ertex solar VSG Series User manual

VSG

Ertex Solartechnik GmbH Tel. +43/7472/28260-610 Page 1 of 7

A3300 Amstetten

Installation Manual

Ertex solar VSG Module

Table of Content:

1 Introduction............................................................................................................................... 2

2 General handling of the modules....................................................................................... 2

3 Product marking, type plate................................................................................................. 2

4 Specification............................................................................................................................. 3

5 Installation instructions/safety instructions .......................................................... 3/4

6 Mounting modules.................................................................................................................. 4

7 Electrical wiring for the system as a whole .....................................................................5

7.1. Plug-in connectors.......................................................................................................... 5

7.2. Laying the solar cables................................................................................................... 5

7.3. Electrical connection....................................................................................................... 5

8 Commissioning the system.................................................................................................. 6

9 Maintenance ..............................................................................................................................6

10 Certificates................................................................................................................................6

VSG

Ertex Solartechnik GmbH Tel. +43/7472/28260-610 Page 2 of 7

A3300 Amstetten

1 Installation instructions/safety instructions

Please read these installation instructions carefully before installing the photovoltaic modules. Failure to

do so can lead to personal injury or damage to property and may invalidate the warranty and product

guarantee.

Installing photovoltaic modules requires expertise and should therefore only be performed by

appropriately qualified and approved contractors. The exporting company is responsible for structural

measures and approvals. Ertex Solar Technik GmbH assumes no liability regarding approval and

building permits.

General handling of the product, its use or precise installation methods are outside the scope of

influence of Ertex Solartechnik GmbH. For this reason Ertex cannot accept any liability for damage,

losses or costs incurred due to incorrect installation or handling of the product or due to incorrect usage.

2 Information on general handling of the modules

Do not open or dismantle the module.

Do not remove any module components.

Do not remove or damage any product labels or type plates.

Do not stand on the module.

Do not drop the module.

Avoid all other kinds of external force.

Do not expose the module to paint, dyes, adhesives, chemicals or other corrosive liquids.

Do not transport the module by its junction box.

Do not pull the module connection cables with any force.

Artificially beaming, focussing, concentrating or reflecting sunlight onto the module is not

admissible.

Never try to service the electrical wiring yourself - always contact your specialist

photovoltaic dealer in the event of any problems.

Observe the maximum system voltage of 1000 V when connecting the modules.

You will find detailed electrical and mechanical properties for each photovoltaic module

under standard test conditions (STC) on the module type plate and on the respective

datasheet. Under real-life conditions, there may be circumstances in which the module

can produce considerably higher values than specified in the above. The values under

STC must therefore be increased by 25 % for system calculation purposes and when

sizing the components.

3 Product marking, type plate

VSG

Ertex Solartechnik GmbH Tel. +43/7472/28260-610 Page 3 of 7

A3300 Amstetten

The type plate is located on the rear of the module and provides information on all the

necessary key electrical and product-specific values.

The type plate must not be damaged or removed, as this will irrevocably invalidate the

warranty and product guarantee.

4 Ertex VSG specification

Electrical data applies under standard test conditions (STC).

Insolation 1000 W/m², AM 1.5 spectrum, cell temperature 25 °C

Electrical data

Module type VSG xxx

Output class

330

335

340

345

350

Rated output (P):

330 Wp

335 Wp

340 Wp

345 Wp

350 Wp

Rated voltage (Vmpp):

45.20 V

45.27 V

45.33 V

45.39 V

45.45 V

Rated current (Impp):

7.30 A

7.40 A

7.50 A

7.60 A

7.70 A

Open circuit voltage (Uoc):

59.10 V

59.19 V

59.28 V

59.35 V

59.42 V

Short-circuit current (Isc):

7.80 A

7.88 A

7.95 A

8.02 A

8.1 A

Output fluctuation

± 3 %

± 3 %

± 3 %

± 3 %

± 3 %

Temperature coefficient

Voltage:

-0.20 %/K

Current:

0.05 %/K

Power:

-0.43 %/K

Reverse current carrying capacity: The modules can only be operated with external power

when using a line fuse with a tripping current <16 A ISC@STC. The individual modules may

only be connected in series up to the maximum system voltage.

Application class A as per IEC 61730

Operating temperature: -40 to +80 °C / wind speed: 135 km/h / maximum system

voltage: 1000 V

5 Installation instructions/safety instructions for VSG modules

It is essential to cover the individual modules with blackout material during installation.

