Espressif ESP01 User manual

Espressif provides email notifications to keep customers updated on changes to technical documentation.

Please subscribe here.

Download certificates for Espressif products from here.

Information in this document, including URL references, is subject to change without notice. THIS DOCUMENT IS

PROVIDED AS IS WITH NO WARRANTIES WHATSOEVER, INCLUDING ANY WARRANTY OF MERCHANTABIL-

ITY, NON-

INFRINGEMENT, FITNESS FOR ANY PARTICULAR PURPOSE, OR ANY WARRANTY OTHERWISE

ARISING OUT OF ANY PROPOSAL, SPECIFICATION ORSAMPLE.

All liability, including liability for infringement of any proprietary rights, relating to use of information in this docu-

ment is disclaimed. No licenses express or implied, by estoppel or otherwise, to any intellectual property

rights

are granted herein. The Wi-Fi Alliance Member logo is a trademark of the Wi-Fi Alliance.

Alltrade names,trademarks and registeredtrademarksmentionedinthis document arepropertyoftheir

respective

owners, and are hereby acknowledged.

Copyright © 2017 Espressif Inc. All rights reserved.

About This Guide

This document provides the specifications for the ESP01 module.

The document structure is as follows:

Chapter

Title

Subject

Chapter 1

Preface

An overview of ESP01

Chapter 2

Pin Definitions

Device pinout and pin descriptions

Chapter 3

Functional Description

Description of major functional modules

Chapter 4

Peripherals and Sensors

Description of peripherals

Chapter 5

Electrical Characteristics

Electrical characteristics and specifications of ESP01

Release Notes

Date

Version

Release notes

2017.10

V1.0

First release.

Documentation Change Notification

Certification

Disclaimer and Copyright Notice

1. O VERVIEW

Note:

* For details on the part number of the ESP32 series, please refer to the document ESP32 Datasheet.

1.

Overview

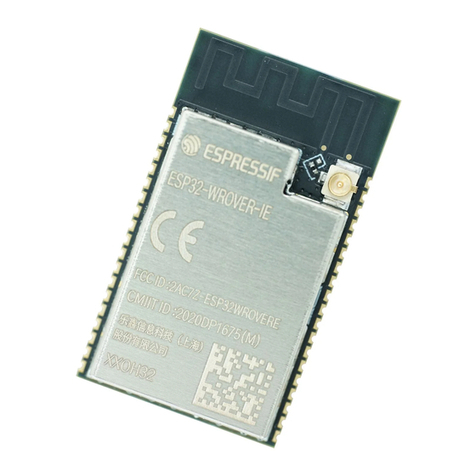

ESP01 is a powerful, generic Wi-Fi MCU module that targets a wide variety of applications,

ranging from low-power sensor networks to the most demanding tasks, such as voice encoding, music streaming

and MP3 decoding. ESP01 integrates a U.FL connector.

At the core of this module is the ESP32-D0WD chip*. The chip embedded is designed to be scalable and adaptive.

There are two CPU cores that can be individually controlled, and the clock frequency is adjustable from 80 MHz

to 240 MHz. The user may also power off the CPU and make use of the low-power co-processor to constantly

monitor the peripherals for changes or crossing of thresholds. ESP32 integrates a rich set of peripherals, ranging

from capacitive touch sensors, Hall sensors, low-noise sense amplifiers, SD card interface, Ethernet, high-speed

SPI, UART, I2S and I2C.

The sleep current of the ESP32 chip is less than 5 µA, making it suitable for battery powered and wearable

electronics applications. As such the chip does offer industry-leading specifications and the best performance

for electronic integration, range, power consumption, and connectivity.

The operating system chosen for ESP32 is freeRTOS with LwIP; TLS 1.2 with hardware acceleration is built in as

well. Secure (encrypted) over the air (OTA) upgrade is also supported, so that developers can continually upgrade

their products even after theirrelease.

