ESAB A2-A6 PEK User manual

Service manual

0740 801 028 GB 20171110 Valid for: serial no. 921-, 943-, 049-, 327-, 628-xxx-xxxx

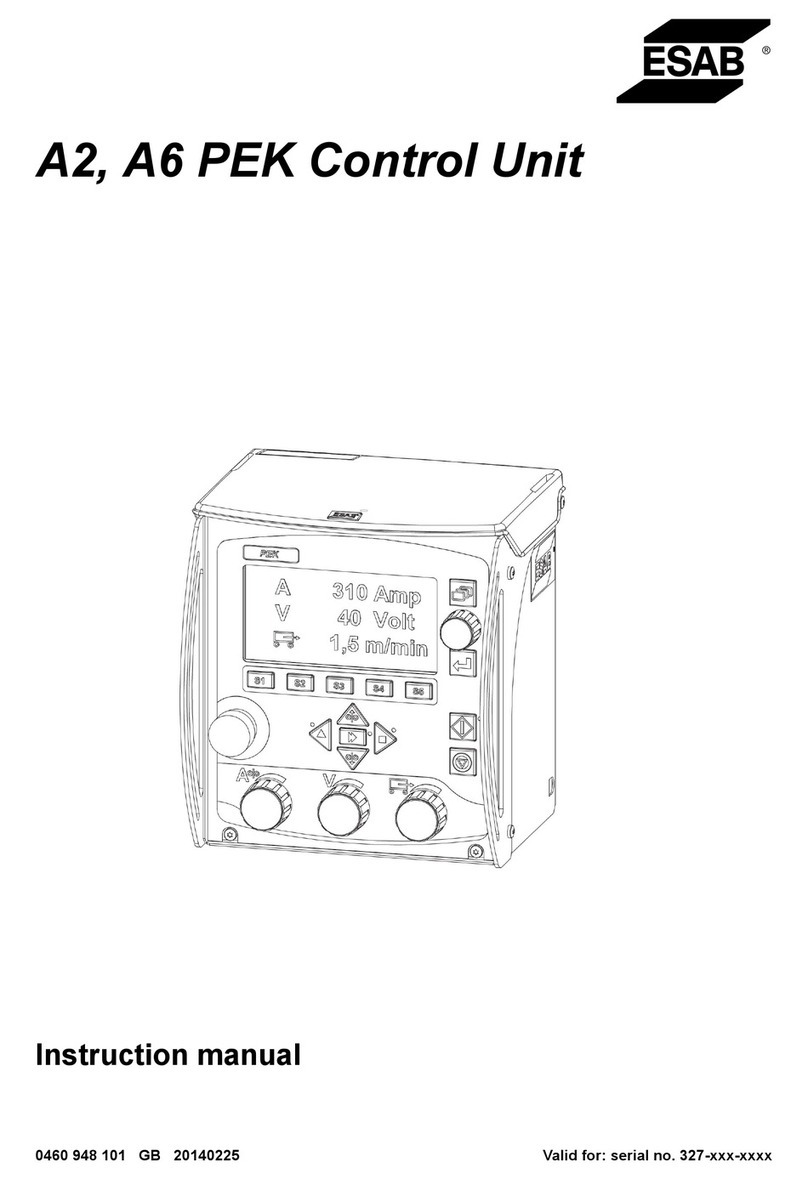

A2, A6 PEK Control Unit

TABLE OF CONTENTS

0740 801 028 © ESAB AB 2017

READ THIS FIRST.................................................................................... 4

INTRODUCTION....................................................................................... 5

WIRING DIAGRAM................................................................................... 7

Component description ......................................................................... 7

A2, A6 PEK Control Unit, Serial no. 921-, 943-, 049-, 327-xxx-xxxx ... 8

A2, A6 PEK Control Unit, Serial no. 628-xxx-xxxx .............................. 10

TECHNICAL DATA ................................................................................... 12

INSTALLATION AND CONNECTIONS .................................................... 13

External connections ............................................................................. 13

