ETERNITY OPzV Series Installation and operating instructions

+971 724 33 535

info@eternitytechnologies.com

www.eternitytechnologies.com

OPzV Standby

Eternity Technologies OPzV VRLA Standby & Solar Batteries are designed to be used as

back-up power to support users that need reliable service continuity in case of power

blackouts and outages of the electricity distribution network. They can also be used in

o-grid and hybrid installations.

Installation, Operation and Maintenance

& Solar Batteries

ET/IOM005-0520

Carefully read this manual in all its parts upon receipt of Eternity Technologies OPzV Standby & Solar Batteries. Please refer to

the latest edition of the battery room standards, eective at the moment of installation IEC 62485-2.

Lead-acid Standby & Solar Batteries are components of a system and although they are maintenance free, they require suitable precautions and

behavioural norms to guarantee safe working conditions and to ensure maximum performance of the battery during its entire life. The Installation, Operation

and Maintenance instruction manual supplies the necessary instructions for the correct care, handling, installation, use and maintenance of Eternity

Technologies OPzV Standby & Solar Batteries.

The non compliance with the instructions given herein may cause injury to personnel and damage to equipment as well as poor operation and performance

of the battery. Any repairs made without authorisation, for example, opening the valves, may render the warranty void.

Store this manual in close proximity to the batteries at all times and ensure it is accessible to the relevant personnel.

Observe the following precautions at all times

Observe the operating instructions - work on the battery should be

carried out by qualified personnel only.

Exposed metal parts of the battery carry a voltage and are electrically

live with the risk of short circuits.

Avoid any electrostatic charge; before starting work on the battery,

first discharge any possible electricity from yourself by touching an

earth-connected part; repeat this action occasionally until work is

complete.

Use protective equipment, such as protective clothing, rubber gloves

and goggles.

OPzV Standby and Solar I&O&M

1. Safety Instructions

2. Introduction

3. Delivery, Unpacking and storage

4. Installation

5. Charging

6. Discharge

7. Temperature & Air Flow

8. Cycle Life

9. Hybrid Applications

10. Solar Applications

11. Maintenance

1. Safety Instructions

No naked flames Corrosive Wear safety goggles Read instructions

Keep away from children Explosive Caution Electric shock risk

First aid /

medical assistance

Use insulated tools.

DO NOT place or drop metal objects on top of the battery.

DO NOT wear rings or bracelets.

Remove any articles of clothing with metal parts that might come into

contact with the battery terminals.

DO NOT smoke and DO NOT use open flames or create electric

sparks.

Take all precaution when using the main supply.

Make sure that the first aid kits and fire extinguishers are easily

accessible.

Used batteries contain recyclable materials. They must not be

disposed with household waste but as a special waste. Methods of

return and recycling must conform to the regulations in operation at

the site where battery is located. If in doubt please contact Eternity

Technologies.

2. Introduction

Eternity Technologies range of OPzV Standby and OPzV Solar 2V

batteries are designed for cyclic and float applications. Examples of

these applications are listed below:

a) Base Stations – accessible and remote

b) Solar and wind sites

c) Utility and switchgear

d) UPS

e) Back-up power systems

f) Peak shaving applications

g) Trac Systems

Eternity Technologies range of OPzV batteries are divided into two

product variants:

a) OPzV Standby – Increased capacity, designed for mainly float /

back up applications.

b) OPzV Solar – optimized for greater cycle life through the addition of

phosphoric acid. For cyclic applications.

Eternity Technologies range of OPzV Standby and OPzV Solar

2V batteries utilise a tubular positive electrode design as well as

other robust components designed to withstand all types of use /

environments.

The gelled electrolyte is maintenance free throughout the life of the

product so no topping up is ever required.

Each gas release valve is 100% tested for functionality as the valve is

a critical part of the battery’s design and performance.

3. Delivery, Unpacking and storage

Unpack the batteries as soon as they are delivered. Verify that the

equipment has been delivered in good condition. Any damage must

be reported immediately to the carrier and the damaged items

retained for inspection by the carrier’s representative.

