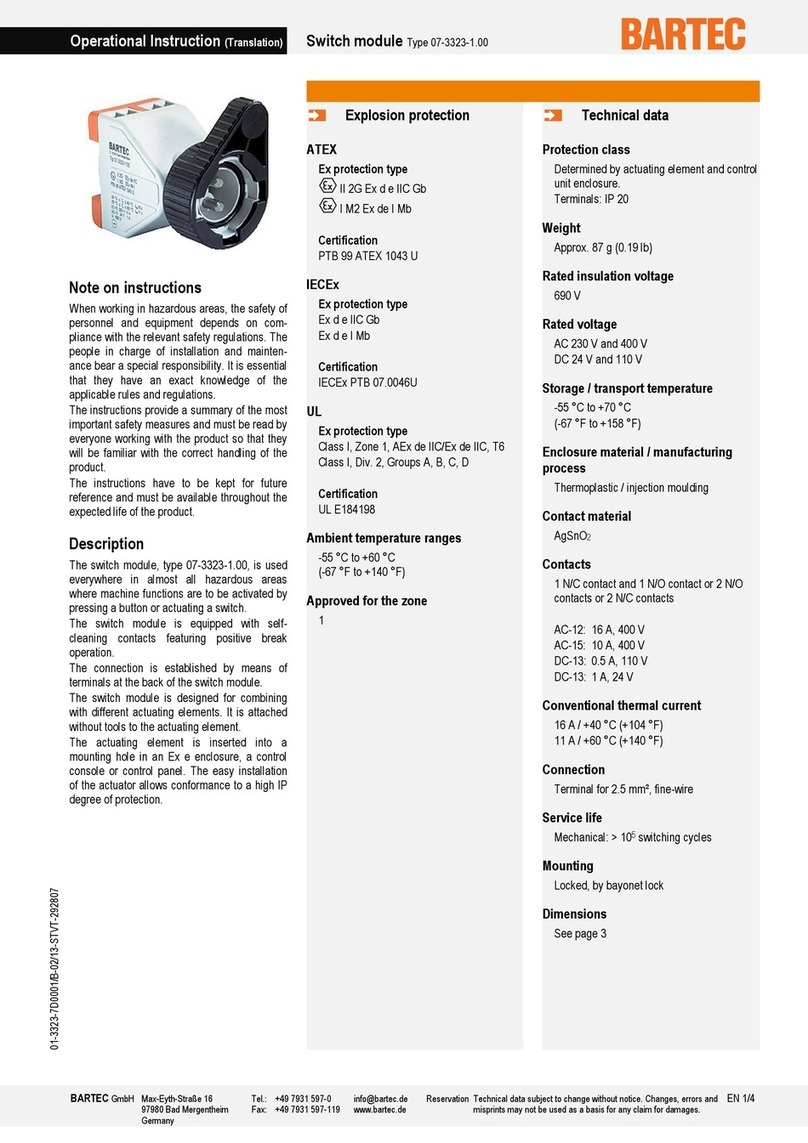

Operational Instruction

(Translation)

Ex d Control Station

Type 07-4230-..../...

BARTEC

GmbH Max-Eyth-Straße 16

97980 Ba Mergentheim

Germany

Tel.: +49 7931 597-0

Fax: +49 7931 597-119

info@bartec. e

www.bartec. e

Reservation Technical ata subject to change without notice. Changes, errors an

misprints may not be use as a basis for any claim for amages.

EN 2/5

-4230-7D0001/C-12/12-STVT-294265

The Ex control station

within the specifie temperature class an the

temperature range in icate for it (see type

label).

The Ex control station

in Zone 0. The Ex control station

operate only if it is clean an not amage in

any way.

Utiliz

ation in areas other than those specifie

an the mo ifications of the pro uct by anyone

other than the manufa

an will exempt BARTEC from liability for

efects an any further liability.

The generally applicable statutory rules an

other bin ing irectives relating to workplace

safety, acci ent prevention an environmental

protection must be observe .

When using electrical systems, the relevant

regulations on installation an operation must

be complie with. The specifications on the

type label must be observe .

Observe the applicable laws an irectives

when commissioning or restarting ope

Always follow the safety instructions on the

operating equipment.

Marking

Particularly important points in these instruc-

tions are marke with a symbol:

DANGER in icates a hazar ous situation

which, if not avoi e , will result in eath

serious injury.

WARNING in icates a hazar ous

which, if not avoi e , coul

serious injury.

CAUTION in icates a hazar ous situation

which, if not avoi e , coul result in minor

mo erate injury.

NOTICE is use to a ress practices not

relate to personal injury.

Note

Important instructions and information on

effective, economical and environmentally

compatible handling.

EN 60079-0:2009

EN 60079-1:2007

EN 60079-7:2007

EN 60079-11:2007

as well as

EN 60439-2:2000 + A1:2005

EN 62208:2003

EN 60445:2010

EN 60529:1991 + A1:2000

Note

For the standards for the installed parts, see

the separate documentation for the built-

component.

Assembly / Disassembly

Death or serious injury due to incorrect

assembly.

Metallic enclosures in hazar ous areas

require equipotential bon ing with at least

4

mm². The connections must be secure

against self loosening.

Risk o injury due to incorrect proceedings.

Only authoriz

who are authorize an traine to assem-

ble electrical components in hazar ous

(potentially explosive) areas

the assembly, isassembly, installation an

commissioning work.

The relevant installation an operating

regulations must be observe when

up or operating explosion-

systems.

Always isconnect the Ex control station

from voltage before assembling / isas-

sembling.

Follow the components mounting instructi-

ons/operating instructions.

Check when assembling:

•Mount the Ex control station with resis-

tance to torsion on an even supporting

surface.

Fixing imensions an the holes

to be ma e, see rawings on page 4.

•

Secure the connections against self

loosening.

Note

For enclosures set up outdoors it may be

necessary to imp

lement measures to ensure

operation in accordance with the intended

purpose (e.g. shelter from the rain or an outer

enclosure with a suitable protection class).

Death or serious injury due to a potentially

explosive atmosphere.

Never open the Ex control station

presence of a potentially explosive atmos-

phere.

Always isconnect the Ex control station

from voltage before opening it.

Pay attention at the opening/closing of flame-

proof enclosures:

•Disconnect the Ex control station

voltage.

•

Loosen the screws in the cover cam until

they are no longer engage with the

threa s.

•

Unscrew the li to the left an make sure

it can’t fall off.

•Close the en

or er.

Installation

Death or serious injury due to improper use.

Extensions or mo ifications to the

control station

are only permissible if the

manufacturer’s approval is obtaine first.

The IEC/EN60079-14 must be observe .

Check when installing:

•

When connecting cables an con uctors

to operating equipment with

type of protection, use Ex-

entries that are suitable for the respective

types of cables an con uctors. They

must conform to the “Ex e” type of protec-

tion an have a suitable sealing element

to maintain the control station’s prot

class.

•

Connect metallic cable entries to the

earthing system.

•Seal unuse cable entry holes with Ex-

certifie stopping plugs.

•When connecting irectly to the flame-

proof enclosure, use Ex-

that are suitable for the enclosure capaci-

ty, the gas sub-group an the con uctor.

Take care when connecting con uctors:

•

Always use suitable crimping tools when

crimping the wire-

consistent quality of pressing each time.

•Take care

to establish the connection

properly.

•Tighten a

ll terminal points (inclu ing those

not in use) securely.