esera ECO 501 PRO User manual

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 1 from 31

OPERATING INSTRUCTIONS

ECO 501 PRO

INDUSTRIAL SENSOR GATEWAY

of the 3rd generation for the

1-Wire bus system

HIGHLIGHTS

Fully automatic PLUG and PLAY

system for up to 30 sensors

⎯

Web server and access point

for configuration, debug and firmware

updates

⎯

Data interface for

Modbus/TCP, MQTT and ASCII

⎯

Auto-E-Connect Plug and Play

Level I to III

⎯

Fast readout of all devices

in 5 seconds cycle

⎯

Low maintenance industrial unit,

because without Linux. Native

programmed with known libraries

⎯

LAN interface

for data, configuration, debug

and firmware updates

⎯

Extended temperature range

-5°C to 50°C

⎯

Rugged industrial design

⎯

Extensive protection circuits and good

device protection

⎯

Simple assembly

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 2 from 31

TABLE OF CONTENTS

TABLE OF CONTENTS.....................................................................................................................................2

1ADDITIONAL DOCUMENTS AND SOFTWARE..................................................................................3

2PRODUCT DESCRIPTION ...................................................................................................................4

3INDUSTRIAL ENVIRONMENT FOR THE ECO 501 SENSOR GATEWAY.........................................5

4ECO GATEWAY SYSTEM....................................................................................................................6

5THE ECO GATEWAY CONCEPT.........................................................................................................6

6DEVICE CONSTRUCTION ...................................................................................................................7

6.1 INTERFACE / SENSOR INTERFACE AND I/O SECTION...................................................................7

7ECO 501 GATEWAY FUNCTIONS.......................................................................................................9

8AUTO-E-CONNECT® PLUG AND PLAY SYSTEM...........................................................................10

9SCOPE OF FUNCTIONS AUTO-E-CONNECT SYSTEM ..................................................................10

10 PATENT AUTO-E-CONNECT® SYSTEM..........................................................................................11

11 TECHNICAL DATA .............................................................................................................................13

12 ENVIRONMENTAL CONDITIONS......................................................................................................14

13 CONFORMITY.....................................................................................................................................14

14 DISPLAY LED .....................................................................................................................................14

15 CONNECTION PLAN..........................................................................................................................15

16 CONNECTION EXAMPLE ..................................................................................................................16

17 ACTIVATE ACCESS POINT...............................................................................................................17

18 SELECT ACCESS POINT...................................................................................................................18

19 CALL WEB SERVER VIA WIFI ..........................................................................................................18

20 CALL WEBSERVER VIA LAN............................................................................................................19

21 WEBSERVER, LOG IN .......................................................................................................................19

22 DATA INTERFACE, ASCII PROTOCOL............................................................................................20

23 ESERA ASCII TEXT PROTOCOL ......................................................................................................20

24 MODBUS/TCP PROTOCOL ...............................................................................................................21

25 MQTT PROTOCOL .............................................................................................................................24

26 YOUR PROTOCOL NOT THERE?.....................................................................................................25

27 1-WIRE NETWORK CABLING ...........................................................................................................26

28 FIRMWARE UPDATE .........................................................................................................................26

29 RECOVERY FUNCTION.....................................................................................................................27

30 RESET BUTTON.................................................................................................................................27

31 EXAMPLES FOR CODESYS / WAGO INTEGRATION .....................................................................28

32 EXAMPLES FOR SIEMENS SPS INTEGRATION.............................................................................28

33 OPERATING CONDITIONS................................................................................................................28

34 ASSEMBLY.........................................................................................................................................28

35 DISPOSAL...........................................................................................................................................28

36 SAFETY INSTRUCTIONS...................................................................................................................29

37 WARRANTY........................................................................................................................................30

38 PROMOTERS OF THE FREE INTERNET..........................................................................................30

39 WARNING ...........................................................................................................................................31

40 CONTACT ...........................................................................................................................................31

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 3 from 31

1 ADDITIONAL DOCUMENTS AND SOFTWARE

The ECO 501 Gateway operating manual consists of these product-specific and cross-product documents.

The cross-product documents apply to several devices.

To obtain the cross-product documents and additional software, please follow the links below to our website

(https://esera.de).

Please read the complete documents to the end and follow the information and instructions.

If you have trouble finding the documents or software you need, you can also contact our customer support.

We will be happy to assist you with any questions or problems.

