As for misunderstandings that may arise refer to your area distributor or

call our help desk. These instructions are part of the device and must be

kept in a well known place.The installer shall follow the provided

intructions thoroughly. products must only be used to

automise doors, gates and lwings. Any initiative taken without

explicit authorization will preserve the manufacturer from

whatsoever responsibility. The installer shall provide warning notices on

not assessable further risks. in its relentless aim to

improve the products, is allowed to make whatsoever adjustment

without giving notice. This doesn’t oblige to up-grade the

past production. can not be deemed responsible for any

damage or accident caused by product breaking, being damages or

accidents due to a failure to comply with the instructions herein. The

guarantee will be void and the manufacturer responsibility will be

nullified if original spare parts are not being used.

Packaging materials such as plastic bags, foam polystyrene, nails etc

must be kept out of children’s reach as dangers may arise.

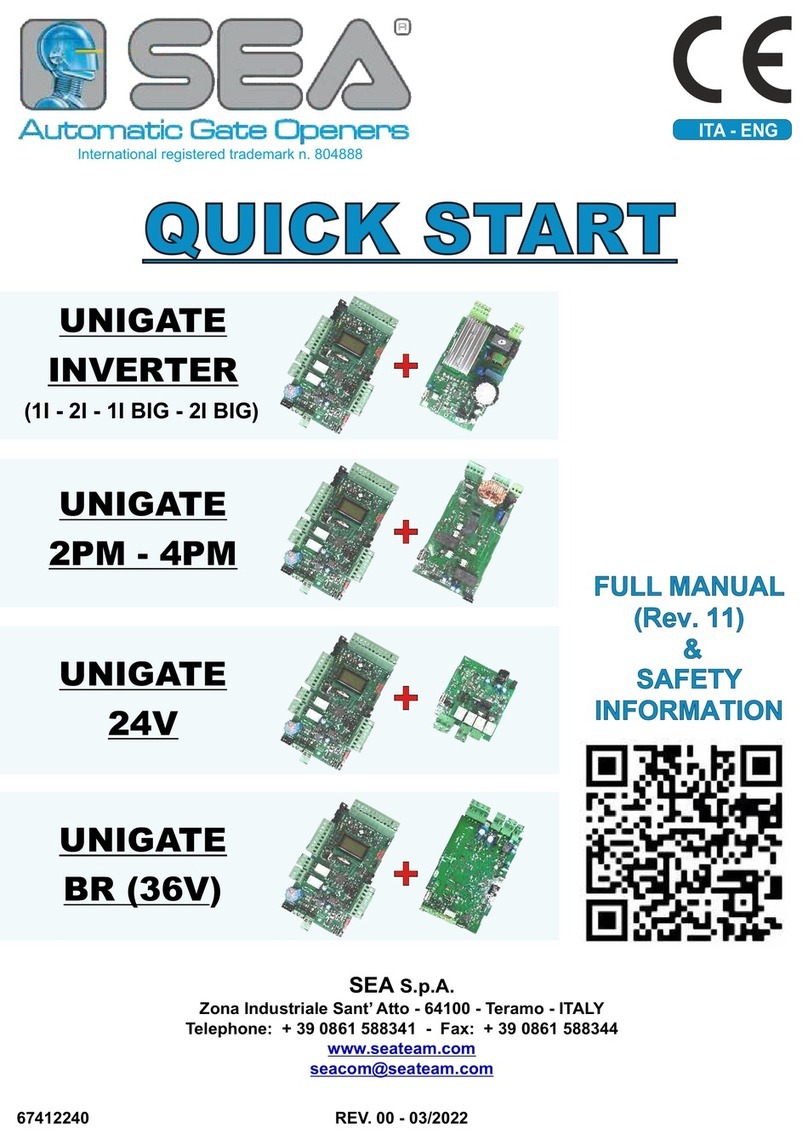

SEA USA Inc.

SEA USA

Inc.

SEA USA Inc.

SEA USA Inc.

SEA USA Inc.

SEA USA Inc. The

electrical installation shall be carried out by a professional technician

who will release documentation as requested by the laws in force.

IMPORTANT SAFETY INSTRUCTIONS

WARNING - To reduce risk of severe injury or deat:

READ AND FOLLOW ALL INSTRUCTIONS

Never let children operate or play with door controls. Keep the remote

control away from children.

Always keep the moving system in sight and away from people and

objects until it is completely closed or stopped. NO ONE SHOULD

CROSS THE PATH OF THE MOVING SYSTEM.

Test the system opener monthly. The system MUST reverse on

contact with a 1 - 1/2 inch high object (or a 2 by 4 board laid flat) on the

floor. After adjusting either the force or the limit of the travel, retest the

door opener. Failure to adjust the opener properly increases the risk of

severe injury or death. For products having an emergency release use it

only when the door is closed. Use caution when using this release with

the door open. Weak or broken springs are capable of increasing the

rate of door closure and increasing the risk of severe injury or death.

