Espin NERO User manual

CONTACT US:

HELLO@ESPINBIKES.COM

PHONE NUMBER :

(888) 296-4550

effortlessly electric

Quick Start Guide

UNSPOOK BRANDING DESIGN MANUAL

>> PAGE 3 // 44

*SCRYPE

BRANDING MATERIAL

CORPORATE DESIGN

AND GUIDELINES

ISSUE 01

BRANDING

DESIGN MANUAL

TABLE OF CONTENTS

1 | Taking the Bike Out of the Box ................ 04

2 | Battery Removal, Installation, and Charging ..... 06

3 | Install the Front Wheel ..................... 08

4 | Install the Handlebar .......................10

5 | Install the Pedals ..........................12

6 | Inflate the Tires ...........................13

7 | Install the Saddle and Adjust the Saddle Height ....14

8 | Front Fender, Front Rack, and Front Light Installation 15

9 | Adjusting Stem Angle .......................16

10 | Adjusting the Suspension Fork.................17

11 | How to Shift Gears and Operate the PAS..........18

12 | Safety Checks............................ 20

13 | Test Ride ................................21

14 | Caring for Your Bike ........................22

15 | Error Codes ............................. 23

16 | Display Settings ...........................24

NERO

ASSEMBLY

GUIDE

Thank you for your purchase, and welcome to the Espin family!

This guide will help you assemble, operate, maintain, and enjoy

your Espin for as long as possible. For any questions or issues

along the way, please reach out to us online or on the phone

and one of our e-bike experts will be glad to help!

UNSPOOK BRANDING DESIGN MANUAL

>> PAGE 5 // 44

*SCRYPE

BRANDING MATERIAL

CORPORATE DESIGN

AND GUIDELINES

ISSUE 01

BRANDING

DESIGN MANUAL

>> PAGE 4 // 36

UNSPOOK BRANDING DESIGN MANUAL

4 5

1TAKING THE BIKE OUT OF THE BOX

1 .4 Remove all packaging on the bike. Zip-

ties are easiest to remove with a pair of wire

cutters. Do not accidentally cut any cables,

hoses, or the zip-ties holding them in place.

While removing the packaging on the bike,

lean it up against something vertical. Do not

lie the bike down on its side. Please leave all

of the packaging inside the main box and hold

onto it for at least 14 days in case the bike

needs to be returned. Make sure to register

your bike at espinbikes.com/pages/espin-sup-

port. The primary purpose of this is to record

the frame number of your bike in case it gets

stolen. The frame number is stamped into the

metal on the front of the head tube.

1 .1 Open the top of the main box and remove

the parts box inside.

1 .2 The parts box checklist :

Bike manual

Pedals

Front and rear reflectors and their

mounting brackets

Front light and 2 mounting bracket options

Charger

Multi-tool and crescent wrench for

assembling your bike

1 .5 If present, remove the plastic insert

wedged in the front brake caliper by pulling

down on it gently until it slides out. This is

there to prevent the pads from clamping to-

gether accidentally.

1 .3 To remove the bike, lift the bike straight

up out of the box. Two people might be need-

ed for this. Remember, NEVER PLACE THE BOX

ON ITS SIDE. This can damage the derailleur

and other components.

1 .6 Remove the metal or plastic dummy axle

from the fork dropouts, where the front wheel

mounts. This is there to protect the fork arms

from damage during shipping. If the dummy

axle is metal, unscrew the nuts holding it on

with the provided tools. If it is plastic, it can

either be pushed out by hand or tapped out

with a hammer or any heavy tool.