The details on the label should be read carefully and the following

points to be observed:

• Cell Type

• Cell Voltage

• Capacity

• Float charge voltage

• Operating Temperature

If the battery cannot be immediately installed, store it in a dry, cool and

clean place with adequate air flow. Temperature should be between

10-30°C.

Do not expose the battery to direct sunlight, to avoid any damage to

containers and lids.

IMPORTANT NOTE Storage time for charged cells is limited. Please

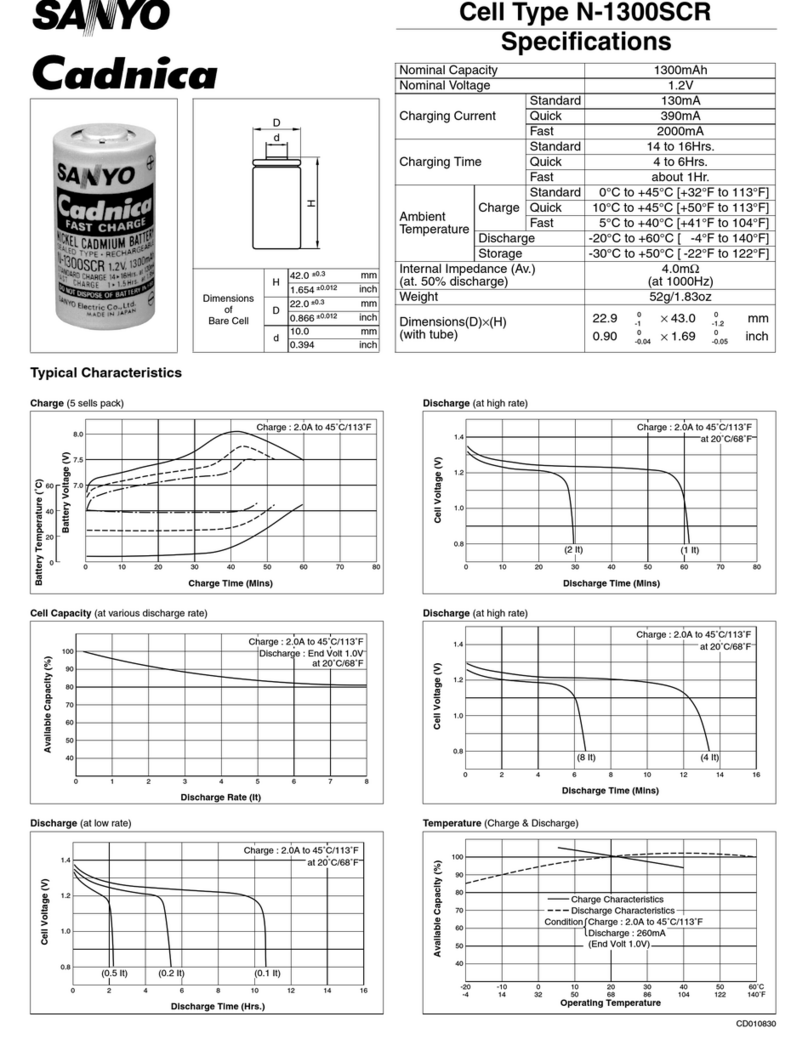

see the self discharge rates at various temperatures below:

During the storage time, the open circuit voltage (OCV) must

periodically be checked.

Cells with OCV below 2.07 Vpc must be recharged providing

constant voltage of 2.35 Vpc with current limitation of 1.5 x I10 (A), for

24 hours.

The OCV of a fully charged battery should result between 2.12-2.15

Vpc.

Failure to observe the above conditions may result in a greatly

reduced capacity and service life or in permanent damage to the

cells.

4. Installation

PLEASE REFER TO THE LATEST EDITION OF THE BATTERY

ROOM STANDARDS, EFFECTIVE AT THE MOMENT OF THE

INSTALLATION OF THE BATTERY.

NORM REF. EN 62485-2

Check that local regulations are also being complied with.