The modules generate electricity as soon as the front side is exposed to light. It does

not matter whether or not the module has already been connected. This effect can lead

to voltages which can be life-threatening under certain circumstances!

Do not touch the ends of cables (especially exposed cables) during installation.

Never operate photovoltaic modules in or in the vicinity of rooms in which flammable

liquids are stored or used or into which they may leak.

When photovoltaic modules are connected in series, only use modules with the same

current intensity, and when modules are connected in parallel, only use modules with

the same voltage.

VSG

Ertex Solartechnik GmbH Tel. +43/7472/28260-610 Page 4 of 7

A3300 Amstetten

The modules may not be operated with a higher voltage than the admissible system

voltage.

The maximum number of modules which can be connected in series can be worked out

from the maximum input voltage/input current range of the inverters/charge regulators

used, the type of module used and local temperature conditions. Under no

circumstances may the system voltage of 1000 V be exceeded.

The maximum reverse current carrying capacity is 16 A. If more than two strings are

connected in parallel, this may be exceeded in the event of a fault, which is why line

fuses with a maximum of 16 A should be used.

Please observe the applicable wind force, wind speed and snow load factors for the

respective region. Static calculations may need to be performed in certain cases.

Always ensure that the modules have sufficient secondary ventilation.

To ensure that the photovoltaic system achieves an optimum yield, please also

establish the most suitable orientation and angle of inclination of the photovoltaic

modules.

Shading leads to reduced yields, so make sure that the photovoltaic modules are free

from shadows all year round.

Shading leads to:

oreduction of yield

ooverload and overheating of the free-wheeling diode and of the module as well

as other components

odestruction of the free-wheeling diodes, which are not made for permanent strain,

in extreme cases

Shading can lead to loss of yield, hot spots on the cells, discoloration of the conductor

track, building of bubbles in the foil and fire –ertex solar does not assume liability for these

cases.

Please pay attention to not shading the modules all year around.

Ertex modules should not be installed in areas in which there is a possibility of any kind

of corrosive atmosphere.

The photovoltaic module is not classed as explosion-protected equipment. Accordingly,

it may not be installed in the vicinity of highly flammable gases and vapours.

6 Mounting Ertex modules

The background and support surfaces must be sufficiently stable in terms of their

dimensions.

Forces acting on the structure must not be transferred to the module.

The supports must be designed such that the glazing can be inserted without twisting.

In accordance with correct block setting procedures, the frame anchor mechanisms for

fixed glazing must be positioned on the lower part of the frame in such a way that a

fixing mechanism is located 150 mm to 200 mm from each corner of the frame and this

fixing mechanism is able to take the weight of the glazing on its own.

Glazing rebates and glazing bars must be pre-treated in accordance with the regulations

in ÖNORM B 3722.

The dimensions of the glazing rebates (width and height) must be stipulated on site in

accordance with ÖNORM B 3722.

VSG

Ertex Solartechnik GmbH Tel. +43/7472/28260-610 Page 5 of 7

A3300 Amstetten

The glass rebate support surfaces on glass roofs must be at least 18 mm wide, but the

height required will depend on the thickness of the glass, the type of glass and the

seals.

The height of the glazing bars may be in line with the glazing rebate height for the

frame, but must comply with the minimum glazing rebate height specified in

ÖNORM B 3722.

Block setting should be carried out in accordance with ÖNORM B 2227:2007.

7 Electrical wiring for the system as a whole

There is a risk of arcing and short circuits when using high DC voltages as in the case of

series connection. To avoid these effects, please always use solar cables with adequate

dimensions and connectors approved for the maximum specified open circuit voltage.

The modules are equipped with a junction box and cable in the factory.

The solar cable used is a 4 mm² insulated, weather- and UV-resistant cable.

The cables used must be approved for the maximum short circuit current.

We recommend solar cables with a cross-section of 4 to 6 mm², where the conductor

cross-section is dependent on the maximum short circuit current and the overall length

of the wiring.

Make sure that the solar cables used are sufficiently insulated and weather- and UV-

resistant.

The rated voltage of the solar cable used must be at least 1000 V.

7.1. Plug-in connectors

Only use plug-in connectors which are intended and tested for use with photovoltaic

systems.

Only connect the plug-in connectors under dry conditions. Make sure that the system is

connected properly.