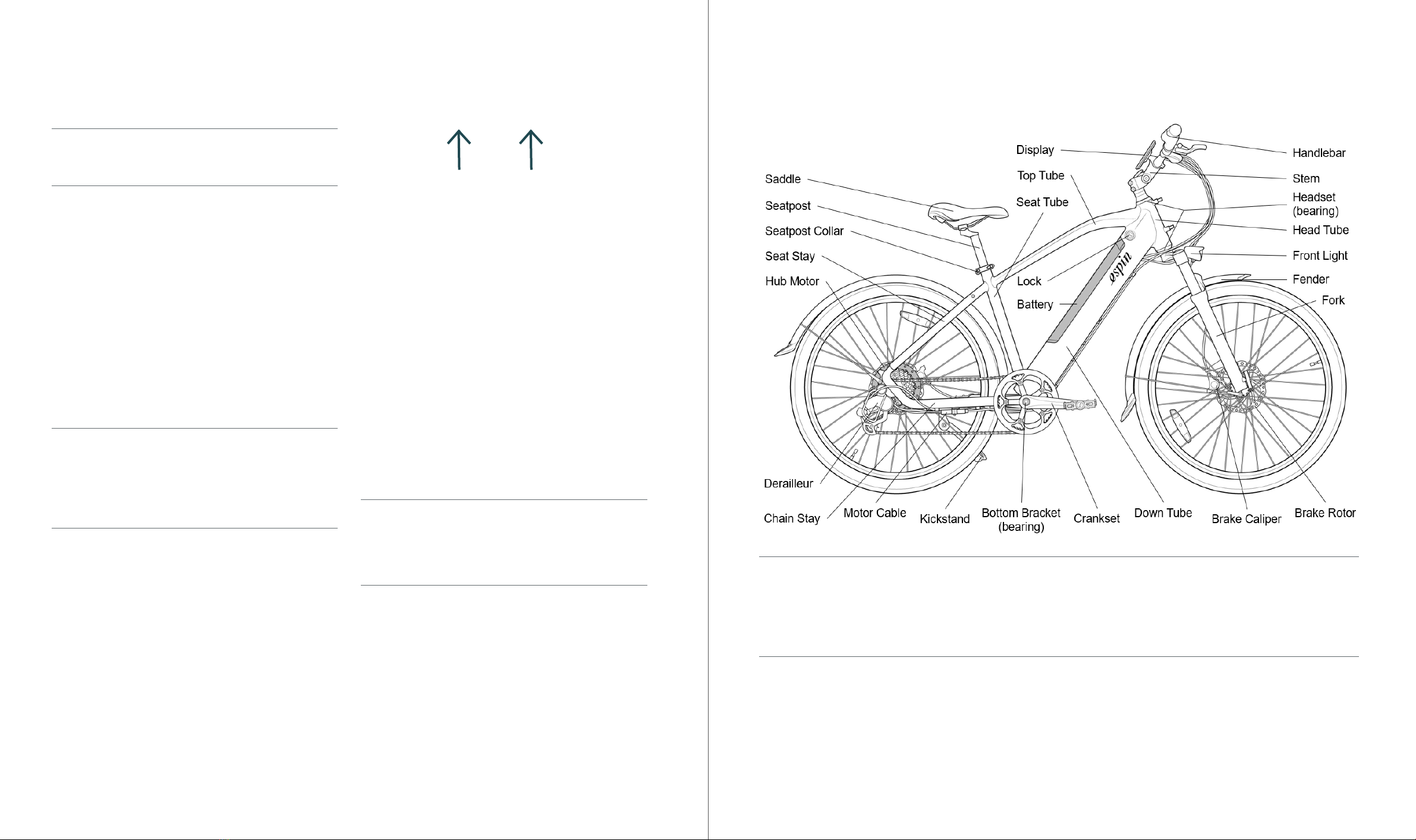

The bike shown above is the 21 Sport. Look through this diagram and find the labeled parts on

your own bike. Other Espin models might not have a top tube, have the battery in a dierent lo-

cation, or have a dierent type of stem. The only part not labeled in this diagram or elsewhere in

the manual is the controller. The controller is the computer of the bike, and is located inside the

frame above the bottom bracket on all Espin models. All Espin frames are made of 6061 alumi-

num.

The Nero comes with a 750W motor and 14.4Ah battery. The brakes are Zoom HB-875E, which take

mineral oil and are compatible with Shimano M06 disc brake pads. The shifter and derailleur are

S-Ride, and are compatible with Shimano Altus parts. The spokes are all 13 gauge, thicker than

normal bicycle spokes. If a replacement spoke is ever needed, contact us at

hello@espinbikes.com for recommendations on proper sizes and spoke suppliers.

>> PAGE 6 // 36

UNSPOOK BRANDING DESIGN MANUAL

For a video of this process, watch the YouTube video here:

CLICK TO PLAY

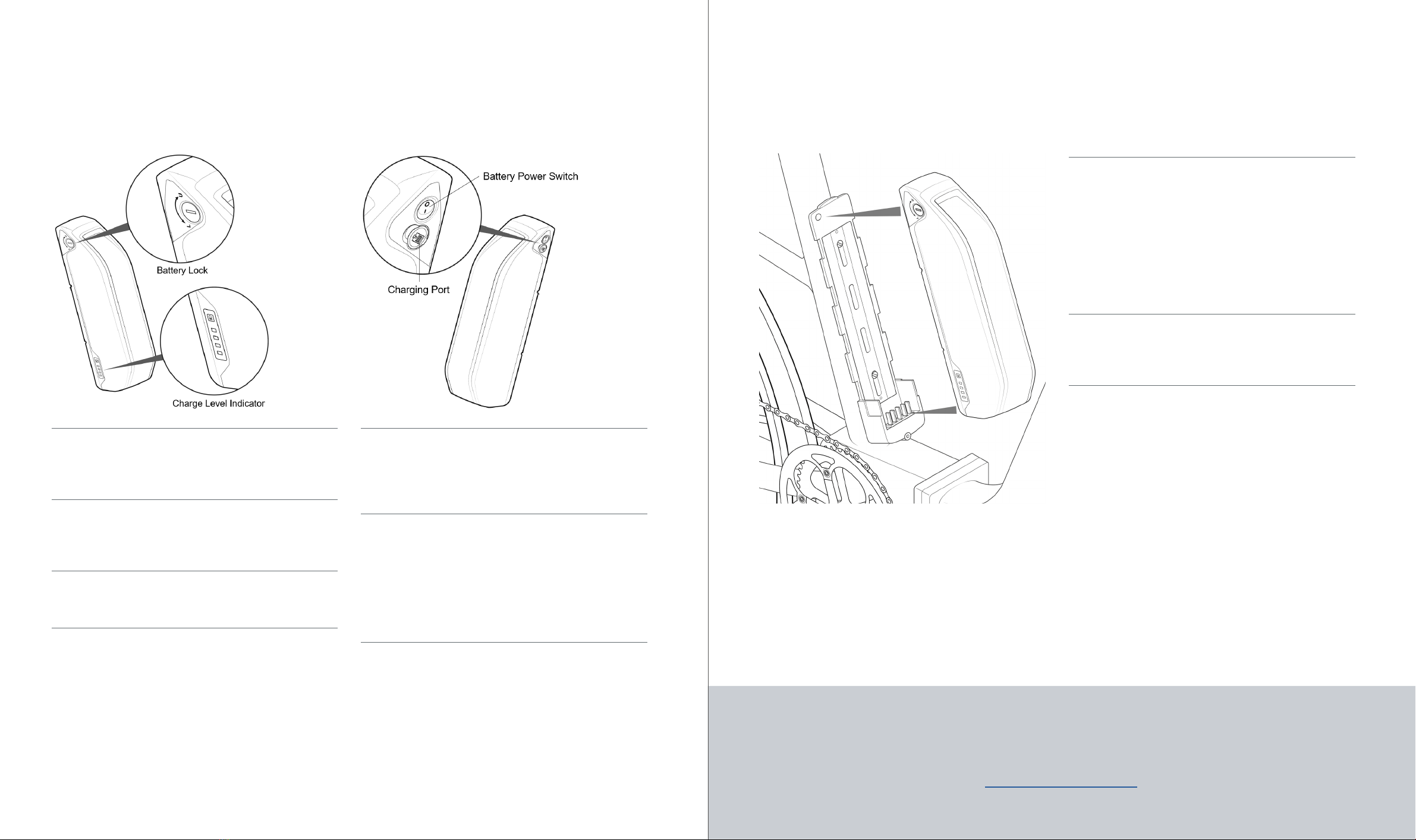

2BATTERY REMOVAL,

INSTALLATION, AND CHARGING

2 .1 Remove the two keys zip-tied to the han-

dlebar. These are for unlocking and locking

the battery. Keep one of the keys in a safe

place in case the other gets lost.

2 .4 When the charger is plugged into the wall

and not the battery, the light on the charger

will be green. When the battery is plugged in

and charging, the light will be red. Once the

battery finishes charging, the light will turn

green again. Simply put, the red light indi-

cates a flow of electricity through the charger.

2 .3 The battery can be charged out of the bike

or while it is still installed. Plug the charger

into a wall outlet, then plug it into the battery.