WARNING

The cells are already charged when delivered and should be

unpacked with care. Avoid short circuiting terminals of opposite

polarity.

Vertical Installation

Place the cells on the rack (or cabinet) and make sure that the

spacing allows the accommodation of the inter-cell connectors

(around 10mm). Most batteries have cells connected in a simple

series arrangement, so the cells should be arranged to preserve the

sequence: positive (+), negative (-), positive (+), negative (-) throughout

the whole battery.

WARNING

NEVER LIFT CELLS BY THE TERMINAL POSTS. ALWAYS USE

APPROPRIATED DEVICES (SUCH AS LIFTING STRAPS AND

SUITABLE MECHANICAL LIFTING DEVICES) TO PREVENT

INJURY TO PERSONAL OR DAMAGE TO THE CELLS.

For batteries to be installed on multiple tiers, start by placing the cells

on the lower tier on either side of the frame where the stand sections

meet. Any unused stand spaces should be on the upper tier.

For batteries on stepped racks, leave any unused space on the back

(top) step.

Where multiple racks are arranged end-to-end, adjust the position

of the adjacent end cells to accommodate the flexible inter-rack

connectors.

Take particular care to preserve the positive to negative sequence

when using flexible inter-tier, inter-step or inter-rack connectors

between rows of cells. Leave the main positive and negative terminals

of the battery free for connection to the charging source.

Check cell alignment.

Prepare the inter-cell connectors by cleaning the contact surfaces

with a soft clean cloth.

Fit the inter-cell and inter-tier connectors using approved, insulated

bolts and nuts. Ensure all bolts, connectors and cell terminals are free

from dust or debris before connecting.

Use insulated wrenches to tighten the parts firmly together, with

torque setting of 23 Nm (203 in lbs).

Pay special attention to avoid short-circuiting the cells with any of the

battery hardware.

Check tightness and cleanliness.

Horizontal Installation

All Eternity Technology standby cells can be stored vertically and

horizontally.

All Eternity Technology Solar cells up to and including 1200Ah can be

stored both vertically and horizontally. If you require larger Solar cells

to be stored horizontally please contact Eternity Technologies. When

storing horizontally ensure that the internal plates are vertical (to

check this is the correct the positive and negative terminals should be

above or below each other ie not on the same level as per the diagram

below):

5. Charging

a) Commissioning Charge

Batteries lose charge while in transit or during storage. For this

reason, a refresh charge should be given before putting the battery

into service.

Recommended charge settings - at the ambient temperature range

of 20 °C to 25 °C – are as follows:

12 hours at constant voltage of 2.35 Vpc at 20°C (68°F)

{Current limitation 1.5 x I10 Amps}

temperature compensation;

0°C = 2,45 Vpc

10°C = 2,40

20°C = 2,35

30°C = 2,32

35°C = 2,30

b) Float Charge

To maintain the battery in fully charged condition during normal

battery operation or, after a discharge, to recover 90% of nominal

capacity within 20 hours, a recommended float charge has to be

applied.

Recommended float voltage settings are as follows:

Constant voltage 2.25 Vpc at 20°C (68°F) ±1%

{Current limitation 2xI10 Amps}

When all cells have been connected up check the terminal voltage,

this should equal to the sum of all the individual cell voltages. If the

total voltage is dierent to the calculated figure, some cells may have

been reversed.

Connect the positive terminal of the battery to the positive terminal of

the charger and the battery negative to the charger negative.

Number the cells by using a set of numbering stickers. It is common

practice to number the cells beginning with #1 at the positive end of

the battery and following the sequence of electrical connection of the

cells, through to the negative end of the battery.

Before installing the cells, clean all parts. Remove the short circuit

ABS protectors from the terminal posts and clean them with a soft

clean cloth.

Before replacing old batteries ensure all electrical loads are switched

o.

Battery Room - Points to Consider:

• Ensure the floor is structurally capable of carrying the battery load

• The floor should be resistant to Electrolyte (diluted sulphuric acid)

• There should be no ignitable sources near to the cells

• Ensure there are no unauthorised access points to the battery room

• All rooms should have the correct fire-fighting equipment fitted in

case of emergency.