INTERFACE MANUAL

MODBUS, MQTT, LoRaWAN, NB-IoT

Manual for configuring the interface via web server and

access point

The manual can be found in the ESERA download area

at:

https://download.esera.de/download/technical/schnittstellen_handbuc

h

CONFIG TOOL 3 SOFTWARE

Comprehensive software for all EC and ECO gateways

with 1-Wire I/O section

You can find the software in the ESERA download area

at:

https://download.esera.de/download/technical/config%20tool%

203

MODBUS INTERFACE MANUAL V2,

GATEWAY WITH WEBSERVER

Manual for configuring the Modbus/TCP and

Modbus/RTU interface for ECO gateways with web

server and access point

The Modbus manual can be found in the ESERA

download area at:

https://download.esera.de/download/technical/programmierha

ndbuch

PLANNING AID FOR 1-WIRE SYSTEMS

Here we offer you a small Excel tool for the calculation

of your 1-Wire system

The Excel tool can be found in the ESERA download

area at:

https://download.esera.de/download/technical/planungshilfe_1

-Wire

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 4 from 31

2 PRODUCT DESCRIPTION

APPLICATION

•Highly up-to-date, universal Modbus/TCP and MQTT sensor interface for all modern machines,

Plants and consumers

•Energetic optimization through many sensors

•Industrial equipment, mechanical engineering, building management, IoT and M2M

•Manufacturer-independent usable

•Up to 30 sensors can be connected via plug and play

ADVANTAGE

•Cost and time savings due to fast installation and commissioning

•Connect, switch on and you already receive measured values

•Intuitive operation via web server

The ECO 501 Gateway is a powerful sensor interface of the latest generation designed for monitoring

machines, plants and systems. It features an access point and an integrated web server to enable

convenient configuration and monitoring.

The gateway supports the connection of up to 30 sensors via the Industrial 1-Wire bus using the Auto-E-

Connect plug-and-play system. This system enables fully automatic sensor connection without manual

configuration, which greatly simplifies installation and integration.

The ESERA Auto-E-Connect system, an extension of the 1-Wire bus standard, is used. It is a European

patent of ESERA.

A wide range of sensors is available, including temperature, humidity, dew point, air quality (CO2, VOC or

particulate matter), digital alarm contacts, glass breakage and smoke detectors. These sensors can be

seamlessly connected to the ECO 501 gateway via the Auto-E-Connect plug-and-play system.

The gateway offers a web server that provides convenient access to the configuration, software updates, and

sensor and production data of the connected sensors. The web server can be accessed via WLAN and the

access point, which is activated at the push of a button.

The ECO 501 gateway was developed as a low-maintenance industrial device, without Linux and with its

own native programming. No unknown libraries are used, which ensured the stability and reliability of the

system.

Each of the maximum 30 sensors can provide up to 5 measured values, so that a total of up to 150 sensor

data points can be sent to your control system or PLC.

Software support includes the Config Tool and ECO Dashboard 100, which are provided free of charge to

facilitate sensor configuration and monitoring.

For reliable operation in industrial environments, the ECO 501 gateway is operated with a voltage of 9-

30VDC.

Note

Before you start assembling the device and put the product into operation, read this

operating manual through to the end at your leisure, especially the section on safety

instructions.

If you have problems downloading the advanced documents or software, please

We are very concerned to act in an environmentally friendly and resource-saving way

for you. That is why we use paper and cardboard instead of plastics wherever possible.

We would also like to make a contribution to the environment with these paperless

instructions.

Please think of the environment before printing these instructions.

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 5 from 31

Overall, the ECO 501 gateway offers a robust and user-friendly solution for monitoring machines, plants and

systems thanks to its extensive functions and easy integration of sensors.

3 INDUSTRIAL ENVIRONMENT FOR THE ECO 501 SENSOR GATEWAY

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 6 from 31

4 ECO GATEWAY SYSTEM

Many sensors, powerful interface and access point

5 The ECO Gateway Concept

For all ECO gateways, we have developed and applied a system concept based on our decades of

experience in the development of electronic devices.

THIS CONCEPT CONTAINS THE FOLLOWING POINTS

CONNECTION OF SENSORS

The system concept allows a large number of sensors to be connected via the Industrial 1-Wire Bus using

Auto-E-Connect. This process is fully automatic, which simplifies installation and configuration.

NUMBER OF SENSORS

Up to 30 sensors can be connected to an ECO gateway. These sensors can provide a maximum of 150

sensor values in total.

ANALOG AND DIGITAL INPUTS

In addition to the sensors connected via 1-Wire bus, the ECO gateways also offer direct analog and digital

inputs. This means that other sensors or devices can also be connected directly to the gateway.

CASE INTERIOR CLIMATE MONITORING

The system concept includes a climate monitoring system for the interior of the case. It monitors various

parameters such as temperature, humidity, etc. and has limit values and an alarm system to detect potential

problems at an early stage.

POWERFUL DATA INTERFACE

The ECO gateways offer an extremely powerful data interface that supports up to 5 simultaneous data

connections to control systems and PLC controllers. This allows the acquired sensor values to be transmitted

efficiently in real time.

CONFIGURATION VIA WEBSERVER

The settings of the device can be made via a web server. This gives users a user-friendly interface for

configuring and monitoring the gateway.

