C:\TEMP\ml59101.doc | Revised: 20JUN18 | Page 6of 39

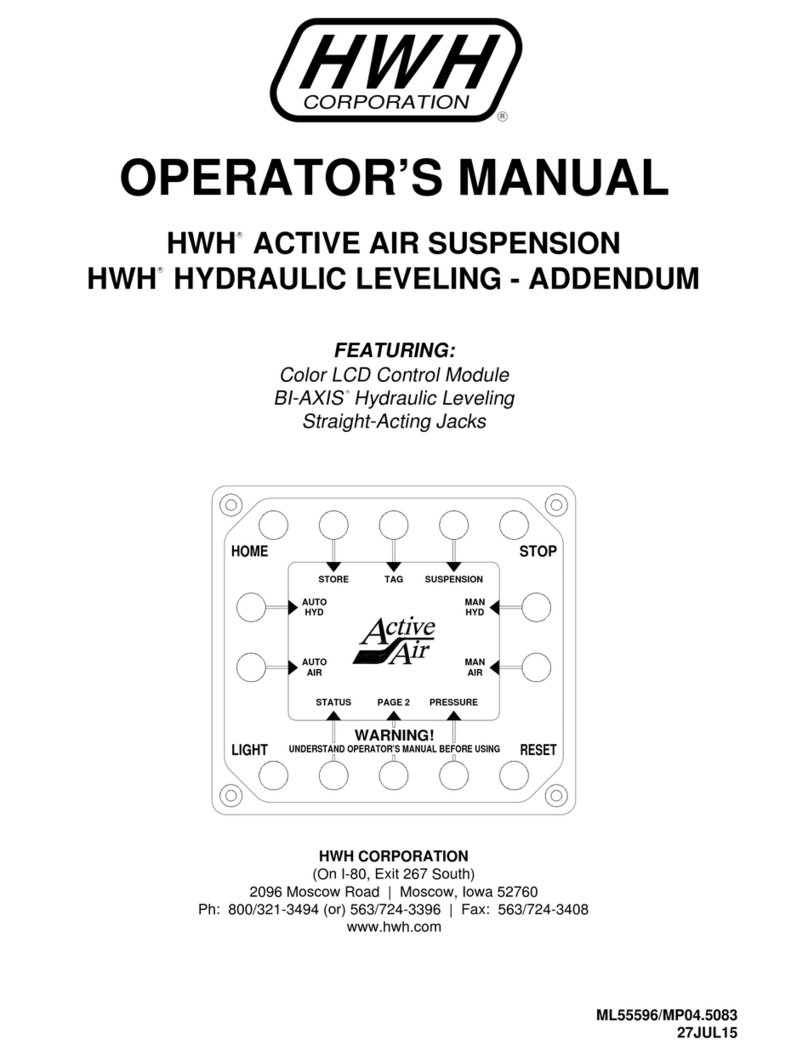

It is best to leave the engine running for the automatic leveling procedure. The ignition must be in the “ON” or “ACC” position

to initiate automatic leveling. The park brake must be set. If not set, the “NOT IN PARK/BRAKE” light will come on while

