esera ECO 305 User manual

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 1 from 25

OPERATING INSTRUCTIONS

ECO 305

PROFESSIONAL EBUS GATEWAY

Gateway of the latest generation for the eBus system

HIGHLIGHTS

eBus Gateway

optimized for ebusd** software

⎯

eBus interface to the

read and write for your

eBus heating system

⎯

Manufacturer-independent

⎯

Plug and Play System

⎯

Automatic eBus level adjustment

⎯

Web server and access point

for configuration, debug and firmware updates

⎯

Low maintenance industrial device, because

without Linux. Native programmed without

unknown libraries

⎯

LAN interface

for data, configuration, debug

and firmware updates

⎯

Rugged industrial design

⎯

Extensive protection circuits and good device

protection

⎯

Easy mounting on

Top-hat rail, 4TE (77mm)

⎯

Power supply 110-240VAC

This manual has been machine translated. The original manual and reference is the German manual.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 2 from 25

TABLE OF CONTENT

1ADDITIONAL DOCUMENTS AND SOFTWARE..................................................................................3

2PRODUCT DESCRIPTION ...................................................................................................................4

3HIGHLIGHTS.........................................................................................................................................5

4ECO 305 EBUS GATEWAY..................................................................................................................6

5TECHNICAL DATA...............................................................................................................................7

6ENVIRONMENTAL CONDITIONS........................................................................................................8

7CONFORMITY.......................................................................................................................................8

8DISPLAY LED .......................................................................................................................................8

9SOFTWARE, EVALUATION EBUS DATA...........................................................................................9

10 FUNCTION TERMINALS ....................................................................................................................10

11 CONNECTION PLAN..........................................................................................................................10

12 ACTIVATE ACCESS POINT...............................................................................................................11

13 SELECT ACCESS POINT...................................................................................................................12

14 CALL WEB SERVER VIA WIFI ..........................................................................................................12

15 CALL WEBSERVER VIA LAN............................................................................................................13

16 WEBSERVER, LOG IN .......................................................................................................................13

17 MAIN PAGE.........................................................................................................................................14

18 ETHERNET INTERFACE SETTINGS.................................................................................................15

19 ASCII PROTOCOL SETTINGS...........................................................................................................16

20 DISABLE AP MODE ...........................................................................................................................17

21 WEBSERVER, CHANGE PASSWORD..............................................................................................18

22 WEBSERVER, FACTORY RESET .....................................................................................................18

23 WEBSERVER, EBUS FIRMWARE UPDATE.....................................................................................19

24 WEBSERVER, INTERFACE FIRMWARE UPDATE ..........................................................................20

25 DATA INTERFACE, ASCII PROTOCOL............................................................................................21

26 ESERA ASCII TEXT PROTOCOL ......................................................................................................21

27 EBUS NETWORK WIRING.................................................................................................................22

28 FIRMWARE UPDATE .........................................................................................................................22

29 RESET BUTTON.................................................................................................................................23

30 OPERATING CONDITIONS................................................................................................................23

31 INTENDED USE ..................................................................................................................................23

32 ELECTRICAL INSTALLATION...........................................................................................................24

33 ASSEMBLY.........................................................................................................................................24

34 MOUNTING LOCATION......................................................................................................................24

35 DISPOSAL...........................................................................................................................................24

36 SAFETY INSTRUCTIONS...................................................................................................................24

37 WARRANTY........................................................................................................................................25

38 WARNING ...........................................................................................................................................25

39 CONTACT ...........................................................................................................................................25

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 3 from 25

1 ADDITIONAL DOCUMENTS AND SOFTWARE

In addition to the ECO 305 eBus Gateway operating manual, we also offer cross-product documents that are

valid for several devices.

You can find these documents and additional software on our website (https://esera.de) by following the links

below.

Please make sure that you read all the documents thoroughly and follow the information and instructions

contained. If you have difficulties finding the documents or software you need, do not hesitate to contact our

customer support (support@esera.de). We will be happy to help you with any questions or problems.

INTERFACE MANUAL

MODBUS, MQTT, LoRaWAN, NB-IoT

Manual for configuring the interface via web server and

access point

The manual can be found in the ESERA download area

at:

https://download.esera.de/download/technical/schnittstellen_handbu

ch

CONFIG TOOL 3 SOFTWARE

Comprehensive software for all EC and ECO gateways

with 1-Wire I/O section

You can find the software in the ESERA download area

at:

https://download.esera.de/download/technical/config%20tool

%203

Note

Before you start assembling the device and put the product into operation, read these

operating instructions through to the end at your leisure, especially the section on

safety instructions.

If you have problems downloading the advanced documents or software, please

We are very concerned to act in an environmentally friendly and resource-saving way

for you. That is why we use paper and cardboard instead of plastics wherever possible.

We would also like to make a contribution to the environment with these paperless

instructions.

Please think of the environment before printing these instructions.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 4 from 25

2 PRODUCT DESCRIPTION

The ECO 305 eBus Gateway is a powerful interface of the latest generation that acts as a link between your

heating system and the ebusd* software. It allows you to access your heating system, independent of the

manufacturer, read and write and perform optimizations.

The eBus Gateway has been optimized especially for the communication with the software "ebusd "* and

supports the extended command set (Enhanced Mode) of ebusd*.

In addition to the eBus functions, the eBus gateway has an access point and a web server to enable easy

operation and configuration. You can communicate via the LAN interface using the ASCII text protocol with

up to 2 data connections.

The ECO 305 is a new eBus coupler with a standard eBus data interface and "Enhanced Mode" extension

for the ebusd software. The gateway does not perform any data analysis or evaluation itself.

The fully automatic level adjustment takes place in a few seconds on your eBus, so that a cumbersome

manual adjustment is no longer necessary.

You can conveniently change device settings, perform software updates and view device data via the web

server. The web server can be accessed via the LAN and via the access point (activated at the push of a

button).

The ECO 305 eBus Gateway is a low maintenance industrial device because it does not use Linux. It has

been programmed natively and no unknown libraries are used.

Extensive software support is available via ebusd** on the web. Additionally, we provide the free eConfig tool

for debug purposes.

Please note that the ECO 305 is not supported by the Vaillant vrDIALOG software.

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 5 from 25

3 HIGHLIGHTS

Optimized for the ebusd** software

The gateway is specially optimized for use with the ebusd software.

eBus interface for reading and writing

You can access your eBus heating system and transfer both read and write data.

Manufacturer-independent

The gateway is compatible with various heating systems from different manufacturers. The heating systems

only need to have an eBus interface.

Plug and Play System

It's easy to install and set up, with no complicated setup processes.

Automatic eBus level adjustment

The level adjustment on the eBus takes place automatically and in a few seconds.

Web server and access point

The gateway has an integrated web server and access point for configuration, troubleshooting and firmware

updates.

Low maintenance industrial device

The gateway has been natively programmed without the use of Linux or unknown libraries to ensure reliable

and low-maintenance performance.

LAN interface

Data transfer, configuration, troubleshooting and firmware updates can be performed via the LAN interface.

Rugged industrial design

The gateway is designed in a rugged industrial version to meet the requirements in various environments.

Extensive protection circuits and good device protection

The gateway provides comprehensive protection circuits and reliable device security.

Simple assembly

The gateway can be easily mounted on a top-hat rail with 4TE (77 mm).

