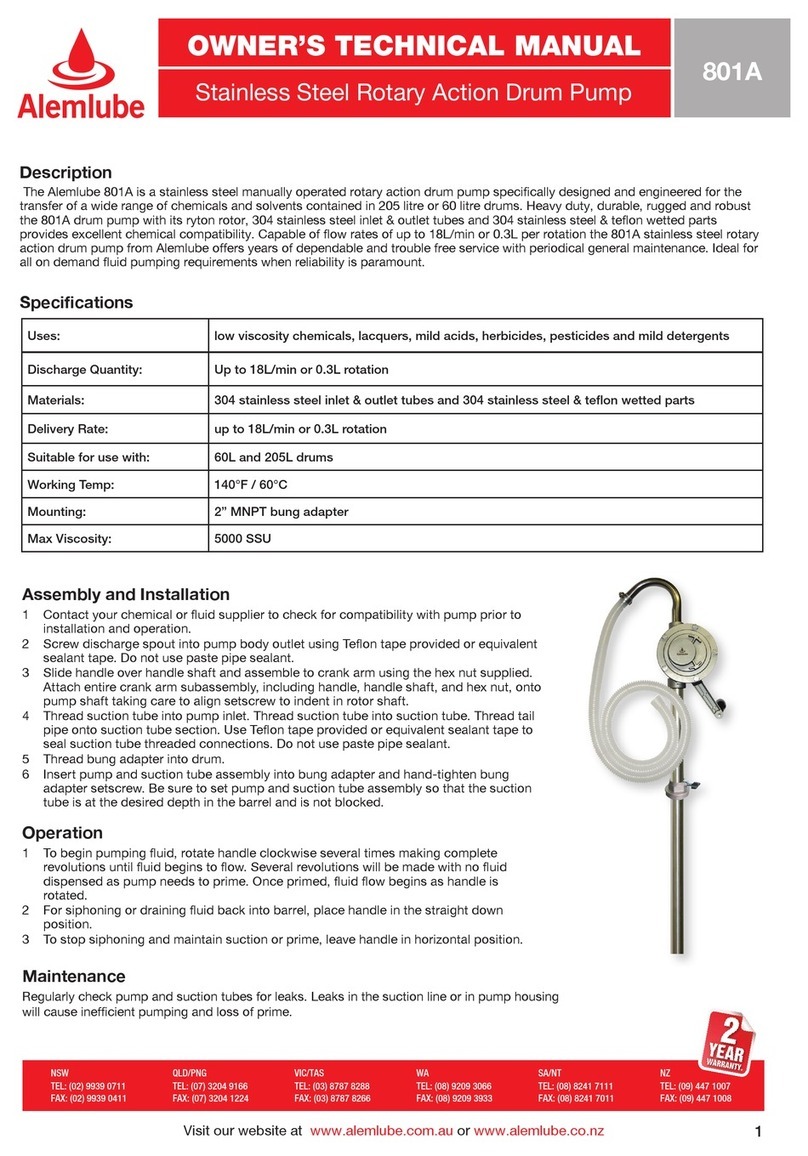

17

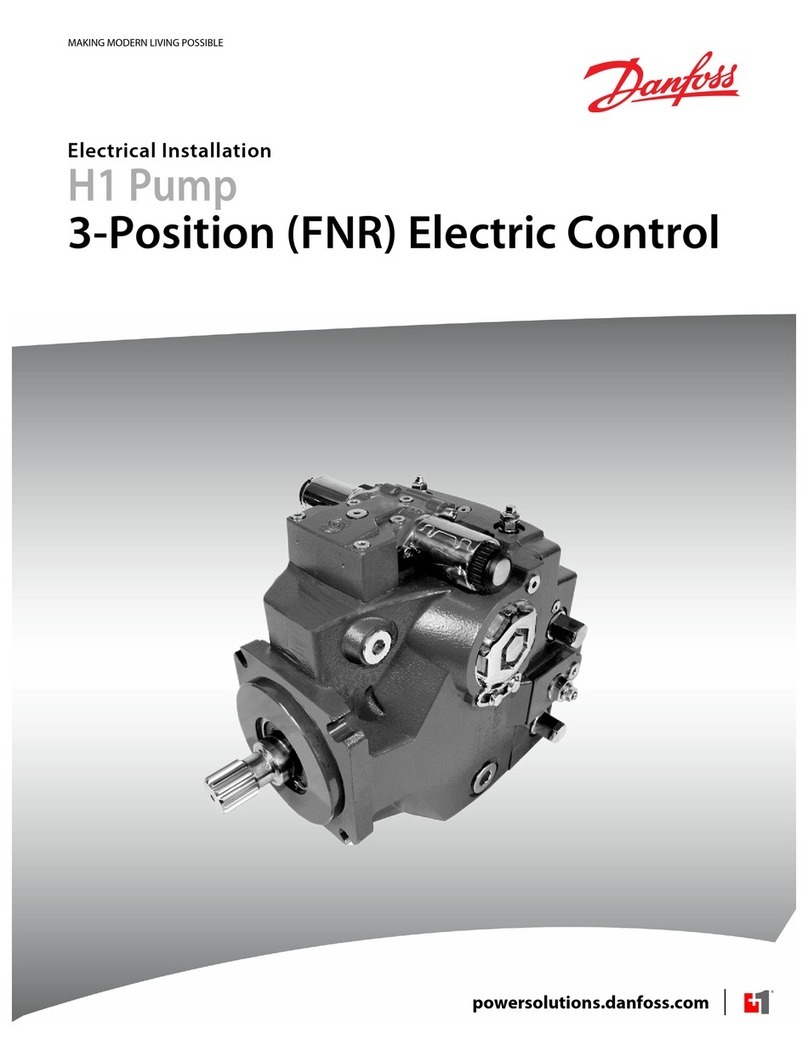

20“PTFE” GASKET PACK REPLACEMENT AND ADJUSTMENT

20.1 GASKET PACK REPLACEMENT (head with execution 21)

After the maintenance procedure is complete, proceed as follows:

9Disconnect the pumping head 1from the system

and lantern of the dosing pump.

9Clean the pumping head to ensure the operator can

safely handle the component.

9Loosen the ring nut 11 and remove it.

9Check if piston 2 is worn out. If it is scored or cut,

replacement is recommended. In this case, loosen

the dowels 15.

9Remove the damaged gasket pack 3and place the

new pack into the pumping head paying attention to

the gasket direction.

9Tighten the clamping ring nut 11 till it touches the

gaskets. Do not overtighten.

9Place the pumping head 1on the piston 2, push it

against the lantern, then fix it with screws 4.

20.2 “PTFE” GASKET PACK ADJUSTMENT AND COMPRESSION

▲ATTENTION!

To ensure this type of gaskets is water-tight, it needs adjusting before it can used inside

the head. To carry out the procedure, follow the steps described below.

9Connect the dosing pump to separate pipes that suck

water,and tighten the ring nut one-fourth of a turn to

apply light pressure on the gaskets.

9The upper part of the head will drip.

9Let the pump run for 4/5 hours before tightening the

ring nut again.

9After this time has elapsed, tighten another fourthof a

turn.

9Let the pump run 2 to 3 hours before tightening the

ring nut again; verify if it drips less.

9This tightening and checking procedure must be

carried out till the dripping stops.

9After making sure that the gaskets are fully tight,

connect the dosing pump to the system.

▲ATTENTION!

The gasket pack must be checked and adjusted

regularly. While carrying out the adjustment operations, make sure not to tighten the ring

nut too strongly to avoid damaging the gaskets.

21HEAD WITH SEAL GASKET CLEANING

This type of head is mainly used with products that may SEDIMENT or CRYSTALLISE, which

requires internal parts to be cleaned to avoid sedimentation and cause abrasion to the piston and

gasket pack.

21.1 SEAL GASKET CLEANING

Continuously washing the gaskets helps remove deposits, and prevents the product from hardening

and causing damage to the sealing profile.

Let water flow through the seal gasket area, at a rate of 40/50 l/h, and pressure of 0.5/1 bar.

13 11

4

2 15

PUMPING HEAD

ASSEMBLY DRAWING