esera STATION 200 V2 User manual

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 1 from 26

Modbus/TCP, Modbus/RTU

INTERFACE MANUAL

ECO GATEWAYS AS OF YEAR OF MANUFACTURE 2023

WITH WEBSERVER

ESERA STATION 200 V2

ECO 110 SENSOR GATEWAY PRO

ECO 501 SENSOR GATEWAY PRO

ECO 502 SENSOR GATEWAY PRO

ECO 503 IT/IOT SWITCH

ECO 608 SENSOR GATEWAY 1-WIRE

UMS2205 ENVIRONMENTAL MONITORING STATION

V2.0 R1.2

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 2 from 26

1. CONTENTS

1. CONTENTS.........................................................................................................................................2

2. PRODUCT OVERVIEW ECO AND EC GATEWAYS ........................................................................3

3. MODBUS/TCP GENERAL .................................................................................................................4

4. MODBUS COMMUNICATION ECO GATEWAY ...............................................................................4

5. ECO GATEWAY SYSTEM .................................................................................................................5

6. THE ESERA ECO GATEWAY CONCEPT.........................................................................................5

7. INTERFACE (MAXI INTERFACE) - AND I/O SECTION....................................................................5

8. CONFIGURATION MODBUS INTERFACE.......................................................................................7

8.1. ACTIVATE ACCESS POINT...............................................................................................................7

8.2. SELECT ACCESS POINT...................................................................................................................8

8.3. CALLING THE WEB SERVER VIA WIFI.............................................................................................8

8.4. CALLING THE WEB SERVER VIA LAN..............................................................................................9

8.5. WEBSERVER, SIGN IN/LOG IN .........................................................................................................9

8.6. HOME/MAIN PAGE...........................................................................................................................10

9. MODBUS TEST SOFTWARE ..........................................................................................................11

10. MODBUS FUNCTION CODES.........................................................................................................12

11.MODBUS ADDRESSES...................................................................................................................14

11.1. MODBUS READ ADDRESSES, SYSTEM VARIABLES...................................................................14

11.2. MODBUS READ ADDRESSES 1-WIRE SENSORS /OWD.............................................................16

11.3. MODBUS READ ADDRESSES 1-WIRE TEMPERATURE SENSORS ............................................18

11.4. MODBUS READ ADDRESSES 1-WIRE ACTUATORS....................................................................19

11.5. MODBUS WRITE ADDRESSES.......................................................................................................21

11.6. MODBUS WRITE ADDRESSES 1-WIRE SENSORS.......................................................................22

11.7. MODBUS WRITE ADDRESSES 1-WIRE ACTUATORS ..................................................................24

12. CONCLUSION AND FEEDBACK ....................................................................................................26

13. WARRANTY .....................................................................................................................................26

14. WARNING.........................................................................................................................................26

15. CONTACT.........................................................................................................................................26

