Eshed Robotec SCORBOT-ER 4pc User manual

5%14$16/'4"6RE

7UGTIU"/CPWCN

Catalog #100118 Rev.A

Copyright © 1999 by Eshed Robotec

(February 1997) February 1999 Reprint/PDF version

Catalog #100118 Rev.A

Every effort has been made to make this book as complete and accurate as possible.

However, no warranty of suitability, purpose, or fitness is made or implied. Eshed

Robotec is not liable or responsible to any person or entity for loss or damage in

connection with or stemming from the use of the software, hardware and/or the

information contained in this publication.

Eshed Robotec bears no responsibility for errors which may appear in this publication

and retains the right to make changes to the software and manual without prior notice.

SCORBOTa registered trademark of Eshed Robotec (1982) Ltd.

Read this manual thoroughly before attempting to install or operate the equipment.

If you have any problems during installation or operation, call your agent for assistance.

Save the original carton and all packing material. You may need them later for shipment.

Table of Contents

CHAPTER 1 General Information 1

About SCORBOT-ER 4pc . . . . . . . . . . . . . . . . . . . . . . . . 1

Acceptance Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Repacking for Shipment . . . . . . . . . . . . . . . . . . . . . . . . . 3

Handling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CHAPTER 2 Specifications 4

Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Work Envelope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Encoders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Microswitches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Gripper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CHAPTER 3 Safety 10

Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

CHAPTER 4 Installation 12

CHAPTER 5 Operating Methods 14

SCORBASE for Windows Software . . . . . . . . . . . . . . . . . . 14

Teach Pendant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

CHAPTER 6 Maintenance 15

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Daily Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Periodic Inspection . . . . . . . . . . . . . . . . . . . . . . . . 16

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjustments and Repairs . . . . . . . . . . . . . . . . . . . . . . . 21

Adjusting the Timing Belts . . . . . . . . . . . . . . . . . . . . . 21

Adjusting Base Anti-Backlash . . . . . . . . . . . . . . . . . . . 22

Tightening the Oldham Coupling in Gripper . . . . . . . . . . . . 23

Gripper Disassembly . . . . . . . . . . . . . . . . . . . . . 23

Gripper Reassembly . . . . . . . . . . . . . . . . . . . . . 23

CHAPTER 7 Parts Lists 24

CHAPTER 8 Wiring 33

Robot Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Single Axis Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

SCORBOT-ER 4pc v User’s Manual

9810

CHAPTER 1

General Information

This chapter contains instructions for unpacking and handling the SCORBOT-ER 4pc

robot.

About SCORBOT-ER 4pc

The SCORBOT-ER 4pc was designed and developed to emulate an industrial robot.

The open structure of the robot arm allows students to observe and learn about its internal

mechanisms.

Figure 1: SCORBOT-ER 4pc Robot Arm

User’s Manual 1 SCORBOT-ER 4pc

9810

Acceptance Inspection

The robot arm and its controller are packed in two separate cartons. Save the original

packing materials and shipping carton. You may need them later for shipment or storage.

After removing the robot arm from its shipping cartons, examine it for signs of shipping

damage. If any damage is evident, do not install or operate the system. Notify your

freight carrier and begin appropriate claims procedures.

The standard SCORBOT-ER 4pc package includes the following items:

•SCORBOT-ER 4pc Robot arm

•Power cable 100/110/220VAC

•3 bolts for mounting robot; set of hex wrenches

•SCORBOT-ER 4pc User’s Manual

Refer to the Controller-PC User’s Manual for information about the control unit’s

standard and optional components.

Make sure you have received all the items listed on the shipment’s packing list. If

anything is missing, contact your supplier.

SCORBOT-ER 4pc 2 User’s Manual

9810

Repacking for Shipment

Be sure all parts are back in place before packing the robot.

òThe robot should be repacked in its original packaging for transport.