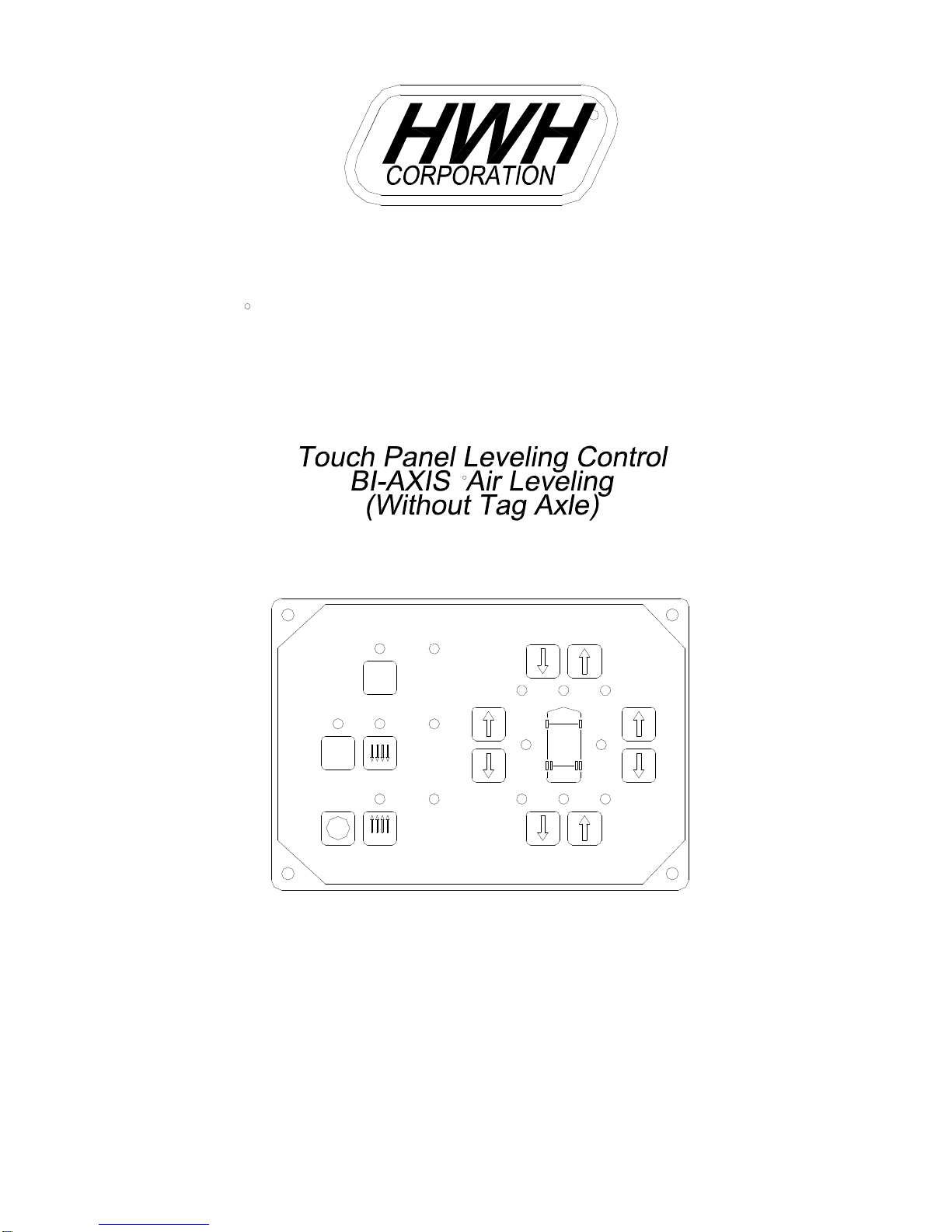

pushing the “AIR” button and the system will not function. One or two yellow level lights may be on at this time.

Pushing the “AIR” button one time will initiate the automatic leveling sequence. The LEVELING SYSTEM ACTIVE light above

the “AIR” button will start to flash. The system will first exhaust the air from all of the air bags, even if no yellow level lights are

lit.If all level lights are off after the dump cycle, the system will go immediately into the SLEEP mode. When the last air bag

pressure switch is made, the processor will determine the high corner of the vehicle. The lower valve load for that corner will

remain on during the complete leveling process and remain onuntil level is achieved with all yellow level lights off or until an

EXCESS SLOPE situation is encountered. The rest of the lower valve loads will be turned off. At this time, the auxiliary air

compressor load will be turned on and like the high corner lower valve, will stay on during the complete leveling process. At

this point, all leveling will be achieved by raising a side or end of the vehicle.

The processor will always level side to side if necessary before leveling the vehicle front to rear. If a front and side level light is

on, the processor will turn the side raise loads on until the side light turns off. After a two second pause, the processor will turn

the front raise loads on until the front level light is off. If the side level light comes back on, the system will ignore that light until

the front light goes out then the processor will turn the side raise load back on until the side level light goes out. When all four

level lights are out, the vehicle is level and the processor will go into the SLEEP mode. The LEVELING SYSTEM ACTIVE light

will now flash rapidly. This will continue until the “CANCEL” button or the “TRAVEL MODE” button is pushed. Releasing the

park brake with the ignition on or off will cancel the SLEEP mode and turn the LEVELING SYSTEM ACTIVE light off.

If only a front or rear level light is on when automatic leveling is initiated, after the initial lowering of the vehicle, the system will

first try to level the vehicle from front to rear. If a side light comes on during the leveling procedure, when the front or rear light

goes out, the system will raise the side for the leveling light that is lit.

FLICKERING YELLOW LEVEL LIGHTS. When an active level light flickers during the automatic leveling procedure, the

system will pause until that light comes on or turns off for two seconds then continue with the leveling process as needed.

Here are a couple examples.

Scenario 1: The front and left side level lights are on. The left side raise loads are on, lifting the left side. If the front level light

flickers, the leveling process is not interrupted. The left side continues to rise. If the left side light flickers, the process stops,

turning the raise loads off, until the light comes on solid or turns off for two seconds. If the light comes on solid, the raise loads

for the left side turn back on and will continue to raise the left side until the light goes out and remains out. If the light flickers

and then stays off, the processor will move to the front level light turning the raise loads for the front on until the front yellow

light goes out.