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 3 from 26

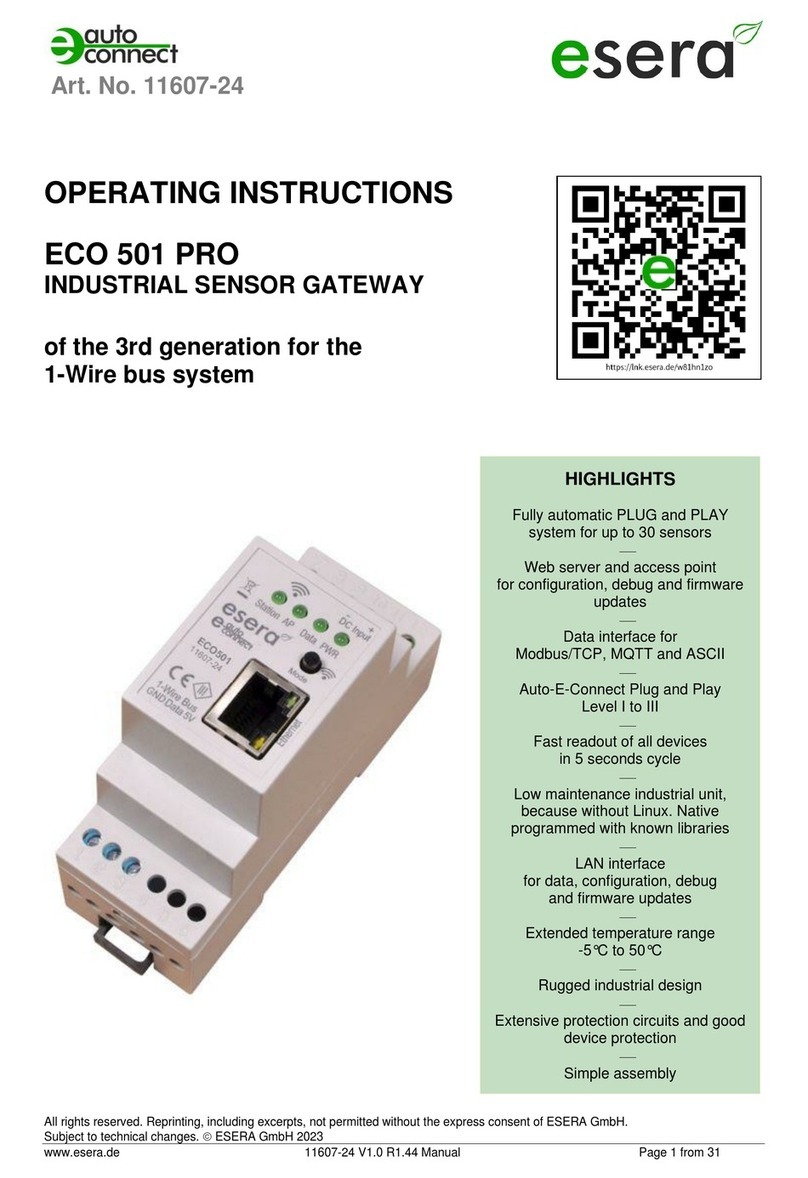

2. PRODUCT OVERVIEW ECO AND EC GATEWAYS

The ESERA EC and ECO gateways of the latest generation are divided into different series.

We offer the right device for different requirements and areas of application, such as private, commercial and

industrial use.

The following is an overview of the ECO and EC gateways.

All gateways have an access point and web server. Only the gateways with this equipment will be discussed

in this manual. In the following overview, the devices for this manual are marked in green.

For the gateways without web server and access point use the manual version 1.0.

ECO GATEWAY WITH MAXI INTERFACE,

MODBUS interface

AND ACCESS POINT AND WEBSERVER

Described below in this manual.

EC and ECO GATEWAY STANDARD

INTERFACE,

WITHOUT WEBSERVER

Not described in this manual

•ECO 110 Sensor Gateway 1-Wire Interface

•ECO 501 Pro, Sensor Gateway Modbus/TCP

MQTT, with 1-Wire Interface

•ECO 502 Pro, Sensor Gateway Modbus/RTU with

1-Wire Interface

•ECO 503, IT/IoT Switch Gateway, Modbus/TCP,

MQTT, 8-channel switching module 10/16A and

dig. inputs

•ECO 608 Pro, Security Sensor Gateway,

Modbus/TCP, MQTT, with 1-Wire Interface,

digital I/O

•UMS 2206 Pro, Smart City environmental

measurement system, wall mount, 8 environmental

sensors, UPS,

1-Wire interface, digital I/O

•1-Wire Gateway 10,

Smart Home Sensor Gateway,

with 1-Wire Interface

•1-Wire Gateway 20,

Smart Home Sensor Gateway,

with 1-Wire Interface Relay + analog Out

•ECO 100,

Smart Building Sensor Gateway with

1-Wire Interface

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 4 from 26

3. MODBUS/TCP GENERAL

Modbus/TCP is a protocol for communication between devices in a network, based on the Modbus protocol

and the TCP/IP protocol.