Table 2 provides the specifications of ESP01

Table 2: ESP01 Specifications

Categories

Items

Specifications

Wi-Fi

Protocols

802.11 b/g/n/e/i (802.11n up to 150 Mbps)

A-MPDU and A-MSDU aggregation and 0.4 µs guard

interval support

Frequency range 2412~2462 MHz

1. O VERVIEW

Categories

Items

Specifications

Hardware

Module interface

SD card, UART, SPI, SDIO, I2C, LED PWM, Motor

PWM, I2S, IR

GPIO, capacitive touch sensor, ADC, DAC, LNA pre-

amplifier

On-chip sensor

Hall sensor, temperature sensor

On-board clock

40 MHz crystal

Operating voltage/Power supply

2.7

~

3.6V

Operating current

Average: 80 mA

Minimum current delivered by

power supply

500 mA

Operating temperature range -40°C ~ +85°C

Ambient temperature range Normal temperature

Package size

18±0.2 mm x 19.2±0.2 mm x 3.2±0.15 mm

Software

Wi-Fi mode

Station/SoftAP/SoftAP+Station/P2P

Wi-Fi Security WPA/WPA2/WPA2-Enterprise/WPS

Encryption

AES/RSA/ECC/SHA

Firmware upgrade

UART Download / OTA (download and write firmware

via network or host)

Software development

Supports Cloud Server Development / SDK for cus-

tom firmware development

Network protocols

IPv4, IPv6, SSL, TCP/UDP/HTTP/FTP/MQTT

User configuration

AT instruction set, cloud server, Android/iOS app

2 . PIN DEFINITIO NS

IO35 NC

39: GND

IO32

IO19

IO33

IO18

IO25 IO5

IO26

IO17

IO27 IO16

IO14 IO4

IO12 IO0

GND

IO23

IO22

TXD0

RXD0

IO21

GND

3V3

EN

SENSOR_VP

SENSOR_VN

IO34

Keepout Zone

GND

IO13

SD2

SD3

CMD

CLK

SD0

SD1

IO15

IO2

2.

Pin Definitions

2.1

Pin Layout

1 38

2 37

3 36

4 35

5 34

6 33

7 32

8 31

9 30

10 29

11 28

12 27

13 26

14 25

Figure 1: ESP01 Pin layout

2.2

Pin Description

ESP01 has 38 pins. See pin definitions in Table 3.

Table 3: Pin Definitions

Name

No.

Type

Function

GND

1

P

Ground

3V3

2

P

Power supply.

EN

3

I

Chip-enable signal. Active high.

SENSOR_VP

4

I

GPIO36, SENSOR_VP, ADC_H, ADC1_CH0, RTC_GPIO0

SENSOR_VN

5

I

GPIO39, SENSOR_VN, ADC1_CH3, ADC_H, RTC_GPIO3

IO34 6

I

GPIO34, ADC1_CH6, RTC_GPIO4

IO35

7

I

GPIO35, ADC1_CH7, RTC_GPIO5

IO32 8 I/O

GPIO32, XTAL_32K_P (32.768 kHz crystal oscillator input), ADC1_CH4,

TOUCH9, RTC_GPIO9

15

16

17

18

19

20

21

22

23

24

2 . PIN DEFINITIO NS

Note:

* Pins SCK/CLK, SDO/SD0, SDI/SD1, SHD/SD2, SWP/SD3 and SCS/CMD, namely, GPIO6 to GPIO11 are connected

to the integrated SPI flash integrated on ESP01 and are not recommended for other uses.