ACCESS POINT

The ECO gateways have a connectable access point that enables independent access by mobile devices

such as smartphones, tablets or laptops. This also allows users to access the gateway wirelessly and

monitor and control the data.

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 7 from 31

6 DEVICE CONSTRUCTION

The basic structure of all ESERA ECO gateways consists of two sections. The following is a general

description of the functions and advantages resulting from the structure.

The description does not apply to all devices, this is a general description about all ECO gateways.

6.1 INTERFACE / SENSOR INTERFACE AND I/O SECTION

The basic structure of all ESERA ECO gateways consists of two sections. The following is a general

description of the functions and advantages resulting from the structure.

The description does not apply to all devices, this is a general description about all ECO gateways.

SECTION I, I/O SECTION/GATEWAY

This section includes the 1-Wire bus, the eBus and/or a sensor unit. It is specially optimized for the

acquisition and communication of sensor information.

The I/O section is designed as an independent, microcontroller-based electronic unit.

SECTION II, DATA INTERFACE, MAXI INTERFACE

The data interface or also called Maxi Interface represents the powerful communication interface of the

gateway. It enables the connection to other systems, control systems or controllers. The Maxi Interface is

also designed as a separate electronic unit based on a microcontroller.

ADVANTAGES OF THE SEPARATE SECTIONS

Below are some of the advantages that result from the device's structure in two sections:

MODULAR EXPANSION OPTIONS

Due to the construction of the device in two sections, extensions and upgrades can be easily carried out.

When a new function or additional module is needed, it can be easily inserted into the appropriate section

without having to replace all the hardware. This allows flexible adaptation of the device to the specific

requirements and needs of the user.

EASY MAINTENANCE AND REPAIR

The modular design also facilitates maintenance and repair of the unit. If a problem occurs in one section, it

can be checked and repaired separately without affecting the functionality of the other section. This reduces

downtime and allows problems to be fixed more quickly.

SCALABILITY AND FLEXIBILITY

The two-section design of the device allows for easy scaling and adaptation to changing requirements.

Different sections with different functions can be combined to meet the requirements of a specific application

area. This makes the device flexible to use and adapt to different scenarios.

SPACE AND COST SAVINGS

Due to the modular design and the possibility of expansion, the device can be used more efficiently. There is

no need to purchase separate devices for different functions, but they can be integrated into a single device.

This saves space and costs for additional hardware.

NATIVELY PROGRAMMED

The sections are natively programmed, which means that they do not rely on Linux or other operating

systems. This contributes to the gateway's low maintenance and enables many years of use without frequent

updates.

SEPARATE CONSTRUCTION

The separate design of the two sections offers advantages in terms of security and operational readiness. In

the event of attempted interference or cyber sabotage attacks on one of the sections, the other section

remains unaffected and operational.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 8 from 31

VARIOUS I/O FUNCTIONS AND INTERFACES

Depending on the requirements and the field of application of the ECO gateways, different I/O functions such

as 1-Wire or eBus as well as different interfaces such as Ethernet, WLAN, NB-IoT and LoRaWAN are

available. This allows the gateways to be adapted to different environments and applications.

Overall, the two-section design and associated benefits of the device provide increased flexibility, security,

scalability and efficiency in the use of the device.

Implementation of specific protection measures

In addition, the implementation of specific protection measures in each section of the gateway

provides increased security and protection against potential attacks. Here are some of the protections that

can be implemented in each section of the gateway:

•Secure Boot

Using Secure Boot ensures that only trusted and authenticated software components are loaded

during the boot process. This prevents malicious or unauthorized code from running and

compromising the system.

•Encryption techniques

Sensitive data exchanged between the sections of the gateway can be protected by encryption

techniques. For example, symmetric or asymmetric encryption algorithms are used here to ensure the

confidentiality and integrity of the data.

•TPM modules

Trusted Platform Modules (TPM) are special hardware modules that are used to securely store

cryptographic keys and perform security-related operations. The use of TPM modules can further

strengthen the security functions of the gateway, as they enable the detection of hardware tampering,

for example, and support the secure generation and management of keys.

These protective measures help to increase the security of the gateway and ward off potential attacks. They

ensure the integrity of the system, protect against unauthorized access to sensitive data, and ensure

trustworthy and secure communication between the sections of the gateway. The use of these security

mechanisms minimizes the risk of security breaches and unauthorized access.

Overall, the separate sections, the powerful communication interface and the security measures provide a

robust and flexible system for the acquisition, transmission and backup of sensor data. The use of native

programming and the absence of Linux ensure reliable and low-maintenance use of the ECO gateways over

a long period of time.

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 9 from 31

7 ECO 501 GATEWAY FUNCTIONS

The ECO 501 gateway offers various functions and interfaces for data communication and management of

1-Wire networks. Here are some important features and information about the functions:

DATA INTERFACE

Ethernet interface with 10/100 Mbit speed. Support of different data protocols like TCP/IP and UDP. Up to 3

simultaneous data connections possible.

