9

Maintenance

Required tools for maintenance

▪ a vise to fasten the regulator

▪ pincers to take out the O-rings

▪ a pair of tongs for a retaining ring 8 mm

▪ a torque wrench

▪ a torque wrench hexagon head key 6 (BD10)

▪ a torque wrench hexagon head key 8

▪ a torque wrench “open end insert tool”, 17 mm (BD(H)15)

▪ a torque wrench “open end insert tool”, 32 mm (BD(H)10)

▪ a torque wrench “open end insert tool”, 38 mm (-DP only)

▪ a torque wrench “open end insert tool”, 44 mm (BD(H)15)

▪ an open end wrench, 6 mm (BD10)

▪ an open end wrench, 15 mm (-DP only)

▪ media and temperature compatible lubricant for reassembling threaded parts

▪ media and temperature compatible lubricant for O-rings

▪ Snoop® liquid leak detector

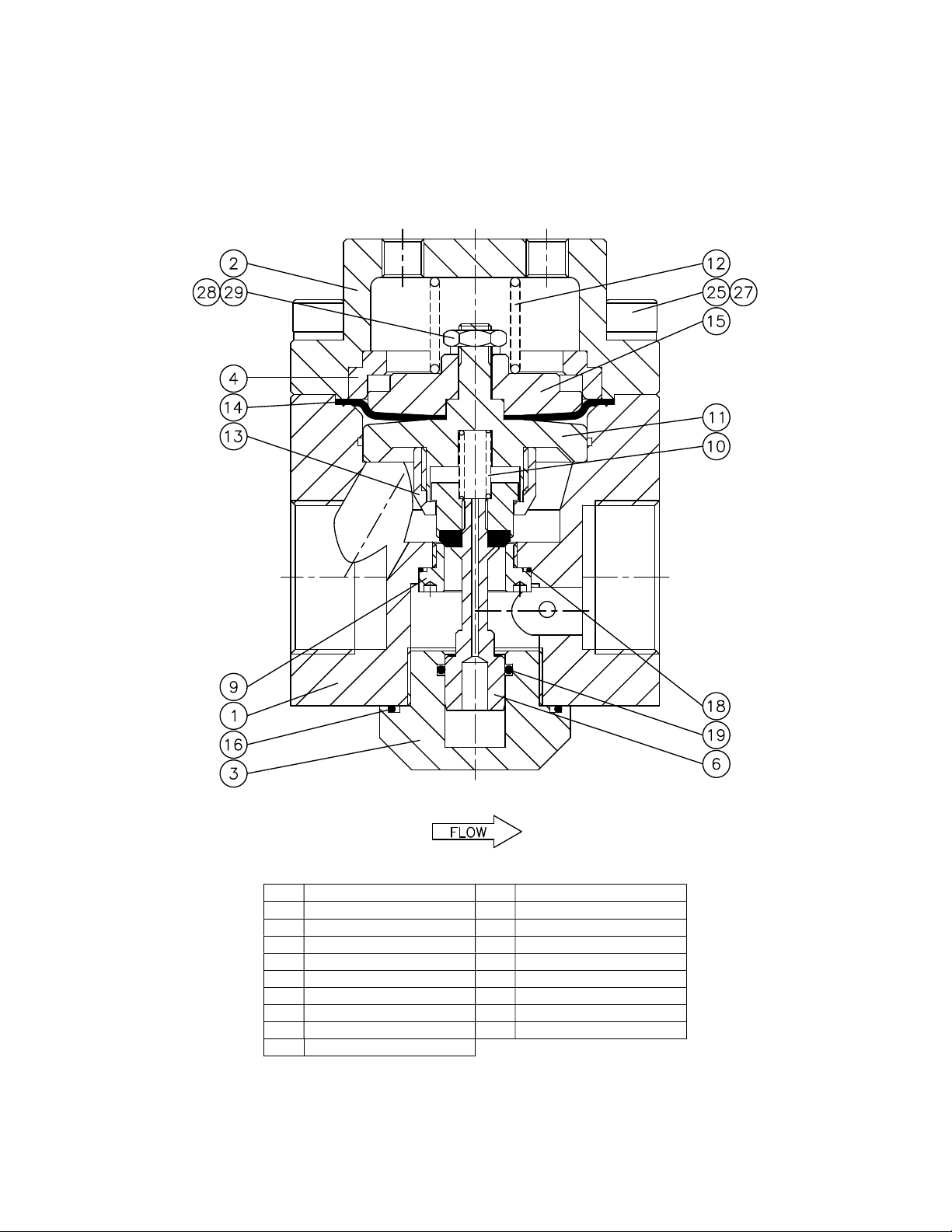

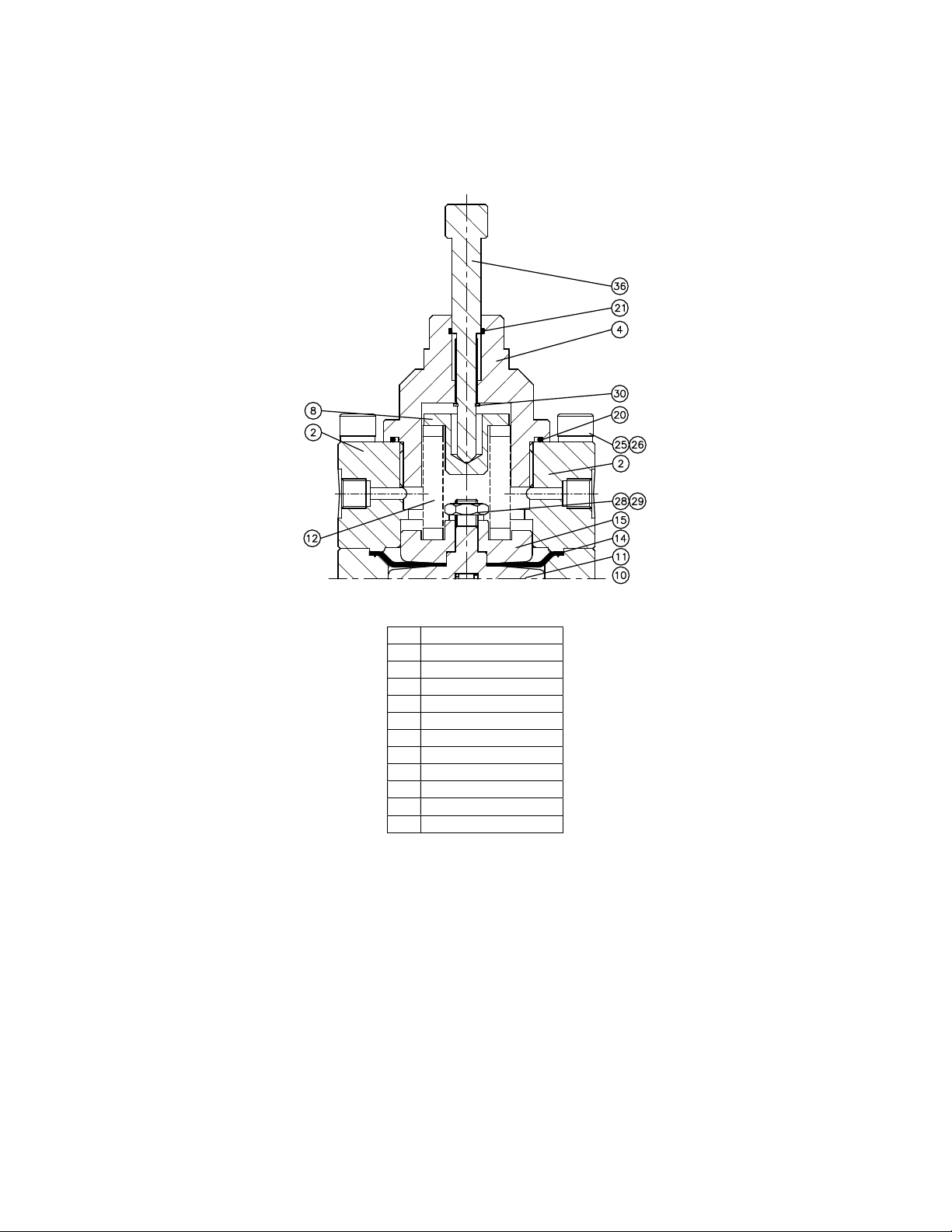

Disassembly

▪ Loosen the hexagon socket head screws and remove the dome, dome plate, diaphragm, body

plate, and valve assembly.

▪ Loosen the retaining screw to remove the valve assembly.

▪ Loosen the bolt or nut from the diaphragm- and dome plate to remove the diaphragm.

▪ Loosen the bodyplug and remove the body plug and seat.

Inspection of disassembled parts

▪ Check all parts for abnormal wear. Replace parts in case of doubt.

Points of attention before assembly

▪ All parts must be clean and undamaged before starting assembly.

▪ Swagelok recommends replacing all O-rings and the diaphragm before assembly.

▪ All threaded parts must be lubricated a little before assembly, this to avoid galling of threads.

▪ All O-rings need to be lubricated a little to improve the lifetime of the O-ring and the performance

of the regulator.