3. Clean and repaint rim parts as necessary.

NOTE: Remove rust, dirt, and foreign material from rim parts. Repainting the rim parts and bare

metal areas will make them last longer. Be careful to keep paint out of the lock ring groove in the

gutter when repainting rim parts.

4 Visually inspect all tire and rim parts to make sure they are positioned properly.

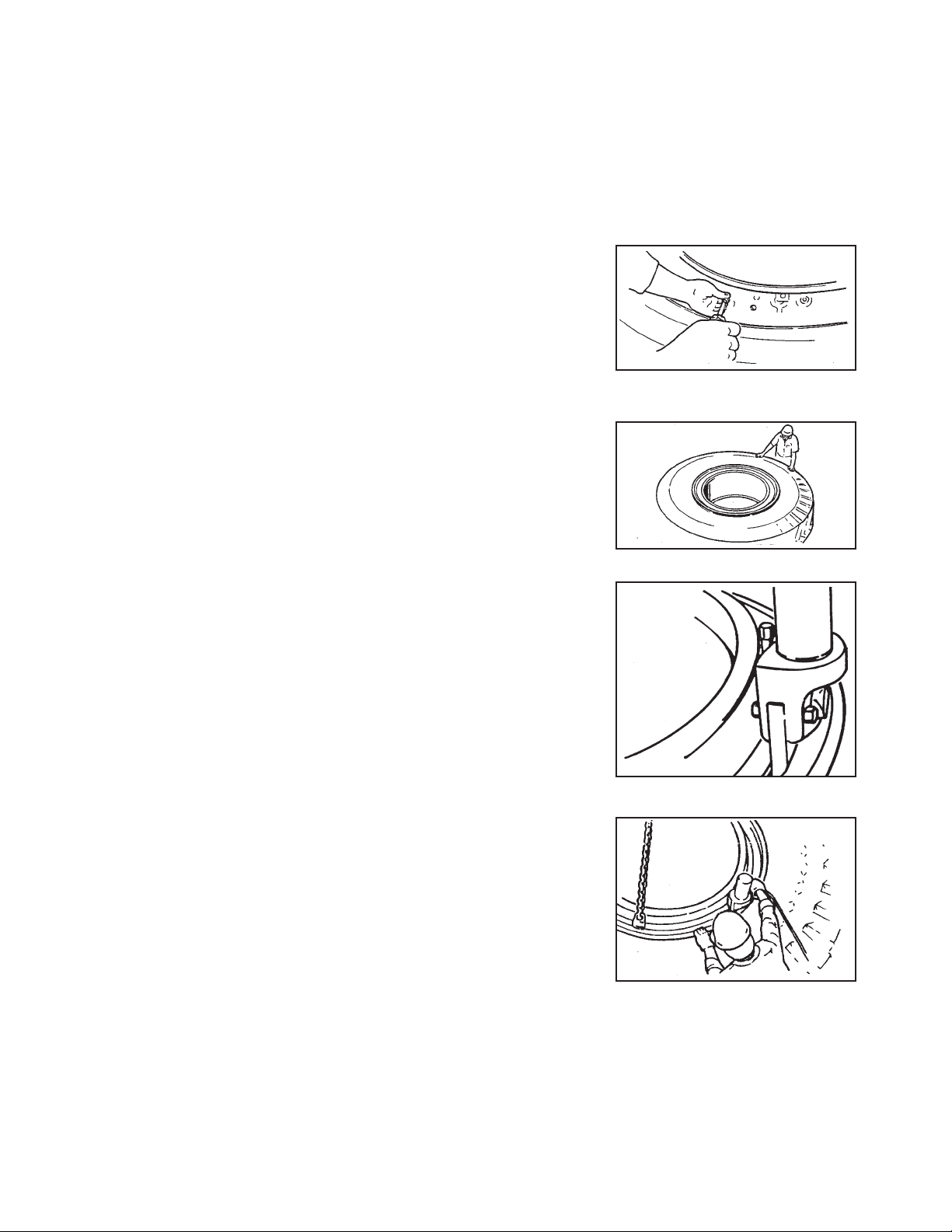

Starting to Inflate the Tire

1. To comply with OSHA Regulation #29CFR1910.177, place the tire in a safety cage or other

restraining device, such as an ESCO Push Bar Model 90201, before inflating the tire. Use a clip-on

air chuck and hose that is long enough to allow you to stand outside the wheel trajectory. The air

line must be equipped with an in-line valve with pressure gauge or regulator that can be preset. Use

ESCO Truck Tire Inflator Model 15136.

ADANGER

Always use a safety cage or restraining device, such as an ESCO Push Bar Model 90201, when

inflating a tire. Not using a safety cage or restraining device can result in serious injury or death.

Always use a clip-on air chuck and a hose that is long enough to allow you to stand outside the

wheel trajectory. The air line must be equipped with an in-line valve with a pressure gauge and a

regulator that can be preset.

Never use starting fluid, ether, gasoline, or any other flammable material to lubricate, seal, or seat

the bead of a tubeless tire. Doing so can cause an explosion and serious injury or death.

2. Inflate the tire to 5 psi [0,345 bar].

3. Check all tire and rim parts again for proper positioning. Make sure the o-ring does not slip out of

its groove.

4. If tire/rim parts are not seated properly, deflate the tire and correct the problem before proceeding.

AWARNING

Never hammer, strike, or pry an inflated or partly inflated tire/rim assembly. If you must seat a

part or correct a problem, always deflate the tire first.

ACAUTION

Do not use a steel hammer on rim or rim parts.This can damage the rim. If you must reposition

tire or rim parts, use a rubber, plastic, or brass-faced hammer.

If a tire/rim assembly does not slide over a cast spoke wheel, do not force the assembly by

hammering. Instead, deflate the tire and inspect for warped or incorrectly seated parts, such as

lock rings.

5. If tire and rim parts are seated properly, proceed to “Finishing the Tire Inflation” below.

Finishing the Tire Inflation

1. Inflate the tire to 20 psi [1,38 bar].

2. Check the tire bead for proper seating.

3. Continue inflating the tire to 40 psi [2,76 bar] If the tire bead is not fully seated, see the Warning

below. If the tire bead is fully seated, continue with Step 4 below.

AWARNING

Never inflate a tire beyond 40 psi [2,76 bar] to seat a tire bead. If the tire bead is not fully seated

at 40 psi: Stop! Deflate the tire and correct the problem.

- 5 -