Chopstick Master™

User Manual

For your optimal enjoyment, please read this manual

completely before beginning.

Congratulations on your purchase of the Chopstick Master™!

The Chopstick Master™ is easy to use and allows young and

old alike to make professional-grade, reusable chopsticks

without woodworking experience or ability. A set of chopsticks

typically takes less than ten minutes to produce and making

your own chopsticks is a rewarding and fun experience that is

sure to bring a smile to your face!

I.How the Chopstick Master™ Works

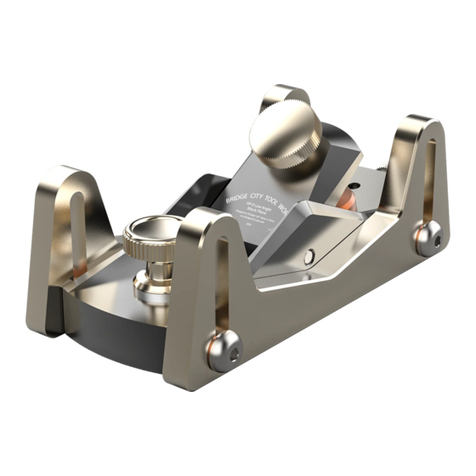

The Chopstick Master™ works by tapering all four sides of the

chopstick blank using a fxed cutting plane (HP-8 block plane

with depth skids). All four sides are tapered to keep the wood

grain running down the centerline of the chopstick blank.

Before beginning, you will need to determine the style

of chopstick you want to make. Generally speaking, the

Chinese prefer chopsticks with a tip diameter of 5 mm. Other

cultures, most notably the Japanese, prefer a tip diameter of

approximately 2 mm. The Chopstick Master™ will allow you

to do either simply by changing the colored adjustable arms:

the red arm is for making chopsticks with 5 mm tips and the

optional green arm will make chopsticks with 2 mm tips.

II.Before Using the Chopstick Master™

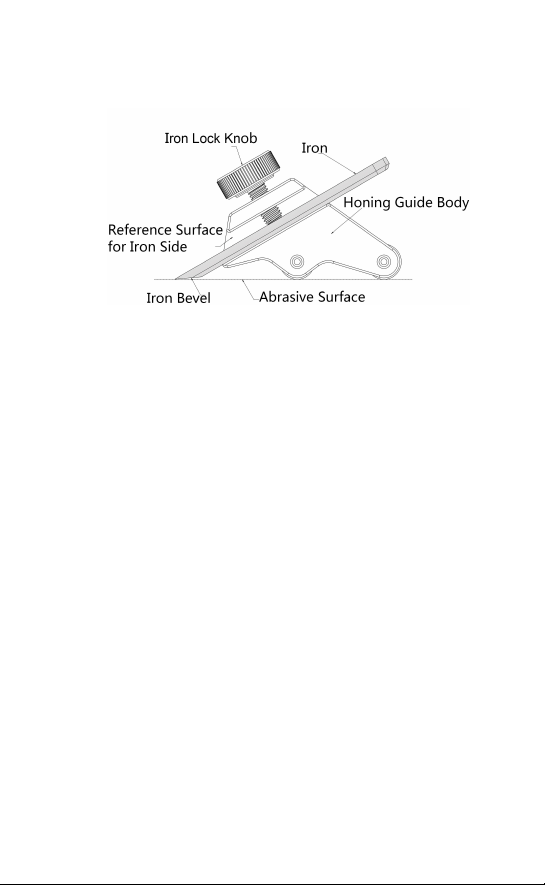

A.Setting the Plane Depth Skids

Before starting to make the chopsticks, it is important to

properly set the depth skids. This can be done following

the illustration in Figure 1, using the gauge built into the