MODBUS PROTOCOL

Modbus/TCP addressing for the gateway, simple and clear.

Addresses available for system and device data. A comprehensive address overview of all available data

points is available for download as a separate document on the website.

MQTT PROTOCOL

For M2M (Machine-to-Machine) and IoT (Internet of Things) applications.

Data connection via MQTT to a broker for sending and receiving data.

Send interval can be set via the web server.

Names can be added for 1-Wire sensors via Config Tool and are used in the send protocol. Default names

are used if no specific names are specified.

More details about the MQTT protocol can be found in the document "Interface manual" on the website.

ASCII TEXT PROTOCOL

The 1-Wire sensor data are output by the ECO 501 gateway ready prepared.

For example, temperature sensors are output cyclically in °C. Scaling only requires a division by 100.

Part numbers for ESERA modules can also be entered, whereby the calculation and output are adapted to

the function of the module.

SENSORS AND ACTUATORS

The ECO 501 Sensor Gateway supports up to 30 sensors.

Sensors are automatically connected to the Industrial 1-Wire bus via the Auto-E-Connect Plug and Play

system.

Each sensor can provide up to 5 measured values, for a total of up to 150 sensor data to your control system

or PLC.

AUTARKIC MANAGEMENT

The Sensor Gateway enables the self-sufficient management of a 1-Wire network.

No 1-Wire commands or formulas are required to evaluate the sensors and actuators.

The ECO 501 PRO gateway automatically scans the 1-Wire network for new 1-Wire devices, reads their

Auto-E-Connect data and outputs the converted data in plain text.

DESIGNED FOR ALL 1-WIRE NETWORKS

The 1-Wire interface of the ECO 501 PRO is specially designed for large 1-Wire networks with long cable

runs. 1-Wire devices can be operated in mixed parasitic or normal mode.

The interface offers maximum data security, even for complex network structures.

VOLTAGE SUPPLY

The ECO 501 gateway can be operated with a voltage of 9-30 VDC.

Suitable for 12V and 24V power supply systems in stationary and mobile applications.

Suitable DIN rail or plug-in power supplies are available in the webshop.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 10 from 31

COMMISSIONING

Support videos for commissioning and configuration can be found on our website www.esera.de under

"Service and Support", Support Videos.

8 AUTO-E-CONNECT® PLUG AND PLAY SYSTEM

The Auto-E-Connect® 1-Wire Plug and Play system enables fully automatic

configurations of the 1-Wire sensors and actuators on the 1-Wire bus. It offers

various added values and time savings for the customer. The system has been

optimized over many years and is optimized for smart building, industrial applications and IoT.

The Auto-E-Connect system automatically recognizes sensors and actuators and starts suitable libraries.

The data is ready formatted and output. These functions run automatically in the background during the

installation and commissioning of sensors and actuators.

The Auto-E-Connect system consists of three complementary levels that extend the functionality. With these

functions, fully automatic configurations of the 1-Wire sensors and actuators on the 1-Wire bus can be

realized.

Please note that the Auto-E-Connect functionality will be available for the ESERA ECO Gateways and

Station 200 Pro from 2021.

9 SCOPE OF FUNCTIONS AUTO-E-CONNECT SYSTEM

The three levels of the Auto-E-Connect system provide advanced functions and automation for the

installation and configuration of sensors and actuators in the 1-Wire bus.

Below are three levels of the Auto-E-Connect system

Level I

OWD Detect stands for "One-Wire Device Detect" and refers to the function of the ECO gateway to

automatically detect new sensors and actuators and to start adapted libraries within the gateway. This

saves time when connecting a new device to a 1-Wire gateway.

When a new sensor or actuator is connected to the 1-Wire bus, the ECO gateway automatically detects the

new device. It then automatically starts the corresponding libraries which are required for the detected

device.

This function makes the integration of new sensors and actuators much easier, as the manual configuration

effort is eliminated. It saves time and simplifies the installation process, as the gateway independently makes

the necessary settings and adjustments.

OWD Detect thus avoids the time-consuming manual configuration of new devices on the 1-Wire gateway,

which saves time overall when connecting new devices.

Level II

The ECO Gateway offers the possibility to read out and visualize the Auto-E-Connect data and

manufacturer data of sensors and actuators. Various information such as article number, date of

manufacture, firmware version and hardware version can be displayed.

Reading out this data gives you a detailed overview of the properties and specifications of the connected

sensors and actuators. This can help you manage and monitor your 1-Wire devices.

The visualization of the data can be done in different ways, depending on the functions and possibilities of

the ECO Gateway. This can be done, for example, via a web-based user interface or special software

provided by the manufacturer.

NOTE

Basics and tips on the 1-Wire bus system can be found in the ESERA Online Shop at

1-Wire Basics or please refer to our eBook in the store under Training/Documentation.