Name No. Type Function

IO33 9 I/O GPIO33, XTAL_32K_N (32.768 kHz crystal oscillator output), ADC1_CH5,

TOUCH8, RTC_GPIO8

IO25

10

I/O

GPIO25, DAC_1, ADC2_CH8, RTC_GPIO6, EMAC_RXD0

IO26

11

I/O

GPIO26, DAC_2, ADC2_CH9, RTC_GPIO7, EMAC_RXD1

IO27

12

I/O

GPIO27, ADC2_CH7, TOUCH7, RTC_GPIO17, EMAC_RX_DV

IO14 13 I/O

GPIO14, ADC2_CH6, TOUCH6, RTC_GPIO16, MTMS, HSPICLK,

HS2_CLK, SD_CLK, EMAC_TXD2

IO12 14 I/O

GPIO12, ADC2_CH5, TOUCH5, RTC_GPIO15, MTDI, HSPIQ,

HS2_DATA2, SD_DATA2, EMAC_TXD3

GND

15

P

Ground

IO13 16 I/O GPIO13, ADC2_CH4, TOUCH4, RTC_GPIO14, MTCK, HSPID,

HS2_DATA3, SD_DATA3, EMAC_RX_ER

SHD/SD2*

17

I/O

GPIO9, SD_DATA2, SPIHD, HS1_DATA2, U1RXD

SWP/SD3*

18

I/O

GPIO10, SD_DATA3, SPIWP, HS1_DATA3, U1TXD

SCS/CMD*

19

I/O

GPIO11, SD_CMD, SPICS0, HS1_CMD, U1RTS

SCK/CLK*

20 I/O

GPIO6, SD_CLK, SPICLK, HS1_CLK, U1CTS

SDO/SD0* 21 I/O GPIO7, SD_DATA0, SPIQ, HS1_DATA0, U2RTS

SDI/SD1* 22 I/O GPIO8, SD_DATA1, SPID, HS1_DATA1, U2CTS

IO15 23 I/O GPIO15, ADC2_CH3, TOUCH3, MTDO, HSPICS0, RTC_GPIO13,

HS2_CMD, SD_CMD, EMAC_RXD3

IO2 24 I/O

GPIO2, ADC2_CH2, TOUCH2, RTC_GPIO12, HSPIWP, HS2_DATA0,

SD_DATA0

IO0 25 I/O GPIO0, ADC2_CH1, TOUCH1, RTC_GPIO11, CLK_OUT1,

EMAC_TX_CLK

IO4 26 I/O

GPIO4, ADC2_CH0, TOUCH0, RTC_GPIO10, HSPIHD, HS2_DATA1,

SD_DATA1, EMAC_TX_ER

IO16

27

I/O

GPIO16, HS1_DATA4, U2RXD, EMAC_CLK_OUT

IO17

28

I/O

GPIO17, HS1_DATA5, U2TXD, EMAC_CLK_OUT_180

IO5

29

I/O

GPIO5, VSPICS0, HS1_DATA6, EMAC_RX_CLK

IO18

30

I/O

GPIO18, VSPICLK, HS1_DATA7

IO19

31

I/O

GPIO19, VSPIQ, U0CTS, EMAC_TXD0

NC

32

-

-

IO21 33 I/O GPIO21, VSPIHD, EMAC_TX_EN

RXD0 34 I/O GPIO3, U0RXD, CLK_OUT2

TXD0

35

I/O

GPIO1, U0TXD, CLK_OUT3, EMAC_RXD2

IO22

36

I/O

GPIO22, VSPIWP, U0RTS, EMAC_TXD1

IO23

37

I/O

GPIO23, VSPID, HS1_STROBE

GND

38

P

Ground

2 . PIN DEFINITIO NS

Note:

Firmware can configure register bits to change the settings of ”Voltage of Internal LDO (VDD_SDIO)” and ”Timing of SDIO

Slave” after booting.

2.3

Strapping Pins

Please refer to ESP01 schematics.

ESP32 has five strapping pins, which can be seen in Chapter 6 Schematics:

•

MTDI

•

GPIO0

•

GPIO2

•

MTDO

•

GPIO5

Software can read the value of these five bits from the register ”GPIO_STRAPPING”.

During the chip’s system reset (power-on reset, RTC watchdog reset and brownout reset), the latches of the

strapping pins sample the voltage level as strapping bits of ”0” or ”1”, and hold these bits until the chip is powered

down or shut down. The strapping bits configure the device boot mode, the operating voltage of VDD_SDIO and

other system initial settings.