Power supply

The gateway supports a power supply in the range of 110-240VAC.

These functions make the ECO 305 eBus Gateway a powerful and versatile tool for controlling and

monitoring your heating system.

**ebusd is not software by ESERA GmbH. We do not assume any liability, promise of function or support for

this software.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 6 from 25

4 ECO 305 eBus Gateway

The ECO 305 eBus Gateway offers several advantages that result in potential savings of

up to 25%* in heating costs and an increase in living comfort.

Here are some ways the gateway can help:

•Optimization of heating control

By accessing your heating system and being able to read and write to it, you can control and adjust

heating parameters more precisely. This allows you to operate your heating more efficiently and

reduce unnecessary energy consumption.

•Improved control of the room temperature

The ECO 305 gateway in combination with the ebusd software allows you to control and adjust the

room temperature more precisely. You can set up individual schedules and temperature profiles to

improve home comfort and save energy at the same time.

•Remote access and control

Thanks to the gateway's web server and access point function, you can conveniently access and

control your heating system from anywhere. This gives you flexible and easy remote monitoring and

control to optimize home comfort while minimizing energy consumption.

It is important to note that actual heating cost reduction and improvement in home comfort depend on

various factors, such as the efficiency of your heating system, building insulation and your individual usage

patterns. However, the ECO 305 eBus Gateway, together with the ebusd** software, offers you the

possibility to better control and optimize these aspects for potential savings and improved comfort.

*The stated heating cost reduction of up to 25% is for illustrative purposes only and may vary depending on

individual circumstances. It is not a guaranteed savings.

**ebusd is not software by ESERA GmbH. We do not assume any liability, promise of function or support for

this software.

DATA INTERFACE

The ECO gateway is equipped with an Ethernet interface that allows a speed of 10/100Mbit. It supports

different data protocols like TCP/IP or UDP. Up to 2 data connections can be used in parallel, which

enables efficient communication and data transfer. The Ethernet interface provides a reliable and fast

connection for data exchange between the gateway and other devices or systems.

ASCII TEXT PROTOCOL

The ECO 305 gateway ensures a direct and unaltered transmission of the data transmitted via the

eBus. It outputs the data in its native form via the data interface without evaluating or analyzing it. The

gateway forwards the data without any additional processing or interpretation. This ensures that the

received data is transmitted to the user unchanged and true to the original.

SELF-SUFFICIENT MANAGEMENT

The eBus gateway ECO 305 enables the independent reading of communication data of the eBus and

also offers the possibility to transfer commands to the eBus. This allows various actions to be carried

out, such as triggering a heating system or transmitting parameters to the central heating system. With

the help of the gateway, data can be written to and read from the eBus heating bus to control the

heating center or peripheral components such as pumps, mixers or a living room control unit. However,

it is important to note that the correctness of the command data is always the responsibility of the user.

The gateway itself does not perform any write or read actions independently.

DESIGNED FOR ALL eBus HEATING SYSTEMS

The eBus is a cross-company bus system used in heating construction. The ECO 305 eBus gateway

enables the connection with all heating systems which have this heating data bus. Please check

whether your heating system is also supported by the ebusd evaluation system. For more information,

please visit the ebusd website at www.ebusd.de.

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 7 from 25

VOLTAGE SUPPLY

For the power supply, the ECO 305 is equipped with an integrated power supply unit that supports a wide-

range voltage input of 100VAC - 240VAC. This makes it ideally suited for stationary operation in a control

cabinet or control box. This voltage input option allows flexible installation of the gateway in different

environments and ensures a reliable power supply for the operation of the device.

5 TECHNICAL DATA

SPECIAL FEATURE

•eBus gateway/data interface is adapted to the ebusd** software

•Access to eBus heating bus reading and writing

•Manufacturer-independent

•For all heating systems with eBus interface, gas, oil, solar and heat

pumps

•Web server for configuration of data connections

•Internal access point available via pushbutton for 30 minutes

•High performance Ethernet interface

•WLAN antenna internal

DATA INTERFACE

•Ethernet, 10/100Mbit, autonegotiation, DHCP or fixed IP address

NUMBER OF DATA

CONNECTIONS

max. 2 parallel TCP/IP socket data connections

1 x binary 2400 baud, 8 data bits, no start bit, 1 stop bit

•1 x binary with enhanced ProProtocol for ebsud* with

115,2kBaud, 8 data bits, no start bit, 1 stop bit

PROTOCOL

ESERA ASCII text for eConfig tool,

19200 baud, 8 data bits, no start bit, 1 stop bit

OPERATING MODES

Standard ebus with 2400 baud and enhanced ProProtocol with

115.2kBaud

TCP Socket, TCP Client, UDP

EBUS INTERFACE

•Standard eBus interface

•Reverse polarity and overvoltage protection

•Automatic level adjustment to correct operating point

Input voltage high: 15-24 V, low: 9-12 V

POWER SUPPLY

110 - 240VAC

STROKE UP

max. 5 Watt at 230VAC, typical 2W at 230VAC

CONNECTION

Screw terminals for stranded wire and cable up to 2.5qmm cross-section

PROTECTIVE CIRCUITS

ESD, overvoltage and reverse polarity protection for the eBus

interface

CONNECTION

Screw terminals for stranded wire and cable up to 2.5qmm cross-

section

ISOLATION

Galvanic isolation between Ethernet and eBus interface

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 8 from 25

6 ENVIRONMENTAL CONDITIONS

Operating temperature

-5°C to +40°C, standard temperature range

Storage temperature

-10°C to +60°C

Relative humidity

10% to 92% (non-condensing)

Room classification

Operate only in dry rooms

Protection class

IP20

Protection class

II

Dimensions

2TE, 77 x 90 x 70mm (WxHxD)

7 CONFORMITY

EN 50090-2-2

EN 61000-4-2, ESD

EN 61000-4-3, HF

EN 61000-4-4, Burst

EN 61000-4-5, Surge

EN 61000-6-1, Noise immunity

EN 61000-6-3, Interference radiation

RoHS

8 DISPLAY LED

The module has different display LEDs. The function of the displays is as follows

ADVERTISEME

NT

DESCRIPTION

FUNCTION

LED Green

PWR

Display for supply voltage

LED Green

DATA

•After switching on the device, the LED flashes 3x

•Flashes during eBus activity

•Flashes when sending data via the data interface

LED Green

LAN

LAN - network status LED

Lights up when LAN network connection

is established

Flashes when the interface is not activated

LED Green

WLAN

WLAN - Network Status LED

Lights up when WLAN network connection is established

Flashes when the WLAN access point is activated and a direct

connection is possible

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 9 from 25

9 SOFTWARE, EVALUATION EBUS DATA

The scope of delivery of the ECO 305 does not include any evaluation software. The ECO 305 gateway is

optimized for the ebusd software.

For the evaluation of the eBus data there are different projects on the Internet. We would like to

recommend the following projects.

The ebusd website also provides information on how to configure ebusd.

•ebusd website*: https://ebusd.de/

•Documentation on ebusd: https://github.com/john30/ebusd/wiki

*ebusd is not software by ESERA GmbH. We do not assume any liability, promise of function or support for

this software.