Modbus is a serial-based protocol that is widely used in industrial automation to transmit measurement data,

control commands, and status messages. It is

also widely used in computer network technology and is used to connect devices in a network.

The Modbus/TCP protocol allows to connect controllers and gateways in Ethernet networks by embedding

Modbus data packets into TCP/IP data packets. It uses the standard port number 502.

The protocol works with two types of packets: Requests and responses. A request is sent from one device to

another to retrieve data or send commands. The response contains the data or confirmation that the

command has been executed.

It also supports various functions, including reading and writing data registers, reading input registers, and

reading and writing lock bits.

Modbus/TCP provides an effective and reliable way to exchange data between different devices on a

network and is used in many different applications in industrial automation, building automation and other

fields.

4. MODBUS COMMUNICATION ECO GATEWAY

Modbus is de facto the common bus standard for communication between PLC machine controllers and the

machine-related environment in industry.

No PLC controller on the market can do without this bus interface. The success story of the Modbus

standard was initiated in 1979 by Gould-Modicon for communication with its programmable logic controllers.

In the industry, Modbus has become a standard because it is an open protocol. Since 2007, the Modbus

TCP version has been part of the IEC 61158 standard. (Source: https://de.wikipedia.org/wiki/Modbus)

ESERA has Modbus/TCP and Modbus/RTU as an integral part of the data interfaces of the ECO Gateway

product series, and can thus connect various industry standards, such as Modbus, MQTT, LoRaWAN, NB-

IoT and 1-Wire, via gateways.

During the development of the ECO sensor gateways, special emphasis was placed on user-friendliness and

many automatic functions. This is additionally supported by a configuration software,

Config Tool 3, which combines all desirable functions up to the documentation and an installation report.

By the ESERA gateways are intended for a wide range of applications, even far outside the industry

attractive. The application areas include all commercial applications, such as smart home, smart building,

data center, OT and IoT systems.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 5 from 26

5. ECO GATEWAY SYSTEM

Many sensors, a powerful interface, a web server and access point, and a fully automated plug and play

system.

6. The ESERA ECO Gateway Concept

•A large number of sensors can be connect fully automatically via Industrial 1-Wire Bus

using Auto-E-Connect.

•Up to 30 sensors with a maximum of 150 sensor values can be connected.

•In addition, there are direct analog and digital inputs of the ECO Gateway.

•Furthermore, there is a housing interior climate monitoring system with alarm system.

•Extremely powerful data interface for up to 5 simultaneous data connections to control rooms and

PLC controllers

•Modern settings of the gateway via web server

•Connectable access point for independent access by mobile devices, such as smartphones, tablet or

laptop.

7. INTERFACE (MAXI INTERFACE) - AND I/O SECTION

The basic structure of all ESERA ECO gateways is such that the devices consist of two sections.

The first section consists of an I/O gateway (1-Wire bus, eBus and/or sensor unit) and

the second section consists of a very powerful interface. This very powerful interface is referred to below as

the Maxi Interface.

The two sections communicate with each other internally.

These two sections are built into separate, electronic units on a gateway basis.

The advantage is that each of the sections is specially optimized for its task. This gives you an extremely

powerful, robust device with low energy consumption. The

ECO gateways are designed for years of use.

No Linux system is used in either of the sections. All sections of the devices are natively programmed and

thus very low-maintenance.

The advantage here is clearly the years of use without any update.

Depending on the ECO gateway, different I/O functions, e.g. 1-Wire or eBus and different

interfaces, e.g. Ethernet, WLAN, NB-IoT, LoRaWAN, are available.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 6 from 26

For the above reason, there are two firmware update buttons. Please avoid confusing the firmware versions.