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 11 from 31

The visualization of the product data gives you a quick overview of the connected devices and their specific

properties. This can be of great benefit when troubleshooting, maintaining and monitoring the 1-Wire

network.

Level III

The advanced plug-and-play system for the 1-Wire bus offers various functions that facilitate the

installation and configuration of sensors and actuators. Here are some of the functions in detail:

PRE-CONFIGURATION

You can write

the desired OWD number (1-Wire Device Number) for the next installation directly into the sensor or

actuator. In this way, the device itself stores the information about its position in the gateway. This enables

automatic assignment of the devices in the target gateway without the need for manual sorting.

AUTOMATIC-POSITIONING

The device automatically logs on to each ECO gateway with Auto-E-Connect III using the pre-configured

OWD number. This automatic login process works up to the maximum possible number of OWDs of the ECO

gateway. No further configuration is required during commissioning.

SENSOR-FINDER-FUNCTION

The ECO 501 PRO gateway can activate the status LED of a sensor in the 1-Wire sensor network. The

status LED flashes for a certain time to facilitate the detection of a sensor within the network. This enables

faster localization of sensors and saves time and costs.

CLASSES-ASSIGNMENT

ESERA 1-Wire Devices are assigned to OWD classes based on their part number. These classes map

comparable properties, variable names and units. This class assignment enables fully automated software

installation, visualization and data evaluation, both locally and in the cloud. The class parameters can be

output via the data interface, e.g., via MQTT protocol.

These advanced features of the plug-and-play system simplify the installation and configuration of sensors

and actuators in the 1-Wire bus. It saves time and enables efficient management of the devices in your

system.

10 PATENT AUTO-E-CONNECT® SYSTEM

The 1-Wire Plug and Play System Auto-E-Connect is protected by a European

patent. This officially documents and confirms the innovation and uniqueness of

this system.

The expansion of functionality and the modernization of the 1-Wire bus through the Auto-E-Connect system

are impressive.

NOTE The above functions of the extended plug-and-play system only apply to sensors and actuators

that support the Auto-E-Connect functionality. It is important to consult the respective operating

instructions and technical specifications of the sensors and actuators to ensure that they are compatible

with the Auto-E-Connect system.

The Auto-E-Connect feature is specific to ESERA 1-Wire Devices and provides additional benefits for

device configuration and management. Please note that not all sensors and actuators on the market

support this feature, and it is important to verify compatibility prior to purchase.

For exact details on Auto-E-Connect support, please refer to the respective operating instructions and

technical documentation of the devices you intend to use.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 12 from 31

The great advantages for customers, such as the significant increase in convenience and the enormous cost

and time savings, make the 1-Wire Plug and Play System Auto-E-Connect extremely attractive.

The benefits are particularly noticeable in commissioning, preparation, inventory, live time management, and

service and maintenance (predictive maintenance).

With the Auto-E-Connect system, the Industrial 1-Wire sensor and actuator bus is state-of-the-art and at

least on par with comparable plug and play sensor systems such as IO-Link.

The system's areas of application are diverse and range from smart home and smart building to IoT and

M2M to mechanical and plant engineering, the German armed forces, and aerospace. This shows that the 1-

Wire Plug and Play System Auto-E-Connect can play out its advantages in various industries and application

areas.

This is a very innovative system that can be used in various areas. The ability to detect and configure

sensors and actuators fully automatically saves time and money and significantly increases the convenience

for the customer. In addition, the system is protected by ESERA's patent, making it unique on the market.

Figure, Patent Certificate for the 1-Wire Bus Auto-E-Connect System

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 13 from 31

11 TECHNICAL DATA

Feature

•Web server for configuring the data connections

•Internal access point available for 30 minutes at the touch of a button

•High-performance Ethernet interface

•Internal WLAN antenna

•Designed for use in extended temperature ranges

•Secure Boot and SSL-encrypted firmware for a high

Security

•Existing TPM chip

Data interfaces

•Ethernet (LAN): TCP/IP, UDP

•Industrial 1-Wire Bus (5V, 1-Wire Data and Ground (GND))

•Modbus/TCP (Ethernet 10/100MBit)

•Text protocol according to ASCII standard

Plug and Play System,

Auto E-connect

functions

- Automatic Positioning: Advanced Plug and Play system for fully

automatic positioning of the sensor / actuator in the ECO

Gateway

- Automatic library assignment: The appropriate library is

assigned fully automatically for the sensor

- Classes Assignment: Output OWD sensor class via ECO

gateway

- Electronic nameplate: output of part number, year of

manufacture, software version, software revision, hardware

version, OWD position, sensor finder function

- Pre-Configuration: Programming of the desired OWD at the next

ECO gateway, storage of the OWD number.

- Sensor Finder Function: LED display for sensor identification.

Let the status LED on the sensor / actuator flash for identification.