Documentation on eBus in general:

•eBus Wiki Page of the eBus Friends

Webside: (https://www.dokuwiki.org/start?id=de:dokuwiki

Notice:

•Vaillant vrDIALOG Software

The ECO 305 gateway is NOT supported by the Vaillant vrDIALOG software.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 10 from 25

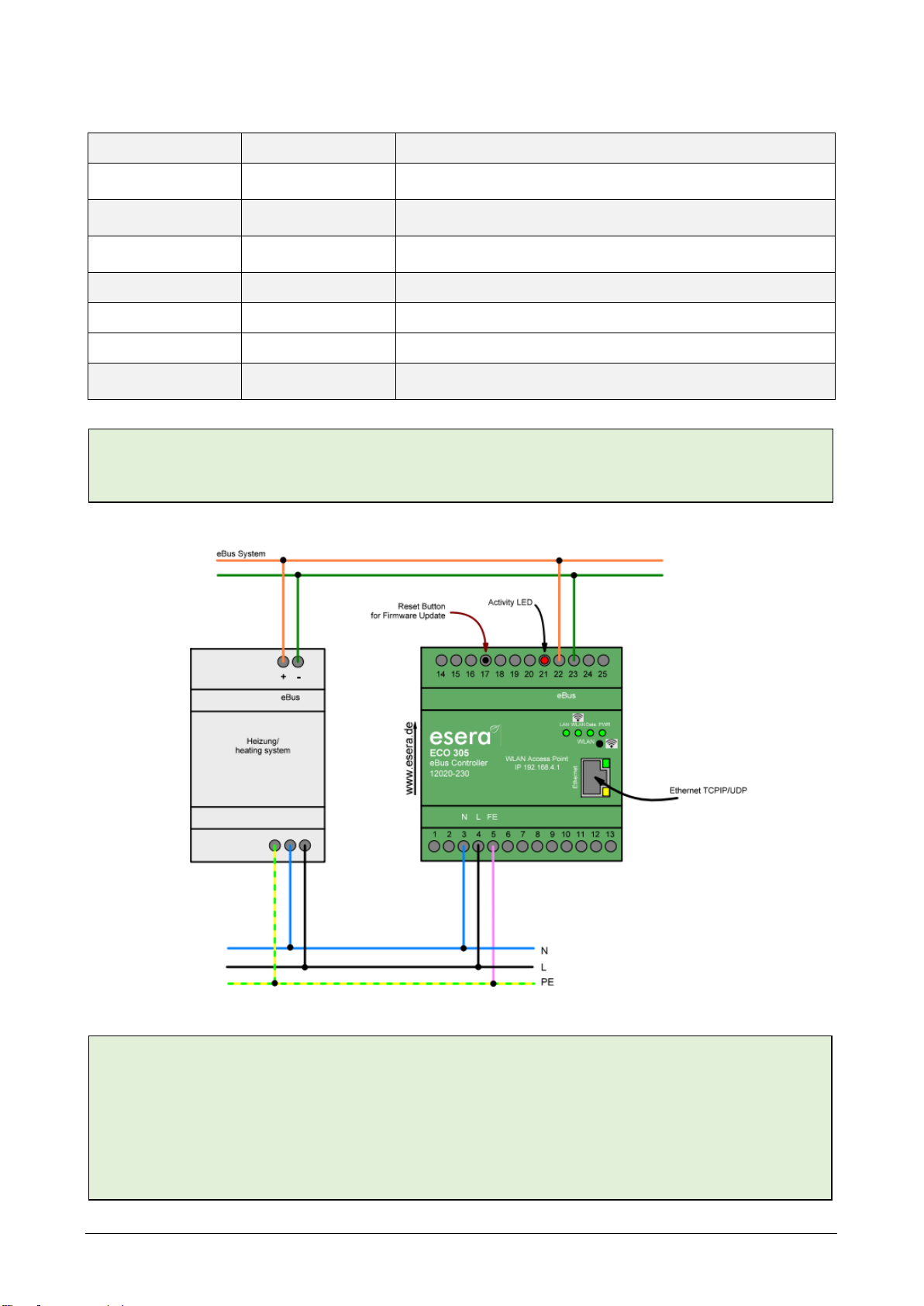

10 FUNCTION TERMINALS

The following is an overview of the terminals and their functions

KLEMME

DESCRIPTION

FUNCTION

3

Mains voltage

neutral conductor

Power supply of the eBus gateway,

Neutral - ladder, N

4

Mains voltage

phase

Power supply of the eBus gateway,

Phase - conductor, L

5

Functional earthing

FE

Connection for functional grounding

22

eBus connection "A

Connection of the eBus heating bus, terminal A

23

eBus connection "B

Connection of the eBus heating bus, terminal B

17

Reset button

Reset button for eBus section, not interface

All other terminals

that are not used

Not used

No function, not used

Do not insert any objects, tools or lines

11 CONNECTION PLAN

NOTE

The module may only be operated at the voltages and under the ambient conditions specified for it. The

operating position of the device is arbitrary.

The modules may only be commissioned by a qualified electrician.

Carry out all connection work in a de-energized state.

For further information on the operating conditions, see the following instructions under "Operating

conditions".

NOTE

The FE connection of the ECO 305 must be connected to ground potential (PE). This establishes a

functional ground for reliable operation.