6. Discharge Rate

The discharge rate of the battery in Amps are is calculated in I10.

I10 = current for 10hr discharge to 100% DOD. This will be the basis

for all discharge rates across this brochure. For example:

Let’s take the Eternity OPZV 10 OPzV 1000

C10 capacity = 1185Ah to an end of discharge voltage of 1.80V @

20°C

1 x I10 = 1 x (10hr discharge)

1 x I10 = 1 x 118.5 = 118.5A

5 x I10 = 5 x 118.5 = 592.5A

End of Discharge Voltage

Discharging too much capacity from the battery will lead to early

failure so the user must ensure that measures are in place to prevent

this. The recommended low voltage disconnect settings are

mentioned below:

g) IUI Charging Profile

The IUI charging method is perceived as the best method of charging

for a lead acid batteries and will increase the cycle life of the cell. The

charging method is similar to the above but an additional constant

current phase is added after the Constant voltage phase. The final

constant current phase equalises the charge over the individual cells

to ensure even finishing. This will help improve the battery eciency

and ultimately increase the cycle life.

Bulk Charge / Phase 1

The charging current is set to a limit between 2-5 x I10 until it reaches

a maximum voltage of 2.35V / cell.

Constant Voltage / Phase 2

Here the voltage is set to 2.35V / cell. During this phase the absorbed

current will start to decrease and finally reach a value of 0.005A / Ah.

At this point the battery is considered fully charged and the rectifier /

charger system should be switched back to the relevant float voltage.

The constant Voltage phase of the charge should be limited to a

maximum of 10hrs with maximum current of <1.2A/100Ah.

I Phase / Phase 3

No voltage limits, but maximum current of <1.2A/100Ah for a duration

of maximum 4 hours.