Each strapping pin is connected with its internal pull-up/pull-down during the chip reset. Consequently, if a strap-

ping pin is unconnected or the connected external circuit is high-impendence, the internal weak pull-up/pull-down

will determine the default input level of the strapping pins.

To change the strapping bit values, users can apply the external pull-down/pull-up resistances, or apply the host

MCU’s GPIOs to control the voltage level of these pins when powering on ESP32.

After reset, the strapping pins work as the normal functions pins.

Refer to Table 4 for detailed boot modes’ configuration by strapping pins.

Table 4: Strapping Pins

Voltage of Internal LDO (VDD_SDIO)

Pin

Default

3.3V

1.8V

MTDI

Pull-down

0

1

Booting Mode

Pin Default SPI Boot Download Boot

GPIO0 Pull-up 1 0

GPIO2 Pull-down Don’t-care 0

Debugging Log on U0TXD During Booting

Pin Default U0TXD Toggling U0TXD Silent

MTDO

Pull-up

1

0

Timing of SDIO Slave

Pin Default

Falling-edge Input

Falling-edge Output

Falling-edge Input

Rising-edge Output

Rising-edge Input

Falling-edge Output

Rising-edge Input

Rising-edge Output

MTDO Pull-up 0 0 1 1

GPIO5 Pull-up 0 1 0 1

3 . FUN CTIO N AL D ESC RIPTIO N

3.

Functional Description

This chapter describes the modules and functions integrated in ESP01.

3.1

CPU and Internal Memory

ESP32-D0WD contains two low-power Xtensa® 32-bit LX6 microprocessors. The internal memory includes:

•

448 kB of ROM for booting and core functions.

•

520 kB (8 kB RTC FAST Memory included) of on-chip SRAM for data and instruction.

–

8 kB of SRAM in RTC, which is called RTC FAST Memory and can be used for data storage; it is

accessed by the main CPU during RTC Boot from the Deep-sleep mode.

•

8 kB of SRAM in RTC, which is called RTC SLOW Memory and can be accessed by the co-processor during

the Deep-sleep mode.

•

1 kbit of eFuse, of which 256 bits are used for the system (MAC address and chip configuration) and the

remaining 768 bits are reserved for customer applications, including Flash-Encryption and Chip-ID.

3.2

External Flash and SRAM

ESP32 supports up to four 16-MB of external QSPI flash and SRAM with hardware encryption based on AES to

protect developers’ programs and data.

ESP32 can access the external QSPI flash and SRAM through high-speed caches.

•

Up to 16 MB of external flash are memory-mapped onto the CPU code space, supporting 8, 16 and 32-bit

access. Code execution is supported.

•

Up to 8 MB of external flash/SRAM are memory-mapped onto the CPU data space, supporting 8, 16 and

32-bit access. Data-read is supported on the flash and SRAM. Data-write is supported on the SRAM.

ESP01 integrates 4 MB of external SPI flash. The 4-MB SPI flash can be memory-mapped onto the CPU code

space, supporting 8, 16 and 32-bit access. Code execution is supported. The integrated SPI flash is connected

to GPIO6, GPIO7, GPIO8, GPIO9, GPIO10 and GPIO11. These six pins cannot be used as regular GPIO.

3.3

Crystal Oscillators

The ESP32 Wi-Fi firmware can only support 40 MHz crystal oscillator for now.

3 . FUN CTIO N AL D ESC RIPTIO N

3.4

RTC and Low-Power Management

With the use of advanced power management technologies, ESP32 can switch between different power modes

(see Table 5).

•

Power modes

–

Active mode: The chip radio is powered on. The chip can receive, transmit, or listen.

–

Modem-sleep mode: The CPU is operational and the clock is configurable. The Wi-Fi base- band and

radio are disabled.

–

Light-sleep mode: The CPU is paused. The RTC memory and RTC peripherals, as well as the ULP

co-processor are running. Any wake-up events (MAC, host, RTC timer, or external interrupts) will wake

up the chip.

–

Deep-sleep mode: Only the RTC memory and RTC peripherals are powered on. Wi-Fi connection

data are stored in the RTC memory. The ULP co-processor can work.