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 11 from 25

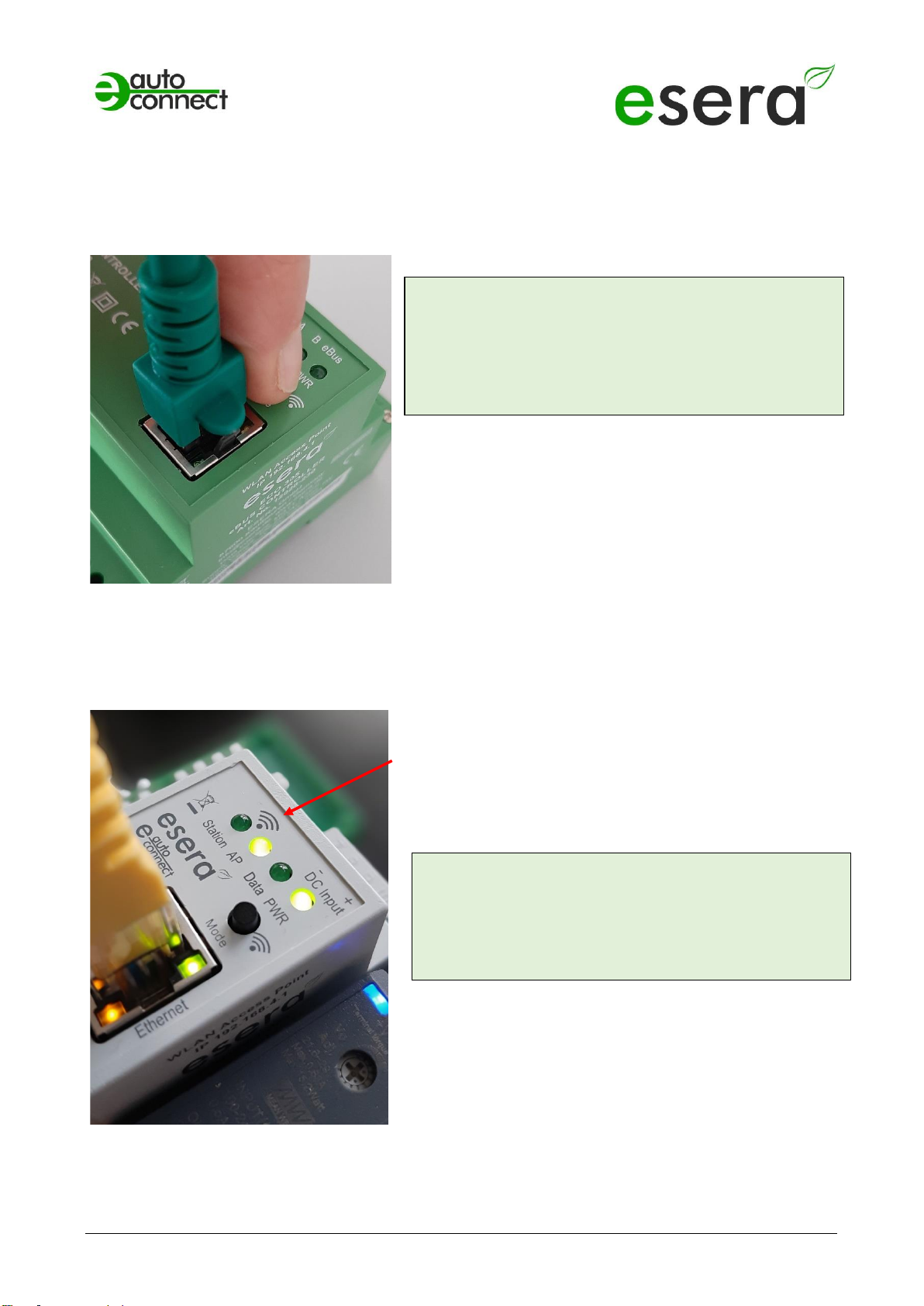

12 ACTIVATE ACCESS POINT

The ECO Gateway with Maxi interface has a switchable WiFi (WLAN) access point.

This means that you can access the device via a mobile device such as a smartphone, tablet or laptop. This

is possible directly - without additional devices via WiFi (WLAN), access point (e.g. Fritzbox).

What is an access point?

With an access point (wireless LAN AP mode), mobile end devices such as laptops, tablets, smartphones,

etc. can be connected directly to the ECO Gateway. No additional wireless LAN access point is required.

When the access point is activated, we talk about the AP

mode of the WLAN interface of the ECO Gateway.

(See figure, LED "AP" is on, LED "Station" is off)

If you no longer need the access point, switch it off by

pressing the button again for atleast 5 seconds.

NOTE

You activate the access point by pressing (for 5 seconds)

the button on the top.

The access point is active for approx. 30 minutes. After

that, it deactivates automatically for security reasons.

You can switch off the access point by pressing it again

for at least 5 seconds.

NOTE

The web server is continuously available via the

Ethernet interface. You can reach it via the

IP address of the device.

The IP address of the ECO Gateway can be found on

the "Ethernet Interface Settings" web page

Access Point is activated

Push button to activate the Access Point

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 12 from 25

13 SELECT ACCESS POINT

The ECO gateway registers itself as a WLAN access point with the identifier "ESERA". In the delivery state,

the Ethernet interface is set to "DHCP".

The access point is open, without an access password.

14 CALL WEB SERVER VIA WIFI

If you have connected to the WLAN network "ESERA", the web browser starts directly on many

smartphones.

If this is not the case, switch to your web browser (e.g. Firefox, Chrome, etc.) and enter

enter the IP address of the ECO Gateway. Now the web server of the ECO Gateway should be visible,

comparable to the following picture.

The configuration of the device is currently only possible via

the web server of the ECO Gateway.

NOTE

The IP address of the ECO Gateway via Access

Point is: 192.168.4.1

The IP address of the access point is printed on the

right side of the gateway housing.

Important:

Enter the IP address without "https://".

Select "ESERA" Access Point

NOTE

The ECO WLAN access point can be found as a

WLAN network at the identifier "ESERA".

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 13 from 25

15 CALL WEBSERVER VIA LAN

You can also connect the web server of the ECO Gateway at any time via LAN interface using the set

Reach IP address.

The IP address of the ECO Gateway is shown on the device display (if the device has a display). If the

device does not have a display, you can

also read out the current IP address (not the

IP address of the access point) via your router/DHCP server.

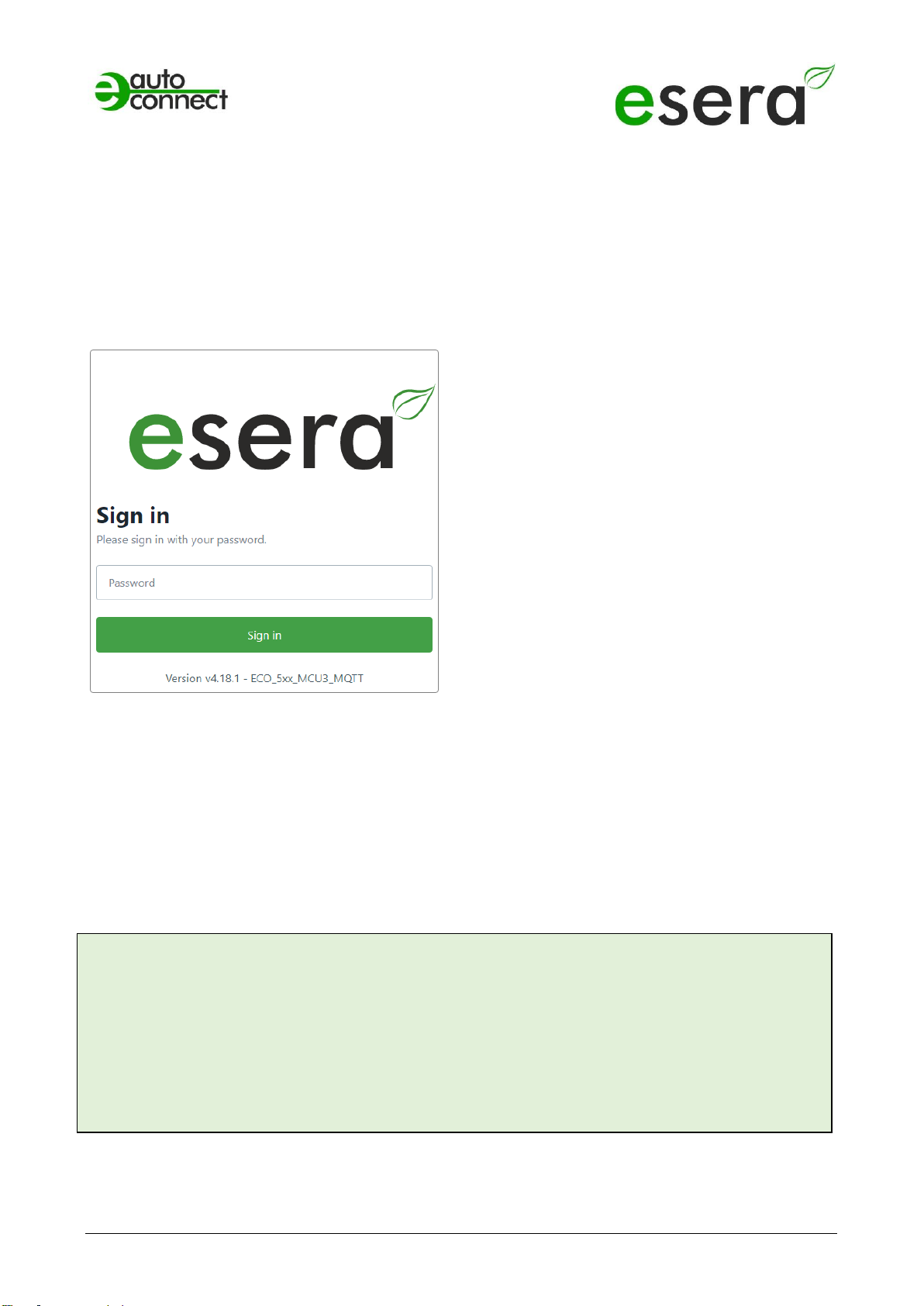

16 WEBSERVER, LOG IN

Password, Log In

To be able to log into the web server of the ECO

Gateway, use for the first login the

Startup/default password: eserapwd

For security reasons, the password is not displayed in

plain text, but with dots.

