ete 90025 User manual

CERTI-CRIMP*

Hand Tool Ratchet

Tool Number

Marking

Crimp

Type

Insulation Crimp

Adjustment Pins

Back of Tool

(Wire Side)

Wire Size

Marking

Terminal

Type

Tool Color

Code

©2011 Tyco Electronics Corporation, a TE Connectivity Ltd. Company

All Rights Reserved

*Trademark

TE Connectivity, TE connectivity (logo), and TE (logo) are trademarks. Other logos, product and/or Company names may be trademarks of their respective owners.

1of 5

Instruction Sheet

TOOLING ASSISTANCE CENTER

1-800-722-1111

PRODUCT INFORMATION

1-800-522-6752

This controlled document is subject to change.

For latest revision and Regional Customer Service,

visit our website at www.te.com LOC B

408-1809

Hand Crimping Tools 90025 and 90026 28 SEP 11 Rev B

PROPER USE GUIDELINES

Cumulative Trauma Disorders can result from the prolonged use of manually powered hand tools. Hand tools are intended for occasional use

and low volume applications. A wide selection of powered application equipment for extended-use, production operations is available.

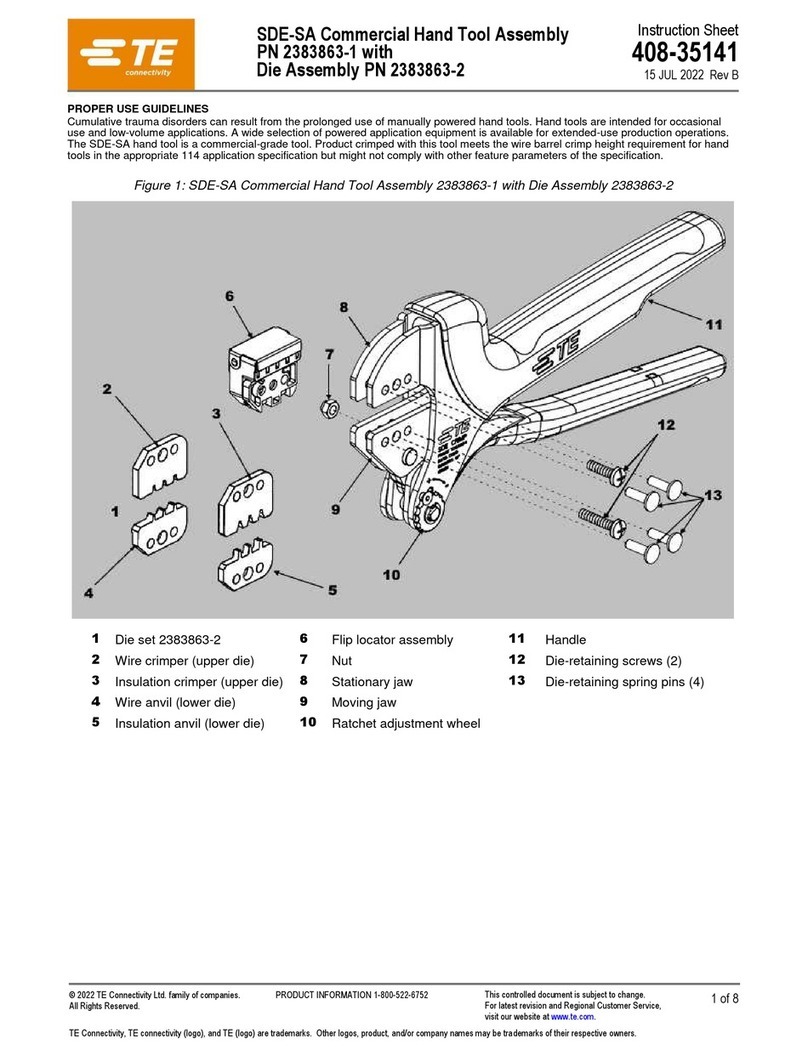

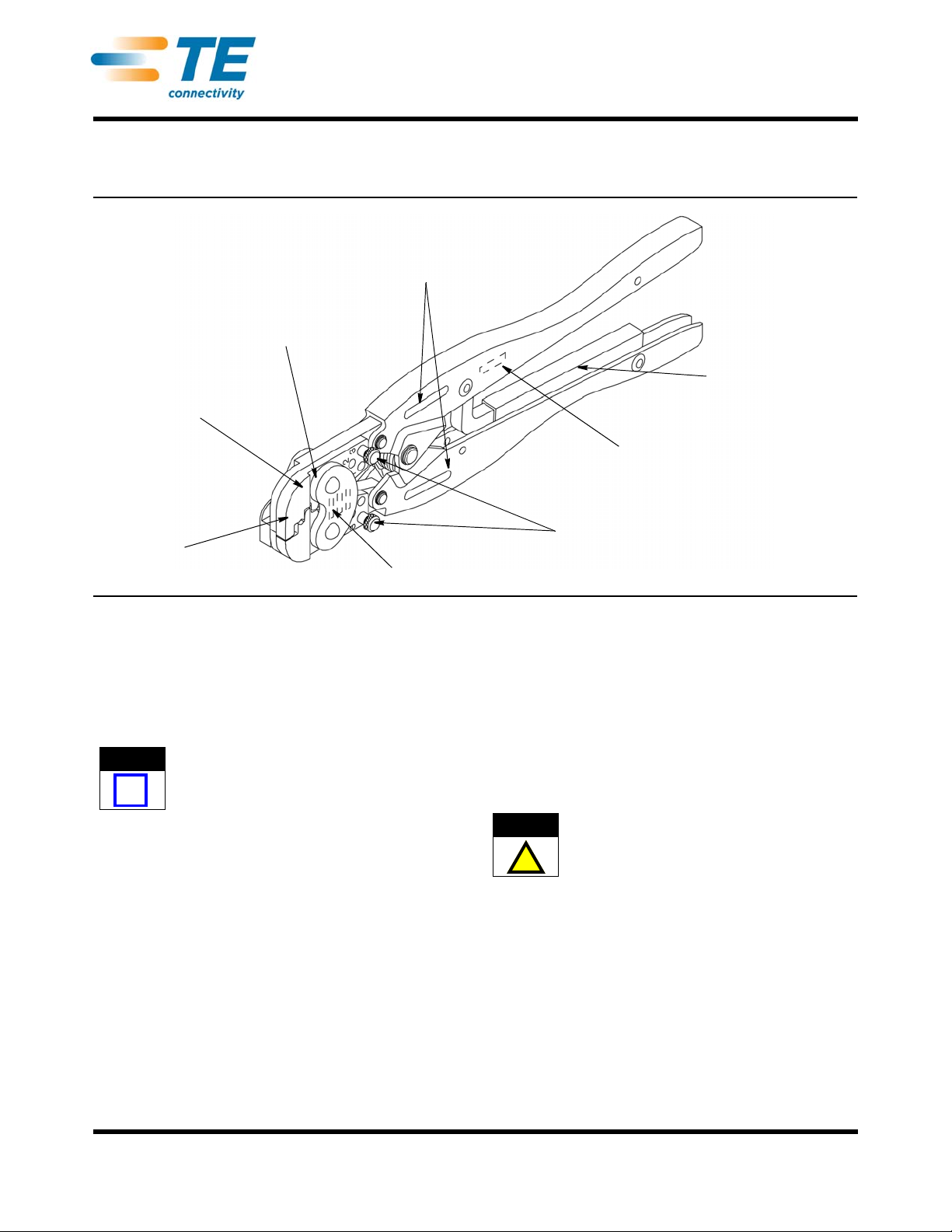

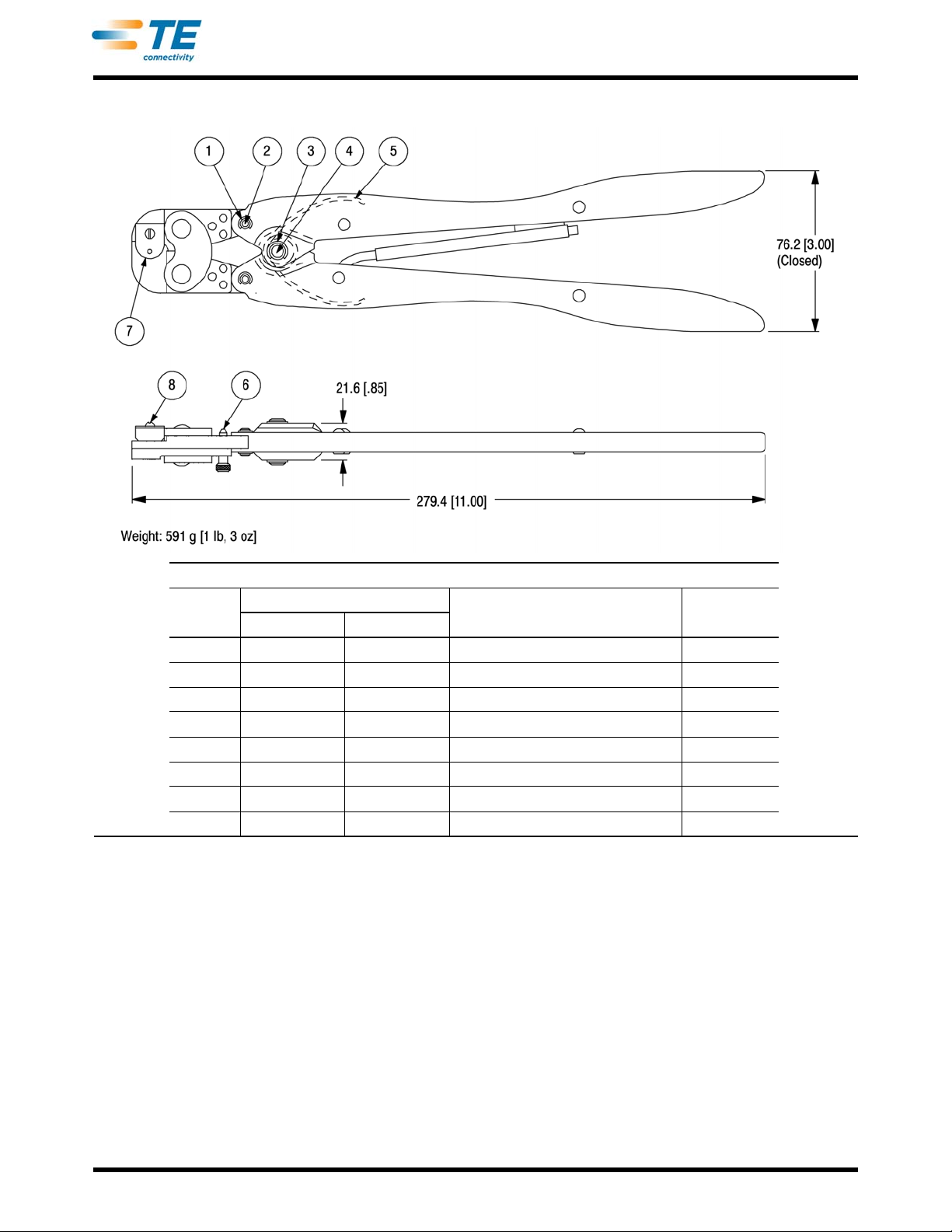

Figure 1

1. INTRODUCTION

Hand Crimping Tools 90025 and 90026 (see Figure 1)

are designed to crimp the PIDG* Taper Pin Terminals

listed in Figure 2. Read these instructions thoroughly

before using the tools.

NOTE

i

Dimensions on this sheet are in millimeters [with

inches in brackets].

Reasons for reissue are provided in Section 7,

REVISION SUMMARY.

2. DESCRIPTION

Refer to Figure 1 and Figure 3.

The FRONT of the tool has the "AMP" marking on the

link. The BACK of the tool (wire side), into which the

wire is inserted, has the tool number marked on the

handle and the crimp type, wire size, and type of

terminal the tool can crimp ("PIDG") marked on the

link.