6

2 .8 To install the battery, first make sure

that it is unlocked. Then line up the teeth

on the battery with the battery base, press

it in as shown in Figure 3, then slide the bat-

tery downwards onto the connector. After

installing the battery, make sure to lock it in

place by rotating the key clockwise 180°. This

extends a deadbolt that prevents the battery

from bouncing up while riding.

2 .9 When turning the bike on, first switch the

battery on with the power switch shown in

Figure 2.

7

Figure 1 Figure 2

2 .2 To unlock the battery, insert the key and

turn it counter-clockwise 180°, then pull up-

wards on the battery until it slides out from

the battery base.

2 .5 Charging an empty battery can take up to

7 hours. The battery has overcharge protec-

tion so it will stop charging as soon as it is

full. This means it can safely be left plugged

in overnight.

2 .7 To check the battery’s charge level, first

switch the battery on with the switch shown in

Figure 2, then press the button by the charge

level indicator shown in Figure 1. With a full

charge, the indicator will show 3 green lights

and 1 red light.

2 .6 While charging, leave the battery and

charger on a smooth hard surface like wood

or tile. The charger may get fairly warm if left

on carpet or other insulating materials. When

done charging, always cover the charging port

with the rubber cap. If water or keys go into

the charging port, the battery will short out

and need to be replaced.

Figure 3

2 .10 To maximize battery life and capacity,

allow the battery to warm up to room tem-

perature before plugging it into the charger.

Charging a cold battery will deplete the capac-

ity. If the bike is not being used for several

months, plugging the battery into the charger

until it is full once a month will also help with

battery life.

>> PAGE 8 // 36

UNSPOOK BRANDING DESIGN MANUAL

For a video of this process, watch the YouTube video here:

CLICK TO PLAY

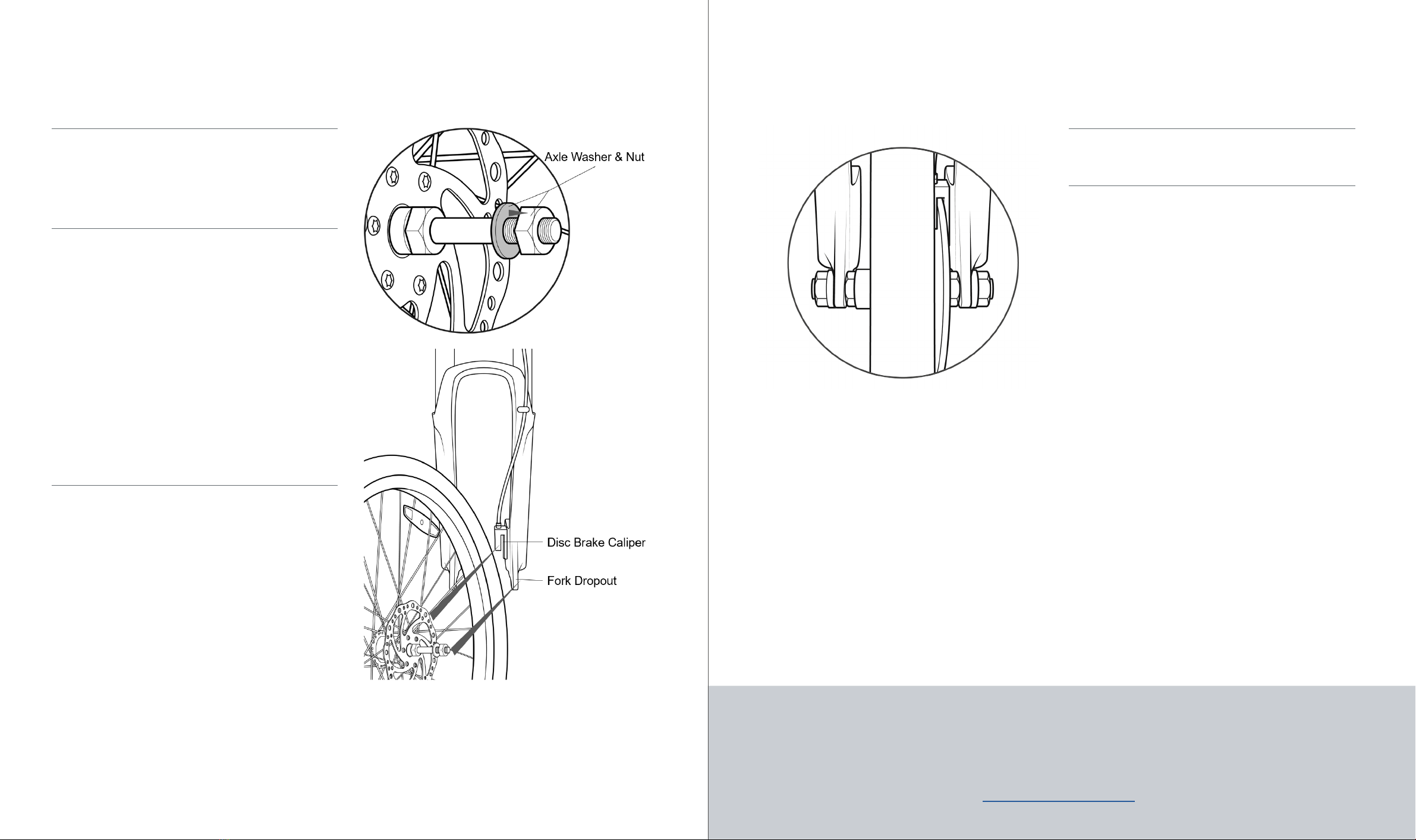

3INSTALL THE FRONT WHEEL

3 .1 Unscrew the front axle nuts until they are

flush with the end of the axle. Pull the axle

washer out against the nut as shown in Figure

4. The washer will need to be between the nut

and the fork dropout once installed.

3 .3 Use the provided 15mm crescent wrench

to tighten the axle nuts. Tighten one side all

the way, then while pressing the top of the

wheel towards the tightened side, tighten the

other nut. This will ensure that both sides of

the axle are fully in the dropouts.

