CONTENT

I. Attention.......................................................................................1

II. BriefIntroduction........................................................................3

III. Specification ..............................................................................5

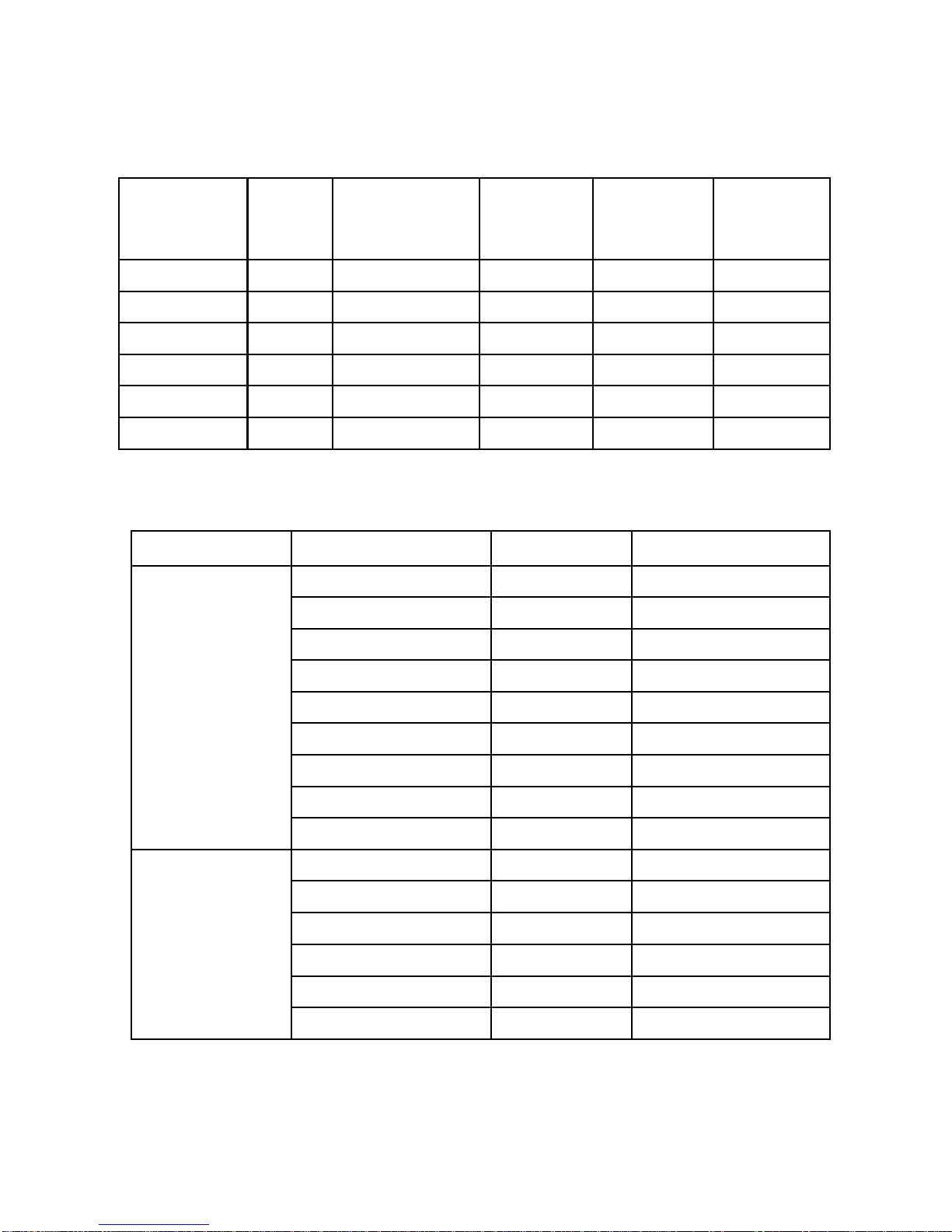

1ModelofSeries..................................................................5

2. RangesandAccuracyofMeasurement..............................5

3. Specifications......................................................................6

IV. StructureofMeter......................................................................7

V. LiquidCrystalDisplay.................................................................8

1. LCD Screen.........................................................................8

2. Description ofSpecialSymbols...........................................9

3. ExamplesIllustrated..........................................................10

VI. OperatingMethod....................................................................11

1.Bootup................................................................................11

2Shutdown.........................................................................12

3ResistanceMeasurement................................................13

*4 Current Measurement....................................................14

5DateLock/Release/Storage.............................................15

6DataAccess.....................................................................16

7AlarmSettings.................................................................16

8Access toAlarmCriticalValue.........................................17

9ClearData........................................................................17

VII. Measurement Principle..........................................................18

1. PrincipleofResistanceMeasurement..............................18

2. PrincipleofCurrent Measurement....................................18

VIII. Measurement MethodofEarthResistance..........................19