ALPHA

International registered trademark n. 2.777.971

3

67410247

Details

General

An appliance shall be provided with an instruction manual. The instruction manual shall give instructions for the installation,

operation, and user maintenance of the appliance.

The installation instructions shall specify the need for a grounding-type receptacle for connection to the supply and shall stress the

importance of proper grounding.

The installation instructions shall inform the installer that permanent wiring is to be employed as required by local codes, and

instructions for conversion to permanent wiring shall be supplied.

Information shall be supplied with a gate operator for:

a) The required installation and adjustment of all devices and systems to effect the primary and secondary protection against

entrapment (where included with the operator).

b) The intended connections for all devices and systems to effect the primary and secondary protection against entrapment. The

information shall be supplied in the instruction manual, wiring diagrams, separate instructions, or the equivalent.

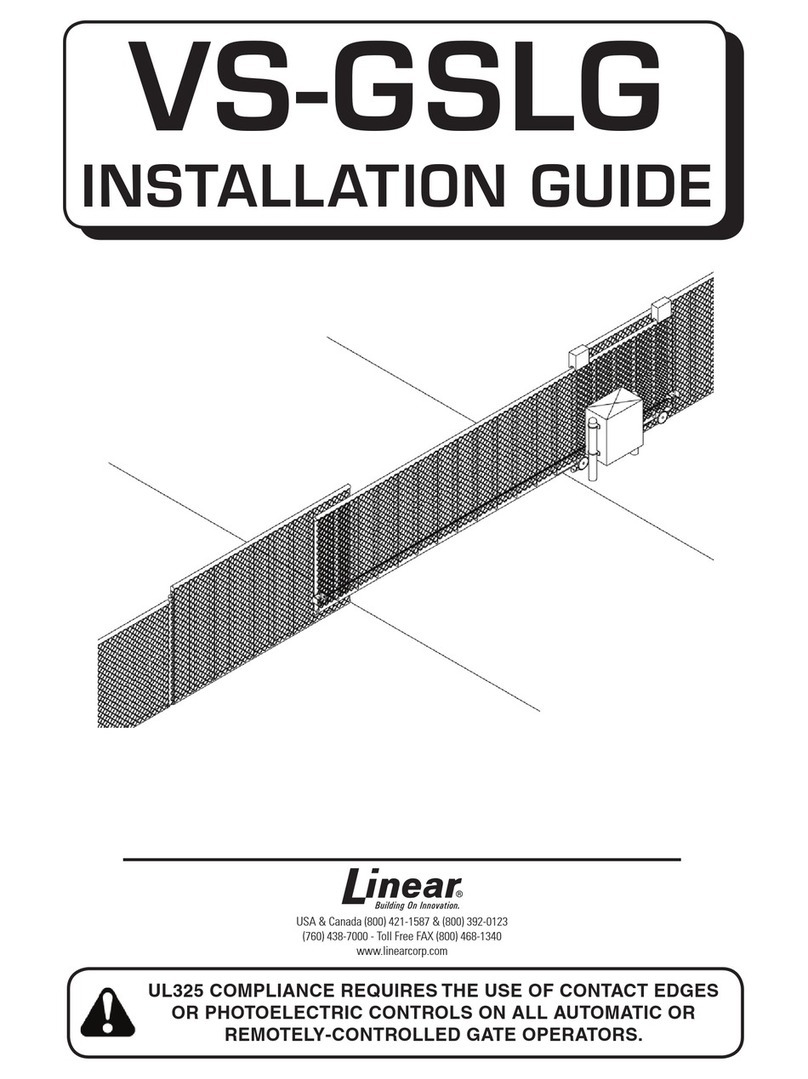

Vehicular gate operators (or systems)

A vehicular gate operator shall be provided with the information in the instruction manual that defines the different vehicular gate

operator Class categories and give examples of each usage. The manual shall also indicate the use for which the particular unit is

intended as defined in Glossary, Section 3. The installation instructions for vehicular gate operators shall include information on

the Types of gate for which the gate operator is intended.

A gate operator shall be provided with the specific instructions describing all user adjustments required for proper operation of the

gate. Detailed instructions shall be provided regarding user adjustment of any clutch or pressure relief adjustments provided. The

instructions shall also indicate the need for periodic checking and adjustment by a qualified technician of the control mechanism

for force, speed, and sensitivity.

