Nord Drivesystems SK 510P User manual

Getriebebau NORD GmbH & Co. KG

Getriebebau-Nord-Straße 1 • 22941 Bargteheide, Germany • www.nord.com

Technical Information / Datasheet STO/SS1

NORDAC PRO (SK 500P) TI 80_0030 V 1.0 3219 en

Functional Safety

To prevent danger to people and material it is necessary to be able to safely switch off machines. For

this, the frequency inverter provides the safety functions STO and SS1-t.

Safely torque switch-off: STO (Safe Torque Off)

With the STO function the drive torque is switched off as quickly as possible and the drive runs down

to a standstill. This behaviour corresponds to stop category 0 according to EN 60204-1. An undefined

time elapses before the drive unit does not carry out any further movement and a safe state is

achieved.

Safe Stop 1 with time control SS1-t (Safe Stop 1 time-controlled)

With the function SS1-t the motor is initially braked by the frequency inverter. After shut-down the STO

input must be externally switched to the STO function. This behaviour corresponds to stop category 1

(controlled braking) according to EN 60204-1.

Information

The safety functions STO/SS1-t are NOT certified and qualified, i.e. they have no warranted safety

characteristics and must only be used for test purposes. It is at the discretion of the user to ensure

adequate safety in the installations.

1 Validity of document

The following information applies for NORDAC PRO (SK 500P) series frequency inverters. The basic

and further information about the frequency inverters can be found in the following documents:

• BU 0530, Issue 1217 (Part. No.: 6075301): Functional safety, supplementary instructions for

SK 500E series

• BU 0600, Issue 2319 (Part. No.: 6076001): NORDAC PRO (SK 500P)

NORDAC PRO (SK 500P) – STO/SS1

2 / 7 TI 80_0030 - 3219

2 Hardware description

The safety functions are available as options.

1. on board (SK 510P/SK 540P)

2. as plug-in interface SK CU5-STO (SK 530P and higher)