Data, Firmware Update

and configuration

Web Server and Config Tool 3

Software Support

Config Tool 3, ECO Dashboard 100

Supply voltage

Wide range 9-30VDC, universal 12VDC / 24VDC supply

Current consumption

•Power consumption max. 2.5W at 24VDC

•max. 10W at 24VDC with full bus load

Power Supply RTC

Goldcap, buffering of the internal clock (RTC) in case of supply

voltage failure for approx. 2 days. In the event of a longer failure,

the RTC must be reset.

The Goldcap is charged after approx. 2 hours.

1-Wire interface

•Advanced 1-Wire bus functions with Plug and Play feature,

Auto-E-Connect system

•max. 30 1-Wire sensors or actuators

•Data line with 5V level

•Output voltage 5V, max. 500mA

Protection circuits

•ESD, overvoltage and reverse polarity protection

•1-Wire Protector for 1-Wire interface (overvoltage protection up to

28VDC) during operation of ECO 501

Connection

Screw terminals for stranded wire and cable up to 2.5qmm cross-

section

Isolation

Galvanic isolation between Ethernet and 1-Wire interface

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 14 from 31

Supported 1-Wire

devices

DS2401, DS1963, DS1990, DS1820, DS18S20, DS18B20, DS2413,

DS2438, DS2450, DS2408, DS2405, DS2406 (only423,

other chips on request.

We will be happy to support additional modules as an OEM product for

you.

12 ENVIRONMENTAL CONDITIONS

Operating temperature

-5°C to +50°C, standard temperature range

Storage temperature

-10°C to +60°C

Relative humidity

10% to 92% (non-condensing)

Room classification

Operate only in dry rooms

Protection class

IP20

Protection class

III

Dimensions

2TE, 32 x 90 x 70mm (WxHxD)

13 CONFORMITY

EN 50090-2-2

EN 61000-4-2, ESD

EN 61000-4-3, HF

EN 61000-4-4, Burst

EN 61000-4-5, Surge

EN 61000-6-1, Noise immunity

EN 61000-6-3, Interference radiation

RoHS

14 DISPLAY LED

The module has different display LEDs. The function of the displays is as follows

ADVERTISEMENT

DESCRIPTION

FUNCTION

LED Green

PWR

Display for supply voltage

LED Green

DATA

•After switching on the device, the LED flashes 3x

•Flashes during 1-Wire activity

•Flashes when sending data via the data interface

•Flashes very quickly when "KAL Receive" has been

activated and the "KAL messages" from the control

system are absent.

LED Green

LAN

LAN - network status LED

Lights up when LAN network connection

is established

Flashes when the interface is not activated

LED Green

WLAN

WLAN - Network Status LED

Lights up when WLAN network connection is established

Flashes when the WLAN access point is activated and a

direct connection is possible

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 15 from 31

15 CONNECTION PLAN

Module bottom

1-Wire Bus Interface

1 = Ground 1-Wire

2 = 1-Wire Data

3 = 5V output

Module top side power supply 10-

30VDC

12 = Minus supply voltage

21 = Plus supply voltage

Notice:

5 = Reset Button

IMPORTANT

It is essential that the module is operated exclusively in accordance with the specified voltages and

ambient conditions.

The operating position of the device is arbitrary, i.e., it can be operated in any orientation.

The installation and commissioning of the assembly may only be carried out by a qualified electrician. A

qualified electrician has the necessary knowledge and skills to ensure that the installation complies with the

appropriate safety standards.

It is also important to perform all connection work on the assembly in a de-energized state. Before starting

any connection work, all power sources should be switched off and appropriate safety precautions taken to

prevent injury or damage.

For more detailed information on the specific operating conditions, I recommend that you read the enclosed

instructions. There you should find all necessary information to operate the module safely and properly.

NOTE

The FE connection (functional ground) of the ECO 501 should be connected to the ground potential (PE) to

establish a functional ground. This is important to ensure reliable operation of the module.

Connecting the FE terminal to ground potential establishes a grounding that helps minimize interference

and electrical problems. Proper functional grounding protects the assembly from electrostatic discharge,

surges, and other potential interference.

It is advisable to follow the manufacturer's instructions and guidelines to ensure that functional grounding is

performed according to the specific requirements of the ECO 501. Also observe possible specifications and

regulations in your specific environment to ensure a safe and reliable installation.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 16 from 31

16 CONNECTION EXAMPLE

Connection example of the ECO 501 Sensor Gateway with many sensors

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 17 from 31

17 ACTIVATE ACCESS POINT

The ECO gateway with Maxi interface has a connectable WiFi

(WLAN) access point. This allows you to access the gateway

directly with a mobile device such as a smartphone, tablet or

laptop without the need for additional devices such as a

separate access point (e.g. a Fritzbox).

