Eteros MOBIUS M60 User manual

M60 USER GUIDE

©2022 ETEROS TECHNOLOGIES INC. ALL RIGHTS RESERVED | MOBIUSTRIMMER.COM

TABLE OF

CONTENTS

4

5SERVICE & REPAIRS

Eteros Technologies Contact Information

6SAFETY INSTRUCTIONS

General Safety

8

GENERAL OPERATION

CONTROL PANEL

CLEANING & MAINTENANCE

TROUBLESHOOTING

SPECIFICATIONS

Small Batch, Dry Milling

Operating The Controls

How To Get The Most Out Of Your Mobius M60 Mill

Basic Steps To Ensure Proper Machine Performance

Performance and Tech Specs

9

10

11

12

14

15

WELCOME

Mobius M60 Mill

GET TO KNOW

ASSEMBLY & INSPECTIONS

Your Mobius M60 Mill

Setup The Mobius M60 Mill

4

INTRO

This User Guide is a comprehensive manual covering the operation and maintenance of

the Mobius M60 Mill as of the date of publication. ETEROS TECHNOLOGIES reserves the

right to make updates to the machine from time to time. In the event of an update, this

User Guide will remain appropriate for the safe operation and maintenance of your unit.

This User Guide, as well as any documentation supplied by component manufacturers,

are to be considered the information package associated with this device. Every operator

must read and understand the User Guide. The manual should be located within easy

access for periodic review.

WELCOME TO THE

MOBIUS M60 MILL

1.866.874.6244 | INFO@MOBIUSTRIMMER.COM | MOBIUSTRIMMER.COM

Repairs may only be carried out by Eteros Technologies or a designated authorized agent

(service technician).

Should the need arise, please notify us:

ETEROS TECHNOLOGIES

26 Industrial Ave. Carleton Place, Ontario, Canada K7C 3T2

www.eteros.com

1.866.874.6244

Improper interfacing, improper repair, or unauthorized modification could result in void

warranty claims.

SERVICES & REPAIRS

6

To ensure operator safety while in use, this device includes decaling, guarding, and other

safety features. Operators are encouraged to use caution and best judgment when using

equipment. Equipment should be serviced when required.

To avoid possible damage to the machine and risk of injury to the operator, consult with

an ETEROS TECHNOLOGIES representative to answer any questions.

All operators must read and understand this User Guide and be trained in safe operation

and use of the machine. We recommend the owner of this equipment develop a standard

operating procedure specific to each worksite to address any local hazards or other conditions

not outlined in this User Guide. The machine must be inspected regularly for damage,

component failure, and wear. Results of inspection activity should be documented.

ETEROS TECHNOLOGIES makes every effort to ensure the machine is compliant with

all current safety standards. It is the responsibility of the owner to ensure all municipal,

provincial, state, county, territorial, and federal codes, regulations, and standards have

been met in each working location.

Do not lend or rent your machine without providing the User Guide. A first-time operator

should receive practical instruction before using the machine.

This machine is not to be used for any purpose other than those expressly stated in the

User Guide, advertising literature, or other ETEROS TECHNOLOGIES written material

pertaining to the machine.

SAFETY INSTRUCTIONS

1.866.874.6244 | INFO@MOBIUSTRIMMER.COM | MOBIUSTRIMMER.COM

General Safety Precautions

READ and become familiar with the entire User Guide. Learn the equipment

applications, limitations, and possible hazards.

1

2

3

8

4

5

6

7

DO NOT USE THE MACHINE IN A DANGEROUS ENVIRONMENT or damp or

wet locations. Never expose the control panel directly to rain or water. Keep

the work area well illuminated.

DO NOT use the device in the presence of flammable liquids or gases.

ALWAYS WEAR EYE PROTECTION.

KEEP WORK AREA CLEAN. Cluttered areas and workspaces invite accidents.

WEAR PROPER APPAREL. Do not wear loose clothing, gloves, neckties, rings,

bracelets, or other jewelry which may get caught in moving parts. Non-slip

footwear is recommended. Wear protective hair covering to contain long hair.