After entering the password, click on the "Login"

button to open the main menu (hereinafter referred to

as the main menu).

Please change the password after the first login,

otherwise unauthorized persons can also

make settings on the

ECO Gateway.

Please enter a new and secure password via the

main menu/"Change Password".

Advice on how to assign secure passwords can be

found on the Internet.

Software version Ethernet interface/Log Out

Display of the software version of the Ethernet

interface installed on the device. The version of the 1-

Wire firmware can be seen via the Config Tool 3.

Log Out

Click on the "Log Out" button to exit the web

interface.

NOTE

The startup/default password for login is: eserapwd

IMPORTANT

Please change the password after the first login.

For more details about functions of the web server, please refer to the document

"Interface Manual" that you can find via our website www.esera.de, download area/technical-

downloads.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 14 from 25

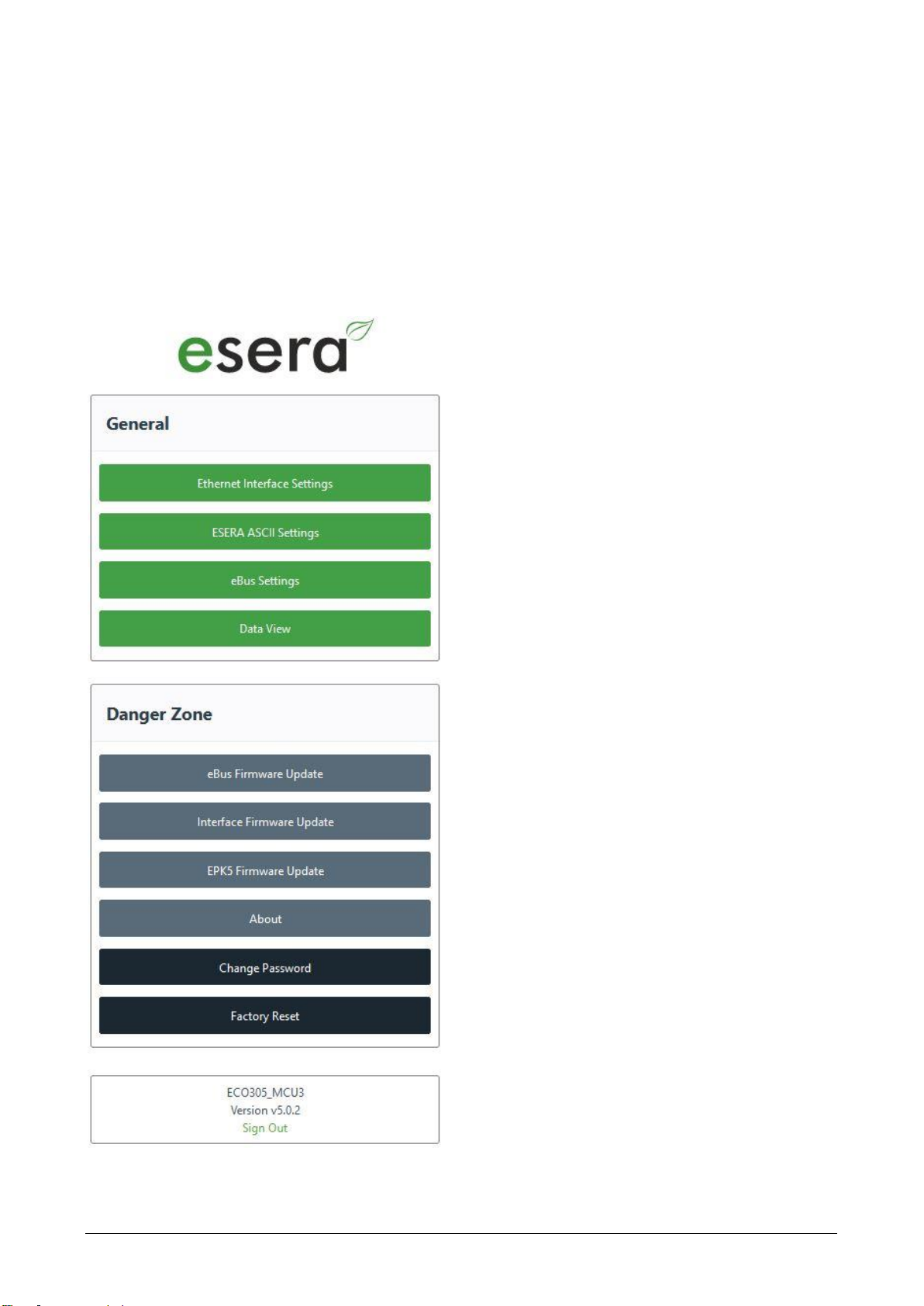

17 Main page

The ECO gateways are delivered with different equipment regarding interfaces and protocols.

The main page is divided into two sections:

General

Here you will find all menus for configuring the interfaces and viewing the gateway

and sensor data. The various buttons (selection keys) take you to the corresponding submenus, which are

described below.

Danger Zone

Here you get to submenus where you should take great care, because the possible changes are usually not

undoable.

Ethernet Interface Setting

Use this button to enter the menu for setting the IP

address, Sub Net and Gateway number.

ESERA ASCII Settings

From here you come to the submenu for setting the

data port. Pressing the button takes you to the menu

for configuring socket interfaces 2 - 5.

Data View

Here you can view the gateway data and the sensors

connected via the 1-Wire bus system. Here you will

also find the Auto-E-Connect information.

Firmware update, eBus, I/O section

Using this button you can perform an update of the

eBus Section perform.

Firmware Update Interface Section

This button allows you to perform a firmware update

of the interface and the web server.

Change Password

To change the password for the web server, click the

"Change Password" button.

Factory Reset

You may reset the Ethernet interface to the delivery

state. For this press the button "Factory Reset

Software version Ethernet interface/Log Out

Display of the software version of the Ethernet

interface installed on the device. The version of the 1-

Wire firmware can be seen via the Config Tool 3.

Sign Out

Click the "Sign Out" button to exit the web server.