3 .2 With the rear wheel resting on the ground

and the bike upright, lift the front end of the

bike up and lower the fork onto the wheel so

that the disc brake rotor goes into the gap in

the disc brake caliper and the axle goes in the

fork dropouts, as shown in Figure 5. Rock the

wheel side-to-side to make sure both sides of

the axle are all the way in the dropouts. DO

NOT FLIP THE BIKE UPSIDE DOWN TO INSTALL

THE WHEEL. This can put too much weight

on the display and other components on the

handlebar and damage them. It is also best

to use the bike’s weight to ensure the axle

is fully in the fork dropouts. Once the front

wheel is in, the kickstand can be used to keep

the bike upright.

Figure 5

8 9

Figure 6

3 .4 The front axle assembly should now look

like Figure 6.

3 .5 Lift the front wheel o the ground and

spin it. If the tire is rubbing the fender or the

disc brake rotor is rubbing the caliper, the axle

might not be fully in the fork dropouts. Place

the wheel back on the ground and unscrew

the axle nuts until they are just loose. Rock

the wheel side-to-side by pushing the top of

the wheel left and right, until the axle clunks

into the top of the dropouts. Once the wheel

is centered and fully in the dropouts, tighten

the axle nuts and give the wheel another test

spin. If something is still rubbing, contact our

tech support agents at hello@espinbikes.com.

Figure 4

>> PAGE 10 // 36

UNSPOOK BRANDING DESIGN MANUAL

For a video of this process, watch the YouTube video here:

CLICK TO PLAY

4INSTALL THE HANDLEBAR 4 .4 To install the handlebar, first the

faceplate must be removed as shown

in Figure 10. Unscrew the 4 faceplate

bolts all the way, and be careful not to

drop them!

4 .6 Thread all 4 bolts back on, but only

halfway. When the faceplate is tight-

ened properly, there will be even gaps

on the top and bottom of the faceplate

as shown in Figure 12. To do this, thread

the top and bottom bolt on the left side

all the way in until the gaps are bal-

anced, but don’t tighten them. Once the

gaps are set, thread the other two bolts

all the way in without tightening them.

4 .7 When tightening the faceplate

bolts, they must be tightened in an X

pattern, similar to the star pattern used

when tightening the lug nuts on a car

wheel. As shown in Figure 13, tighten

1, 2, 3, and 4 in that order, one quar-

ter turn each. After one quarter turn

each, go back to bolt 1 and give them

all another quarter turn and repeat this

process until they are all evenly tight.

The torque for these bolts is 5 to 6Nm.

Figure 12

Figure 13

4 .1 If the bike arrived with the stem rotated

around as shown in Figure 7, the stem will

need to be rotated forwards. The stem on

some of our models may come pointing back-

wards to save space in the box. If the stem is

pointing forwards as shown in Figure 9, pro-

ceed to installing the handlebar in 4.4.

4 .2 To rotate the stem around, first loosen

the two bolts clamping the stem onto the

steerer tube, labeled in Figure 8. Once the

bolts are loose, brace the fork with your feet

or legs and rotate the stem around clockwise

as shown in Figure 8. After rotating the stem

around, if the fork seems harder to turn (tight

headset bearings), then the top cap bolt la-

beled in Figure 8 needs to be loosened. While

the two stem bolts are still loose, loosen the

top cap bolt one quarter turn. If the headset

bearings still feel tight, loosen the top cap

bolt one more quarter turn. The fork should

be able to rotate with little force.

Figure 9

4 .3 Once the top cap bolt is set and the stem

is pointing directly forwards, tighten the stem

bolts previously loosened in Figure 8. The

torque for these is 11 to 12Nm. These bolts

should be tightened progressively. Turn the

top one a quarter turn, then the bottom one a

quarter turn, then the top one etc. The stem

and fork should now be oriented as shown in

Figure 9.

For a video of this process, watch the YouTube video here:

CLICK TO PLAY

4 .5 Place the center of the handlebar in

the stem with the Espin logo on the dis-

play facing the rider. Put the faceplate

back into place over the handlebar,

as shown in Figure 11. There is no top

or bottom side of the faceplate. Make

sure there are no wires between the

faceplate, stem, or handlebar as these

can get pinched and damaged. When

riding the bike, the handlebar should be

angled so that your wrists are straight

when grabbing the brake levers.

Figure 10

Figure 11

10 11

Figure 7

Figure 8

UNSPOOK BRANDING DESIGN MANUAL

>> PAGE 13 // 44

UNSPOOK

BRANDING MATERIAL

CORPORATE DESIGN

AND GUIDELINES

For a video of this process, watch the YouTube video here:

CLICK TO PLAY

•Before every ride, it is very important to check the tire pressures. Too low of a tire pressure

will make pedaling more dicult, decrease range, and can cause pinch flats. The recommended

pressure range is printed on the drive side of every tire, so make sure to check the label on the

tire before inflating it. When removing the bike from the packaging, the tires will be at too low

of a pressure to ride safely. This is because the bike will have been inside the box for at least a

month before being delivered, and in this time the tire pressure will slowly decrease.

•The Nero and Nesta come with 26” x 4.0” and 20” x 4.0” tires respectively. These might not in-

clude a pressure range printed on the side, and instead just say 20PSI. We recommend 20PSI for

paved surfaces, 15PSI for hard dirt trails, and 10PSI for snow, sand, or soft dirt/mud.

•Make sure to check the tire pressures about once a week. Although tires may seem air tight,

the rubber is still a semi-permeable membrane that will slowly let air molecules through. This is

why bicycles have flat tires after being left alone for a couple months. If a tire goes flat overnight

however, the inner tube has a slow leak that will either need to be patched or replaced.

•All Espin bikes use tires with schrader valve inner tubes. Do not use tubes with presta valves.

The rims are not compatible with tubeless tires. Espin uses tires with the standard level of

puncture protection, but for maximum puncture protection, we recommend using either Tannus

Armour Inserts or Mr. Tuy Tire Liners. Check your tire size and the charts on their websites to

see which sizes to get. To maximize traction in icy winter conditions, there are options available

in most tire sizes for studded tires. For specific recommendations for which winter tires will work

with your model, contact our tech team at hello@espinbikes.com.

5INSTALL THE PEDALS

5 .1 Remove the pedals from the parts box.

One is labeled R for right (drive side) and the

other is labeled L for left (non-drive side). The

left pedal is threaded opposite from all the

other bolts, READ THESE INSTRUCTIONS THOR-

OUGHLY!

5 .2 The right pedal is threaded normal-

ly. Thread it into the crank arm clockwise.