Each tool features two crimping jaws, a locator, two

insulation crimp adjustment pins, color-coded tool

handles, and a CERTI-CRIMP tool ratchet.

Each terminal features a color-coded sleeve which

matches the color coded tool handle marking of the

applicable crimping tool. The locator aids in

positioning the terminal between the crimping jaws.

The insulation crimp adjustment pins are used to

regulate the crimp height of the terminal insulation

barrel. The ratchet assures full crimping of the

terminal. Once engaged, the ratchet will not release

until the tool handles have been FULLY closed.

CAUTION

!

The crimping jaws bottom before the ratchet

releases. This is a design feature that assures

maximum electrical and tensile performance of the

crimp. Do NOT re-adjust the ratchet.

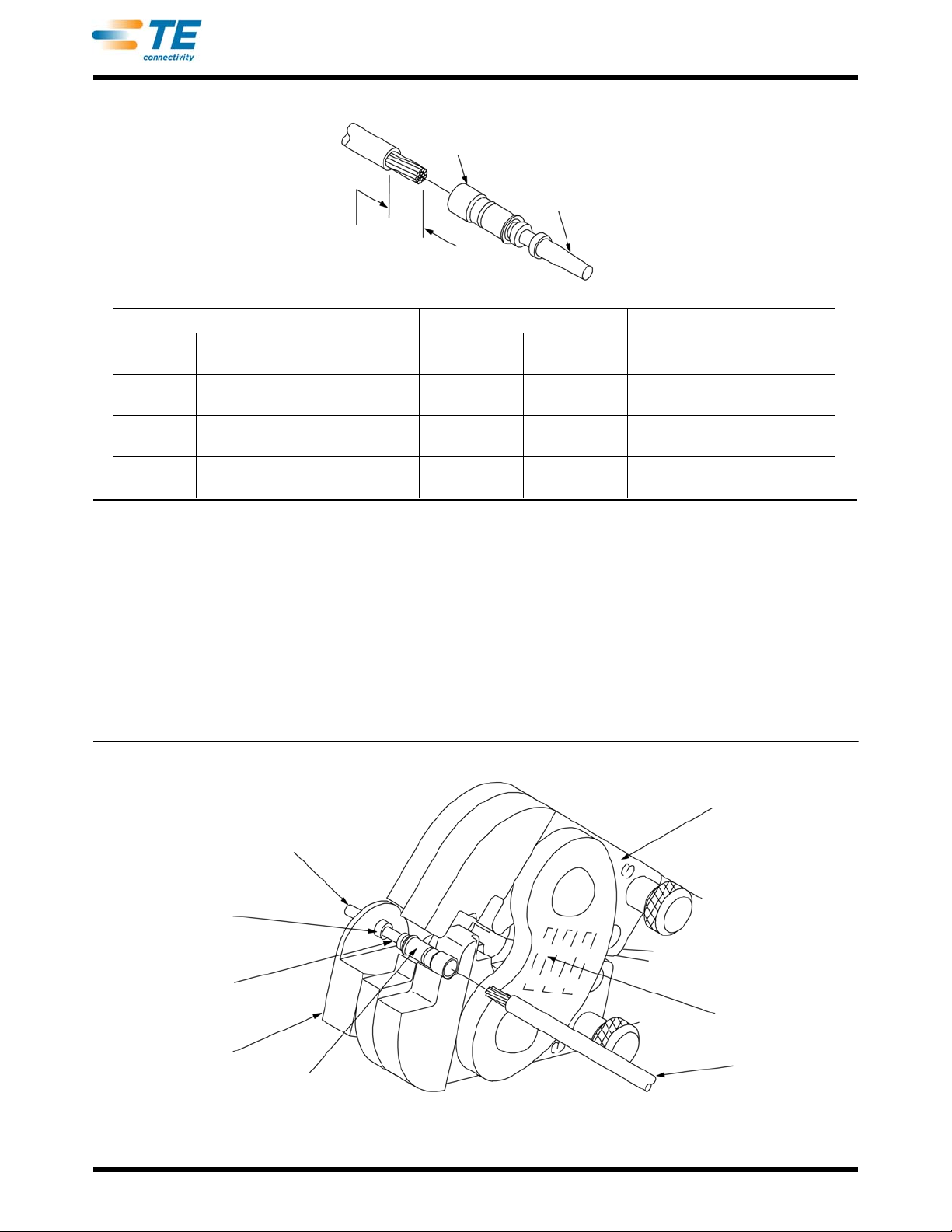

3. CRIMPING PROCEDURE

Refer to the table in Figure 2 and check the selected

wire, terminal, and crimping tool for compatibility.