If the original carton is not available, wrap the robot in plastic or heavy paper. Put the

wrapped robot in a strong cardboard box at least 15 cm (about 6 inches) longer in all

three dimensions than the robot. Fill the box equally around the robot with resilient

packing material (shredded paper, bubble pack, expanded foam chunks).

Seal the carton with sealing or strapping tape. Do not use cellophane or masking tape.

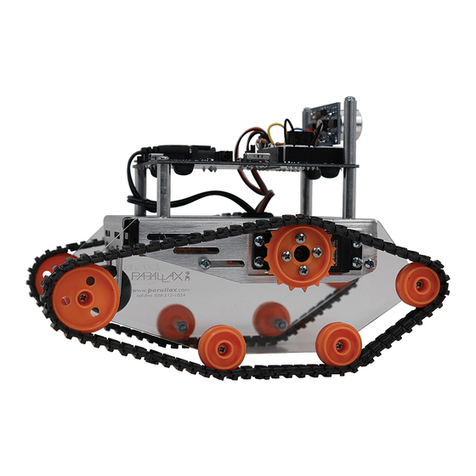

Handling Instructions

Lift and carry the robot arm only by grasping the body or the base.

See Figure 2.

Do not lift and/or carry the robot arm by its gripper,

upper arm or forearm.

Do not touch the microswitches, cams or encoders.

Figure 2: Robot Arm Parts

User’s Manual 3 SCORBOT-ER 4pc

9810

CHAPTER 2

Specifications

This chapter includes the specifications the SCORBOT-ER 4pc robot arm and

descriptions of its components.

SCORBOT-ER 4pc Specifications

Mechanical Structure Vertical articulated

Number of Axes 5 axes plus servo gripper

Axis Movement

Axis 1: Base rotation

Axis 2: Shoulder rotation

Axis 3: Elbow rotation

Axis 4: Wrist pitch

Axis 5: Wrist roll

310°

+130° / –35°

±130°

±130°

Unlimited (mechanically); ±570° (electrically)

Maximum Operating Radius 610mm (24.4")

End Effector

DC servo gripper, with optical encoder,

parallel finger motion;

Measurement of object’s size/gripping force

by means of gripper sensor and software.

Maximum Gripper Opening 75 mm (3") without rubber pads

65 mm (2.6") with rubber pads

Hard Home Fixed position on each axis,

found by means of microswitches

Feedback Optical encoder on each axis

Actuators 12VDC servo motors

Motor Capacity (axes 1–6) 15 oz. in Peak Torque (stall)

70 W Power for Peak Torque

Gear Ratios Motors 1, 2, 3: 127.1:1

Motors 4, 5: 65.5:1

Motor 6 (gripper) 19.5:1

Transmission Gears, timing belts, lead screw

Maximum Payload 1 kg (2.2 lb.), including gripper

Position Repeatability ±0.2 mm (0.008") at TCP (tip of gripper)

Weight 11.5 kg (25 lb)

Maximum Path Velocity 600 mm/sec (23.6"/sec)

Ambient Operating Temperature 2°–40°C (36°–104°F)

SCORBOT-ER 4pc 4 User’s Manual

9810

Structure

The SCORBOT-ER 4pc is a vertical articulated robot, with five revolute joints. With

gripper attached, the robot has six degrees of freedom. This design permits the end

effector to be positioned and oriented arbitrarily within a large work space.

Figures 3 and 4 identify the joints and links of the mechanical arm.

The movements of the joints are described in the following table:

Axis No. Joint Name Motion Motor No.

1Base Rotates the body. 1

2Shoulder Raises and lowers the upper arm. 2

3Elbow Raises and lowers the forearm. 3

4Wrist Pitch Raises and lowers the end effector (gripper). 4+5

5Wrist Roll Rotates the end effector (gripper). 4+5

Figure 2-3: Robot Arm Links Figure 2-4: Robot Arm Joints

User’s Manual 5 SCORBOT-ER 4pc

9810

Work Envelope

The length of the links and the degree of rotation of the joints determine the robot’s work

envelope. Figures 5 and 6 show the dimensions and reach of the SCORBOT-ER 4pc.