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 15 from 25

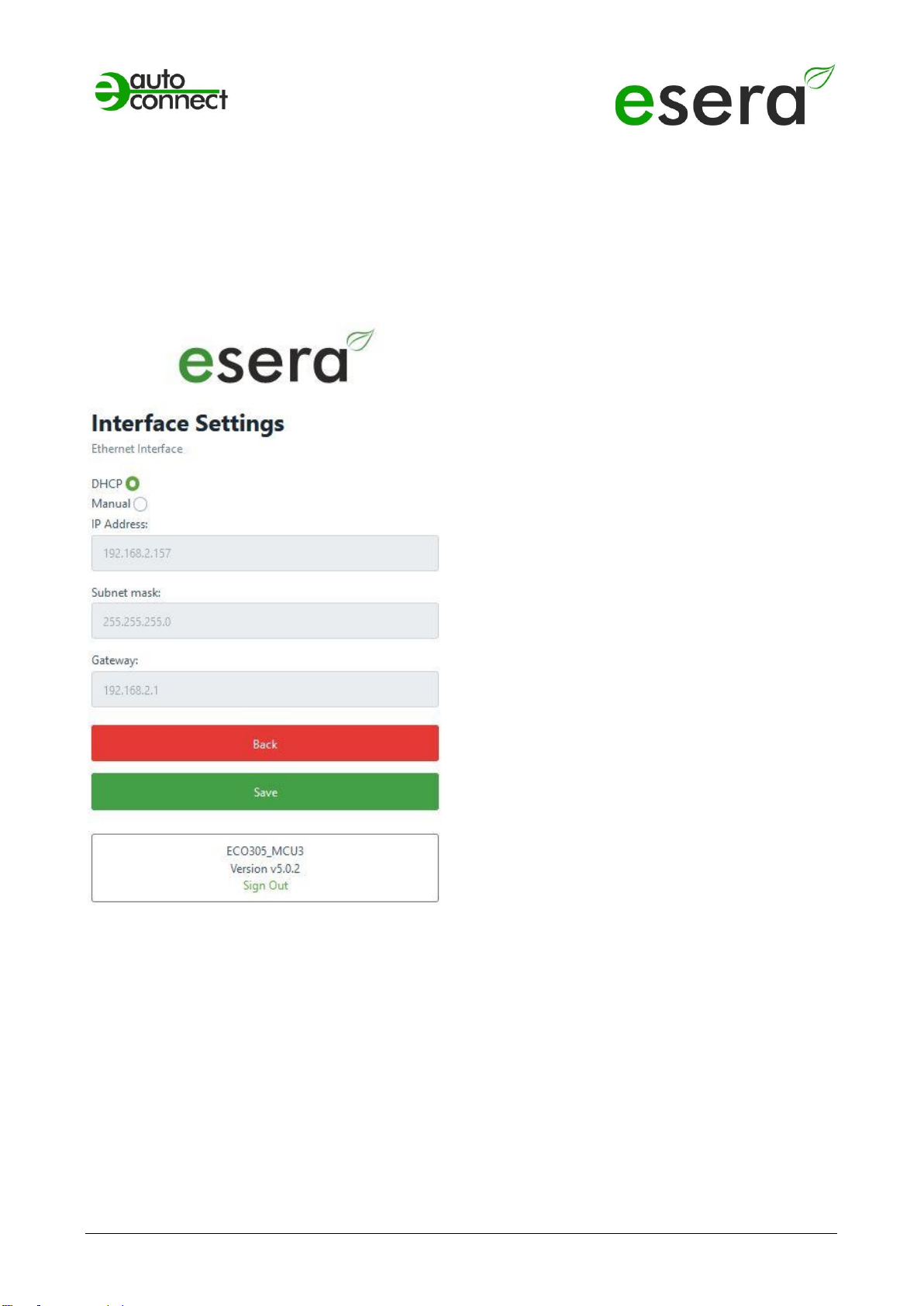

18 ETHERNET INTERFACE SETTINGS

Use the "Interface Setting" page to set the basic settings for the Maxi interface. The device IP address,

subnet mask and gateway IP address are set in

this menu.

These settings are also relevant for the web server and the ESERA ASCII text interface.

DHCP/Manual,

Operating mode IP address assignment

You can choose between automatic (DHCP) and

manual assignment of the IP address.

DHCP is activated in the delivery state.

IP Address

In case of automatic address assignment (DHCP),

the assigned IP addresses are displayed.

If the IP addresses are assigned manually, the

corresponding settings must be IP-Address,

Subnet mask and Gateway must be entered.

Save/Back

The "Save" button permanently saves the current

settings.

If you do not want to make any changes, press the

"Back" button.

Software version Ethernet interface/LogOut

Display of the software version of the Ethernet

interface installed on the device. The version of the

1-Wire firmware can be seen via the Config Tool 3.

