General safety instructions and checklist

This electric gate operator complies with European Directives: 89/336/EEC and 73/23/EEC and subsequent

amendments.

When installed correctly this electrically operated motor complies with all relevant safety standards.

Please ensure the operating manual is fully read and understood before installation and operation.

Installation should only be carried out by a competent and qualified person.

Always ensure that all people especially children, animals and objects are well away from the gate opening area

during the gates operation.

Keep remote control transmitters out of reach of children, to prevent unintentional operation.

Do not intentionally obstruct the gate/s in any way during operation.

Do not modify or attempt to modify any part of the gate motor or control system.

This gate motor should always be installed with safety in mind as prescribed by the standard EN12978. Safety

Photocells, safety edge or induction loops should be used correctly wherever possible.

In case of malfunction or power failure, this device is supplied with a manual release which is operated by a

manual key to release the motor.

Always ensure that the power supply is off before attempting installation or to alter any settings.

Only allow gate operation when in full view of the complete gate system.

Basic maintenance should be carried out regularly, such as to ensure safe working of the gate. Safety devices

should be checked on a monthly basis. The gate motor should be kept clean at all times.

The mechanical parts of the gate motor conform to standards EN12604 and EN12605.

It is the responsibility of the installer to ensure the safe working of the automated gate. The installation must

conform to standards EN12453 and EN12445. Test pressure settings and Safety Photocells conform to EN

12445.

The end user should be fully instructed in the safe working of the gate, and should be given all safety and

installation manuals.

All packaging material and unused equipment should be disposed of in the correct, environmentally friendly way.

Never install devices where a user can reach over or through an automated gate system. All external electrical

components (Photocells, keypads, flashing lights etc), must be connected in accordance to EN 60204-1 and

amendments made to point 5.2.2 of EN 12453.

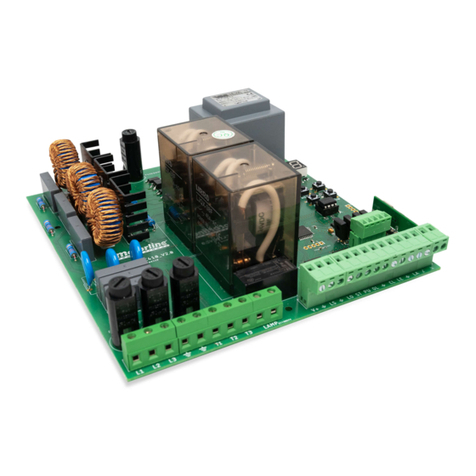

The power supply, control panel and motor should be earthed properly. The mains power supply should be fit for

purpose and fitted with omnipolar switch with a contact opening distance of 3mm or more. A 6A thermal circuit

breaker is also recommended.

The motor is CE marked by Stateurop, the manufacturer. The automated gate system must be certified by the

installer as being compliant with the European Machinery Directive, and be given an appropriate CE certificate to

state that the gate and automation comply with current regulations for safety.

Gateway Control Ltd declines all responsibility for any consequences resulting from improper use or installation,

or failing to observe good technical practice.