Internal connections .............................................................................. 15

DESCRIPTION OF OPERATION.............................................................. 23

1 MMC unit .............................................................................................. 23

Circuit board identity............................................................................. 23

1AP1:1 Power supply and CAN bus..................................................... 24

CAN bus & termination...................................................................... 26

1AP1:2 Display control ......................................................................... 27

1AP1:3 Pushbutton monitoring............................................................. 27

Buzzer ............................................................................................... 28

1AP1:4 USB memory ........................................................................... 28

1AP1:5 Encoder monitoring ................................................................. 29

1AP1:6 Ethernet interface, from serial no. 628-xxx-xxxx ..................... 30

1AP1:7 USB-host B (internal), from serial no. 628-xxx-xxxx................ 31

1AP1 Component positions.................................................................. 32

26 Motor control & motor drive ............................................................. 34

26AP1 Motor control .............................................................................. 34

Circuit board identity............................................................................. 34

26AP1:1 Power supply ......................................................................... 34

26AP1:2 CAN bus & termination .......................................................... 35

26AP1:3 Encoder for wire feed motor .................................................. 36

26AP1:4 Encoder for travel motor ........................................................ 37

26AP1:5 Travel limit switches............................................................... 37

26AP1:6 Laser lamp supply ................................................................. 38

26AP1:7 External Start/Stop switch ..................................................... 38

26AP1 Component positions................................................................ 39

26AP2 Motor drive.................................................................................. 40

26AP2:1 Power supply ......................................................................... 40

26AP2:2 Motor 1 drive (Wire feed at CN7)........................................... 41

26AP2:3 Motor 2 drive (Travel motion at CN6) .................................... 43

26AP2:4 Relay outputs......................................................................... 44

26AP2 Circuit board versions............................................................... 45

26AP2 Component positions................................................................ 46

TABLE OF CONTENTS

0740 801 028 © ESAB AB 2017

FAULT CODES ......................................................................................... 47

Error log .................................................................................................. 47

Error code description ........................................................................... 48

SERVICE INSTRUCTIONS....................................................................... 55

What is ESD? .......................................................................................... 55

Service aid .............................................................................................. 55

Replacing the battery ............................................................................. 56

SOFTWARE UPDATE............................................................................... 57

Motor control 26AP1 .............................................................................. 57

Welding data unit 1AP1.......................................................................... 57

Updating software ................................................................................ 60

Reset with reset.txt............................................................................... 61

SPARE PARTS ......................................................................................... 63

Rights reserved to alter specifications without notice.

READ THIS FIRST

0740 801 028 -4- © ESAB AB 2017

READ THIS FIRST

Maintenance and repair work should be performed by an experienced person, and electrical

work only by a trained electrician. Use only recommended replacement parts.

This service manual is intended for use by technicians with electrical/electronic training for

help in connection with fault-tracing and repair.

Use the spare parts list as a guide to where the components are located in the equipment.

The spare parts list is published as a separate document, see "Spare Parts" section.

This manual contains details of design changes that have been made up to and including

July 2016.

The manual is valid for PEK with serial number 921-xxx-xxxx, 943-xxx-xxxx, 049-xxx-xxxx,

327-xxx-xxxx and 628-xxx-xxxx.

NOTE!

The unit is tested by ESAB in a general set-up. The responsibility for safety and

function, of the specific set-up, lies with the integrator.

CAUTION!

Read and understand the instruction manual before

installing or operating.

INTRODUCTION

0740 801 028 -5- © ESAB AB 2017

INTRODUCTION

Block diagram of the PEK

Design structure of the control unit

PEK is a control unit for power sources intended for submerged arc welding (SAW) and for

gas metal arc welding (GMAW) The control unit includes a motor control for use together

with automatic welding machines, column and booms.

It has connections for:

• welding power source

• emergency stop

• CAN bus

• USB-memory (Fromserialno.628-xxx-xxxx the unit is equipped with a second USB

connector, located inside the unit on the MMC/Welding data board.)