The base of the robot is normally fixed to a stationary work surface. It may, however, be

attached to a slidebase, resulting in an extended working range.

Figure 5: Operating Range (Top View)

Figure 6: Operating Range (Side View)

SCORBOT-ER 4pc 6 User’s Manual

9810

Motors

The robot’s five axes and gripper are

operated by DC servo motors. The

direction of motor revolution is

determined by the polarity of the operating

voltage: positive DC voltage turns the

motor in one direction, while negative DC

voltage turns it in the opposite direction.

Each motor is fitted with an encoder for

closed-loop control.

Encoders

The location and movement of each axis is

measured by an electro-optical encoder

attached to the shaft of the motor which

drives the axis.

When the robot axis moves, the encoder

generates a series of alternating high and

low electrical signals. The number of

signals is proportional to the amount of

axis motion. The sequence of the signals

indicates the direction of movement.

The controller reads these signals and

determines the extent and direction of axis

movement.

Figure 7: Encoder

Figure 8: Motor

User’s Manual 7 SCORBOT-ER 4pc

9810

Microswitches

The SCORBOT-ER 4pc has five microswitches— one

on each axis—which serve to identify the robot’s home

position.

During the homing procedure, the robot joints are moved

one at a time. Each axis is moved until the its home

switch is activated. The axis is then moved slightly until

the the switch shuts off—at that point the joint is at home.

When all joints are at home, the robot is at home. This is

the point of reference for robot operation. Whenever the

system is turned on, the robot should be sent to this

position, by means of a software homing routine.

Transmissions

Several kinds of transmissions are used to

move the links of the robot arm.

•Spur gears move the base and shoulder

axes.

•Pulleys and timing belts move the elbow

axis.

•Pulleys and timing belts, and a bevel

gear differential unit at the end of the

arm move the wrist pitch and roll axes.

•A lead screw transmission opens and

closes the gripper.

Figure 9: Microswitch

Figure 10: Transmissions

SCORBOT-ER 4pc 8 User’s Manual

9810

Gripper

The SCORBOT-ER 4pc has a servo jaw gripper

fitted with rubber pads. These pads can be removed

to allow the attachment of other end effector

devices, such as suction pads.

Three bevel gears form a differential gear train

which moves the wrist joint. When motors 4 and 5

are driven in opposite directions, the wrist pitch

moves up and down. When motors 4 and 5 are

driven in the same direction, the wrist rolls

clockwise and counterclockwise. A leadscrew

coupled directly to motor 6 causes the gripper to

open and close.

Figure 11: Gripper

User’s Manual 9 SCORBOT-ER 4pc

9810

CHAPTER 3

Safety

This chapter contains important safety guidelines and warnings.

òRead this chapter carefully before you attempt to install or use the robot system.

Precautions

This manual provides complete details for proper installation and operation of the

SCORBOT-ER 4pc. Do not install or operate the robot until you have thoroughly

studied this User’s Manual. Be sure you heed the safety guidelines for both the robot and

the controller.

1. Make sure the robot base is properly and securely bolted in place.

2. Make sure the robot arm has ample space in which to operate freely.

3. Make sure a guardrail, rope or safety screen has been set up around the

SCORBOT-ER 4pc operating area to protect both the operator and bystanders.

4. Do not enter the robot’s safety range or touch the robot when the system is in operation.

Before approaching the robot, make sure the motor switch on the controller front panel

has been shut off.

5. Make sure loose hair and clothing is tied back when you work with the robot.

òTo immediately abort all running programs and stop all axes of motion, press the

EMERGENCY STOP button on either the teach pendant or the control box.

SCORBOT-ER 4pc 10 User’s Manual

9810

Warnings

•Do not install or operate the SCORBOT-ER 4pc under any of the following conditions:

•Where the ambient temperature or humidity drops below or exceeds the specified

limits.