Illustration:

Extract from the main page of the web

server

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 7 from 26

8. CONFIGURATION MODBUS INTERFACE

NOTE

The following description is intended for ECO Sensor Gateways from year of manufacture 2023 with

web server and access point. If you have a 1-Wire gateway without web server, please use the

interface manual Modbus V1.0

8.1. ACTIVATE ACCESS POINT The ECO Gateways with Maxi interface have a connectable

WiFi (WLAN) access point.

This means that you can access the device via mobile end

device, such as smartphone, tablet or laptop. This is possible

directly - without additional devices via WiFi (WLAN), access

point (e.g. Fritzbox).

What is an access point?

With an access point (wireless LAN AP mode), mobile end

devices such as laptop, tablet, smartphone, etc. can be

connected directly to the ECO Gateway. No additional

wireless LAN access point is required.

When the access point is activated, we talk about the AP

mode of the WLAN interface of the ECO Gateway.

(See figure, LED "AP" is on, LED "Station" is off)

If you no longer need the access point, switch it off by

pressing the button again for at least 5 seconds.

Push button to activate the Access Point

NOTE

You activate the access point by pressing

(of 5 seconds length) on the button on the top.

The access point is active for approx. 30 minutes. After

that, it deactivates automatically for security reasons.

You can switch off the access point by pressing the

button again for at least 5 seconds.

NOTE

The web server is continuously available via the

Ethernet interface. You can reach it via the

IP address of the device.

The IP address of the ECO gateway can be found on

the "Ethernet Interface Settings" web page

Access Point is activated

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 8 from 26

8.2. SELECT ACCESS POINT

The ECO gateway with Maxi interface registers as a WLAN access point with the identifier "ESERA". In the

delivery state, the Ethernet interface is set to "DHCP".

The access point is open, without an access password.

8.3. CALL WEB SERVER VIA WIFI

If you have connected to the WLAN network "ESERA", the web browser starts directly on many mobile

phones.

If this is not the case, switch to your web browser (e.g. Firefox, Chrome, etc.) and enter the IP address of the

ECO Gateway. Now the web server of the ECO Gateway should be visible, comparable to the following

picture.

The configuration of the device is currently only possible via

the web server of the ECO Gateway.

NOTE

The IP address of the ECO Gateway via Access

Point is: 192.168.4.1

The IP address of the access point is printed on the

right side of the gateway housing.

Important:

Enter the IP address without "https://".

Select "ESERA" Access Point

NOTE

The ECO WLAN access point can be found as a

WLAN network at the identifier "ESERA".

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 9 from 26

8.4. CALL WEBSERVER VIA LAN

You can also connect the web server of the ECO Gateway at any time via LAN interface using the set

Reach IP address.

The IP address of the ECO Gateway is shown on the device display (if the device has a display). If the

device does not have a display, you can

also read out the current IP address (not the

IP address of the access point) via your router/access point/DHCP server.

8.5. WEBSERVER, SIGN IN/LOG IN

Password, Sign in/Log in

To be able to log into the web server of the ECO

Gateway, use for the first login the

Startup/default password: eserapwd

For security reasons, the password is not displayed in

plain text, but with dots.

After entering the password, click on the "Log in"

button to open the main menu (hereinafter referred to

as the main menu).

Please change the password after the first login,

otherwise unauthorized persons can also make

settings on the

ECO Gateway.

Please enter a new and secure password via the

main menu/"Change Password".

Advice on how to assign secure passwords can be

found on the Internet.

Software version Ethernet interface/Log Out

Click on the "Log Out" button to exit the web

interface.

NOTE

The startup/default password for Log In is: eserapwd

IMPORTANT

Please change the password after the first login.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 10 from 26

8.6. HOME/MAIN PAGE

The ECO gateways are delivered with different equipment regarding interfaces and protocols.

The main page is divided into two sections:

•General

Here you will find all menus for configuring the interfaces and viewing the gateway

and sensor data. The various buttons (selection

keys) take you to the corresponding submenus,

which are described below.