Wire size and insulation diameter must be within the

specified range for the terminal. Strip the wire to the

length indicated - do NOT cut or nick the wire strands.

The hand tool must be the one designed for crimping

the wire and terminal.

WIRE TERMINAL HAND TOOL

SIZE

(AWG) INSULATION

DIAMETER STRIP

LENGTH PART

NO. COLOR PART

NO. HANDLE

COLOR

24 to 22 1.02 to 2.03 [.040

to .080] 5.54 [.218] 66071 Yellow 90026 2 Yellow

20 to 18 1.52 to 2.54 [.060

to .100] 6.73 [.265] 66072 White 90025 1 White and

1 Black

16 2.03 to 2.92 [.080

to .115] 6.73 [.265] 66073 Black 90025 1 White and

1 Black

Taper Pin

Color-Coded Sleeve

Wire Strip Length

408-1809

2of 5

Rev B

Figure 2

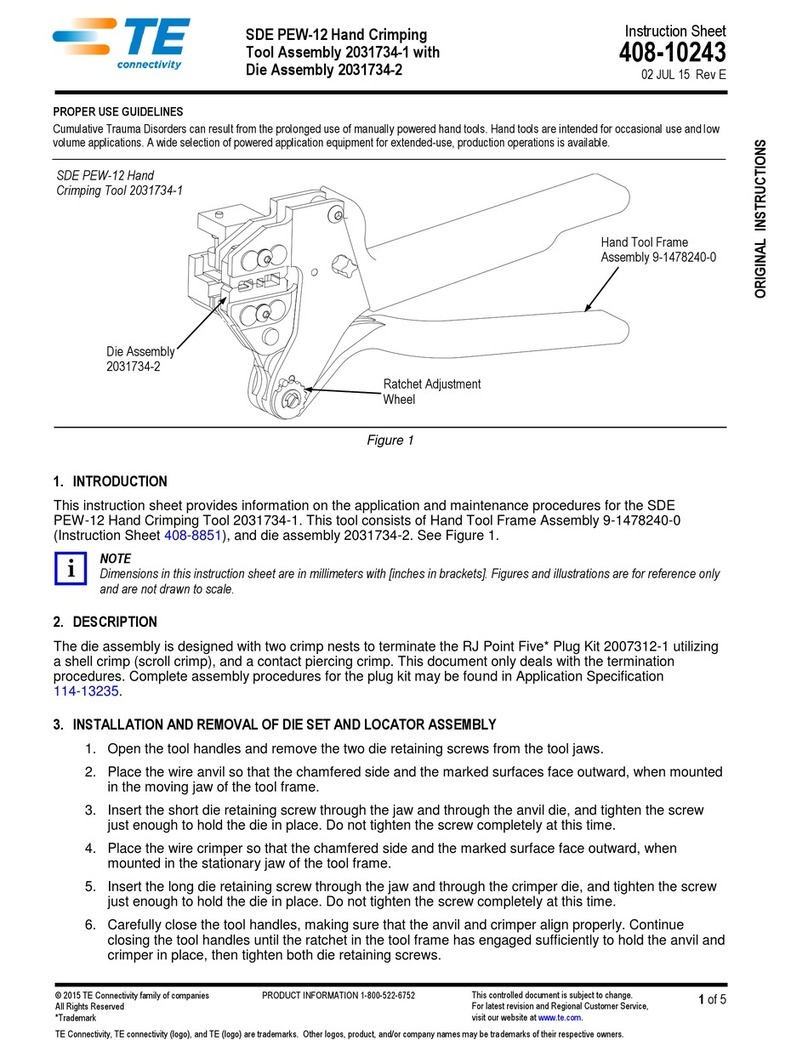

Refer to Figure 3 and proceed as follows:

1. Hold tool so BACK (wire side) faces you.

2. Make sure ratchet is released - squeeze tool

handles together and allow them to open FULLY.