Scenario 2: The front and left side level lights are on. The left side raise loads are on. The left side level light goes out. The

processor turns the front raise loads on and starts lifting the front. The left side level light comes back on. The processor will

ignore that light until the front level light goes out. The front level light flickers. If the front light turns back on solid, the

processor continues to raise the front until that light remains off. If the light goes out for 2 seconds, the processor will go back

to the left side level light,turn the left side raise loads on and keep them on until the left side level light goes out. If the front

light comes back on, the processor would go back and try to turn the front level light out.

SLEEP MODE

SLEEP mode happens only if automatic leveling has been used. The processor will put the system in the SLEEP mode when

all the yellow level lights are out in the automatic leveling process. The LEVELING SYSTEM ACTIVE light will start flashing

rapidly. The ignition can be turned off and the system will stay in the SLEEP mode. Thirty (30) minutes after the SLEEP mode

is initiated, the processor will wake up and monitor the yellow level lights. If any yellow level light comes on solid, the

processor will initiate a leveling procedure. The LEVELING SYSTEM ACTIVE light will flash slowly. Depending on lit level

lights and air bag pressure switch conditions, the processor may do a lower procedure before starting the normal level by

raising the vehicle procedure. Once leveling is achieved, the processor will return the system to the SLEEP mode for thirty (30)

minutes. The LEVELING SYSTEM ACTIVE light will again flash rapidly.

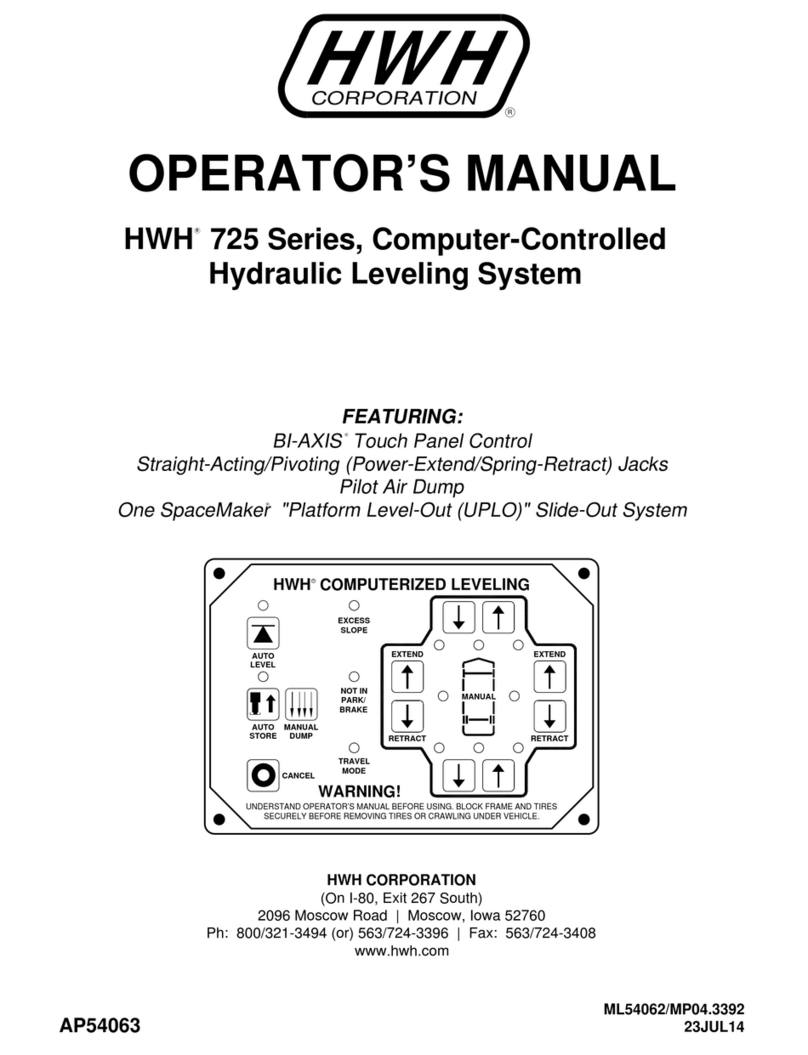

EXCESS SLOPE

EXCESS SLOPE is a timed sequence. Very simply, approximately fifteen (15) minutes after the “AIR” button has been

pushed, if any yellow level light is on, the EXCESS SLOPE light will come on and all loads will turn off. The EXCESS SLOPE

light will remain on until the park brake is released or the “TRAVEL MODE” button has been pushed. The ignition can be off or

on. The manual UP and DOWN arrow buttons will function with the EXCESS SLOPE light on, if the ignition is in “ON” or “ACC”

position. The “AIR”, “DUMP” AND “RAISE” buttons will not function if the EXCESS SLOPE light is on.