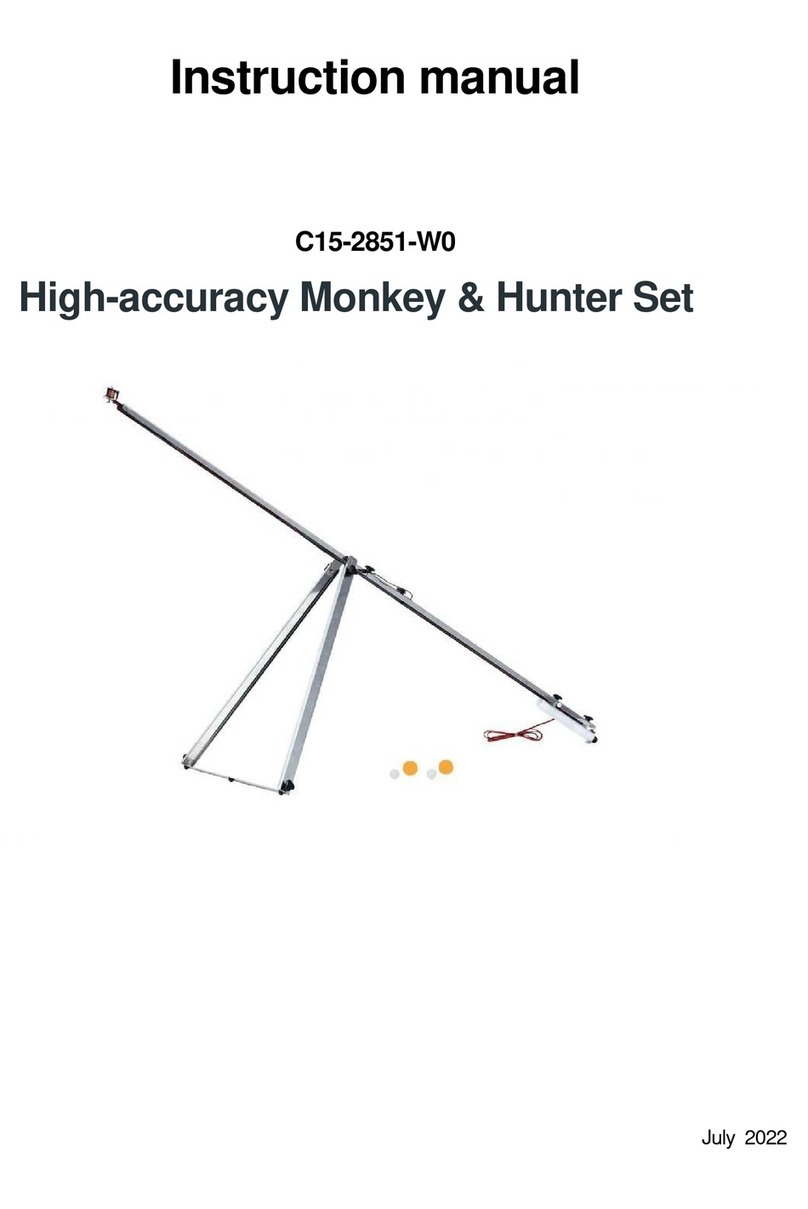

SK 510P SK CU5-STO

Figure 1: Hardware

NORDAC PRO (SK 500P) – STO/SS1

TI 80_0030 - 3219 3 / 7

2.1 Electrical connection

2.1.1 On board (SK 510P/SK 540P)

Connection X19 Designation No. Description

24VOut 43 24 V voltage output

GND 40 Reference potential for 24 V output and SS1-t- input

VISD_24V

94

Digital input for controlled shut-down (SS1-t)

VIS_0V

93

Reference potential for STO input

VIS_24V

91

24 V STO input

The STO function is implemented as a single channel. Therefore the connection and wiring conditions

as described in BU0530 apply.

For the SS1-t function the function "Quick stop" must be triggered via the dedicated SS1-t input. Only

the digital input VISD_24V with terminal number 94 must be used for this. The function is set with

parameter P424.

2.1.2 SK CU5-STO plug-in interface

The STO function is implemented as two channels. For a single channel version the inputs VIS1_24V

and VIS2_24V must be connected in parallel. In this case the connection and wiring conditions as

described in BU0530 apply.

For the SS1-t function the function "Quick stop" must be triggered via the dedicated SS1-t input. Only

the digital input VISD_24V with terminal number 94 must be used for this. The function is set with

parameter P424.

Connection X20 Designation No. Description

top side

VIS2_24V

92

24 V STO input 2 (SI2)

VIS12_0V

93

Reference potential for STO inputs(SI1/2)

VISD_24V

94

Digital input for controlled shut-down (SS1-t)

bottom side

VIS12_0V

93

Reference potential for STO inputs(SI1/2)

VIS1_24V

91

24 V STO input 1 (SI1)

VISD_0V

95

Reference potential for controlled shut-down (SS1-t)

Safe Pulse Block Switch

The switch-off of the 24 V supply via contacts VIS1_24V_SH and VIS2_24V must be carried out by a

fail-safe switching device. As the interface SK CU5-STO is implemented as two channels with 2 x 24 V

IN (terminals 91 and 92) and as there is only one common ground, the Low side (GND) must not be

switched.

NORDAC PRO (SK 500P) – STO/SS1

4 / 7 TI 80_0030 - 3219

2.2 Installation of an SK CU5-STO customer unit

DANGER

Danger of electric shock

The frequency inverter has a hazardous voltage for up to 5 minutes after it has been switched off.

• Only carry out work when the frequency inverter has been disconnected and at least 5 minutes

have elapsed since the mains was switched off!

Installation must be carried out as follows:

1. Switch off the mains voltage, observe the waiting period.

2. Push the control terminal cover down or remove.

3. Remove the blank cover by activating the release mechanism at the lower edge and removing it

with an upward rotating movement.

4. Break out the internal jumper of the STO contact with the aid of a small screwdriver or small

needle-nose pliers. Otherwise the customer unit cannot be installed.

Information

Once the jumper has been removed the frequency inverter cannot be operated with functional safety

without CU5.

5. Hook the customer unit onto the upper edge and press in lightly until it engages. Take care that the

connector strip makes proper contact.