3. Slide terminal tip through hole in locator until

terminal shoulder butts against locator.

4. Hold terminal in this position and squeeze tool

handles together just enough so crimping jaws hold

terminal in place. Do NOT deform insulation barrel

or wire barrel.

5. Insert a properly stripped wire into terminal wire

barrel until it bottoms.

6. Holding wire in place, squeeze tool handles

together until ratchet releases.

7. Allow tool handles to open FULLY and remove

crimped terminal from tool.

Stripped Wire

Wire Size

Back of Tool

(Wire Side)

Terminal Tip

Terminal

Shoulder

Terminal

Locator

Wire Barrel

Figure 3

408-1809

3of 5

Rev B

4. INSULATION CRIMP ADJUSTMENT

The insulation barrel crimp height is regulated by

placing the insulation crimp adjustment pins in one of

three positions: (1) small, (2) medium, or (3) large.

Determine the proper insulation crimp setting as

follows:

1. Place adjustment pins in No. 3 position. Insert

terminal into tool according to Section 3, CRIMPING

PROCEDURE, Steps 1 through 4.

2. Insert an UNSTRIPPED wire into terminal

insulation barrel. Crimp terminal and remove from

tool.

3. Check insulation crimp by bending wire back and

forth one time. If wire pulls out, place adjustment

pins in next smaller position and repeat these

procedures. Crimp should hold wire insulation firmly

without cutting into it.

5. MAINTENANCE AND INSPECTION PROCEDURE

The company recommends that a maintenance and

inspection program be performed periodically to

ensure dependable and uniform terminations.

Frequency of inspection depends on:

•The care, amount of use, and handling of the hand

tool.

•Abnormal amounts of dust and dirt.

•The degree of operator skill.

•Your own established standards.

The hand tool is inspected before being shipped;

however, TE recommends that the tool be inspected

immediately upon arrival to ensure that the tool has

not been damaged during shipment. Due to the

precision design, it is important that no parts of these

tools be interchanged except those replacement parts

listed in Figure 5.

5.1. Daily Maintenance

1. The hand tools should be immersed (handles

partially closed) in a reliable commercial degreasing

compound to remove accumulated dirt, grease, and

foreign matter. When degreasing compound is not

available, tool may be wiped clean with a soft, lint-

free cloth. Do NOT use hard or abrasive objects that

could damage the tool.

2. Make certain that the retaining pins are in place

and that they are secured with retaining rings.

3. All pins, pivot points, and bearing surfaces should

be protected with a THIN coat of any good SAE† 20

motor oil. Do not oil excessively.

° SAE is the Society of Automotive Enginners.

4. When the tool is not in use, keep handles closed

to prevent objects from becoming lodged in the

crimping jaws. Store the tool in a clean, dry area.

5.2. Periodic Inspection

A. Lubrication

Lubricate all pins, pivot points, and bearing surfaces

with SAE 20 motor oil as follows:

— Tools used in daily production - lubricate daily

—Tools used daily (occasional) - lubricate weekly

— Tools used weekly - lubricate monthly

Wipe excess oil from tool, particularly from crimping

area. Oil transferred from the crimping area onto

certain terminations may affect the electrical

characteristics of an application.

B. Visual Inspection

1. Close tool handles until ratchet releases and then

allow them to open freely. If they do not open

quickly and fully, the spring is defective and must be

replaced. See Section 6, REPLACEMENT AND

REPAIR.

2. Inspect head assembly for worn, cracked, or

broken jaws. If damage is evident, return the tool to

AMP for evaluation and repair. See Section 6,

REPLACEMENT AND REPAIR.