•Where exposed to large amounts of dust, dirt, salt, iron powder, or similar

substances.

•Where subject to vibrations or shocks.

•Where exposed to direct sunlight.

•Where subject to chemical, oil or water splashes.

•Where corrosive or flammable gas is present.

•Where the power line contains voltage spikes, or near any equipment which

generates large electrical noises.

•Do not overload the robot arm. The combined weight of the workload and gripper

may not exceed 1kg (2.2 lb). It is recommended that the workload be grasped at its

center of gravity.

•Do not use physical force to move or stop any part of the robot arm.

•Do not drive the robot arm into any object or physical obstacle.

•Do not leave a loaded arm extended for more than a few minutes.

•Do not leave any of the axes under mechanical strain for any length of time.

Especially, do not leave the gripper grasping an object indefinitely.

•Since the SCORBOT-ER 4pc motors are rated 12VDC nominal, while the controller

motor drivers supply 24VDC, do not drive axes continuously in one direction at

maximum speeds.

User’s Manual 11 SCORBOT-ER 4pc

9810

CHAPTER 4

Installation

Before installing the SCORBOT-ER 4pc, be sure you have read and understood the

safety instructions and warnings detailed in Chapter 1.

Be sure you have ample space to set up the robotic system, as shown in Figure 12.

1. Set up the SCORBOT-ER 4pc on a sturdy surface with a minimum 700mm of free

space all around the robot.

2. Fasten the base of the robot arm to the work

surface with at least 3 bolts 120° apart, as

shown in Figure 13.

Robot Base ∅240 mm (9.49")

Pitch Circle ∅207 mm (8.15" )

Hole (6 off) ∅8.5 mm (0.33")

Make sure the robot is securely bolted in

place. Otherwise the robot could become

unbalanced and topple over while in motion.

3. Set up a guardrail, rope or safety screen

around the robot’s operating area to protect

both the operator and bystanders.

Figure 12: SCORBOT-ER 4pc Installation

Figure 13: Robot Base Plate Layout

SCORBOT-ER 4pc 12 User’s Manual

9810

4. Place the controller and computer on a sturdy surface at a safe distance from the

robot—well outside the robot’s safety range.

5. Connect the robot cable (D50 connector) to the SCORPOWER box.

6. Make sure all other connections have been made in accordance with the instructions in

the Controller-PC User’s Manual.

7. Turn on the computer and the SCORPOWER box.

User’s Manual 13 SCORBOT-ER 4pc

9810

CHAPTER 5

Operating Methods

The SCORBOT-ER 4pc can be programmed and operated by means of SCORBASE

for Windows software and by a teach pendant. Software and teach pendant operation is

described fully in the other manuals supplied with the system.

SCORBASE for Windows Software

SCORBASE for Windows is a robotic control software package which has been

designed for use with the SCORBOT-ER 4pc. Its menu-driven structure and off-line

capabilities facilitate robotic programming and operation.

SCORBASE communicates with the robot controller by means of an RS232 channel.

SCORBASE for Windows can be operated in three levels, which are comparable to

Levels 1, 3 and 5 of the original DOS-based SCORBASE software. SCORBASE for

Windows Level 1 and Level 3 are recommended for those who wish to learn robotic

programming from the most basic stages. SCORBASEpro contains programming

commands and options for advanced users.

SCORBASE for Windows is described fully in the SCORBASE for Windows User’s

Manual.

Teach Pendant

The teach pendant is an optional device.

The teach pendant is a hand-held terminal which is used for controlling the robot and

peripheral equipment connected to the same robot controller. The teach pendant is most

practical for moving the axes, recording positions, and sending the axes to recorded

positions. Other functions can also be executed from the teach pendant.

The Teach Pendant for Controller-PC User’s Manual fully describes the various

elements and functions of the teach pendant.

SCORBOT-ER 4pc 14 User’s Manual

9810

Table of contents

Other Eshed Robotec Robotics manuals