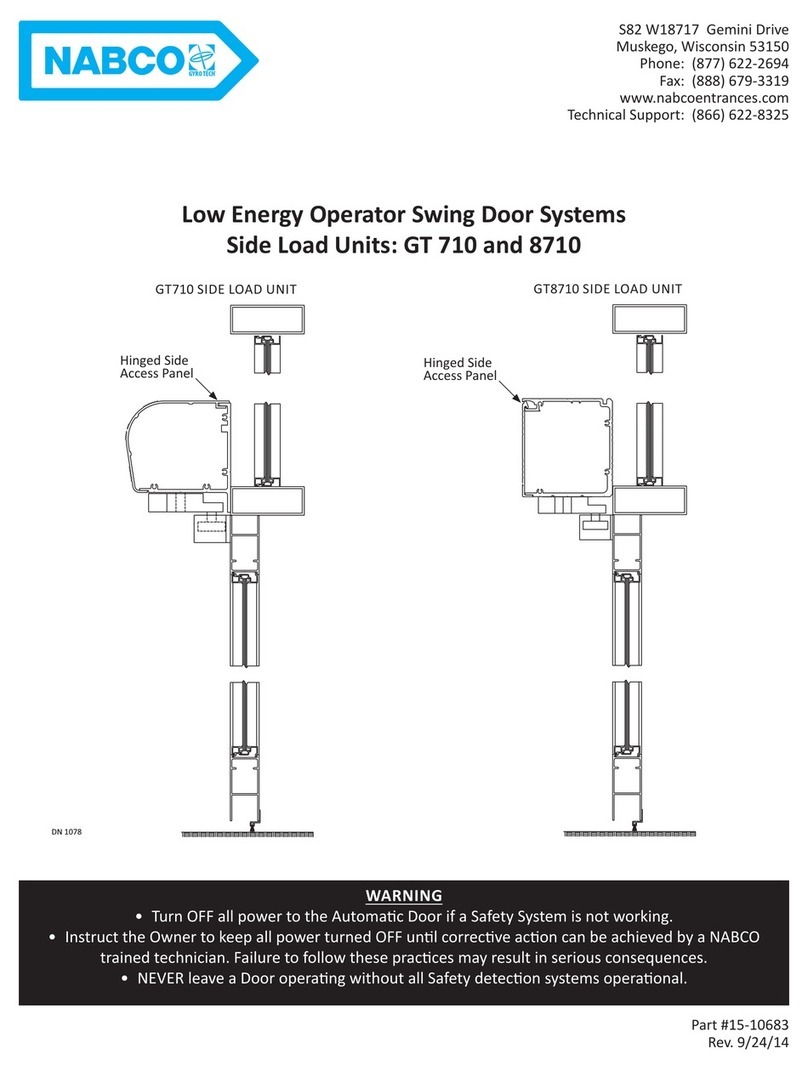

Instructions for the installation, adjustment, and wiring of external controls and devices serving as required protection against

entrapment shall be provided with the operator when such controls are shipped with the operator.

Instructions regarding intended installation of the gate operator shall be supplied as part of the installation instructions or as a

separate document. The following instructions or the equivalent shall be supplied where applicable:

a) Install the gate operator only when:

1) The operator is appropriate for the construction of the gate and the usage Class of the gate,

2) All openings of a horizontal slide gate are guarded or screened from the bottom of the gate to a minimum of 4 feet (1.22

m) above the ground to prevent a 2-1/4 inch (57.2 mm) diameter sphere from passing through the openings anywhere in

the gate, and in that portion of the adjacent fence that the gate covers in the open position,

3)All exposed pinch points are eliminated or guarded, and

4) Guarding is supplied for exposed rollers.

b) The operator is intended for installation only on gates used for vehicles. Pedestrians must be supplied with a separate access

opening. The pedestrian access opening shall be designed to promote pedestrian usage. Locate the gate such that persons will

not come in contact with the vehicular gate during the entire path of travel of the vehicular gate.

c) The gate must be installed in a location so that enough clearance is supplied between the gate and adjacent structures when

opening and closing to reduce the risk of entrapment. Swinging gates shall not open into public access areas.

d) The gate must be properly installed and work freely in both directions prior to the installation of the gate operator. Do not over-

tighten the operator clutch or pressure relief valve to compensate for a damaged gate.

e) (not applicable)

f) Controls intended for user activation must be located at least six feet (6’) away from any moving part of the gate and where the

user is prevented from reaching over, under, around or through the gate to operate the controls. Outdoor or easily accessible

controls shall have a security feature to prevent unauthorized use.

REV 03 - 05/2011