✓

FA-200

INSTALLATION

INSTRUCTION

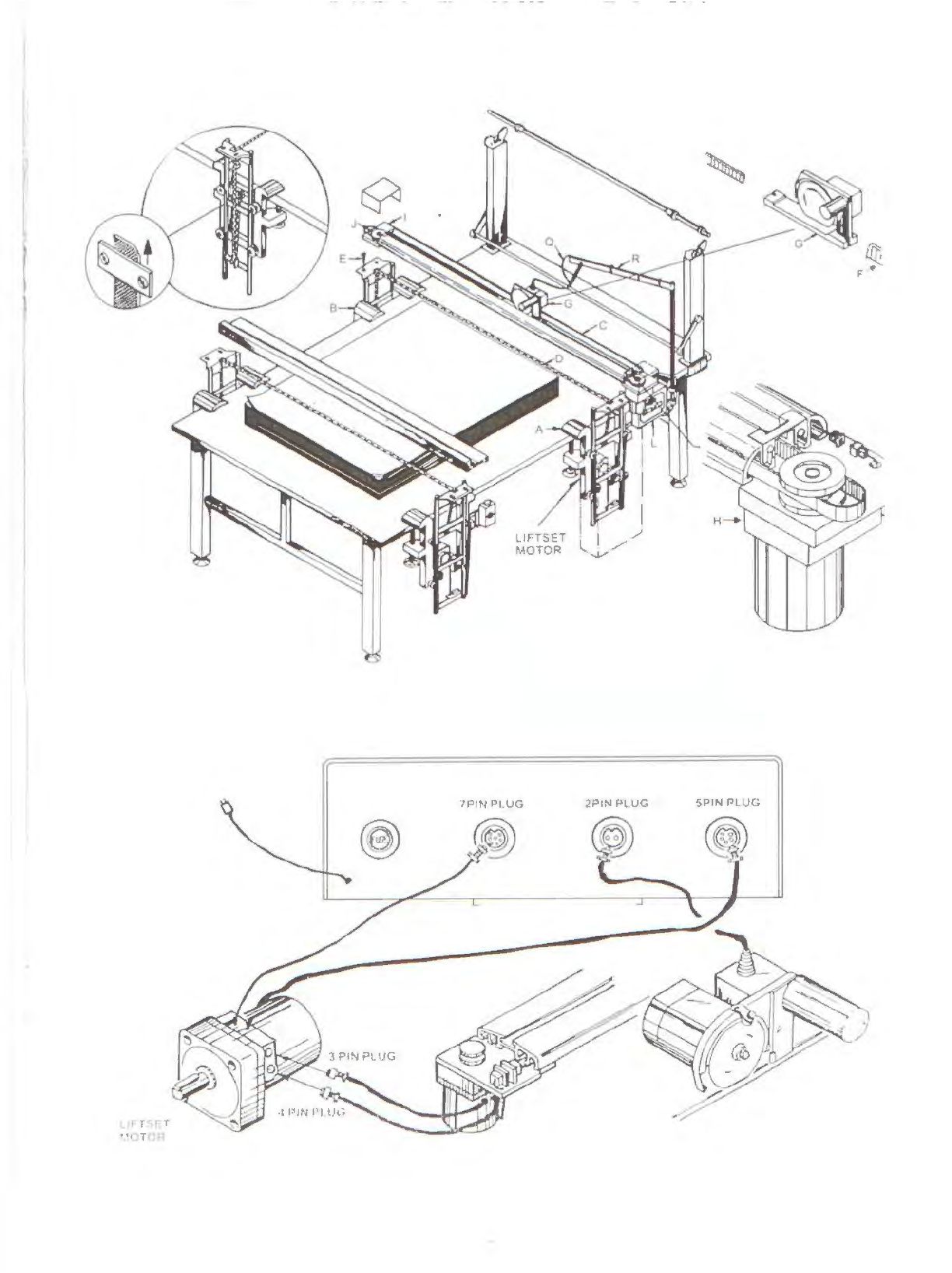

1. Following

the

figure instruction, fixing

lift

motor

set

clamp

(A)

at

the rightside

of

thecutting table.

2.

Fixing anotherset clamp (B}

at

the left

side

of

thetableoppos,teto the lift motorset clamp.

3.

Fasten fistone end

of

the LIFT BELT ,nto

the

BELT PRESS PIECE

of

the CLAMP ASSEMBLY and

allow the other end to pass through ttte ROLLER

of

theBAR LIFTER, crossing under the RAIL

thread through the ROLLER

of

the BAR LIFTER, then throughthe DOWN ROLLER

on

the BAR

LIFTER finally tinghten

it

in

theBELT PRESS PIECE.

4. Place rail (C) onto lift rod. Note: The end with powerline

out

shoutd

be

placed at thelift

motor

set

clampside.

5. Fasten

both

ends

of

the rail (C) onto theliftrod with setscrews

(E)

.

6. Hook the gear

bell

hook

(F)

from bottom upward

onto

the rear side. Put cutter (G) insiderail (C).

7. FixTransmission

motor

assembly (H)

at

the power line

out

end

with rail fixing screw (E). and

connector the

two

plugs.

8. Fixbeltpulley (I)

at

the

other

end

of

rail with rail fixing screw(E).

9. Wmd the other end

of

beltacross transmissiongear(H). through bottom

of

therail (C),

up

to the

opposite

side

belt pulley,back toinside

of

rail (C), then

hook

on

to the front

of

cutter.

(Note: Inspect the belt, make sure

it

Isnot twisted, otherwiseitwillendanger theoperation)

10. AdJust gearbelt

by

means

of

belt adjusting screw (J)

lo

a suitable tension (about5 mm)

11

. Installcontrol box frame (K)

and

place control box(L) onto it.

12. Installation of wiringbracket:

a. Fixingset

clamp

(M)

at

cutting table.

b. Installwi,ing

pipe

(N) and supporting bracket

(0)

.

c. Lead twin hole electricwire

(0)

through wiring

pipe

(R)

downward from the

top

d. Install receptaclereserve suitableend length, then fix

it

with binding belt.

13. Installationof fabricsupporting rack:

a. Fix fabric supporting rack to

both

sides

of

the cutting table.

b. Install leverrespectively to the two fabric supporting rack.

c. Insertthe Iron

lube

.

d. Place

on

the fabric supportrod to finish the installation.

14

. Insert three wiresrespectively twinholes. five holes. and seven holes rnto the receptacles

underneathcontrol

box

(L).