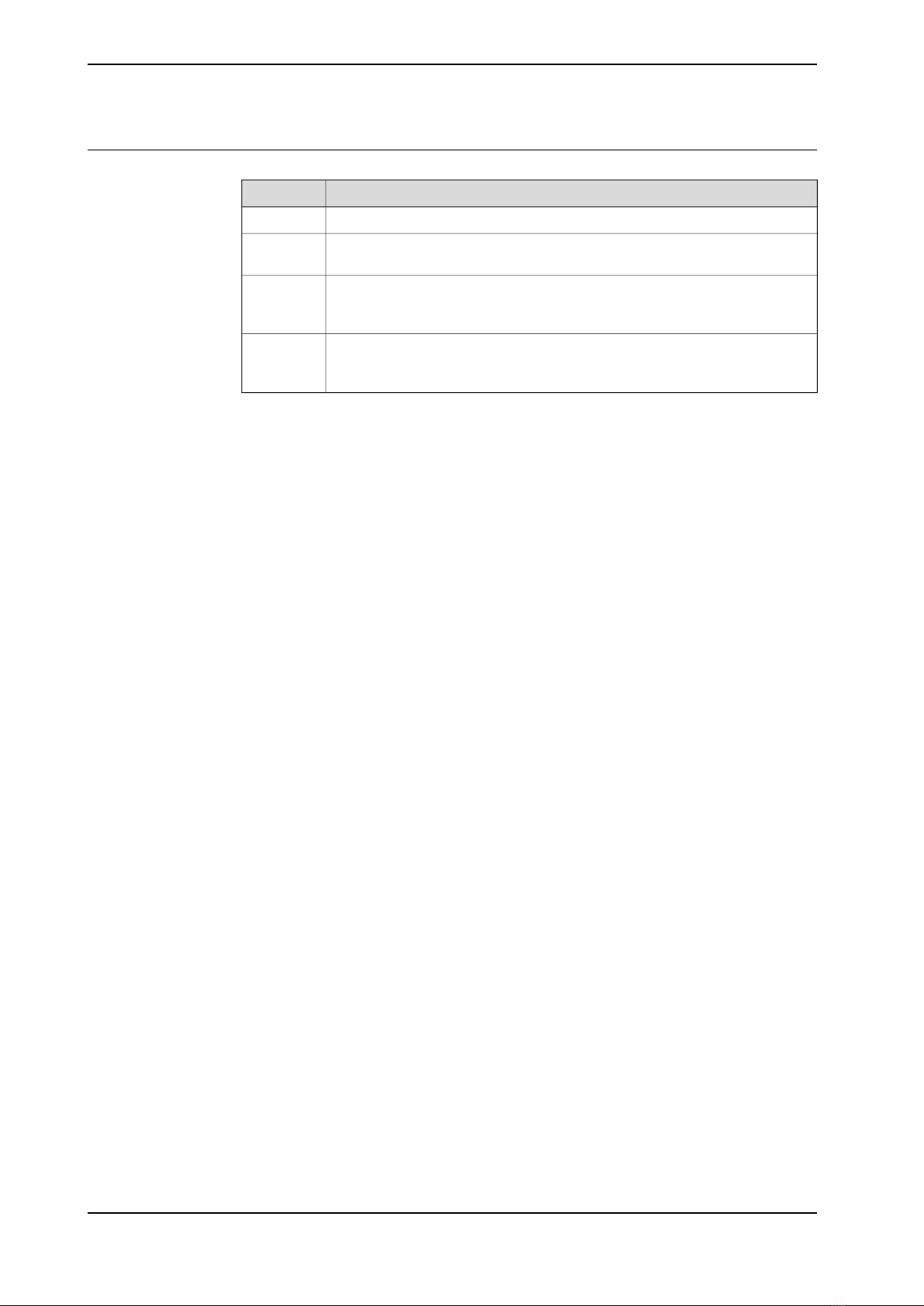

Table of contents

7Overview of this manual ...................................................................................................................

9Product documentation ....................................................................................................................

111 Safety

111.1 Safety signals in the manual ................................................................................

131.2 Make sure that the main power has been switched off ..............................................

141.3 Risks associated with live electric parts .................................................................

152 Introduction to BullsEye®

152.1 Product overview ..............................................................................................

172.2 Theory of operation ...........................................................................................

192.3 Limitations .......................................................................................................

212.4 Safety information .............................................................................................

233 Installation

274 Maintenance

295 User guide

305.1 Overview .........................................................................................................

315.2 Data storage .....................................................................................................

325.3 Using BullsEye .................................................................................................

335.3.1 The global methods of BullsEye .................................................................

345.3.2 Defining a tool ........................................................................................

375.3.3 Default BullsEye data ...............................................................................

385.3.4 Selecting different BullsEye data ................................................................

415.3.5 Creating new BullsEye data instances .........................................................

455.3.6 BullsEye data parameters .........................................................................

465.3.7 QuickCheck ...........................................................................................

475.4 BullsEye status codes ........................................................................................

515.5 Frequently asked questions ................................................................................

556 RAPID reference

556.1 Data types .......................................................................................................

556.1.1 be_device - Device data ...........................................................................

586.1.2 be_scan - Scan data ................................................................................

616.1.3 be_tooldesign - Tool design ......................................................................

656.2 Instructions ......................................................................................................

656.2.1 BECheckTcp - BullsEye check TCP ............................................................

686.2.2 BEDebugState - Debug state control ...........................................................

696.2.3 BERefPointer - BullsEye reference pointer ...................................................

726.2.4 BESetupToolJ - BullsEye setup tool joint move .............................................

776.2.5 BETcpExtend - BullsEye extend TCP ..........................................................

796.2.6 BEUpdateTcp - BullsEye update TCP ..........................................................

826.3 Functions ........................................................................................................

826.3.1 OffsToolXYZ - Offsets tool cartesian ...........................................................

836.3.2 OffsToolPolar - Offsets tool cartesian ..........................................................

857 Spare parts

87Index

Application manual - BullsEye 5

3HAC050989-001 Revision: C

© Copyright 2004-2018 ABB. All rights reserved.

Table of contents