POWER DOWN AND DISCONNECT EQUIPMENT before washing or servicing

and when changing accessories.

CHECK FOR DAMAGED PARTS PRIOR TO OPERATION. The equipment should

be inspected prior to use to ensure proper operation when performing its

intended function. Check for alignment of moving parts, binding of moving

parts, breakage of parts, mounting, and any other conditions that may affect

its operation. Any damaged part including guards should be properly repaired

or replaced.

8

GET TO KNOW YOUR

MOBIUS M60 MILL

HOPPER

ROTOR

ROTOR SHAFT

SCREEN

CHUTE

LATCH

CONTROL PANEL

DOOR

HANDLETOTE

Your M60 Arrives With The Following Components:

M60 Machine1

1

1

1

1

1

366 cu. in / 1.58 gal / 6L

Tote Lid

1/8" Perforated Screen

1.6mm Rasp Screen

Hopper

WHAT'S IN THE

BOX

1.866.874.6244 | INFO@MOBIUSTRIMMER.COM | MOBIUSTRIMMER.COM

INITIAL

ASSEMBLY &

INSPECTION

To set up the Mobius M60, follow these steps:

1.

Inspect the package and package contents to ensure no damage occurred during

shipping

2. Remove the machine from the package

3. Confirm the power cord is in good condition

4. Remove the HOPPER from the TOTE and fasten to the machine using both HOPPER

SCREWS

5. Ensure the ROTOR is properly installed with the spring-pin latch in place

6.

Ensure that the equipment is in a clear and tidy workspace and that all controls are

accessible and clearly visible

10

The M60 is washdown rated and features easily removable components. With the

exception of the motor and control panel, the M60 can be washed, cleaned, and wiped

down with normal detergents, degreasers, and disinfectants.

The door, rotor, screen, and hopper can all be removed to facilitate cleaning. The door can

be removed by simply lifting it off the hinges. To remove the rotor, lift up and hold the

pin on the spring plunger while sliding the rotor off of the shaft. To remove the hopper,

unfasten both hopper screws.

If necessary, the door gasket can also be removed for cleaning. The gasket is pressed by

hand into the groove around the circumference of the door.

Take care to not spray water directly onto the control panel.

The M60 is largely maintenance-free. The door gasket is the only wear component within

the M60. The condition of the door gasket should be inspected prior to each use. A faulty

or worn door gasket will not affect the operation of the machine, however it is necessary

for dust mitigation.

This User Guide does not include instructions for machine repair. For your safety, repairs

must be completed by ETEROS TECHNOLOGIES or an authorized service technician.

1. Ensure the power switch is in the off position, the power cord is unplugged, and the

emergency stop has been pressed.

2. Tilt the machine onto its back.

3.

Twist the fuse holder cap protruding from the bottom of the electrical box

counterclockwise. The cap will have white lettering that says “FUSE.”

4. Remove and safely discard the expended fuse. Insert the new fuse into the cap.

5.

Insert the new fuse and cap back into the electrical box and twist clockwise to secure.

Should the need arise, the 3A fuse can be replaced without any tools. To replace the fuse:

CLEANING THE MOBIUS M60

FUSE REPLACEMENT

PREVENTATIVE MAINTENANCE

CLEANING &

MAINTENANCE

1.866.874.6244 | INFO@MOBIUSTRIMMER.COM | MOBIUSTRIMMER.COM

MILLING

GENERAL OPERATION

The M60 is designed to be hand fed for small batch, dry milling. To begin milling product:

When all product has been fed into the machine, you can check if product is still being

milled by looking through the tote to see if ground product is being pressed through the

screen.

Once satisfied that milling is complete, turn the machine off. The tote can now be safely

removed and stowed away with the lid.

1. Install either the ⅛” perforated screen, or 1.6mm rasp screen depending on how fine

or coarse of a grind you prefer by sliding the screen into the groove of the milling

chamber. Additional screen sizes are available by request, please contact your dealer

or Eteros Technologies for availability and pricing.

2. Slide the tote into the milling chamber until bottomed out.

3.