Once it is threaded in a couple turns, it can

be quickly threaded in the rest of the way by

holding the flats of the pedal axle with the

provided tool and pedaling backwards, as

shown in Figure 14. Tighten this well.

5 .3 The left pedal has left-hand threading,

meaning it threads COUNTER-CLOCKWISE.

Once it is threaded in a couple turns, it can

be quickly threaded in the rest of the way by

holding the flats of the pedal axle with the

provided tool and pedaling backwards, as

shown in Figure 15. Tighten this well.

Figure 14 Figure 15

12

5 .4 Using the wrench to thread in the pedals

is just a tip for threading them in quickly. The

wrench is only necessary for the final tight-

ening of the pedals. The pedals should be

able to be threaded in all the way with just

your fingers. If screwing the pedals in be-

comes too hard after just a couple turns, STOP

and make sure that the pedals aren‘t getting

cross-threaded. If the pedal isn‘t threaded in

completely straight, the threads of the pedal

and crank arm could be getting damaged.

6INFLATE THE TIRES

13

UNSPOOK BRANDING DESIGN MANUAL

>> PAGE 15 // 44

UNSPOOK

BRANDING MATERIAL

CORPORATE DESIGN

AND GUIDELINES

>> PAGE 14 // 36

UNSPOOK BRANDING DESIGN MANUAL

•Remove the packaging from the seatpost and saddle.

•Make sure the seatpost collar is loose, then insert the seatpost into the seat tube.

•If the seatpost collar has a lever, that operates the same as the quick release skewer for the

front wheel. Hold the lever open 90°, make the adjustment nut finger tight, then close the lever

pointing forwards, so it is parallel with the seatpost collar.

•If the seatpost collar only has a hex bolt, that can be tightened with the provided hex wrenches.

Make sure that the gap in the seatpost collar is lined up with the gap in the seat tube.

•The saddle angle and position can be adjusted by loosening the large hex bolt directly under-

neath the saddle, where the seatpost clamps onto the saddle rails. A good starting point for

making saddle adjustments is to have the saddle angle flat, and the saddle clamp in the middle

of the rails. From there most riders like to angle the saddle down a bit and move the saddle fur-

ther forward.

•To adjust the saddle height, stand next to the bike and raise the saddle up to hip level. When

seated on the saddle and pedaling, the balls of your feet should be in the center of the pedal. At

the bottom of the pedal stroke, your leg should be almost fully extended but still slightly bent.

With correct saddle height, you should NOT be able to rest your feet flat on the ground while

seated. This would indicate too low of a saddle height and can cause knee damage. You should

only be able to touch the ground with your toes while seated. When stopping on a bicycle, you

will always need to stand up o the saddle until you start going again.

8 .3 The front light also mounts to the back of

the fork bridge when not using a front rack, as

shown in Figure 16.

8 .5 When mounting the front rack, make sure

that the provided spacers are between the

rack and the frame mounts to provide space

for the cables to be routed behind the rack.

After the front rack is mounted, turn the han-

dlebar all the way left and all the way right

and check to see if any of the cables are get-

ting caught. There should be enough range of

motion for the suspension caps or the brake

levers to touch the frame. If there is too

much tension on the cables for this to happen

easily, the cables will need to be moved to a

better position, either to the left or right side

of the rack mounts.

Figure 17

8 .4 When using a front rack, the front light

must be mounted to the underside of the rack

as shown in Figure 17. If the light is mounted

to the fork, the suspension travel will ram the

light up into the rack and damage the light.

8FRONT FENDER, FRONT RACK, AND

FRONT LIGHT INSTALLATION

8 .1 Our bikes come with the front fender, front

light, and front rack removed for safer ship-

ping.

Figure 16

8 .2 The front fender mounts onto the fork

using the supplied bolts, nuts, and washers.

The two metal arms of the fender attach to

the sides of the fork dropouts. The metal tab

at the top of the fender mounts to the back of

the fork bridge. The hole in this tab is an oval.

When fastening the bolt for this tab, make

sure that the fender is as high in the oval as it

will go to provide maximum clearance be-

tween the tire and the fender. If the fender is

too low, leaves and other debris can get stuck

in the fender.

7INSTALL THE SADDLE AND ADJUST

THE SADDLE HEIGHT

14 15

UNSPOOK BRANDING DESIGN MANUAL

>> PAGE 17 // 44

UNSPOOK

BRANDING MATERIAL

CORPORATE DESIGN

AND GUIDELINES

>> PAGE 16 // 36

UNSPOOK BRANDING DESIGN MANUAL

9 ADJUSTING STEM ANGLE

9 .2 Your stem might not have the bolt under

the stem shown in Figure 19. If it doesn’t, set

the stem to the desired angle and then tighten

the joint bolt. If your stem has the bolt shown

in Figure 19, then loosen this bolt until the

stem angle can be changed.

9 .1 The Nesta does not have an adjustable

angle stem. Proceed to 11. To adjust your

stem angle, first loosen the left side bolt on

the stem joint, as shown in Figure 28. The bolt

on the right does not need to be loosened. If

your stem only has one bolt on the joint, then

loosen that bolt until the stem can be rotated.

Figure 18

Figure 19

9 .3 Set the stem to the desired angle. To

ensure the silver plate under the bottom bolt

engages with the teeth in the joint, press up-

wards on the plate while rotating the stem so

that the engagement can be felt. The arrow in

Figure 19 shows where to press on the plate.

While still pressing on the plate, tighten the

bottom bolt to secure the plate. Then, tighten

the left side joint bolt. Recommended torque

is printed by the bolts.

9 .4 After setting the stem angle, the handle-

bar angle will need to be adjusted to compen-

sate for the change in stem angle. Loosen the

4 faceplate bolts until the handlebar can be

rotated. Get on the bike as if you are riding it

and adjust the handlebar angle so that your

wrists are straight when grabbing the brake

levers. Make sure the handlebar is centered

on the stem and tighten the 4 faceplate bolts

using the X pattern discussed in the handlebar

installation section.

For a video of this process, watch the YouTube video here:

CLICK TO PLAY

10 ADJUSTING THE SUSPENSION

FORK

• The Sport, Flow, Nero, and Nesta all come with the same type of suspension fork. It has a black

lockout lever on the top of the right side, and a clear yellow cap labeled PRELOAD on the top of

the left side.