KEEP THE SYSTEM PROPERLY BALANCED AND MAINTAINED.

An improper balancing or maintaining increases the risk of severe injury

or death. Have a qualified service person make repairs to cables, spring

assemblies and other hardware.

Vehicular gate operator systems offer convenience to their users and

limit vehicular traffic onto your property. Gate operator systems can

and do produce high levels of force. It is important that you are aware of

the possible hazards associated with your gate operator system.

Hazards may include, but are not limited to pinch points, entrapment,

absence of reversing devices, absence of pedestrian access, traffic

backup, etc.

Your installer should instruct you on the proper operation of your gate

operator system. You and your installer shouid review the basic

functions of the reversing devices on your gate operator system and

how to periodically test them. Reversing devices include one or more of

the following: reversing loops, photo-eyes, reversing edges, etc. Your

installer needs to instruct you on how to remove the gate operator

system from service, shut power off at service panel and how to use the

gate operator system manually.

Do not allow children or pets to play in the area of the gate and gate

operator system. Do not allow children to play with any access

control device.

Operate gate only when fully visible, properly adjusted and free of

obstructions. The owner/operator and/or installer should determine,

prior to use, whether the equipment and optional devices, or

combination thereof are suitable and sale for the use intended. Since

individual installations may be subject to many variations and are

usually augmented by devices not always obtained from or through

SEA USA Inc. and since SEA USA Inc. has no control over the end use

of the products it distributes, SEAUSA Inc. makes no representations or

warranties as to the suitability of safety of this equipment for a specific

application.

Warranty void if unit was installed and/or wired improperly, used wrong

power source, used wrong hydraulic fluid, or if damage was caused by

fire, flood, lightning or any other acts of God.

This manual is your property. Please keep for future reference.

Opening

Electronic Systems

SEA USA Inc.

2806 N.W. 79th AVENUE - MIAMI, FL 33122

Tel. +1.305.594.1151 - +1.305.594.7325

Toll free: +1.800.689.4716

web site: www.sea-usa.com

e-mail: sales@sea-usa.com

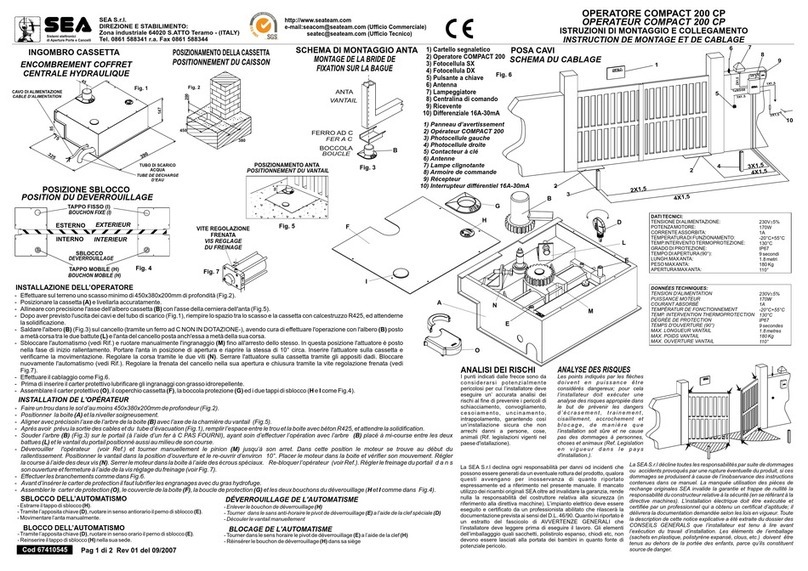

CABLE LAYOUT

2x5

1,

2x1,5

3x1,5

1x1,5

215

x,

13 x , 5

1,5

2x

3x1,5

6x1,5

8x1,5

1xRG58

1

2

3

4

10

5

6

78

9

1) TAURUS operator

2) Rx photocell

3) Tx photocell

4) Pneumatic safety edge

5) Key switch

6) Flashing warning lamp

7) Radio receiver

8) Antenna

9) Warning notice

10) RCD Circuit breaker 16A- 30mA

RISK EXAMINATION

The points pointed by arrows are potentially dangerous. The

installer must take a thorough risk examination to prevent

crushing, conveying, cutting, grappling, trapping so as to

guarantee a safe installation for people, things and animals.

(

)

Re. Laws in force in the country where installation has been

made.

REV 00 - 10/2003

Opening

Electronic Systems

TAURUS

FITTING AND CONNECTION INSTRUCTIONS