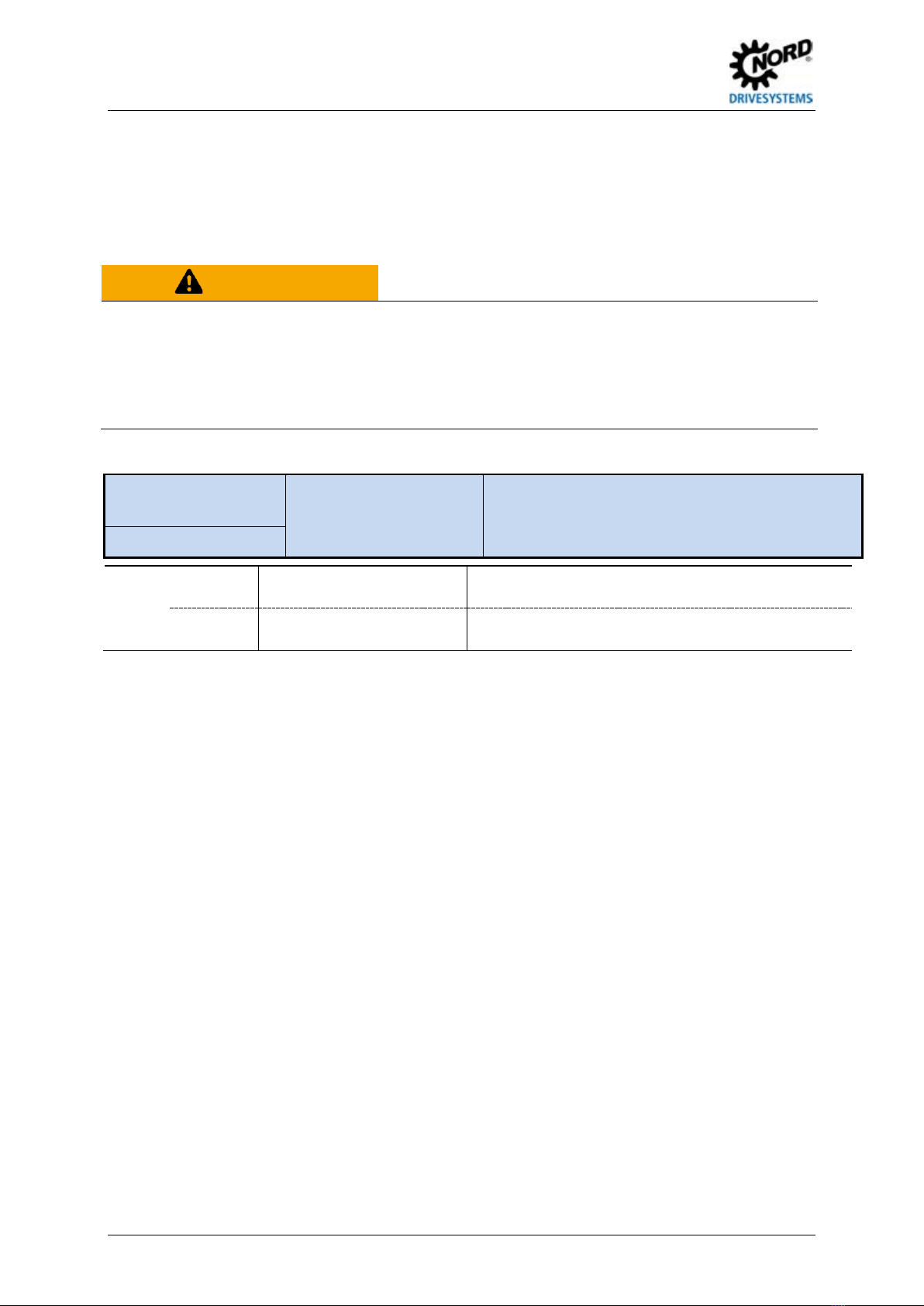

Remove the control

terminals and blank

cover.

Remove the STO

contact jumper.

Install the customer unit

SK CU5-STO.

Install the control

terminals and blank

cover.

NORDAC PRO (SK 500P) – STO/SS1

TI 80_0030 - 3219 5 / 7

3 Commissioning

After installation, the necessary parameter settings must be made. The relevant parameters for

functional safety can be found under P424.

Parameters for functional safety

P424 Function Safety Dig. input

Setting range

0 … 2

Arrays

[-01] =

STO/SS1

[-02] =

SLS (in preparation)

Factory setting

{ all 0 }

Scope of Application

SK 510P

,

SK 540P

SK 530P and higher with SK CU5-MLT or SK CU5-STO

Description

Assignment of a fail-safe stop function for the safe digital input of the frequency

inverter.

Note

Changes to the parameter setting are only adopted after a restart of the frequency

inverter (Power Off 60 s Power On).

In case of a separate 24 V DC supply of the control board, this must also be switched

off.