–

Hibernation mode: The internal 8-MHz oscillator and ULP co-processor are disabled. The RTC recovery

memory is powered down. Only one RTC timer on the slow clock and some RTC GPIOs are active.

The RTC timer or the RTC GPIOs can wake up the chip from the Hibernation mode.

•

Sleep Patterns

–

Association sleep pattern: The power mode switches between the Active mode, Modem- and Light-

sleep mode during this sleep pattern. The CPU, Wi-Fi and radio are woken up at predeter- mined

intervals to keep Wi-Fi connections alive.

–

ULP sensor-monitored pattern: The main CPU is in the Deep-sleep mode. The ULP co-processor takes

sensor measurements and wakes up the main system, based on the data collected from sensors.

Table 5: Functionalities Depending on the Power Modes

Power mode

Active

Modem-sleep

Light-sleep

Deep-sleep

Hibernation

Sleep pattern Association sleep pattern

ULP sensor-

monitored pattern -

CPU

ON

ON

PAUSE

OFF

OFF

Wi-Fi baseband and radio

ON

OFF

OFF

OFF

OFF

RTC memory and RTC pe-

ripherals

ON

ON

ON

ON

OFF

ULP co-processor

ON

ON

ON

ON/OFF

OFF

Thepowerconsumption varies with differentpowermodes/sleeppatternsandwork statusesoffunctional modules.

Please see Table 6 for details.

Table 6: Power Consumption by Power Modes

Power mode Description Power consumption

Active (RF working)

Wi-Fi Tx packet 14 dBm

~

19.5 dBm

Please refer to ESP32 Datasheet.

Wi-Fi Tx packet 0 dBm

Wi-Fi Rx and listening

Association sleep pattern (by Light-sleep)

1 mA

~

4 mA @DTIM3

3 . FUN CTIO N AL D ESC RIPTIO N

Note:

•

When Wi-Fi is enabled, the chip switches between Active and Modem-sleep mode. Therefore, power consumption

changes accordingly.

•

In Modem-sleep mode, the CPU frequency changes automatically. The frequency depends on the CPU load and

the peripherals used.

•

During Deep-sleep, when the ULP co-processor is powered on, peripherals such as GPIO and I2C are able to

work.

•

When the system works in the ULP sensor-monitored pattern, the ULP co-processor works with the ULP sensor

periodically; ADC works with a duty cycle of 1%, so the power consumption is 100 µA.

Power mode Description Power consumption

Modem-sleep

The CPU is powered on.

Max speed 240 MHz: 30 mA ~ 50 mA

Normal speed 80 MHz: 20 mA

~

25 mA

Slow speed 2 MHz: 2 mA

~

4 mA

Light-sleep - 0.8 mA

Deep-sleep

The ULP co-processor is powered on.

150

µ

A

ULP sensor-monitored pattern

100 µA @1% duty

RTC timer + RTC memory

10

µ

A

Hibernation

RTC timer only

5

µ

A

Power off

CHIP_PU is set to low level, the chip is powered off

0.1

µ

A

4 . P ERIP H ERALS AN D SENSO RS

4.