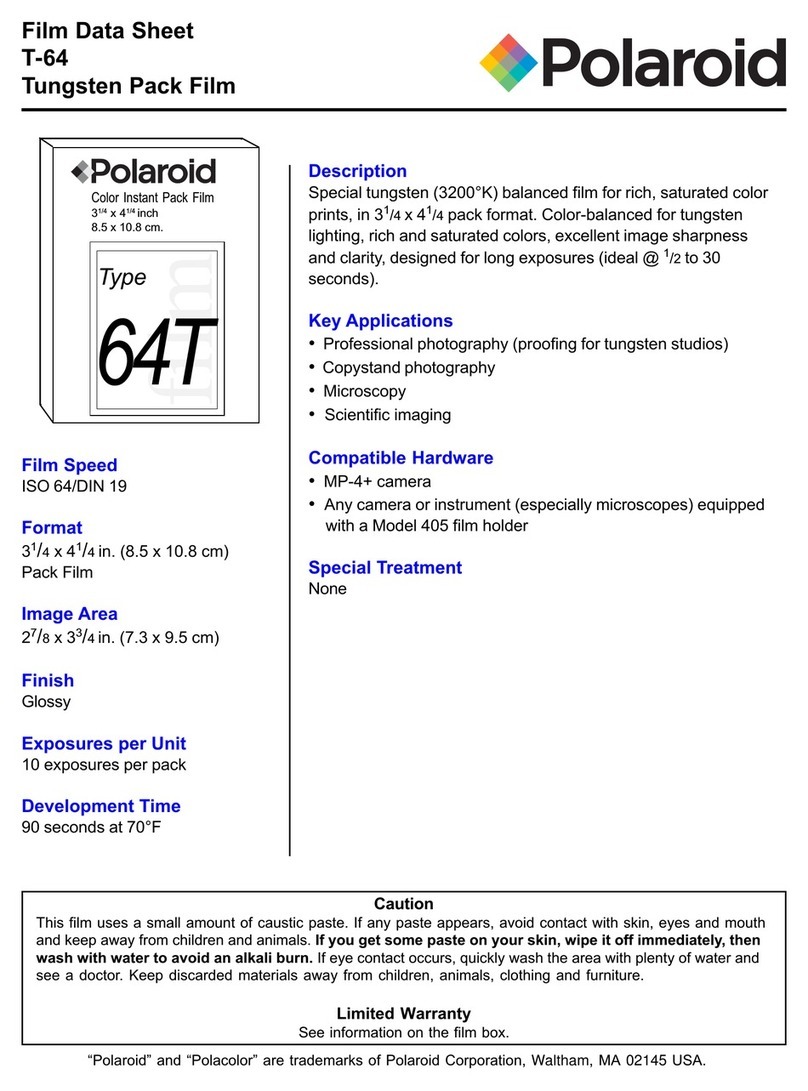

The float voltage value requires a thermal compensation of -3.5mV/

cell/°C for temperature increases. For temperature decreases in the

cell the voltage should be increased by 3.5mV/Cell/°C. See graph

below. Failure to change these values will lead to capacity problems

and reduction in operational life.

c) Equalizing / Boost charge 2.35 – 2.4V

Chargers usually have two adjustable charging voltages: one for the

“floating” charge and one for the “equalizing” charge (also known as

“boost”, “high rate” or “recharge”).

The equalizing charge is generally required:

- when the total voltage spread between the cells is greater than 0.04

V under float charging conditions

- after exhaustive discharges

- for fast recharging after a discharge

- when charging cells in standby applications with frequent power

outages

- for float charge using voltages below 2.23 Vpc

Boost charge voltage is 2.35 – 2.4V per cells for a maximum duration

of 48 hours. It can be turned o earlier though if the current has

decreased to a value lower than 0.05 x I10.

d) Charge current limit

The limit for the charging current using the float charge voltage after a

discharge is limited to 5 x I10

e) Charging Time

Use the graph below for to estimate typical charging times:

f) IU Charging Profile

The IU charge is the most common method for fast recharging or

when batteries are charged in cyclic applications. It consists of two

phases:

Bulk Charge / Phase 1

The charging current is set to a limit between 2-5 x I10 until it reaches

a maximum voltage of 2.35V / cell.

Constant Voltage / Phase 2

Here the voltage is set to 2.35V / cell. During this phase the absorbed

current will start to decrease and finally reach a value of 0.05A / Ah.

At this point the battery is considered fully charged and the rectifier /

charger system should be switched back to the relevant float voltage.

The constant Voltage phase of the charge should be limited to a

maximum of 10hrs with maximum current of 5A/100Ah.

Back up time (h) U (V) per cell

0,5-1,5 1,70

1,5-3 1,75

>3-24 1,80

24-240 1,85

Temperature eect on cycle life

Eternity Technologies recommends that the operating temperature

range for OPzV batteries be within the region of +10°C to + 30°C.

Operating in higher temperatures will lead to decreased operational

life, operating in lower temperatures will lead to a reduction in

available capacity.

Air flow for cooling

When batteries are cycled, they generate heat. Eternity Technologies

recommend a minimum gap of at least 10.0mm between cells to

allow for the heat to disperse from around the cells. Where natural

cooling is not enough to keep the temperature of the battery to a

recommended level, a cooling system may be required. We can work

out the size of the required cooling by calculation, please see below:

A 48V battery is discharged twice daily, delivering 3 hours back-up

and 3kW of power

Heat loss from the battery = 2 (2 discharges/day) x 3kW x 3 hours x

0.15 (15%) = 2.7kWh = 2700Wh per day.

If we calculate the cooling power required to keep the room at a

consistent temperature then we take 2700Wh and divide by 24 hours

= 112.5W

Air exchange to exhaust Hydrogen

Due to the chemistries involved within Eternity Technologies OPzV

battery range, hydrogen evolution and emittance is unavoidable.

Although the levels are minimal, if they are allowed to accumulate

or there is a fault within the system and hydrogen gas increases

to a dangerous level, there is a risk of explosion if a spark or flame

becomes present.

8. Cycle Life

Please see the graph below showing our maximum number of cycles

vs the depth of discharge. There are two lines on the graph. One

line states the charging profile with IU charging profile. The other

line shows the cycle life with an IUI charging profile. The graph is

referenced to 20°C, operating at temperatures either side of this

figure will result in a dierent number of cycles.