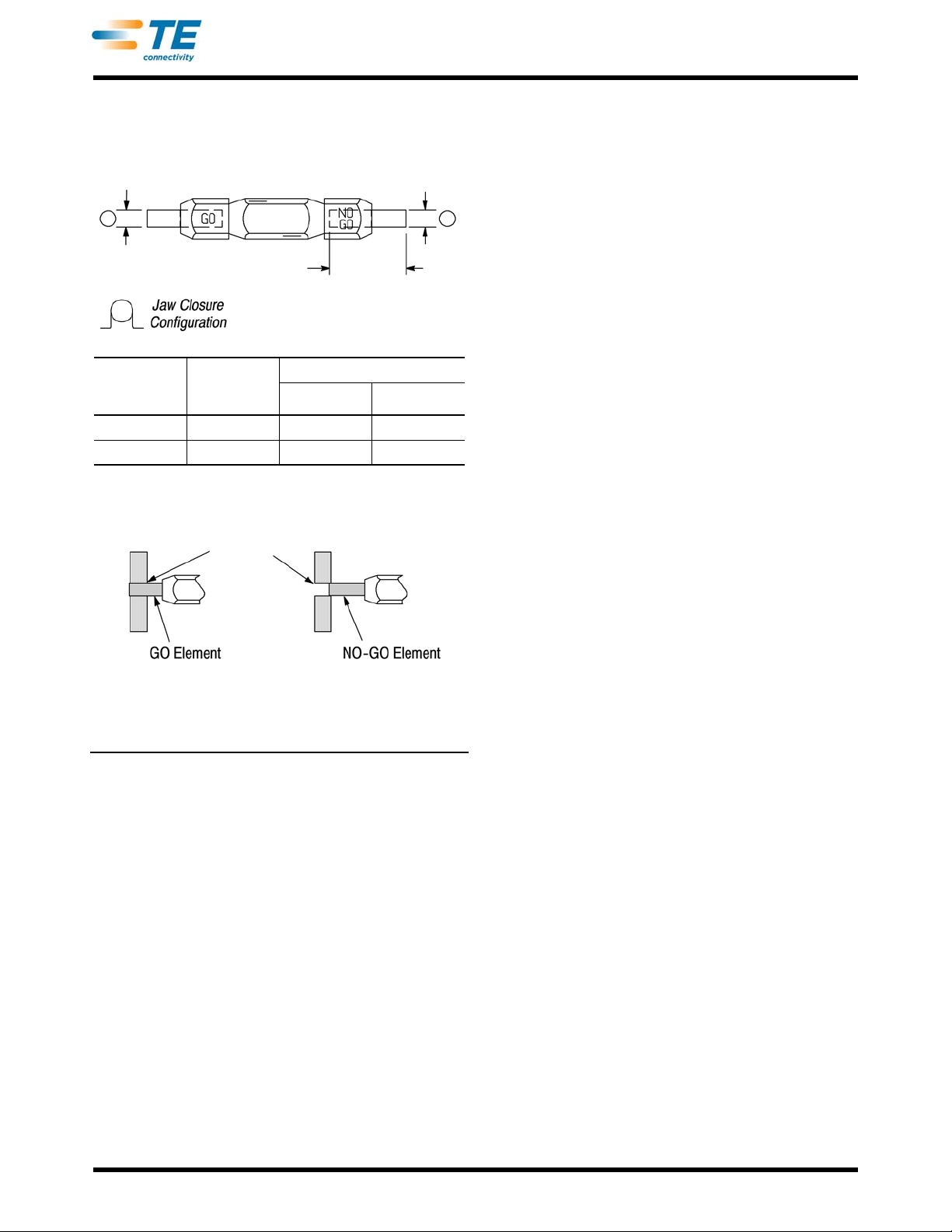

C. Gaging The Crimping Chamber

This inspection requires the use of a plug gage

conforming to the dimensions provided in Figure 4. TE

does not manufacture or market these gages. To gage

the crimping chamber, proceed as follows:

1. Remove traces of oil or dirt from the crimping

chambers and plug gage.

2. Close tool handles until jaws are bottomed, and

hold in this position. Do not force beyond initial

contact.