•Danger Zone

Here you get to submenus where you should take

great care, because the possible changes are

usually not undoable.

Ethernet Interface Setting

Use this button to enter the menu for setting the IP

address, Sub Net and Gateway number.

MQTT Settings (if supported by the device)

In this menu you can enter e.g. access data of the

MQTT broker.

ESERA ASCII Settings

From here you come to the submenu for setting the

data port. Pressing the button takes you to the menu for

configuring socket interfaces 2 - 5.

Modbus Settings

In this menu you can set e.g. the port number of the

Modbus/TCP interfaces.

Data View

Here you can view the gateway data and the sensors

connected via 1-Wire bus system. Here you will also

find the Auto-E-Connect information.

Firmware update, 1-Wire bus, I/O section

Using this button you can perform an update of the

Perform 1-Wire section.

Firmware Update Interface Section

This button allows you to perform a firmware update of

the interface and the web server.

Change Password

To change the password for the web server, click the

"Change Password" button.

Factory Reset

You may reset the Ethernet interface to the delivery

state. For this press the button "Factory Reset

Software version Ethernet interface/Log Out

Display of the software version of the Ethernet interface

installed on the device. The version of the 1-Wire

firmware can be seen via the Config Tool 3.

Sign Out

Click the "Sign Out" button to exit the web server.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 11 from 26

9. MODBUS TEST SOFTWARE

To perform first tests via Windows and a small test program, you can use e.g. the program Modbus Master

(qmodmaster). It is an open source program. Below the link for the download.

https://sourceforge.net/projects/qmodmaster/

We do not take any liability for the link and the test program.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 12 from 26

10. MODBUS FUNCTION CODES

Structure and function codes Modbus

RTU, RS485 interface

Structure and function codes

Modbus TCP, Ethernet interface

FC1,2 (reads single bits):

Example:

FC1,2 (reads single bits):

Example:

Gateway no.

1

Transactionsnr high

0

Function code

1

Transactionsnr low

0

Start address high (bit)

0

Protocol ident high

0

Start address low (bit)

32

Protocol ident low

0

Number of bits high

0

Bytes from here

6

Number of bits low

8

Recognition

e.g. 1

CRC high

x

Function code

1

CRC low

x

Start address high (bit)

0

Start address low (bit)

32

Number of bits high

0

Number of bits low

8

FC3,4 (reads words):

FC3,4 (reads words):

Gateway no.

1

Transactionsnr high

0

Function code

4

Transactionsnr low

0

Start address high (word)

238

Protocol ident high

0

Start address low (word)

102

Protocol ident low

0

Word count high

0

Bytes from here

6

Word count low

9

Recognition

e.g. 1

CRC high

x

Function code

4

CRC low

x

Start address high (word)

238

Start address low (word)

102

Word count high

0

Word count low

9

FC5 (sets one bit):

FC5 (sets one bit):

Gateway no.

1

Transactionsnr high

0

Function code

5

Transactionsnr low

0

Start address high (bit)

0

Protocol ident high

0

Start address low (bit)

32

Protocol ident low

0

Bit value high

255 or 0

Bytes from here

6

Bit value low

0

Recognition

e.g. 1

CRC high

x

Function code

5

CRC low

x

Start address high (bit)

0

Start address low (bit)

32

Bit value high

255 or 0

Bit value low

0

FC6 (writes a word):

FC6 (writes a word):

Gateway no.

1

Transactionsnr high

0

Function code

6

Transactionsnr low

0

Start address high (word)

1

Protocol ident high

0

Start address low (word)

146

Protocol ident low

0

Write value high

0

Bytes from here

6

Write value low

85

Recognition

e.g. 1

CRC high

x

Function code

6

CRC low

x

Start address high (word)

1

Start address low (word)

146

Write value high

0

Write value low

85

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 13 from 26

FC16 (writes words):

FC16 (writes words):

Gateway no.