• The PRELOAD cap is actually a rebound adjuster. To make rebound slower for slow speed o

road riding, turn the cap clockwise. To make rebound faster for going over bumps at high speeds,

turn the cap counter-clockwise. Turning the cap all the way counter-clockwise will make the fork

feel like a pogo stick. We recommend leaving this cap in a middle setting, which should work fine

for most conditions.

• The lockout lever can only be rotated a quarter turn, either to closed or open. Set to open, the

fork will have suspension. Set to closed, the suspension will be locked out. Locking out the sus-

pension is recommended for flat, paved terrain and especially for climbing hills. When riding o

road or going downhill, the lockout can be left open to take advantage of the suspension.

16 17

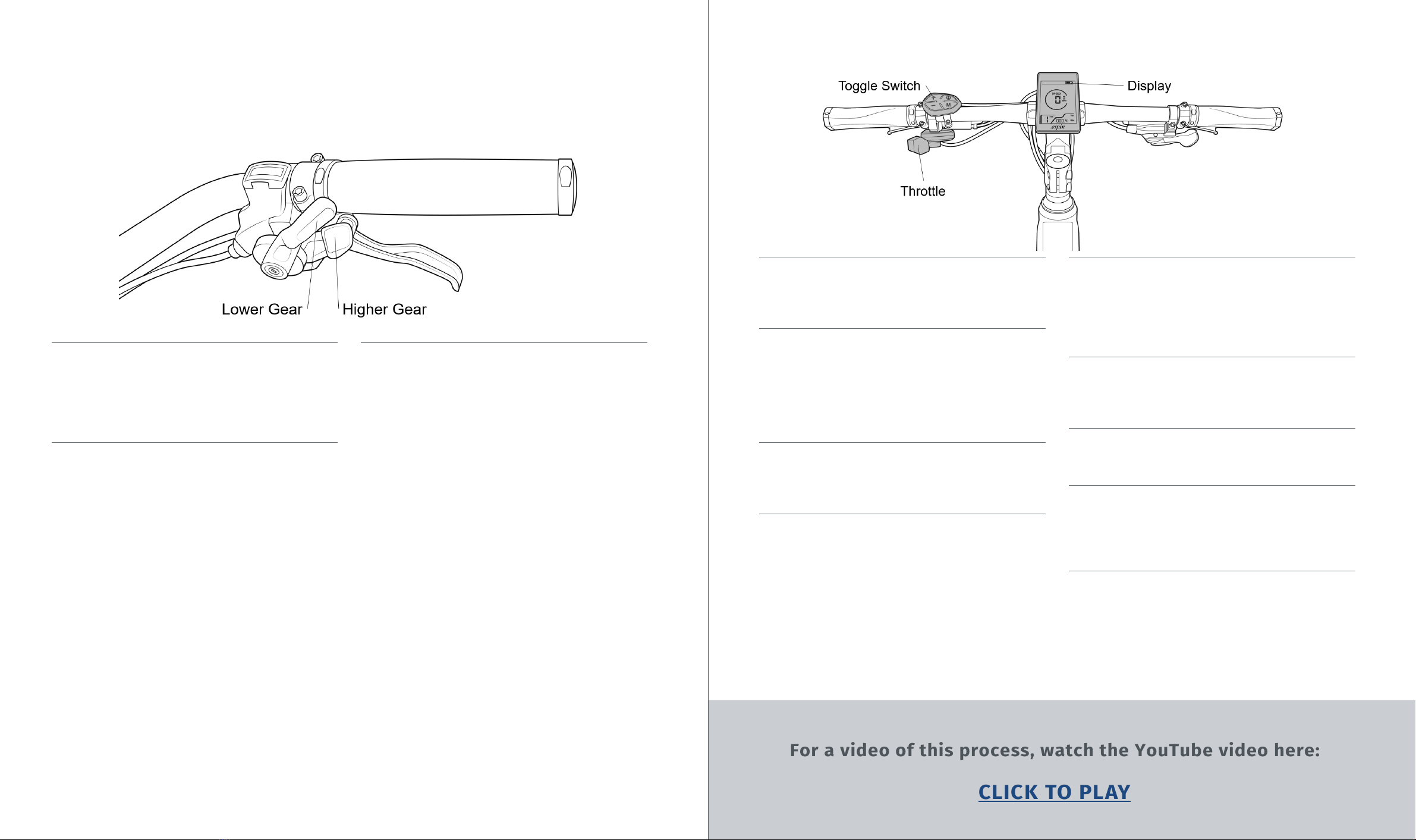

11 .1 The shifter is located on the right side

of the handlebar and has 2 levers, shown in

Figure 20. DO NOT shift the bike unless pedal-

ing, this can damage the shift line. Only shift

while pedaling.

11 .2 The high gear lever shifts the derailleur

into higher gears (smaller cogs). Pressing it

forward will make it click once and shift the

derailleur into a higher gear. If pedaling feels

too fast or easy, shift into a higher gear.

11 .3 The low gear lever shifts the derailleur

into lower gears (larger cogs). This lever has

a larger range of motion than the high gear

lever, and pressing it all the way forward will

make it click multiple times. Each click signi-

fies one lower gear. This larger range helps to

quickly shift into a lower gear if a hill is sud-

denly encountered. If pedaling feels too slow

or dicult, shift into a lower gear.

Figure 20

11 .4 The electrical controls are located on the

left side of the handlebar, and are highlighted

in Figure 21.

11 .5 The throttle is used for instantaneous

power, and the toggle switch is used to select

PAS levels, turn the lights on or o, activate

walk mode, turn on the USB charger, and

toggle through all of the display options and

settings.

11 .6 The display shows current speed, dis-

tance traveled, battery level, PAS level, and all

of the bike’s functions and settings.

11 .7 To turn the bike on, make sure the battery

is connected, locked, and turned on, then hold

the power button (I/O) on the toggle switch for

one second. When turning the bike on, it will

start in PAS 1. This is the slowest PAS level.

To select faster PAS levels, press the + button.

The fastest speed is PAS 5. For slower speeds

or to turn the PAS o with PAS 0, press the -

button.

11 .8 Whether using the throttle or PAS, the

motor can be instantly shut o by squeezing

either of the brake levers. The brake levers

have integrated motor cuto switches, the

wires for which come out of the lever next to

the brake line.

11 .9 To activate walk mode for walking the

bike uphill or up stairs, hold the - button. The

motor will kick in after a second and will keep

providing power until the - button is released.

11 .10 To turn the lights on, hold the + button

for one second. To turn the lights o, also

hold the + button for one second.