Safety instructions: Never take out the plug-in connections when the system is under

load, i.e. when the system is operational. This can have life-threatening consequences

VSG

Ertex Solartechnik GmbH Tel. +43/7472/28260-610 Page 6 of 7

A3300 Amstetten

under certain circumstances. These safety instructions are also printed on the module

cables supplied with the photovoltaic modules.

7.2. Laying the solar cables

Keep the overall cable connections as short as possible to prevent possible fault

sources and line losses. This point should preferably be taken into account in the

advance planning stages.

Secure loose solar cables after installation to protect them from damage. Only use

appropriate fixing materials for this purpose, e.g. cable ducts incorporated in support

frames or by laying in separate plastic pipes.

The solar cables should not be excessively bent or kinked.

Lay cables in the cable routes or cable ducts provided and secure in position.

Ensure they have the correct polarity.

7.3. Electrical connection

Protect the solar cables from damage.

Earthing must comply with national or international standards and regulations.

8 Commissioning the system

Before commissioning the system, please test all installed individual components (also

observe the commissioning information for the individual components).

Solar PV systems with a DC voltage in excess of 50 V must only be commissioned by

trained specialists.

The open circuit voltage for each series connection should be checked after

commissioning. The following rule applies:

Result of this measurement = sum of the open circuit voltages for the individual

modules.

9 Maintenance

If the modules become dirty, clean as required using plenty of water and a soft cloth or

sponge, but no detergent. If other materials such as harsh chemicals, abrasive cleaners,

blades, steel wool, etc. are used, the product warranty will be invalidated. Under no

circumstances should dirt be scraped or rubbed off in the dry state.

Check at regular intervals to ensure that the module cables and individual plug-in

contacts are clean and intact, with no corrosion and that they are positioned securely.

CAUTION: Never remove plug-in contact under load.

Remove excess snow from the modules if applicable.

Try not to open or repair parts of the module or junction box yourself.

All other problems, repairs and maintenance operations must be performed by trained

specialists.

10 Certificates

VSG

Ertex Solartechnik GmbH Tel. +43/7472/28260-610 Page 7 of 7

A3300 Amstetten

IEC 61215

IEC 61730

Safety Class II

DIBt Z-70.3-172

Please consult the General Terms and Conditions issued by Ertex Solartechnik GmbH for

additional information concerning warranties.