9. Hybrid Applications

Eternity Technologies Solar OPzV batteries can be used in a hybrid

system alongside a diesel generator where the batteries are used

to decrease the run time of the generator. Charging is critical in

this application and the user must ensure that the charging time is

sucient to fully charge the battery between cycles. Failure to do this

will result in reduced cycle life.

The charging criteria must comply with the figures set out in section 5

of this document.

10. Solar Applications

Batteries used without a generator and no mains power are classified

as solar batteries. The important thing here is to limit the charge and

discharge currents.

When there is an abundance of sunlight, it is necessary to limit the

charge and not overcharge the battery. When there are times of

continuous darkness, it is important not to discharge the battery too

much. Please use the end of discharge voltage recommendations in

this brochure for guidance.

Failure to comply with this will result in reduced capacity and cycle life.

It is recommended to perform a boost charge every 1-3 months in

solar applications.

In order to avoid a build-up of hydrogen to dangerous levels, the

battery room or area needs to be ventilated. We can calculate the

required ventilation based on the number of cells and their capacity.

Eternity Technologies recommends the international standard for the

safety stationary batteries, IEC 62485-2 be consulted.

7. Temperature and Air flow

Temperature eect on float life

Increased temperatures have a great eect on the life of a battery.

When the battery is operated at increased temperatures, the

corrosion of the positive terminal is accelerated which leads to early

failure. When operated at 20°C, Eternity technologies OPzV range of

batteries will last for 20 years. For every 10°C increase in the average

operating temperature, the battery’s life is halved.

The graph below shows the eect of temperature on the float life of

the battery.

11. Maintenance

Eternity Technologies OPzV are sealed-maintenance free lead-acid

batteries and need no water addition.

Cleanliness

The containers and lids must be kept dry and free from dust.

Cleaning must be done only with a damp cotton cloth.

Avoid static discharges generated during cleaning.

Voltages

Individual cell voltages will vary greatly when the cells are first put

into operation. This is expected and variation will start to decrease

within the first 12 months. Monitor these as per below. If there isn’t

any significant change in the voltages after 12 months, an additional

equalisation charge should be performed.

Please see graph below for expected voltage variation vs time.

Every 6 months:

- Check for evidence of damage on the battery and equipment.

- Check and record the total battery float voltage, the voltage on pilot

cells* and temperature.

Once a year:

- Check and record individual cell voltages.

- Perform a discharge test according to IEC 60896-21 standard until

the battery shows signs of degradation and then every six months

thereafter.

Keep a log book to record all maintenance and inspection operations,

which will be helpful to monitor long-term changes of the battery

condition.

Do not attempt to open the safety valve. Opening could cause

damage to the battery.

*Pilot Cell

For regular monitoring of the battery condition, select one cell near

the middle of the battery string as a “pilot” cell (for battery consisting

of more than 60 cells, it is advisable to select one pilot cell out of 60).

Additional Information

For any further information on Eternity OPzV VRLA Standby & Solar

batteries, please contact:

Eternity Technologies FZ-LLC

Al Hamra / Al Jazeera

PO Box 35102

Ras Al Khaimah

U.A.E

Phone + 971 72 433 535

Fax + 971 72 433 536

Web www.eternitytechnologies.com

Network Power

Motive Power

Accessories

Service

Chargers

Bloc Batteries

POWER FOR

TOMORROW

Eternity Technologies FZ-LLC

Al Jazeera / Al Hamra, PO Box 35102,

Ras Al Khaimah, UAE

Sales & service

info@eternitytechnologies.com

www.eternitytechnologies.com

The Eternity Technologies range is

built using only the highest quality

and most efficient production

processes at our state-of-the-art

manufacturing centre in the UAE.

It is this innovation, modern design

criteria and industry-leading

machinery that allows Eternity

Technologies to not only meet the

needs of the global industrial market

with increased reliability but define it

for the future.

TODAY

This manual suits for next models

3

Table of contents