11 .11 To turn on the USB charging port, hold

the M button for one second. To turn it o,

also hold the M button for one second. The

USB port is on the front side of the display,

covered by a rubber cap.

For a video of this process, watch the YouTube video here:

CLICK TO PLAY

Figure 21

11 .12 To turn the bike o, hold the power but-

ton for one second. If the bike is not moving

and receiving no user inputs for 5 minutes, it

will automatically turn o. When o the bike

or walking it, ALWAYS either turn it o or set

to PAS 0.

11 HOW TO SHIFT GEARS AND OPERATE THE

PEDAL ASSIST SYSTEM (PAS)

18 19

UNSPOOK BRANDING DESIGN MANUAL

>> PAGE 21 // 44

UNSPOOK

BRANDING MATERIAL

CORPORATE DESIGN

AND GUIDELINES

>> PAGE 20 // 36

UNSPOOK BRANDING DESIGN MANUAL

Before the first ride, please make sure the following are tight and secure:

All bolts on the stem and stem faceplate (DO NOT tighten the top cap bolt unless adjusting the

headset)

Seatpost Collar and Saddle Bolt

Front Wheel Axle Bolt or Quick Release

Pedals (right side/drive side clockwise, left side/non-drive side counter-clockwise)

Front Fender, Light, and Rack Bolts

All electronic plugs, including the motor cable plug behind the pedals, as well as the plugs by

the handlebar for the display, throttle, and brake motor cutos. All the plugs have arrows on the

male and female sides that should be aligned when plugged in.

There are two small screws on the derailleur that look like they are unscrewed partway. They

are limiting screws and are set as intended. DO NOT screw these in unless you have experience

adjusting bicycle derailleurs.

For the first test ride, please test the following at slow speeds with the power o and

while wearing a helmet:

•Brakes, rear and front separately, then together. Right brake is rear, left brake is front. When

squeezing the rear brake lever all the way, there should be enough braking force for the tire to

skid. Disc brakes might squeak for the first mile because of the fresh brake rotors and pads. If

the brakes continue squeaking or if there seems to be a lack of braking force, contact us at hel-

lo@espinbikes.com.

•While constantly pedaling, shift all the way from gear 1 to 8, then back to 1. Pedal several rev-

olutions for each gear. If the chain is making unusual noises, feels like it’s getting stuck on any

gears or skipping, contact us at hello@espinbikes.com.

•After ensuring operational brakes and smooth shifting, stand up o the saddle and pedal as

hard as you can! If the maximum rider pedaling force produces any rhythmic clicking or creaking

timal braking force and brake pad wear, always squeeze both brake levers at the same time with

equal force. Never lean forward when braking.

•Turn the power on. The Nero and Nesta will need the battery switched on before the display

can be turned on. Test the throttle without any pedaling. Then, without using the throttle and

while pedaling, test the Pedal Assist System starting with PAS 1, progressively moving to PAS 5.

As programmed, PAS 1 should be about 10mph, and PAS 5 should be about 25mph. There will be

a slight delay when the PAS turns on or o, but the throttle should be immediate. If there seem

to be any issues with the motorized performance or any unusual sounds coming from the motor,

contact us at hello@espinbikes.com.

•Before riding at night, test the front and rear lights by holding the + button to turn them on. If

either do not turn on, contact us at hello@espinbikes.com.

20

12 SAFETY CHECKS 13 TEST RIDE

21

UNSPOOK BRANDING DESIGN MANUAL

>> PAGE 23 // 44

UNSPOOK

BRANDING MATERIAL

CORPORATE DESIGN

AND GUIDELINES

•The most frequent maintenance necessary for a bicycle is to inflate the tires once a week and

to keep the chain clean and lubricated. We recommend any bicycle chain lube, but Tri-Flow can

be used for the chain and derailleur joints and pulleys. If the chain gets dirty or gunked up, good

chain cleaners are either isopropyl alcohol or Clean Streak. These can be sprayed directly onto

the chain and wiped clean with a rag or paper towel. Most bicycle shops oer complete drive-

train cleaning services.

•The main components of a bicycle that wear out are the tires, brake pads, chain, cassette,

shifting cable/housing, and brake fluid or brake cable/housing. If the bike is being ridden almost

every day, these will likely all need to be replaced about once a year. Most bicycle shops carry

replacement parts that will fit our bikes. Nesta tires and inner tubes can either be purchased

•All Espin bikes (except the Aero and some models before 2021) have hydraulic disc brakes. If

these brakes ever lose their stopping power, or if one lever feels squishier than the other, it

might be time for a brake bleed. Most bike shops offer this as a service. Our bikes have Zoom

hydraulic disc brakes and use mineral oil. DO NOT use DOT fluid. DO NOT get oil or grease on the

brake rotor or pads. This will ruin the brake pads.

•Other components that can wear out over a much longer period of time are the chainring, de-

railleur pulleys, spokes, suspension fork, saddle, handlebar grips, and all of the bearings includ-

ing those for the headset, bottom bracket, and hubs. All of these items will likely be fine for at

least 5 years.

•For e-bikes, the main component that can wear out is the battery. Espin batteries are rated to

maintain their charge capacity for at least 500 charge/discharge cycles. The hall sensor of the

hub motor can burn out, but this is a fairly rare occurrence and should always be brought up with

Espin at hello@espinbikes.com.

•If the bike gets dirty or dusty, it can be washed o like a regular bicycle. First, turn o the pow-

er at the display, and turn o the battery for the Nero and Nesta. Leave the battery attached to

maintain the water-tight seal over the connection. Use a hose on the mist or shower setting to

rinse o the bike. DO NOT use the jet setting or high-pressure flow on any bearings or electrical

components. The bike can be wiped o with a soft cloth or paper towels. Leave the bike outside

to dry completely before turning the bike back on.

15 .1 Occasionally your display might show one of the above error codes with an H next to it. This

generally happens because a plug somewhere is loose due to jostling during shipping or after a

crash while riding the bike.

15 .2 All of the plugs on the bike are round, water resistant plugs with two arrows pointing to-

wards each other to indicate proper alignment. The seam for the plug is between the two arrows,

and can just be pulled apart.

15 .3 The inside of the throttle plug is orange, the display plug green, and the motor cuto plugs

red. These 4 plugs are all located in front of the handlebar, and are in the middle of the cables

coming out of their respective components.

