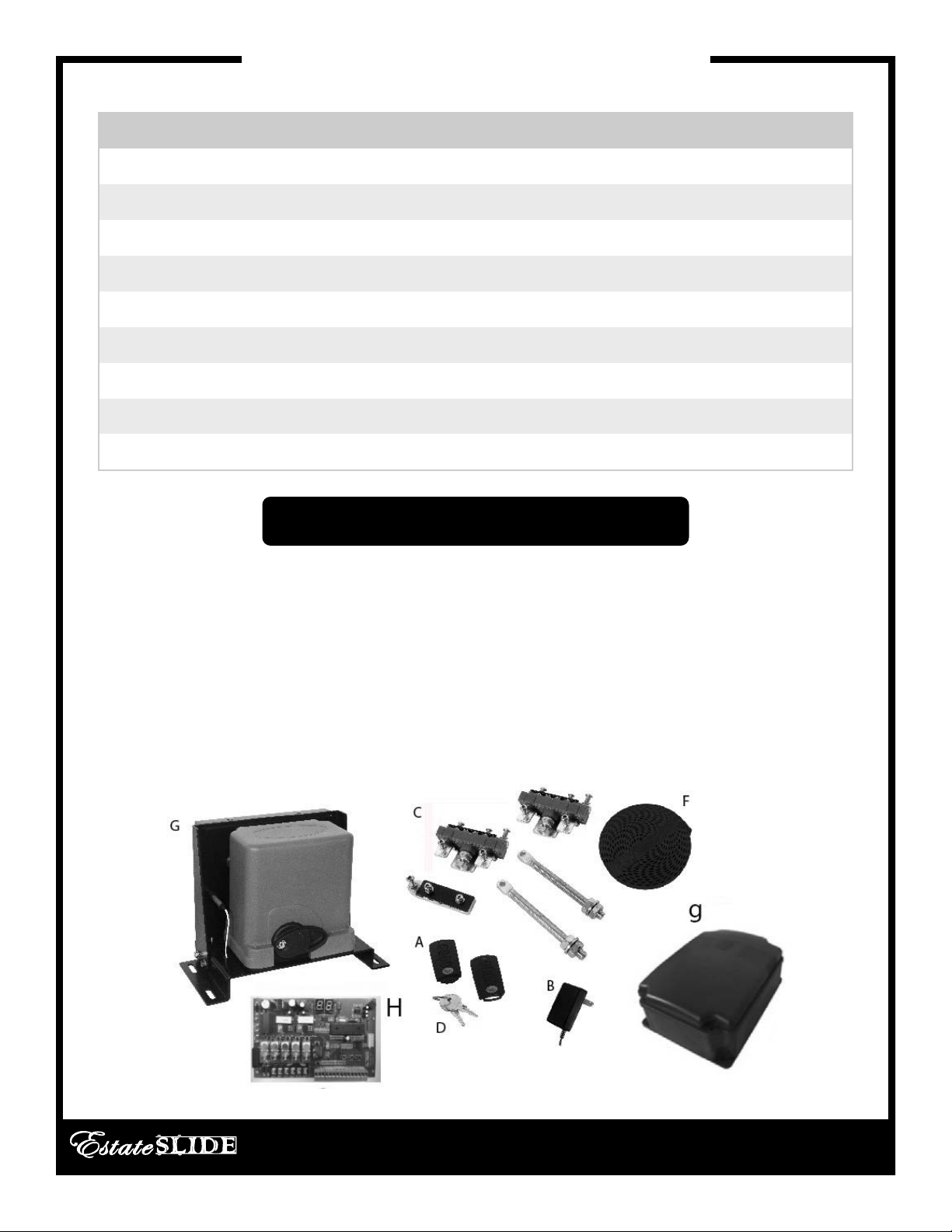

E-SL 450BD Series Instrucon Manual

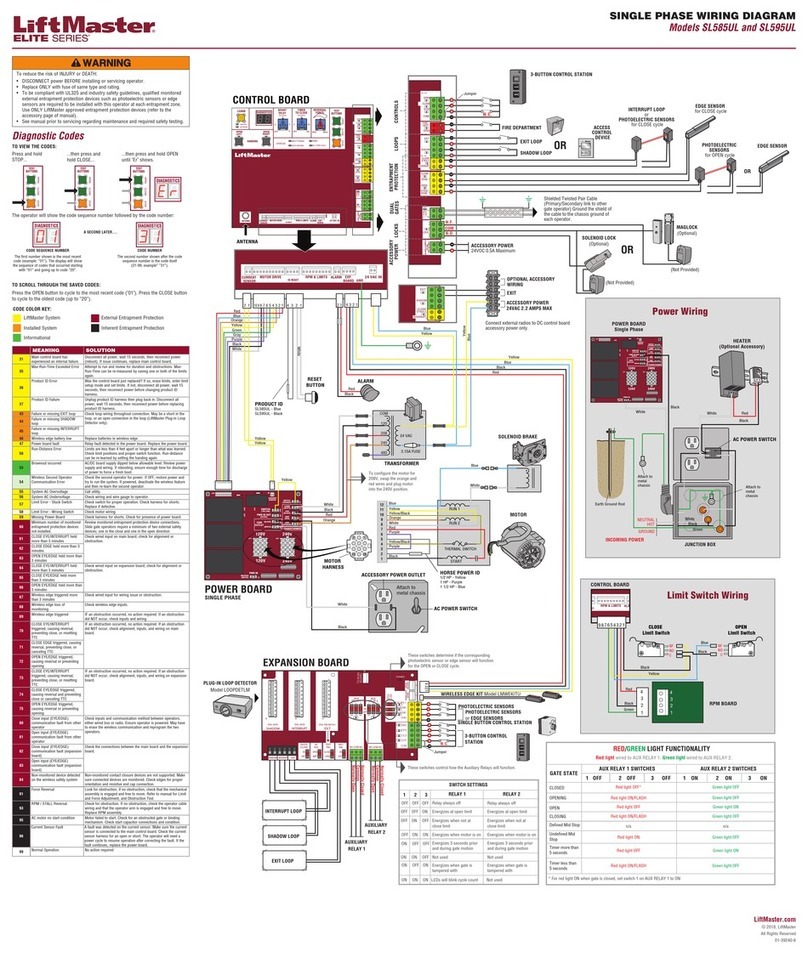

Control Board Overview

16

CAUTION! Do not run 110V AC power direct to the board. This will cause permanent

damage to both boards and void your warranty. Caution!

Gate Opener reactions to signals:

PUSH2 (PUSH 2 terminal and PUSH 2 button):

Details:

• Will activate gate with momentary contact (momentary contact between PUSH2and V+).

• Controls both leaves in 2 leaf mode (Dip switch 2 in the ON position)

• Only opens the gate, never closes it.

• Pause time is able to be re-set if this terminal is closed through a momentary contact. Then the

time will be reset, count down the pause time, and re-close.

• Ideal for exit wand or exit loop.

Operational Sequence for terminal with auto-close ON (Dip switch 1 in on position):

1. In closed position - momentary contact will open gates.

2. When opening - momentary contact will have no effect.

3. When stopped mid cycle from PUSH 1 or the Receiver - momentary contact will open the gate.

4. When open with auto-reclose on - momentary contact will re-set pause time and will start counting

again after release of momentary contact.

5. When pause time countdown is stopped in open from a momentary contact of PUSH 1 or the

Receiv-er - momentary contact will have no effect.

6. When closing - momentary contact will re-open the gate.

Operational Sequence for terminal with auto-close OFF (Dip switch 1 in off position):

1. In closed position - momentary contact will open gates.

2. When opening - momentary contact will have no effect.

3. When stopped mid cycle - momentary contact will open the gate.

4. When open with auto-reclose off - momentary contact will have no effect.

5. When closing - momentary contact will re-open the gate.

PUSH 1 and PUSH 2 – these terminals can hold as many normally open connections as needed, they

will be wired in parallel. They are used for keypads, push buttons, universal receivers, etc.