Peripherals and Sensors

4.1

Peripherals and Sensors Description

Table 7: Description of Peripherals and Sensors

Interface

Signal

Pin

Function

ADC

ADC1_CH0

SENSOR_VP

Two 12-bit SAR ADCs

ADC1_CH3

SENSOR_VN

ADC1_CH4

IO32

ADC1_CH5

IO33

ADC1_CH6

IO34

ADC1_CH7

IO35

ADC2_CH0

IO4

ADC2_CH1

IO0

ADC2_CH2

IO2

ADC2_CH3

IO15

ADC2_CH4

IO13

ADC2_CH5

IO12

ADC2_CH6

IO14

ADC2_CH7

IO27

ADC2_CH8

IO25

ADC2_CH9

IO26

Ultra-Low Noise

Analog Pre-Amplifier

SENSOR_VP

IO36 Provides about 60 dB gain by using larger

capacitors on PCB

SENSOR_VN

IO39

DAC

DAC_1

IO25

Two 8-bit DACs

DAC_2

IO26

Touch Sensor

TOUCH0

IO4

Capacitive touch sensors

TOUCH1

IO0

TOUCH2

IO2

TOUCH3

IO15

TOUCH4

IO13

TOUCH5

IO12

TOUCH6

IO14

TOUCH7

IO27

TOUCH8

IO33

TOUCH9

IO32

SD/SDIO/MMC Host

Controller

HS2_CLK

MTMS

Supports SD memory card V3.01 standard

HS2_CMD

MTDO

HS2_DATA0

IO2

HS2_DATA1 IO4

HS2_DATA2 MTDI

HS2_DATA3

MTCK

Espressif Systems 9 ESP01 Datasheet V1.0

4 . P ERIP H ERALS AN D SENSO RS

Interface

Signal

Pin

Function

Motor PWM

PWM0_OUT0~2

Any GPIOs*

Three channels of 16-bit timers generate

PWM waveforms. Each channel has a pair

of output signals, three fault detection

signals, three event-capture signals, and

three sync signals.

PWM1_OUT_IN0

~

2

PWM0_FLT_IN0

~

2

PWM1_FLT_IN0

~

2

PWM0_CAP_IN0~2

PWM1_CAP_IN0~2

PWM0_SYNC_IN0~2

PWM1_SYNC_IN0

~

2

LED PWM

ledc_hs_sig_out0

~

7

Any GPIOs* 16 independent channels @80 MHz

clock/RTC CLK. Duty accuracy: 16 bits.

ledc_ls_sig_out0~7

UART

U0RXD_in

Any GPIOs*

Two UART devices with hardware

flow-control and DMA

U0CTS_in

U0DSR_in

U0TXD_out

U0RTS_out

U0DTR_out

U1RXD_in

U1CTS_in

U1TXD_out

U1RTS_out

U2RXD_in

U2CTS_in

U2TXD_out

U2RTS_out

I2C

I2CEXT0_SCL_in

Any GPIOs*

Two I2C devices in slave or master modes

I2CEXT0_SDA_in

I2CEXT1_SCL_in

I2CEXT1_SDA_in

I2CEXT0_SCL_out

I2CEXT0_SDA_out

I2CEXT1_SCL_out

I2CEXT1_SDA_out

4 . P ERIP H ERALS AN D SENSO RS

Interface Signal Pin Function

I2S

I2S0I_DATA_in0

~

15

Any GPIOs*

Stereo input and output from/to the audio

codec, and parallel LCD dataoutput

I2S0O_BCK_in

I2S0O_WS_in

I2S0I_BCK_in

I2S0I_WS_in

I2S0I_H_SYNC

I2S0I_V_SYNC

I2S0I_H_ENABLE

I2S0O_BCK_out

I2S0O_WS_out

I2S0I_BCK_out

I2S0I_WS_out

I2S0O_DATA_out0~23

I2S1I_DATA_in0

~

15

I2S1O_BCK_in

I2S1O_WS_in

I2S1I_BCK_in

I2S1I_WS_in

I2S1I_H_SYNC

I2S1I_V_SYNC

I2S1I_H_ENABLE

I2S1O_BCK_out

I2S1O_WS_out

I2S1I_BCK_out

I2S1I_WS_out

I2S1O_DATA_out0~23

Remote Controller

RMT_SIG_IN0

~

7

Any GPIOs* Eight channels of IR transmitter and

receiver for various waveforms

RMT_SIG_OUT0~7

11 ESP01 Datasheet V1.0

4 . P ERIP H ERALS AN D SENSO RS

Interface Signal Pin Function

Parallel QSPI

SPIHD

SHD/SD2

Supports Standard SPI, Dual SPI, and

Quad SPI that can be connected to the

external flash and SRAM

SPIWP

SWP/SD3

SPICS0

SCS/CMD

SPICLK

SCK/CLK

SPIQ

SDO/SD0

SPID SDI/SD1

HSPICLK

IO14

HSPICS0

IO15

HSPIQ

IO12

HSPID

IO13

HSPIHD

IO4

HSPIWP

IO2

VSPICLK

IO18

VSPICS0

IO5

VSPIQ

IO19

VSPID

IO23

VSPIHD

IO21

VSPIWP IO22

General Purpose

SPI

HSPIQ_in/_out

Any GPIOs*

Standard SPI consists of clock,

chip-select, MOSI and MISO. These SPIs

can be connected to LCD and other

external devices. They support the

following features:

•

both master and slavemodes;

•

4 sub-modes of the SPI format

transfer that depend on the clock

phase (CPHA) and clock polarity

(CPOL) control;

•

configurable SPI frequency;

•

up to 64 bytes of FIFO and DMA.

HSPID_in/_out

HSPICLK_in/_out

HSPI_CS0_in/_out

HSPI_CS1_out

HSPI_CS2_out

VSPIQ_in/_out

VSPID_in/_out

VSPICLK_in/_out

VSPI_CS0_in/_out

VSPI_CS1_out

VSPI_CS2_out

JTAG

MTDI

IO12

JTAG for software debugging

MTCK

IO13

MTMS

IO14

MTDO IO15

12 ESP01 Datasheet V1.0

4 . P ERIP H ERALS AN D SENSO RS

Note:

•

Functions of Motor PWM, LED PWM, UART, I2C, I2S, general purpose SPI and Remote Controller can be configured

to any GPIO except GPIO6, GPIO7, GPIO8, GPIO9, GPIO10 and GPIO11.

•

For the items marked with ”Any GPIOs*” in the ”Pin” column, users should note that GPIO6, GPIO7, GPIO8, GPIO9,

GPIO10 and GPIO11 are connected to the integrated SPI flash of ESP01 and are not recommended for other

uses.

Interface Signal Pin Function

SDIO Slave

SD_CLK

IO6

SDIO interface that conforms to the

industry standard SDIO 2.0 card

specification.

SD_CMD

IO11

SD_DATA0

IO7

SD_DATA1

IO8

SD_DATA2 IO9

SD_DATA3 IO10

EMAC

EMAC_TX_CLK

IO0

Ethernet MAC with MII/RMII interface

EMAC_RX_CLK

IO5

EMAC_TX_EN IO21

EMAC_TXD0

IO19

EMAC_TXD1

IO22

EMAC_TXD2

IO14

EMAC_TXD3

IO12

EMAC_RX_ER

IO13

EMAC_RX_DV

IO27

EMAC_RXD0

IO25

EMAC_RXD1

IO26

EMAC_RXD2

TXD0

EMAC_RXD3

IO15

EMAC_CLK_OUT

IO16

EMAC_CLK_OUT_180

IO17

EMAC_TX_ER

IO4

EMAC_MDC_out

Any GPIOs*

EMAC_MDI_in Any GPIOs*

EMAC_MDO_out

Any GPIOs*

EMAC_CRS_out

Any GPIOs*

EMAC_COL_out

Any GPIOs*

13 ESP01 Datasheet V1.0

5.

Electrical Characteristics

5.1

Absolute Maximum Ratings

Table 8: Absolute Maximum Ratings

Parameter Symbol Min Typ Max Unit

Power supply

VDD

2.7

3.3

3.6

V

Minimum current delivered by

power supply

IV

DD

0.5 - -

A

Input low voltage

V

IL

-0.3 -

0.25×V

IO

1

V

Input high voltage

V

IH

0.75×V

IO

1

-

V

IO

1

+0.3

V

Input leakage current

I

I

L

- - 50 nA

Input pin capacitance

C

pad

-

-

2

pF

Output low voltage

V

OL

-

-

0.1×V

IO

1

V

Output high voltage

V

OH

0.8×V

IO

1

-

-

V

Maximum output drive capability

I

MAX

-

-

40

mA

Storage temperature range

T

STR

-40

-

85

°C

Operating temperature range

T

OPR

-40

-

85

°C

1. V

IO

is the power supply for a specific pad. More details can be found in the ESP32 Datasheet, Appendix IO_MUX. For

example, the power supply for SD_CLK is the VDD_SDIO.