15 .4 The motor plug is underneath the non-drive side chain stay (refer to the bike diagram on

page 5). This plug has a metal ring on it that must be unscrewed before the plug can be pulled

apart. Espin models before 2021 did not have this ring, and can simply be pulled apart.

15 .5 The controller is located in the compartment between the pedals. To access this, remove

the panel on the non-drive side held in place with 4 bolts. All of the controller plugs and wires

are matched by color.

14 CARING FOR YOUR BIKE

22

15 ERROR CODES

23

CONTACT US:

HELLO@ESPINBIKES.COM

PHONE NUMBER :

888 2964550

Quick Start Guide

UNSPOOK BRANDING DESIGN MANUAL

>> PAGE 25 // 44

*SCRYPE

BRANDING MATERIAL

CORPORATE DESIGN

AND GUIDELINES

ISSUE 01

BRANDING

DESIGN MANUAL

>> PAGE 24 // 36

UNSPOOK BRANDING DESIGN MANUAL

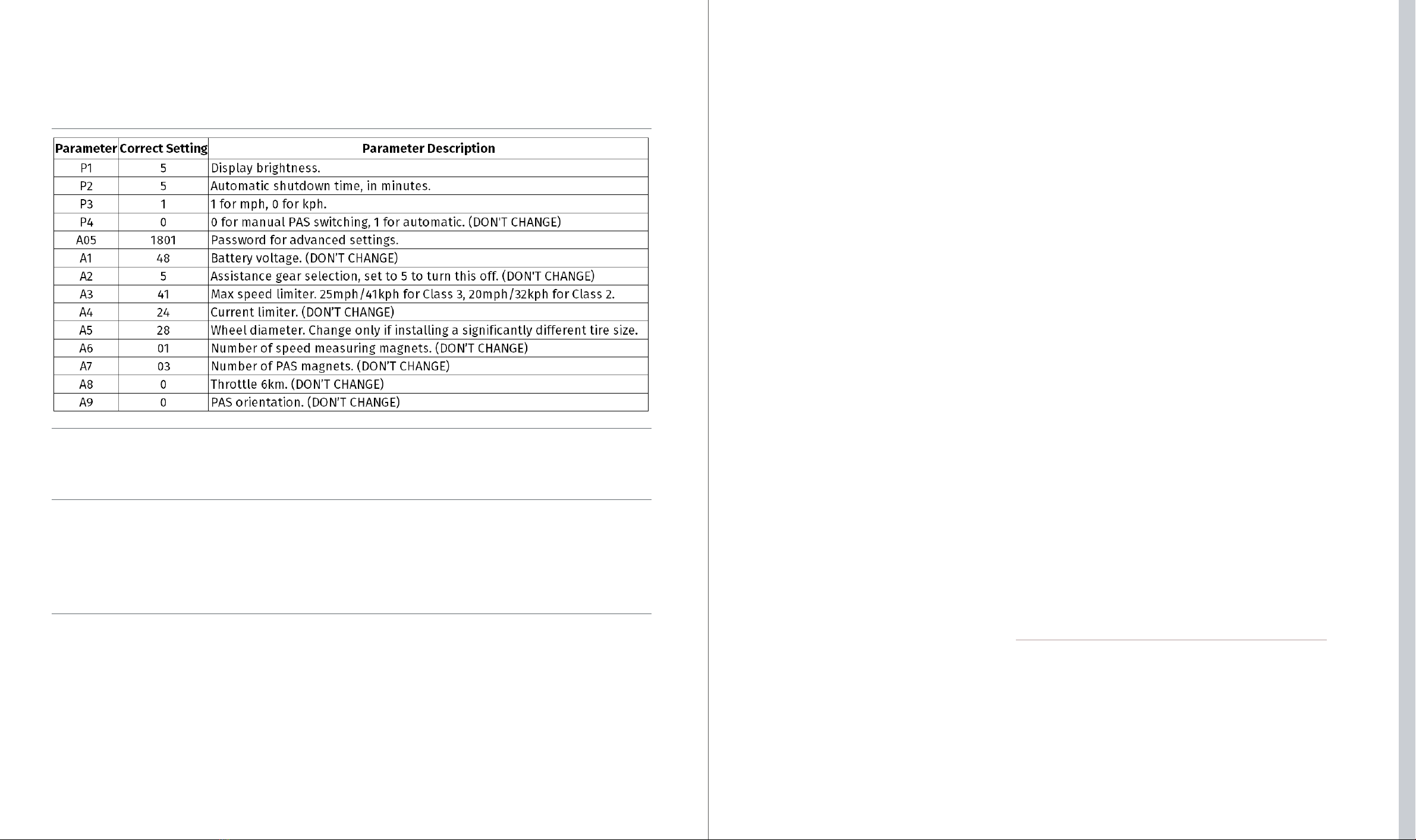

16 .1 You can access most of the settings programmed into the controller through the display and

toggle switch. Some of these settings are welcome to be changed by the user, including P1, P2,

P3, and A3. Most of the other parameters should not be changed from the settings recommended

above, or else the bike might not function correctly or the circuitry could even get fried.

16 .2 To access the parameter menu, turn on the bike, then double tap the M button. Press the +

button to move from P1, to P2, P3, etc. To change a parameter, press the M button once while on

that parameter, then use the + or - buttons to adjust the value at the bottom of the display. Once

the value has been adjusted, press the M button once to enter the new value and to start mov-

ing to other parameters. Once the password section is reached, use the + and - buttons to input

1801 and press M to enter each value. After adjusting any necessary settings, double tap M to

escape the parameters menu or simply wait 30 seconds.

16 .3 To adjust the power output of the individual PAS levels, navigate to parameter A2. Then,

press and hold + and - together to get to the PAS adjustment menu. You will see 1 (Indicating PAS

1) set to 40 and blinking. This means that PAS 1 will give you 40% motor power, which will make

the bike go about 10mph. Press the + or - button to adjust this to the desired setting and hit M.

Then you will be on the parameter for PAS 2. Adjust PAS 2 to the desired setting and hit M. Do

this for 3, 4 & 5. Once you hit M after setting PAS 5 you will be brought back to the regular display

menu.

Note: Doing this will not change the value of A2. Pressing + and - together at the A2 screen will

safely navigate away from A2.

16 DISPLAY SETTINGS

24 25

This manual suits for next models

3

Table of contents

Other Espin Bicycle manuals