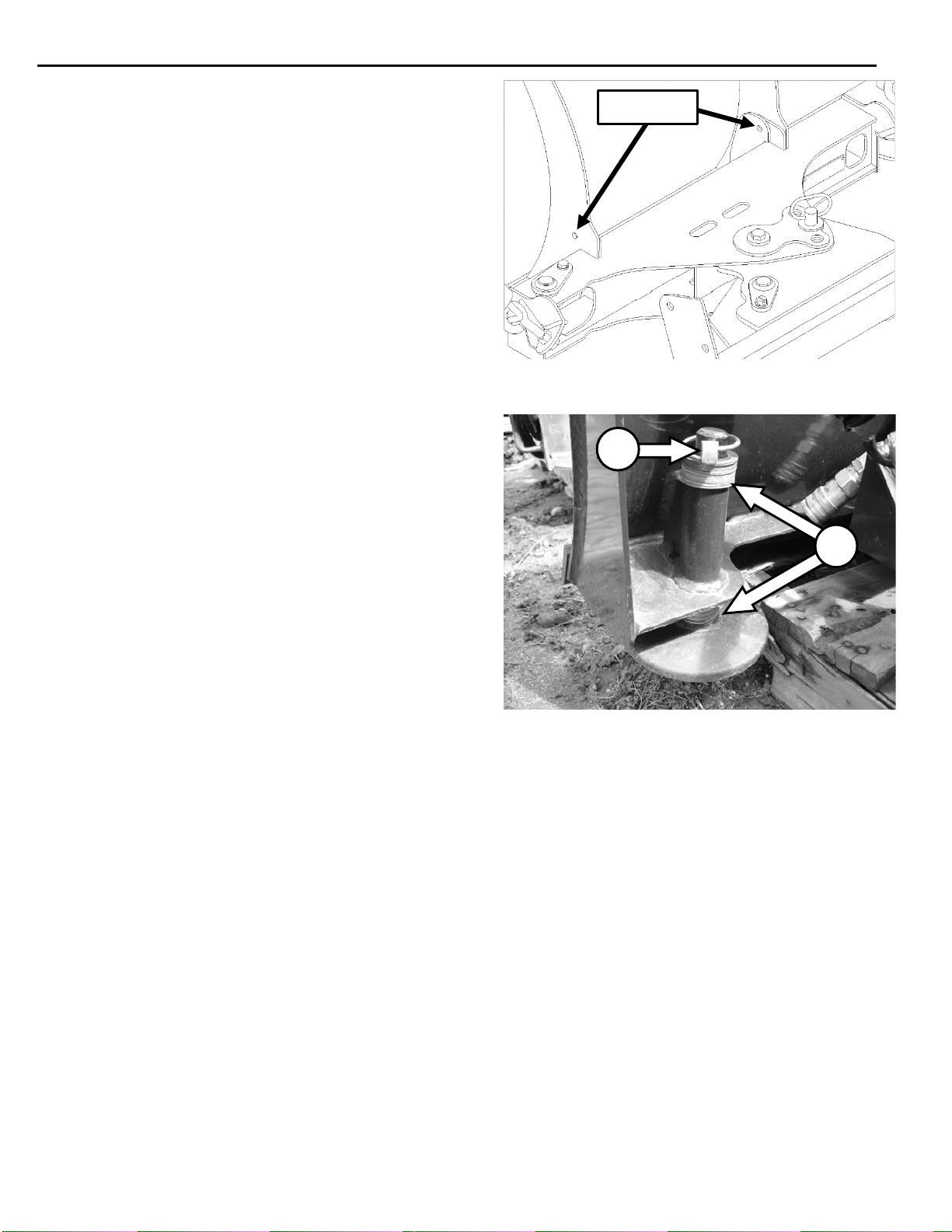

Trip Springs

The mini snow blade is equipped with trip springs that

allow the moldboard to tilt forward when the cutting

edge strikes an obstruction. This helps protect the

attachment and the obstruction from damage.

To reset the trip springs after striking an obstruction,

raise the loader lift arms to lift the attachment slightly

off of the ground, or slowly drive the loader backward

a few feet.

The trip spring tension can be adjusted by tightening

or loosening the eye bolts. Make sure the tension of

both springs is about the same.