Seal the milling chamber by closing the door of the machine, turning the latch one

quarter turn clockwise, and flipping the latch down. You will hear a click and the latch

will snap into place when properly engaged.

4.

Ensure the emergency stop is not pressed. If you are unsure, rotate the e-stop

counterclockwise. If depressed, it will reset when turned counterclockwise. The machine

will not start unless the door is sealed and the e-stop is in the default position.

5.

Ensure the power cord is plugged into a 120 V (North America) or 240 V (international)

outlet.

6. Start the rotor by switching the rotor switch to the ON position.

7.

Look down the chute and ensure the rotor is rotating clockwise (when viewed from

the front of the machine). If it isn’t, flip the direction switch to the opposite position.

8. Feed product one handful at a time into the hopper.

9.

Adjust the speed of the rotor as necessary to maintain a consistent feed rate and output.

1.866.874.6244 | INFO@MOBIUSTRIMMER.COM | MOBIUSTRIMMER.COM

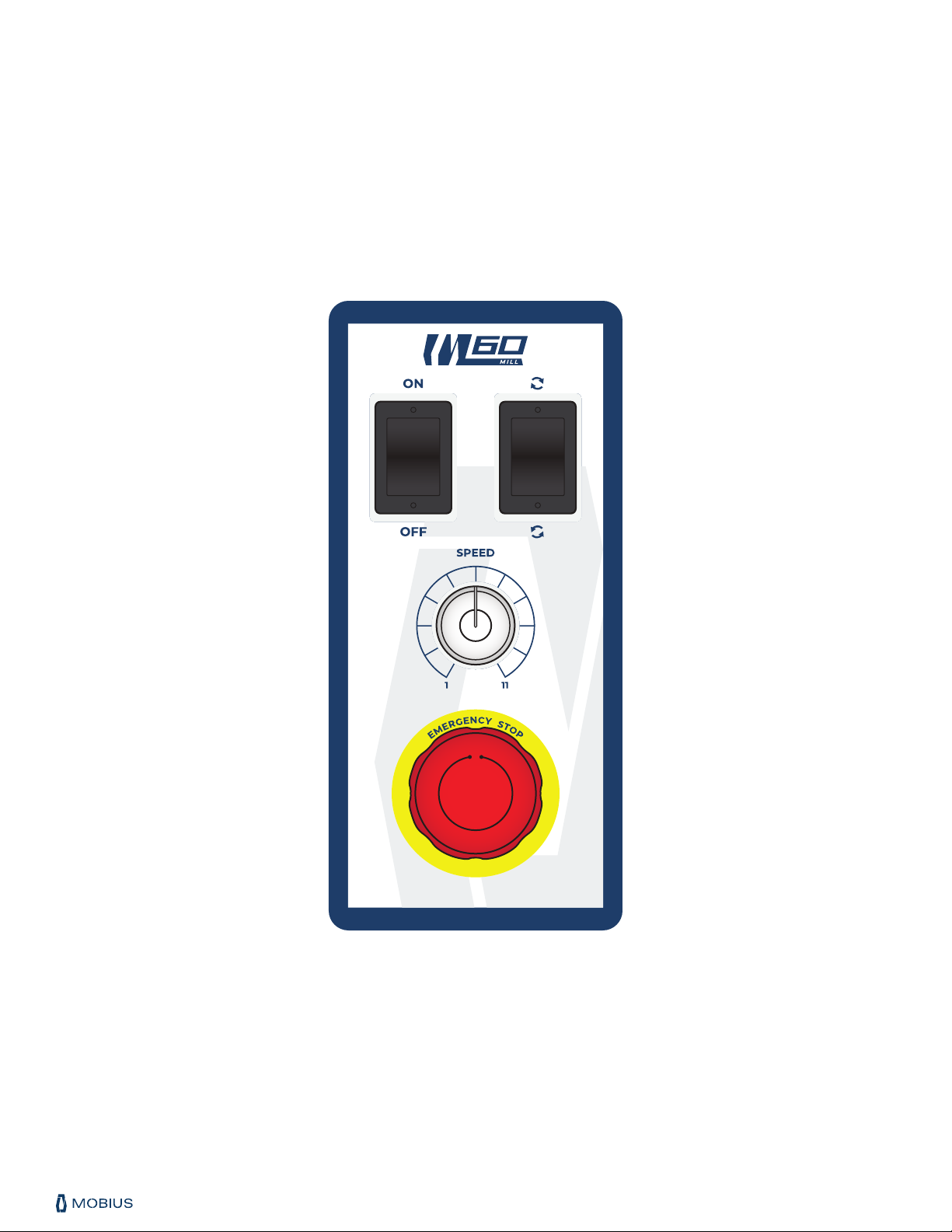

MOBIUS M60 MILL

CONTROL PANEL

13

LIFTING & MOVING

The M60 is easily moved using the aluminum handles on either side of the machine.

Exercise proper ergonomics and lifting technique when moving the machine. When setting

the machine down, ensure that all four rubber feet are firmly planted on the work surface.

TOP LEFT - POWER ON/OFF:

In the on position, the rotor will immediately begin rotating at the set speed and direction.

In the off position, the motor is disabled and the rotor is stationary.

MIDDLE - SPEED CONTROL:

Rotate the knob clockwise or counterclockwise to reduce the rotor speed.

TOP RIGHT - DIRECTION CONTROL:

Initiating the switch in the up position, will spin the rotor clockwise, which is the forward

position. Selecting the down position, you will initiate the rotor to spin counter-clockwise

(the reverse position).