By activating the WiFi access point on the ECO gateway, you

can establish a wireless connection and access the gateway's

functions and settings. This allows you, for example, to

configure network settings, monitor sensor data or control

connected devices.

To access the gateway via WiFi, make sure that your mobile

terminal is connected to the WiFi access point of the gateway.

You can then access the gateway via a web browser or

special application software and use the desired functions.

Please note that you may need to follow the manufacturer's

instructions for activating and configuring the WiFi access

point on the ECO gateway. These instructions should help you

to successfully set up and use access via WiFi.

See figure, LED "AP" is on, LED "Station" is off

NOTE

To access the web server of the ECO gateway, use the

Ethernet interface and the IP address of the device. You can

get the exact IP address from the "Ethernet Interface Settings"

web page.

The following steps can help you to determine the IP

address of the ECO gateway:

•Make sure that the ECO Gateway is connected to your

network and turned on.

•Open a web browser on a device connected to the same

network.

•In the browser's address bar, type the IP address you

normally use to access a router's configuration interface. For

example, this could be "192.168.0.1" or "192.168.1.1".

•On the web page that is displayed, look for the "Ethernet

Interface Settings" section or similar options that contain

information about the IP address of the ECO gateway.

•Make a note of the specified IP address of the ECO gateway.

Once you have the IP address of the ECO gateway, you can enter it in the address bar of your browser and

access the web server of the gateway. This will give you access to the configuration settings and other

functions of the ECO gateway via the web user interface.

Push button to activate the Access Point

NOTE

You activate the access point by pressing (for 5 seconds)

the button on the top.

The access point is active for approx. 30 minutes.

After that, it deactivates automatically for security

reasons.

You can switch off the access point by pressing it

again for at least 5 seconds.

Access Point is activated

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 18 from 31

Please note that the exact steps and user interface may vary depending on the model and firmware version

of the ECO Gateway.

18 SELECT ACCESS POINT

The ECO gateway with Maxi interface reports as WLAN access point with the identification "ESERA". In the

delivery state, the Ethernet interface is set to "DHCP".

The access point is open, without access password.

19 CALL WEB SERVER VIA WIFI

If you have connected to the WLAN network "ESERA", the web browser starts directly on many

smartphones.

If this is not the case, switch to your web browser (e.g. Firefox, Chrome, etc.) and enter

enter the IP address of the ECO Gateway. Now the web server of the ECO Gateway should be visible,

comparable to the following picture.

The configuration of the device is currently only possible via

the web server of the ECO Gateway.

NOTE

The IP address of the ECO Gateway via Access Point

is: 192.168.4.1

The IP address of the access point is printed on the

right side of the gateway housing.

Important:

Enter the IP address without "Error! Link reference

invalid.".

Select "ESERA" Access Point

NOTE

The ECO WLAN access point can be found as a

WLAN network at the identifier "ESERA".

Art. No. 11607-24

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 19 from 31

20 CALL WEBSERVER VIA LAN

You can also connect the web server of the ECO Gateway at any time via LAN interface using the set

Reach IP address.

The IP address of the ECO Gateway is shown on the device display (if the device has a display). If the

device does not have a display, you can

also read out the current IP address (not the

IP address of the access point) via your router/DHCP server.

21 WEBSERVER, LOG IN

Password, Log In

To be able to log in to the web server of the ECO

Gateway, use for the first login the

Startup/default password: eserapwd

For security reasons, the password is not displayed in

plain text, but with dots.

After entering the password, click on the "Login"

button to open the main menu (hereinafter referred to

as the main menu).

Please change the password after the first login,

otherwise unauthorized persons can also

make settings on the

ECO Gateway.

Please enter a new and secure password via the

main menu/"Change Password".

Advice on how to assign secure passwords can be

found on the Internet.

Software version Ethernet interface/Log Out

Display of the software version of the Ethernet

interface installed on the device. The version of the 1-

Wire firmware can be seen via the Config Tool 3.

Click on the "Log Out" button to exit the web

interface.

NOTE

The startup/default password for login is: eserapwd

IMPORTANT

Please change the password after the first login.

It is a good security practice to change the password after the initial login to ensure the security of the

system. After you have successfully logged in, you should change the default password and set a new,

strong password.

This will minimize the risk of unauthorized access to the system. Make sure that the new password is

sufficiently complex and contains both letters, numbers and special characters. Avoid using passwords

that are easy to guess and use a combination of different characters instead.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. © ESERA GmbH 2023

www.esera.de 11607-24 V1.0 R1.44 Manual Page 20 from 31

To get more details about the functions of the web server of the ECO Gateway, we recommend that you

consult the document "Interface manual". You can find this document via the website www.esera.de in the

download area/technical downloads.

The "Interface Manual" should contain detailed information about the various functions and possibilities of

the web server of the ECO gateway. It can help you to optimally configure and use the gateway to meet your

requirements.