3. Carefully insert GO element into the crimping

chamber; do not force it. The GO element must

pass completely through the crimping chamber. See

Figure 4.

4. In the same manner, try to insert NO-GO element

into the same crimping chamber. The NO-GO

element may begin entry, but may not pass through

the crimping chamber. See Figure 4.

If crimping chambers conform to gage inspection, the

tool is considered dimensionally correct, and should

be lubricated with a THIN coat of any good SAE 20

motor oil. If not, refer to Section 6, REPLACEMENT

AND REPAIR for customer repair service.

Suggested Plug Gage Design

GO

Diameter NO-GO

Diameter

19.05 [.750]

Min Typ

TOOL

NO. CRIMPING

CHAMBER

MARKING

GAGE ELEMENT DIAMETER

GO NO-GO

90025 20-16 2.16 [.085] 2.31 [.091]

90026 24-22 1.600 [.063] 1.75 [.069]

Inspection of the Crimping Chamber

Crimping

Chamber

GO element must

pass completely

through the crimping

chamber.

NO-GOelementmayenter

partially,butmustnotpass

completely through the

crimping chamber.

408-1809

4of 5

Rev B

Figure 4

D. Ratchet Inspection

Obtain a 0.025 [.001] shim that is suitable for checking

the clearance between the bottoming surfaces of the

crimping jaws and proceed as follows.

1. Select a terminal and a wire (maximum size) for

the tool you are using (see Figure 2).

2. Position the terminal and wire between the

crimping jaws, according to Section 3, CRIMPING

PROCEDURE (Steps 1 through 5). Holding the wire

in place, squeeze the tool handles together until the

CERTI-CRIMP ratchet releases. Hold the tool

handles in this position, maintaining just enough

pressure to keep the jaws closed.

3. Check the clearance between the bottoming

surfaces of the crimping jaws. If the clearance is

0.025 [.001] or less, the ratchet is satisfactory. If

clearance exceeds 0.025 [.001], the ratchet is out of

adjustment and must be repaired (see Section 6,

REPLACEMENT AND REPAIR).

If the tool conforms to these inspection procedures,

lubricate it with a THIN coat of any good SAE† 20

motor oil and return it to service.

6. REPLACEMENT AND REPAIR

Customer-replaceable parts are listed in Figure 5.

Parts other than those listed in Figure 5 should be

replaced by TE to ensure quality and reliability of the

tool. Order replacement parts through your TE

representative, or call 1-800-526-5142, or send a

facsimile of your purchase order to 1-717-986-7605, or

write to:

† Society of Automotive Engineers

CUSTOMER SERVICE (038-035)

TYCO ELECTRONICS CORPORATION

PO BOX 3608

HARRISBURG PA 17105-3608

For customer repair service, call 1-800-526-5136.

7. REVISION SUMMARY

Revisions to this instruction sheet include:

•Changed company name and logo

REPLACEMENT PARTS

ITEM PART NUMBERS DESCRIPTION QTY PER

TOOL

90025 90026

1 21045-3 21045-3 Ring, Retaining 4

2 1-23619-6 1-23619-6 Pin, Retaining, .187 Dia x .521 L 2

3 21045-6 21045-6 Ring, Retaining 2

4 2-23620-9 2-23620-9 Pin, Retaining, .250 Dia x .838 L 1

5 39364 39364 Spring, Handle 1

6 39207 39207 Pin, Insulation Adjustment 2

7 125083-1 125083-2 Locator 1

8 3-21016-7 3-21016-7 Screw 1

408-1809

5of 5

Rev B

Figure 5

This manual suits for next models

1

Table of contents

Other ete Tools manuals

Popular Tools manuals by other brands

DS Produkte

DS Produkte OS220 instruction manual

Jefferson

Jefferson JEFUNIPCPGR user manual

Hitachi

Hitachi G23SR - 9" Angle Grinder parts list

Milwaukee

Milwaukee M12 FPTR Operator's manual

Pattfield

Pattfield PMF-300G manual

FEDERAL PACIFIC

FEDERAL PACIFIC PSE Supplement to Inspection and Maintenance Recommendations