BOTTOM - EMERGENCY STOP:

Pressing the e-stop will immediately disable all power to the machine and stop the

rotor. Power will remain disabled until the e-stop is reset by turning the red knob

counterclockwise and the power button is cycled off and back on.

1.866.874.6244 | INFO@MOBIUSTRIMMER.COM | MOBIUSTRIMMER.COM

SPECIFICATIONS

Milling Chamber Dimensions

Tote Dimensions

Screen/Rasp Size

Screen/Rasp Options

Power Requirements

Motor

Throughput

Rotor Speed

Speed Adjustment

7 ¾” diameter x 5” depth

7 ¼” tall x 8 ⅜” wide x 8 ⅜” deep

60 sq. in (387 sq.cm)

⁄” perforated screen

⁄” perforated screen

1.6 mm rasp screen

115 VAC, 1.5 A or 230 VAC, 0.75 A

1 / 10 HP

20 lbs / hour

0 - 110 RPM

1 - 11

Length

Tote Volume

Weight

Width

Hopper Volume

Height

13" / 33 cm

76 cu. in / 0.3 gal / 1.25L

22 ¼" / 57 cm

16" / 41 cm

366 cu. in / 1.58 gal / 6L

60 lbs

MOBIUS M60 MILL

1.866.874.6244 | INFO@MOBIUSTRIMMER.COM | MOBIUSTRIMMER.COM

TROUBLESHOOTING

Device is Abnormally Noisy / Rotor Rubbing

Mobius M60 Will Not Start

Ensure the machine is plugged in

Ensure e-stop is disengaged (pulled out)

Ensure the door is closed and sealed

Cycle the power button off then on

Ensure the rotor is not jammed or lodged

Ensure the rotor is properly seated and the spring pin is engaged to

the shaft

Inspect upper milling chamber for product / resin build up, clean as

required

Contact ETEROS TECHNOLOGIES to discuss different milling screen

options

Contact ETEROS TECHNOLOGIES to discuss milling screen options

Remove the rotor, wipe/wash down rotor, shaft, and milling chambers

Milled Material is Over / Under-Processed vs. Desired Consistency

Debris & Product Buildup on the Rotor and/or Milling Chambers

1.866.874.6244 | INFO@MOBIUSTRIMMER.COM | MOBIUSTRIMMER.COM

©2022 ETEROS TECHNOLOGIES INC. ALL RIGHTS RESERVED | MOBIUSTRIMMER.COM

Table of contents

Other Eteros Industrial Equipment manuals