Sign Out

By clicking the "Sign Out" button you will leave the

web server.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 16 from 25

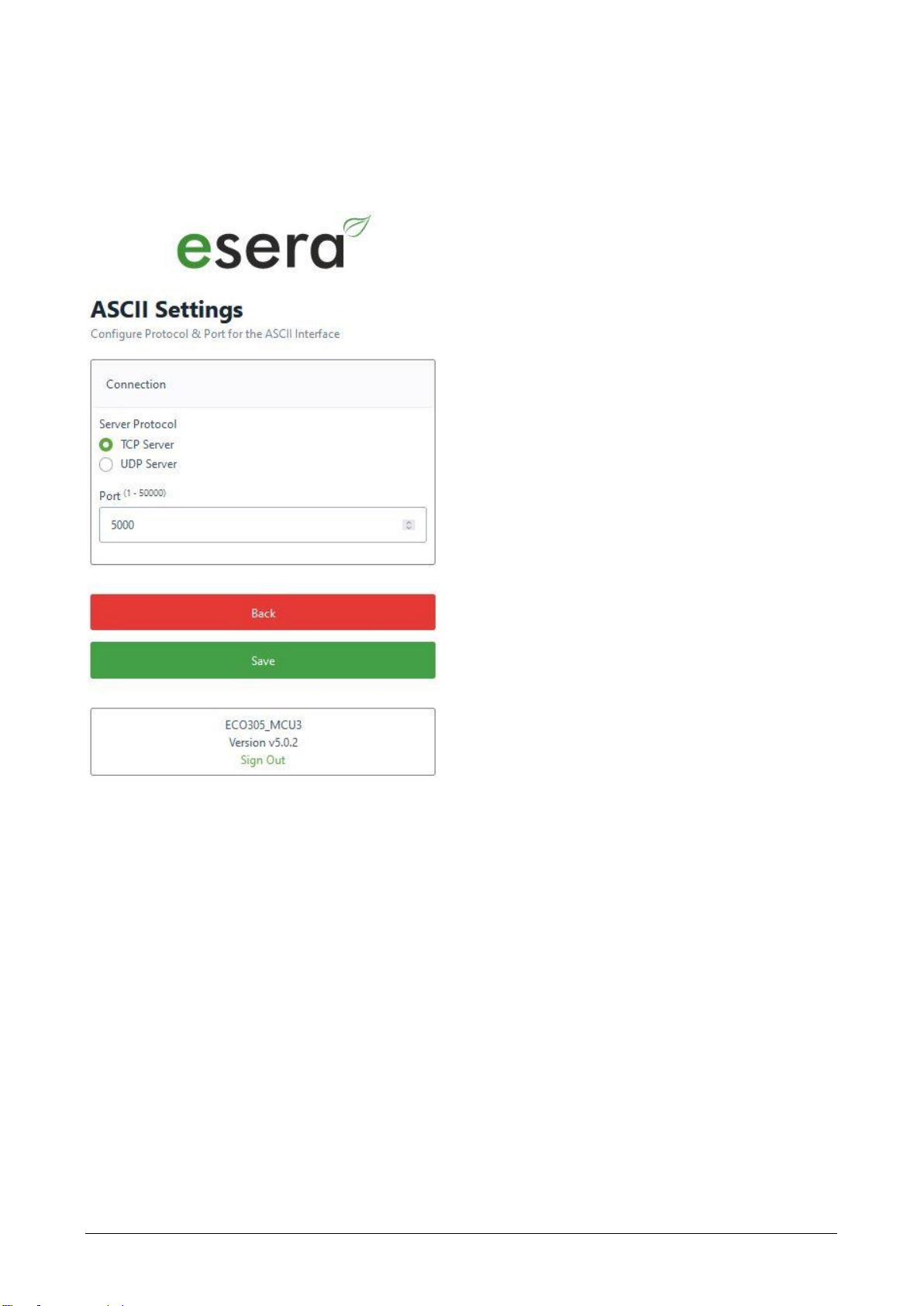

19 ASCII PROTOCOL SETTINGS

The ASCII Setting web page is used to configure the settings for the ESERA ASCII data interface (text

interface), e.g. for the Config Tool or the ECO DASHBOARD 100.

TCP Server/UDP Server

Here you can set the operating mode of the ASCII

data interface.

You can choose between TCP server and UDP

server.

Delivery state is TCP Server.

Port

The port for the ASCII data interface is assigned

here.

The port can be selected in the range of 1 - 5000.

The

default port is 5000, which

is the default setting for the ESERA Config Tool 3

and the ESERA ECO DASHBOARD 100.

Save/Back

The "Save" button permanently saves the current

settings.

If you do not want to make any changes, press the

"Back" button.

Software version Ethernet interface/LogOut

Display of the software version of the Ethernet

interface installed on the device. The version of the

1-Wire firmware can be seen via the Config Tool 3.

Sign Out

By clicking the "Sign Out" button you will leave the

web server.

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 17 from 25

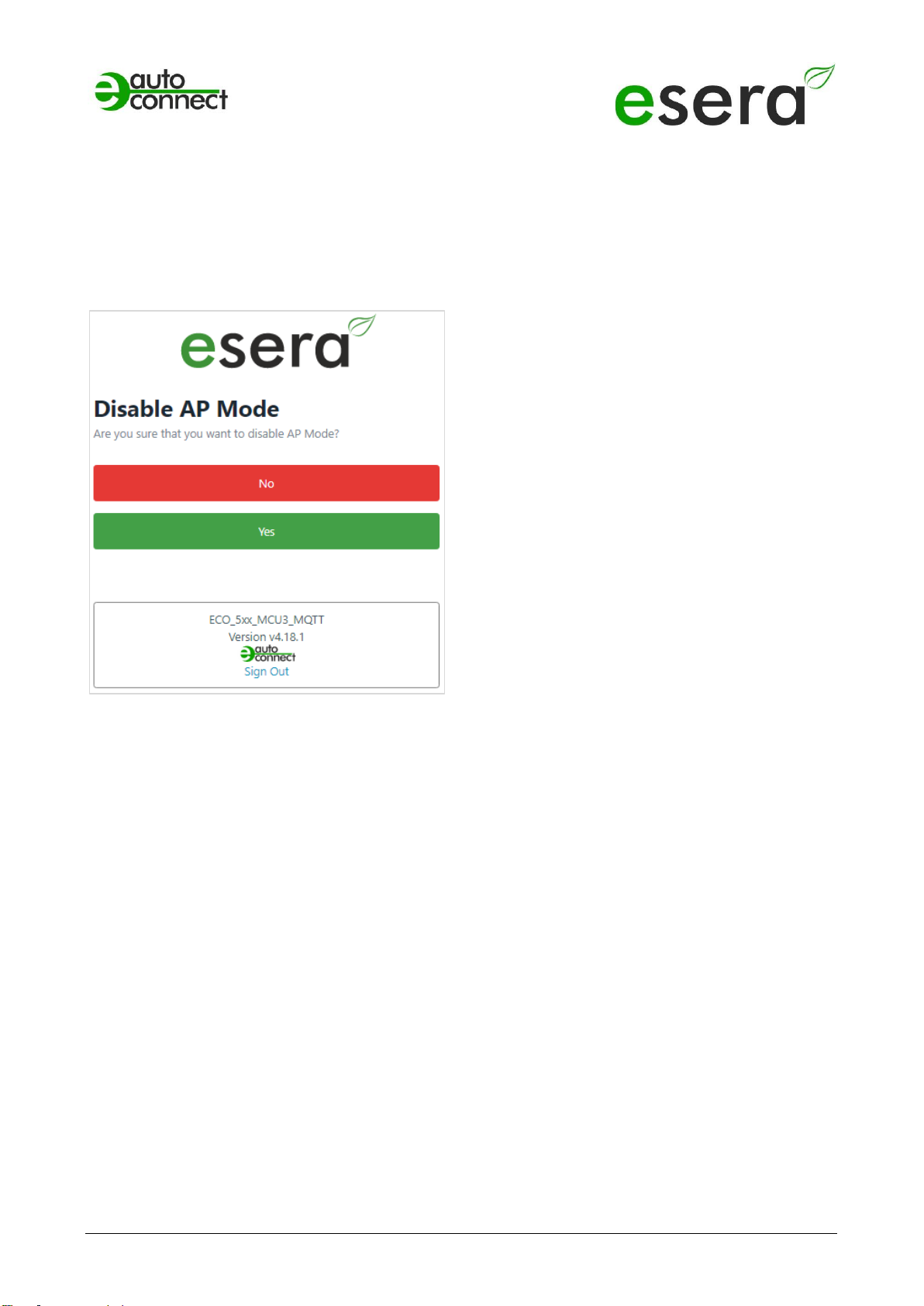

20 DISABLE AP MODE

In addition to a LAN interface, the ECO Gateway also has a connectable WLAN access point that you can

use to connect for configuration and data communication.

The access point is activated via a button on the device interface. For details, see above, under point 4.

Disable AP Mode

Yes/No

To turn off the WLAN access point, press the "Yes"

button.

Press the "No" button to exit the menu without

making any changes.

Software version Ethernet interface/Log Out

Display of the software version of the Ethernet

interface installed on the device. The version of the

1- Wire firmware can be seen via the Config Tool 3.