Setting values

Value Meaning

0 No function

1

Disable voltage

The FI output voltage is switched off; the motor runs down freely.

2

Quick stop

The FI reduces the frequency according to the programmed fast

stop time from P426.

NORDAC PRO (SK 500P) – STO/SS1

6 / 7 TI 80_0030 - 3219

4 Operating status messages

All faults which result in a switch-on block of the frequency inverter and are associated with functional

safety are listed below.

WARNING

Loss of safe function

In case of an EEPROM fault, the digital input functions "Block Voltage" and "Fast Stop" of the SS1-t

input VISD_24V may not function or may function incorrectly.

• After an EEPROM fault, the digital inputs associated with safety functions must be revalidated.

This ensures that the safety functions operate correctly.

Error messages

Display in the

SimpleBox / ControlBox Fault

Text in the ParameterBox

Cause

•Remedy

Group Error

E018

18.0

Safety circuit

(SafetyCirc)

While the frequency inverter was enabled, the Safe Pulse

Block safety circuit has triggered.

18.1

Safety circuit

(Safety SS1)

While the frequency inverter was enabled, the SS1 function

(controlled switch-off) has triggered.

NORDAC PRO (SK 500P) – STO/SS1

TI 80_0030 - 3219 7 / 7

5 Technical Data

Safe Pulse Block

SK 510P SK CU5-STO

Input voltage

+ 24 V

Voltage tolerance

± 25 % (18 V … 30 V)

Operation with OSSD

- 20 % … + 25 % (19,2 V … 30 V)

Current consumption

STO

≤150 mA

VIS1: t.b.d (≤ 20 mA)

VIS2: ≤ 180 mA

(Average value)

SS1

≤10 mA

≤10 mA

Peak current (peak, when

switching on or on the OSSD)

STO

≤750 mA

VIS1: ≤ 75 mA

VIS2: ≤ 750 mA

SS1

≤25 mA

≤25 mA

Cable length

≤100 m

Cable capacitance

≤ 20 nF per connected frequency inverter

(≤ 4 nF * tOSSD / 0.1 ms with tOSSD max. 0.5 ms)

Switch-on delay

≤200 ms

Response time (the value in brackets

corresponds to a typical value)

STO

≤200 ms (t.b.d.)

≤200 ms (t.b.d)

SS1

≤10 ms (t.b.d.)

≤10 ms (t.b.d.)

Cycle time

≥1 s

Requirements for OSSDs

Test pulse width

≤500 µs

Duty (High level)

≥90 %

Time between double pulses

≥1 ms (observe the duty factor)

Safety integrity level

(as per IEC 61508)

STO

SIL 3

SIL 3

SS1

SIL 1

SIL 1

Probability of a hazardous failure

per hour

STO

PFH = t.b.d.

PFH = t.b.d.

SS1

PFH = t.b.d.

PFH = t.b.d.

Proportion of safe failures

STO

SFF = t.b.d. SFF = t.b.d.

SS1

SFF = t.b.d.

SFF = t.b.d.

Safety category

(as per EN ISO 13849-1)

STO

Category 4

Category 4

SS1

Category 1

Category 1

Performance Level

(as per EN ISO 13849-1)

STO

PL e

PL e

SS1

PL c PL c

Mean time until hazardous failure

STO

MTTF

d

= "High" (>100 years)

SS1

MTTF

d

= t.b.d.

Degree of diagnostic coverage

STO

DC = t.b.d.

DC = t.b.d.

SS1

DC = t.b.d.

DC = t.b.d.

Operational life

TM = 20 years

This manual suits for next models

1

Table of contents

Other Nord Drivesystems Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Sigicom

Sigicom INFRA C22 Ex manual

Siemens

Siemens 2000A operating instructions

IFM Electronic

IFM Electronic AS-i AirBox AC2030 installation instructions

Manntek

Manntek CBC operating manual

Digital Control

Digital Control DigiTrack Falcon F1 quick start guide

Biocontrol

Biocontrol topcat Instructions for use

Danfoss

Danfoss BPHE Series instructions

Zaber

Zaber LRT-EC Series user manual

Scheppach

Scheppach HF60 Translation of original instruction manual

Mayr

Mayr ROBA-DS 956 Series Installation and operational instructions

ABB

ABB HT584209 Operation manual

Henkel

Henkel Loctite EQ CL36 LED Cure Chamber operating manual