1

Transactionsnr high

0

Function code

16

Transactionsnr low

0

Start address high (word)

238

Protocol ident high

0

Start address low (word)

102

Protocol ident low

0

Word count high

0

Bytes from here

11

Word count low

2

Recognition

e.g. 1

Byte count

4

Function code

16

Write value1 high

0

Start address high (word)

238

Write value1 low

123

Start address low (word)

102

Write value2 high

0

Word count high

0

Write value2 low

234

Word count low

2

CRC high

x

Byte count

4

CRC low

x

Write value1 high

0

Write value1 low

123

Write value2 high

0

Write value2 low

234

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 14 from 26

11. MODBUS ADDRESSES

NOTE: Only for ECO Sensor Gateways from year of manufacture 2023 with web server, e.g. ECO 501, ECO 502, ECO 608

11.1. MODBUS READ ADDRESSES, SYSTEM VARIABLES

Description

Reading addresses

Comment

Address

Word

Quantity

(16Bit)

Data

type

Bit

address

System inputs and outputs and sensors of the ECO Gateway

Binary inputs

Only:

Gateway 2,

Gateway 20

ECO 200

50001

1

Word

Status of the binary inputs of the 1-Wire Gateway 2 / 1-Wire Gateway 20

HHLL

Binary outputs

Gateway 2,

Gateway 20,

ECO 200

Outputs

50002

1

Word

32 to 36

Status of the binary outputs of the 1-Wire Gateway 2 / 1-Wire Gateway 20

HHLL

Analog output

Only:

Gateway 2,

Gateway 20

50003

1

Word

16 to 19

Status of the analog output of the 1-Wire gateway 2 / 1-Wire gateway 20

HHLL

Binary input or

output (optional)

ECO 100

ECO 200

50004 -

50009

1

Word

Status of binary / digital inputs or outputs, depending on the equipment of the

ECO gateways.

(For details see operating instructions of the respective ECO gateway)

HHLL

Sensor value 1-8

ECO 100,

ECO 200

50020 -

50029

1

Integer

Depending on the integrated sensor,

Temperature, rel. humidity, dew point, etc.

(For details see operating instructions of the respective ECO gateway)

HHLL

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 15 from 26

Modbus addresses System variables

Gateway no.

60000

1

Word

Output of the assigned number of the 1-Wire gateway / 1-Wire gateway

HHLL

Item no.

60001

1

Word

Part number of the 1-Wire gateway / 1-Wire gateway

HHLL

Firmware version

61000

5

String

Firmware version of the 1-Wire gateway / 1-Wire gateway

HHLL

Hardware version

61010

3

String

Hardware version of the 1-Wire gateway / 1-Wire gateway

HHLL

Serial number

61020

9

String

Serial number of the 1-Wire gateway / 1-Wire gateway

HHLL

Time

61030

4

String

Time off (RTC)of the 1-Wire gateway / 1-Wire gateway

hh:mm:ss

Date

61035

4

String

Date (RTC) 1-Wire Gateway / 1-Wire Gateway

dd.mm.yy

Time, date

61030

9

String

Combination of time and date (RTC)

hh:mm:ss

dd.mm.yy

OWD Quantity

61039

1

Word

Output how many 1-Wire (OWD) sensors or actuators are stored

HHLL

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 16 from 26

11.2. MODBUS READ ADDRESSES 1-WIRE SENSORS / OWD

Reading addresses

Multisensors

Temperature and

rel. humidity

Art. No. 11131,

11132, 11134,

11135, 11150,

11160, 11167,

11168

and more

Multisensors

with air quality

Art. No. 11151,

11152, 11165,

11171 and others

PV sensor

e.g. 11112

Brightness

sensor

e.g. 11129

Comment

Address

Word

Quantit

y

(16Bit)

Data

type

Bit

address

1-Wire Multisensors Standard and PRO

OWD 1

Sensor data

40100

1

Integer

Temperature

HL LH

40101

1

Integer

Dew point

not used (255)