Sign Out

By clicking the "Sign Out" button you will leave the

web server.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 18 from 25

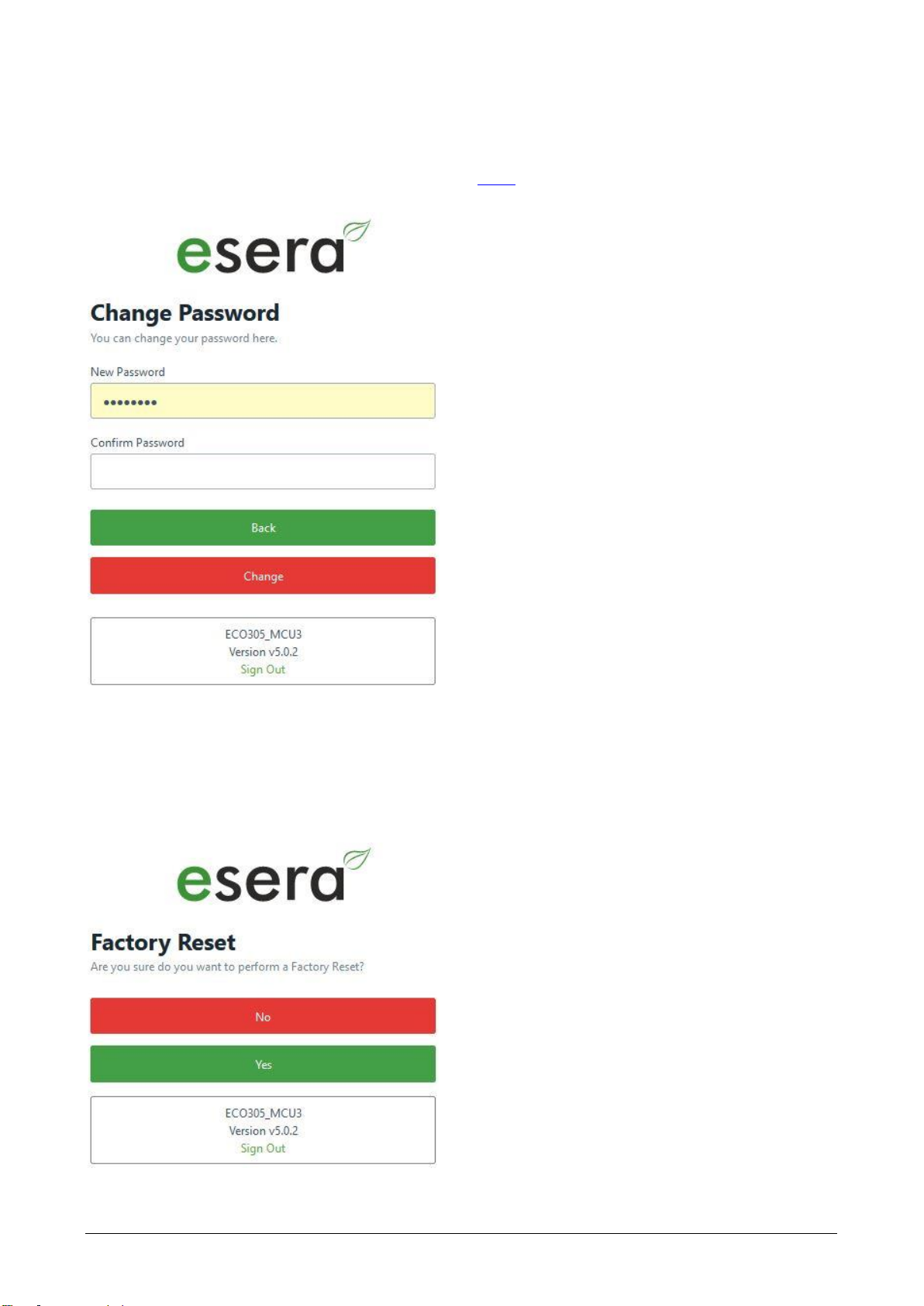

21 WEBSERVER, CHANGE PASSWORD

Use the "Change Password" page to set your individual access password.

Important

Please change the access password with the first login! Use a secure password if possible. What is a secure

password? Here are tips for creating a strong password: https://de.wikipedia.org/wiki/Passwort. Keep the

password in a safe place.

22 WEBSERVER, FACTORY RESET

Use the Factory Reset web page to clear all your settings and restore the interface to factory defaults.

NOTE

No changes are made to the I/O section, e.g. 1-Wire or eBus, settings.

Change Password

Here you enter the new access password for the

web server twice.

Save/Back

The "Save" button permanently saves the current

settings.

If you do not want to make any changes, press the

"Back" button.

Software version Ethernet interface/Log Out

Display of the software version of the Ethernet

interface installed on the device. The version of the

1-Wire firmware can be seen via the Config Tool 3.

Sign Out

By clicking the "Sign Out" button you will leave the

web server.

Factory Reset

Do you really want to delete all Ethernet Interface

settings and reset them to factory defaults?

If yes, press the "Yes" button.

Otherwise press the "No" button. This will also exit

the menu.

Software version Ethernet interface/Log Out

Display of the software version of the Ethernet

interface installed on the device. The version of the

1- Wire firmware can be seen via the Config Tool 3.

Log Out

Click on the "Sign Out" button to exit the web

interface.

Art. No. 12020-230

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 19 from 25

23 WEBSERVER, eBus FIRMWARE UPDATE

Via this web page you can update the firmware of the eBus section of the ECO Gateway. This replaces the

possibility to perform an update via the Config Tool.

eBus firmware update

Update procedure

1. Firmware file

First download the new firmware via the download

directory of the Config Tool 3 or the ESERA

website (www.esera.de).

Via the button "Firmware File" you can select the

new firmware version from your computer or tablet.

Select file

Use the "Upload" button to copy the new firmware

version to the interface of the ECO Gateway.

You can see the progress of the upload by the

progress bar.

2. Start firmware update

Now you will be asked if you really want to start the

firmware update.

Pressing "Yes" starts the update. The progress is

displayed via a progress bar.

With "No" no update is performed and the menu is

left.

Software version Ethernet interface/Log Out

Display of the software version of the Ethernet

interface installed on the device. The version of the

1- Wire firmware can be seen via the Config Tool

3.

Log Out

Click on the "Sign Out" button to exit the web

interface.

All rights reserved. Reprinting, including excerpts, not permitted without the express consent of ESERA GmbH.

Subject to technical changes. ESERA GmbH 2023

www.esera.de 12020-230_Manual Page 20 from 25

24 WEBSERVER, INTERFACE FIRMWARE UPDATE

Via this web page you can update the Ethernet firmware interface of the ECO Gateway.

NOTE

With the update of the interface no changes are made to the I/O / 1-Wire side of the

ECO Gateway.

Firmware file

First download the new firmware from the ESERA

website (www.esera.de).

Via this button "Firmware File" you can select the

new firmware file from your computer or tablet.

Upload

Use the button "Upload" to copy the new firmware

file into the interface of the ECO controller.

You can see the progress of the upload by the

progress bar.

Start firmware update

Now you will be asked if you really want to start the

firmware update.

Pressing "Yes" starts the update. The progress is

displayed via a progress bar.

With "No" no update is performed and the menu is

left.

Clicking the "No" button will cancel the update and

you will exit this menu.

Software version Ethernet interface

Display of the software version of the Ethernet

interface installed on the device. The version of the

1- Wire firmware can be seen via the Config Tool 3.

Log Out

Click on the "Sign Out" button to exit the web

interface.

Other manuals for ECO 305

1

This manual suits for next models

1

Table of contents

Other esera Gateway manuals

Popular Gateway manuals by other brands

RTA

RTA 460PSMS-N700 Product user guide

olympia electronics

olympia electronics GR-7602 quick start guide

Beam

Beam Man Down RST410 Configuration guide

ZyXEL Communications

ZyXEL Communications P-660HN-51 - quick guide

Rainforest Automation

Rainforest Automation EAGLE-200 quick start guide

Alcatel-Lucent

Alcatel-Lucent OmniAccess 8550 Brochure & specs