• motors

• control of flux/gas

• encoders

• limit switches

• the ESAB WeldCloud™ Mobile unit (via Ethernet connection)

(fromserialno.628-xxx-xxxx)

1AP1 MMC module

The control unit has an MMC with processor, memory, control buttons and a display. The

MMC is connected to the welding power source and the motor control board with a 500

kbit/s CAN bus. The unit is powered with 12 V supplied via the CAN connection.

INTRODUCTION

0740 801 028 -6- © ESAB AB 2017

26AP1 Motor control board

The motor control board handles the motor driver board, reads the motor encoders and the

limit switches. The unit is powered from the motor driver board except for the CAN circuits

supplied with 12 V via the CAN connection. The board can supply 5 V to a laser lamp and

5,15 or 24 VDC for the motor encoder.

26AP2 Motor driver board

The motor driver board is supplied with 42 VAC from the welding power source via a

rectifier. It has two H-bridge motor driver circuits making it possible to reverse the motors.

The board also holds the relay that controls flux or gas.

WIRING DIAGRAM

0740 801 028 -7- © ESAB AB 2017

WIRING DIAGRAM

Component description

Component Description

1AP1 MMC module

1AP2 Display

1AP3 Buttons, rubber keypad

1L1, 26L1, X1L1 Ferrite ring cores

1L2 Ferrite ring core (from serial no. 628-xxx-xxxx)

26AP1 Motor control board

26AP2 Motor driver board

BR1 Rectifier bridge

C1 Filter capacitor

C2 Filter capacitor

S1 Emergency stop

X1 Terminal block

XP1 Connector

XS1/24AP1 CANbus connection

XS2 USB connector

XS3 Ethernet connector (from serial no. 628-xxx-xxxx)

200 Wire

14.2, 14.4, 14.5 Wire from CN14:1, CN14:4 and CN14:5

18.2 Wire from CN18:2

3.1, 3.3 Wire from CN3:1 and CN3:3

4.1, 4.3 Wire from CN4:1 and CN4:3

5.1, 5.5 Wire from CN5:1 and CN5:5

X1.4, X1.6, X2.1,

XB.2, X4.J, X4.A,

X6.B, X6.C, X9.F,

X1.G, XB.H

Wire from X1

CAUTION!

STATIC ELECTRICITY can damage circuit boards and

electronic components.

• Observe precautions for handling electrostatic

sensitive devices.

• Use proper static-proof bags and boxes.

WIRING DIAGRAM

0740 801 028 -8- © ESAB AB 2017

A2, A6 PEK Control Unit, Serial no. 921-, 943-, 049-, 327-xxx-xxxx

Updates: From serial no. 921-010-XXXX: Cable 18.1 removed

From serial no. 921-010-XXXX: Wire jumper X1:12 to X1:15 introduced

WIRING DIAGRAM

0740 801 028 -9- © ESAB AB 2017

WIRING DIAGRAM

0740 801 028 - 10 - © ESAB AB 2017

A2, A6 PEK Control Unit, Serial no. 628-xxx-xxxx

Table of contents

Other ESAB Control Unit manuals

Popular Control Unit manuals by other brands

Festo

Festo Compact Performance CP-FB6-E Brief description

Elo TouchSystems

Elo TouchSystems DMS-SA19P-EXTME Quick installation guide

JS Automation

JS Automation MPC3034A user manual

JAUDT

JAUDT SW GII 6406 Series Translation of the original operating instructions

Spektrum

Spektrum Air Module System manual

BOC Edwards

BOC Edwards Q Series instruction manual

KHADAS

KHADAS BT Magic quick start

Etherma

Etherma eNEXHO-IL Assembly and operating instructions

PMFoundations

PMFoundations Attenuverter Assembly guide

GEA

GEA VARIVENT Operating instruction

Walther Systemtechnik

Walther Systemtechnik VMS-05 Assembly instructions

Altronix

Altronix LINQ8PD Installation and programming manual