HL LH

40102, 40103

2

Dwort

Power Good

HH HL LH

LL

40104, 40105

2

Dwort

rel. Humidity

Brightness

Brightness

HH HL LH

LL

40106, 40107

2

Dwort

Brightness*

Air Quality

Irradiation

Status input binary

HH HL LH

LL

40108, 40109

2

Dwort

not used (255)

HH HL LH

LL

40110, 40111

2

Dwort

not used (255)

HH HL LH

LL

40112, 40113

2

Dwort

Status

0=sensor/actuator active, 5=currently not readable, 10=no sensor/actuator

present

HH HL LH

LL

40114, 40115

2

Dwort

Error Counter

HH HL LH

LL

40116, 40117

2

Dwort

Part number / Type

HH HL LH

LL

OWD 1

Auto-e-connect

data

40118

1

Word

Part number / Type

HL LH

40119

1

Word

Herstelljahr / Date of Manufacture

HL LH

40120

1

Word

Software version

HL LH

40121

1

Word

Software revision

HL LH

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 17 from 26

40122

1

Word

Hardware version

HL LH

40123

1

Word

Interface version

HL LH

40124

1

Word

OWD Position, OWD Desired position of the sensor in the ECO Gateway

HL LH

40125

1

Word

Auto e-connect class

HL LH

OWD 2

Sensor data

40200

1

Integer

Temperature

HL LH

40201

1

Integer

Dew point

not used (255)

HL LH

40202, 40203

2

Dwort

Power Good

HH HL LH

LL

40204, 40205

2

Dwort

rel. Humidity

Brightness

Brightness

HH HL LH

LL

40206, 40207

2

Dwort

Brightness*

Air Quality

Irradiation

Status input binary

HH HL LH

LL

40208, 40209

2

Dwort

not used (255)

HH HL LH

LL

40210, 40211

2

Dwort

not used (255)

HH HL LH

LL

40212, 40213

2

Dwort

Status

0=sensor/actuator active, 5=currently not readable, 10=no sensor/actuator

present

HH HL LH

LL

40214, 40215

2

Dwort

Error Counter

HH HL LH

LL

40216, 40217

2

Dwort

Part number / Type

HH HL LH

LL

OWD 2

Auto-e-connect

data

40218

1

Word

Part number / Type

HL LH

40219

1

Word

Herstelljahr / Date of Manufacture

HL LH

40220

1

Word

Software version

HL LH

40221

1

Word

Software revision

HL LH

40222

1

Word

Hardware version

HL LH

40223

1

Word

Interface version

HL LH

40224

1

Word

OWD Position, OWD Desired position of the sensor in the ECO Gateway

HL LH

40225

1

Word

Auto e-connect class

HL LH

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 18 from 26

11.3. MODBUS READ ADDRESSES 1-WIRE TEMPERATURE SENSORS

Reading addresses

Temperature sensors

z. B 11106

Comment

Address

Word

Quantity

(16Bit)

Data

type

Bit

address

1-Wire temperature sensor

OWD 1

Sensor data

40100

1

Integer

Temperature

HL LH

40101

1

Integer

not used (255)

HL LH

40102, 40103

2

Dwort

not used (255)

HH HL LH LL

40104, 40105

2

Dwort

not used (255)

HH HL LH LL

40106, 40107

2

Dwort

not used (255)

HH HL LH LL

40108, 40109

2

Dwort

not used (255)

HH HL LH LL

40110, 40111

2

Dwort

not used (255)

HH HL LH LL

40112, 40113

2

Dwort

Status

HH HL LH LL

40114, 40115

2

Dwort

Error Counter

HH HL LH LL

40116, 40117

2

Dwort

Part number / Type

HH HL LH LL

OWD 1

auto-e-connect

data

40118

1

Word

Part number / Type

HL LH

40119

1

Word

not used (255)

HL LH

40120

1

Word

not used (255)

HL LH

40121

1

Word

not used (255)