This manual suits for next models

5

Table of contents

Popular Control Unit manuals by other brands

IOTWorkshop

IOTWorkshop HF2421 Quick use manual

Murata

Murata Type1LD quick start guide

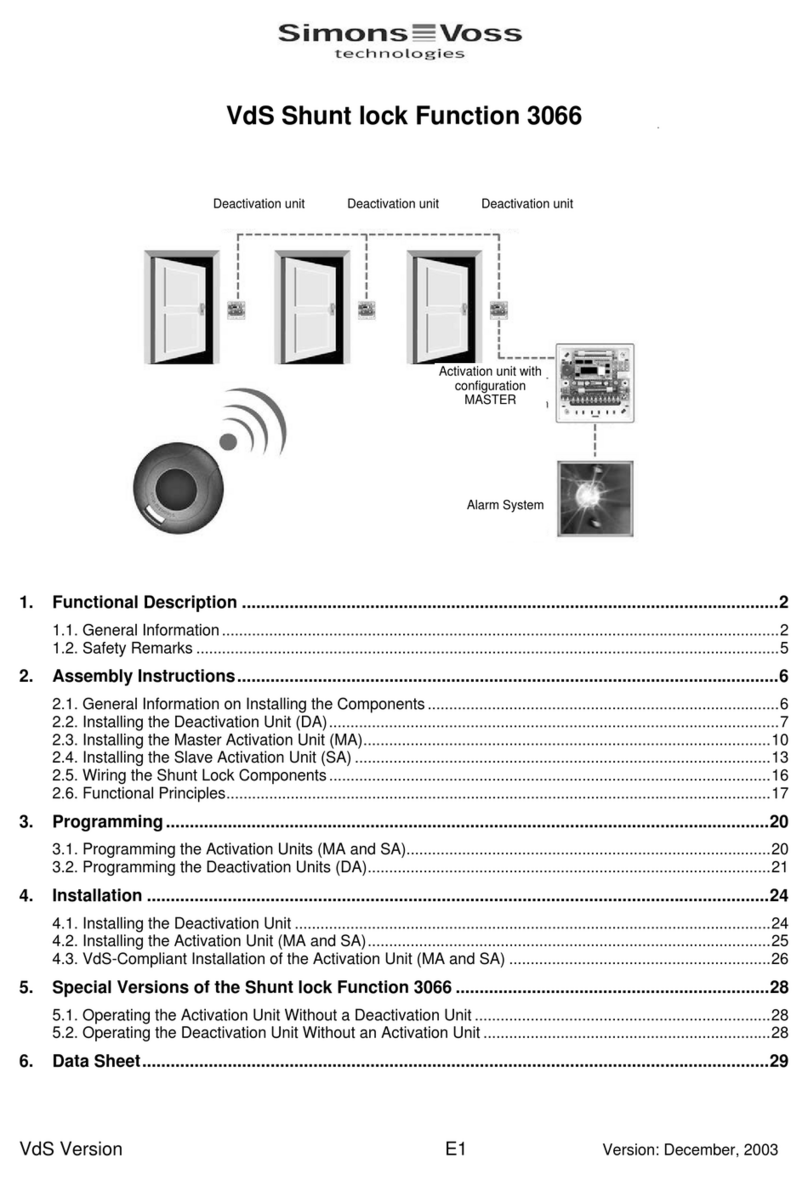

Simons Voss Technologies

Simons Voss Technologies 3066 manual

RadiSys

RadiSys CE915GM quick start guide

VirtuaPin

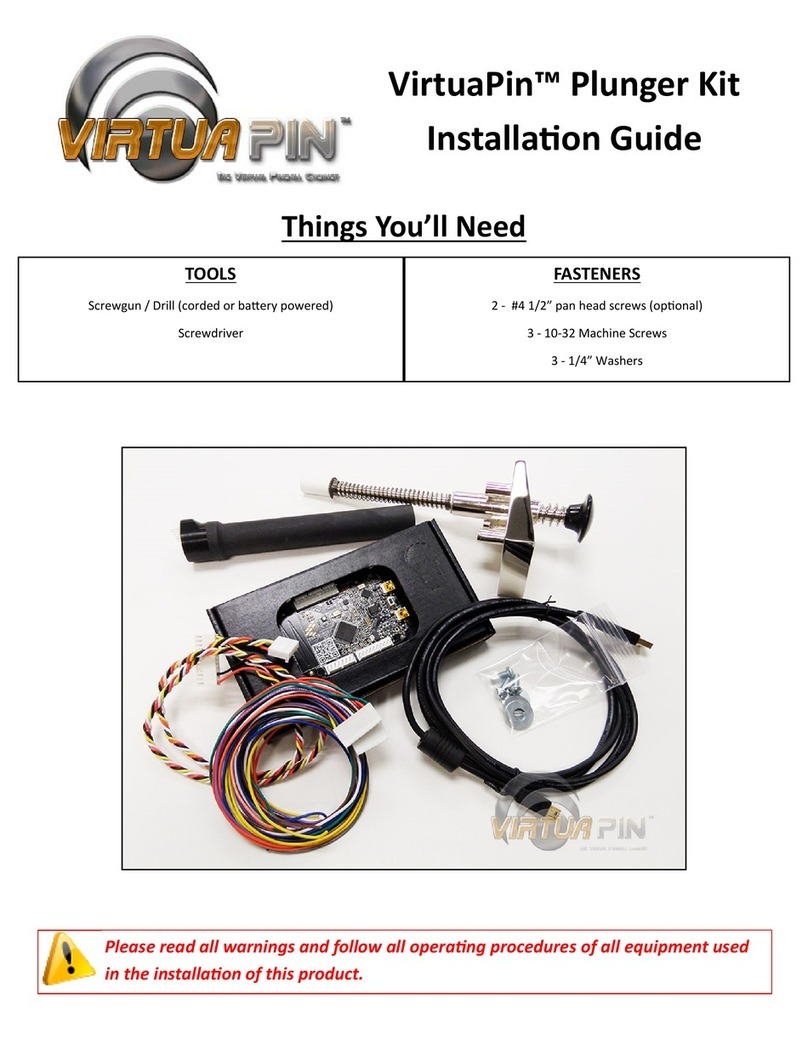

VirtuaPin Plunger Kit installation guide

Brocade Communications Systems

Brocade Communications Systems 6542 Hardware reference manual