Please note that the exact procedure for navigating the website and downloading the manual may depend

on the specific website structure and layout. If you have difficulty finding the manual, I recommend that you

use the website search function or contact esera technical support directly for further assistance.

22 DATA INTERFACE, ASCII PROTOCOL

You configure the Ethernet interface with the help of the Windows ESERA program Config Tool 3. You

find this program in the download area of the ESERA Onlineshop Tool 3 software.

23 ESERA ASCII TEXT PROTOCOL

The ASCII text protocol is a communication protocol used to transfer data between different devices via

serial interfaces.

The abbreviation "ASCII" stands for "American Standard Code for Information Interchange" and refers to the

standard code used to represent characters, numbers and symbols in digital form.

In the ASCII text protocol, data is transmitted in the form of character strings, with each character coded in its

ASCII representation. A character string can represent different types of data, such as measured values,

control commands or status messages.

The ASCII text protocol is comparatively simple and easy to implement because it uses the standardized

ASCII character set. Data is transmitted in plain text, which facilitates the readability and traceability of the

transmitted data.

Other manuals for ECO 501 PRO

1

Table of contents

Other esera Gateway manuals

Popular Gateway manuals by other brands

Yeastar Technology

Yeastar Technology TB200 installation guide

SATION

SATION GW2301.0201 user manual

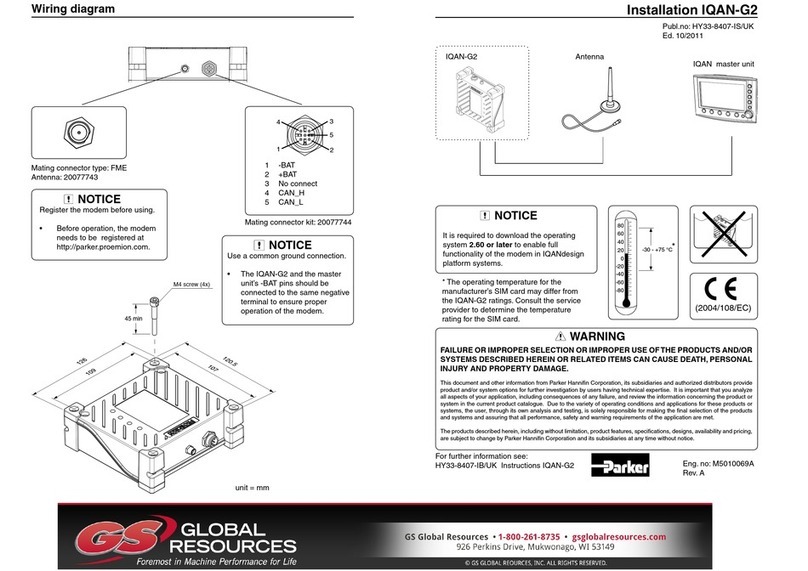

GS

GS Parker IQAN-G2 quick start guide

Planet Networking & Communication

Planet Networking & Communication LCG-300 Series user manual

B&B Electronics

B&B Electronics Vlinx MESR9xx user manual

MSI

MSI MS-6848 user guide

MiTWell

MiTWell KUBER-1000 Series user manual

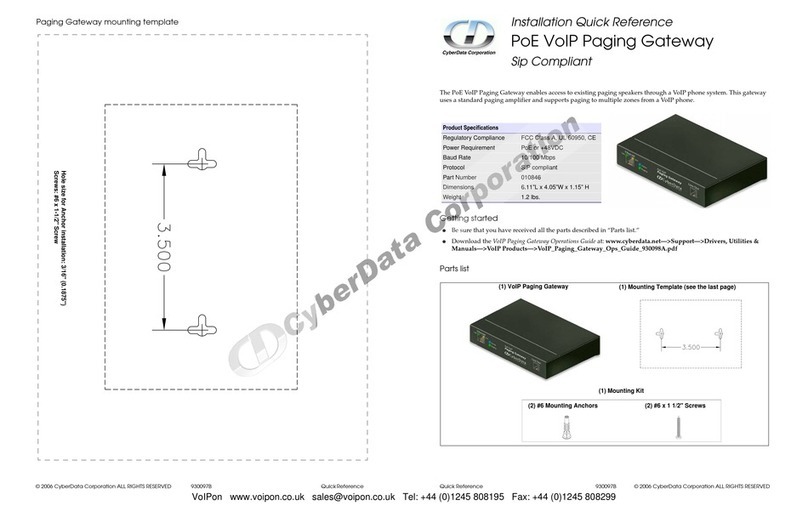

CyberData

CyberData SiP Compliant 010846 Installation quick reference

Pettinaroli

Pettinaroli Alpha Smartware IOTG 26001 Series manual

AudioCodes

AudioCodes Mediant 4000 SBC user manual

Atlas

Atlas Zone Controller Pro ZCM-V2 Install Sheet

Mediatrix

Mediatrix 1102 installation guide