HL LH

40122

1

Word

not used (255)

HL LH

40123

1

Word

not used (255)

HL LH

40124

1

Word

OWD Position, OWD Desired

position of the sensor in the ECO

Gateway

HL LH

40125

1

Word

Auto e-connect class

HL LH

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 19 from 26

11.4. MODBUS READ ADDRESSES 1-WIRE ACTUATORS

Description

Reading

addresses

8-fold binary

output/

Switch module

(binary output)

with pushbutton

interface

e.g. 11220, 11228

Dual switch

module

e.g. 11218,

11233

8-fold switching

module (binary

output)

e.g. 11229

iButton

DS2401 and

more

Comment

Address

Word

Quantit

y

(16Bit)

Data

type

Bit address

OWD 1

40102, 40103

2

Dwort

1632 to 1639

(102*16)

Status input decimal

not used (255)

not used (255)

not used (255)

HH HL LH LL

40104, 40105

2

Dwort

Status input binary

not used (255)

not used (255)

0 or 1 (bit)

HH HL LH LL

40106, 40107

2

Dwort

Status output

decimal

Status output

decimal

Status output

decimal

not used (255)

HH HL LH LL

40108, 40109

2

Dwort

Status output binary

Status output

binary

Status output

binary

not used (255)

HH HL LH LL

40110, 40111

2

Dwort

not used (255)

not used (255)

not used (255)

not used (255)

HH HL LH LL

40112, 40113

2

Dwort

Status

0=sensor/actuator active, 5=currently not readable, 10=no sensor/actuator

present

HH HL LH LL

40114, 40115

2

Dwort

Error Counter

HH HL LH LL

40116, 40117

2

Dwort

Part number / Type

HH HL LH LL

OWD 2

40201,40202

2

Dwort

2

Dwort

1632 to 1639

(102*16)

Status input

decimal

not used (255)

HH HL LH LL

40203,40204

2

Dwort

2

Dwort

Status input

binary

not used (255)

HH HL LH LL

40205,40206

2

Dwort

2

Dwort

Status output

decimal

Status output

decimal

HH HL LH LL

40207,40208

2

Dwort

2

Dwort

Status output

binary

Status output

binary

HH HL LH LL

40209,40210

2

Dwort

2

Dwort

not used (255)

not used (255)

HH HL LH LL

40211,40212

2

Dwort

2

Dwort

Status

0=sensor/actuato

r active,

5=currently not

readable, 10=no

HH HL LH LL

HH HL LH LL

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH, 2023

www.esera.de Interface-Manual Modbus V2.0 Page 20 from 26

sensor/actuator

present

40213,40214

2

Dwort

2

Dwort

Error Counter

HH HL LH LL

HH HL LH LL

40215,40216

2

Dwort

2

Dwort

Part number /

Type

HH HL LH LL

HH HL LH LL

OWD 3 to

OWD 30

40201,40202

2

Dwort

2

Dwort

1632 to 1639

(102*16)

Status input

decimal

not used (255)

HH HL LH LL

40203,40204

2

Dwort

2

Dwort

Status input

binary

not used (255)

HH HL LH LL

40205,40206

2

Dwort

2

Dwort

Status output

decimal

Status output

decimal

HH HL LH LL

40207,40208

2

Dwort

2

Dwort

Status output

binary

Status output

binary

HH HL LH LL

40209,40210

2

Dwort

2

Dwort

not used (255)

not used (255)

HH HL LH LL

40211,40212

2

Dwort

2

Dwort

Status

0=sensor/actuato

r active,

5=currently not

readable, 10=no

sensor/actuator

present

HH HL LH LL

HH HL LH LL

40213,40214

2

Dwort

2

Dwort

Error Counter

HH HL LH LL

HH HL LH LL

40215,40216

2

Dwort

2

Dwort

Part number /

Type

HH HL LH LL

HH HL LH LL

This manual suits for next models

6

Table of contents

Other esera Gateway manuals