FCC Statement:

Please take attention that changes or modification not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired

operation.

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled environment. This

equipment should be installed and operated with minimum distance 20cm between the radiator & your

body.

IC Statement:

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the

following two conditions:

(1) this device may not cause interference, and

(2) this device must accept any interference, including interference that may cause undesired operation of

the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radioexempts de

licence. L'exploitation est autorisée aux deux conditions suivantes :

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

This equipment complies with IC RSS-102 radiation exposure limits set forth for an uncontrolled

environment. This equipment should be installed and operated with minimum distance 20cm between the

radiator & your body.

ce matériel est conforme aux limites de dose d'exposition aux rayonnements, CNR-102 énoncée dans un

autre environnement.cette eqipment devrait être installé et exploité avec distance minimale de 20 entre le

radiateur et votre corps.

(1) Operational use conditions

Module has professional users use condition limitations, Host product manufacturer please ensure

giving such warning like “Product is limited to professional users use” in your product’s instruction.

(2) Antenna used

Antenna

Type

Max. Antenna

Gain

Dipole

3dBi

(3) Labelling Instruction for Host Product Integrator

Please notice that if the FCC and IC identification number is not visible when the module is installed

inside another device, then the outside of the device into which the module is installed must also

display a label referring to the enclosed module. For FCC, this exterior label should follow “Contains FCC

ID: 2AZLQ-ESP01”. In accordance with FCC KDB guidance 784748 Labeling Guidelines. For IC, this

exterior label can use wording “Contains IC: 27189-ESP01”.

§ 15.19 and RSS-Gen Labelling requirements shall be complied on end user device. Labelling rules for

special device, please refer to §2.925, § 15.19 (a)(5) and relevant KDB publications. For E-label, please

refer to §2.935.

(4) Installation Notice to Host Product Manufacturer

The OEM integrator is responsible for ensuring that the end-user has no manual instruction to

remove or install module.

The module is limited to installation in mobile application, a separate approval is required for all

other operating configurations, including portable configurations with respect to §2.1093 and

difference antenna configurations.

(5) Antenna Change Notice to Host manufacturer

If you desire to increase antenna gain and either change antenna type or use same antenna type

certified, a Class II permissive change application is required to be filed by us, or you (host manufacturer)

can take responsibility through the change in FCC ID and IC ID (new application) procedure followed by

a Class II permissive change application.

(6) FCC other Parts, Part 15B Compliance Requirements for Host product manufacturer

This modular transmitter is only FCC authorized for the specific rule parts listed on our grant, host

product manufacturer is responsible for compliance to any other FCC rules that apply to the host not

covered by the modular transmitter grant of certification.

Host manufacturer in any case shall ensure host product which is installed and operating with the

module is in compliant with Part 15B requirements.

Please note that For a Class B or Class A digital device or peripheral, the instructions furnished the user

manual of the end-user product shall include statement set out in §15.105 Information to the user or

such similar statement and place it in a prominent location in the text of host product manual. Original

texts as following:

For Class B

Note: This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful

interference to radio communications. However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

—Reorient or relocate the receiving antenna.

—Increase the separation between the equipment and receiver.

—Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

—Consult the dealer or an experienced radio/TV technician for help.

For Class A

Note: This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful interference in which case the user will be

required to correct the interference at his own expense.

Table of contents

Other Espressif Control Unit manuals

Popular Control Unit manuals by other brands

Genebre

Genebre 2105 Installation, operation and maintenance manual

urmet domus

urmet domus Agora 1372 USE, PROGRAMMING AND INSTALLATION GUIDE

Allen-Bradley

Allen-Bradley 1771-OD Installation data

Nice

Nice Moon MC824H quick guide

Emerson

Emerson Rosemount Analytical NGA2000 CLD instruction manual

RedRat

RedRat RedRat-X Integration guide