3

Table of Contents

Safety Instructions

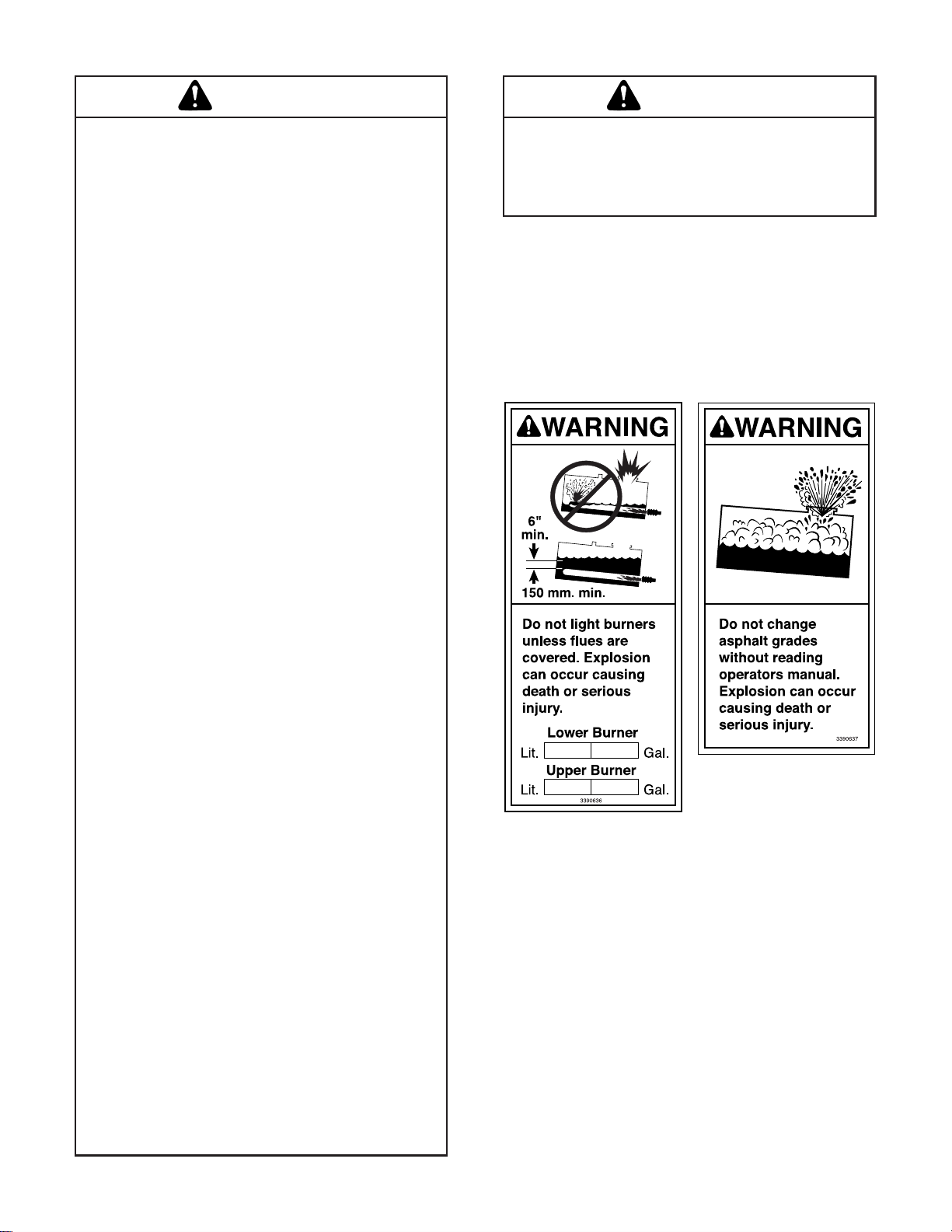

Warning And Instruction Plates......................... 5

General Safety Instructions .............................. 7

Safety Precautions, Hazard Seriousness Level 7

WARNINGS ...................................................... 8

Fluoroelastomer Handling.............................. 8

Foaming .......................................................... 10

Asphalt Institute .............................................. 10

Introduction ................................................... 11

Reporting Safety Defects................................ 11

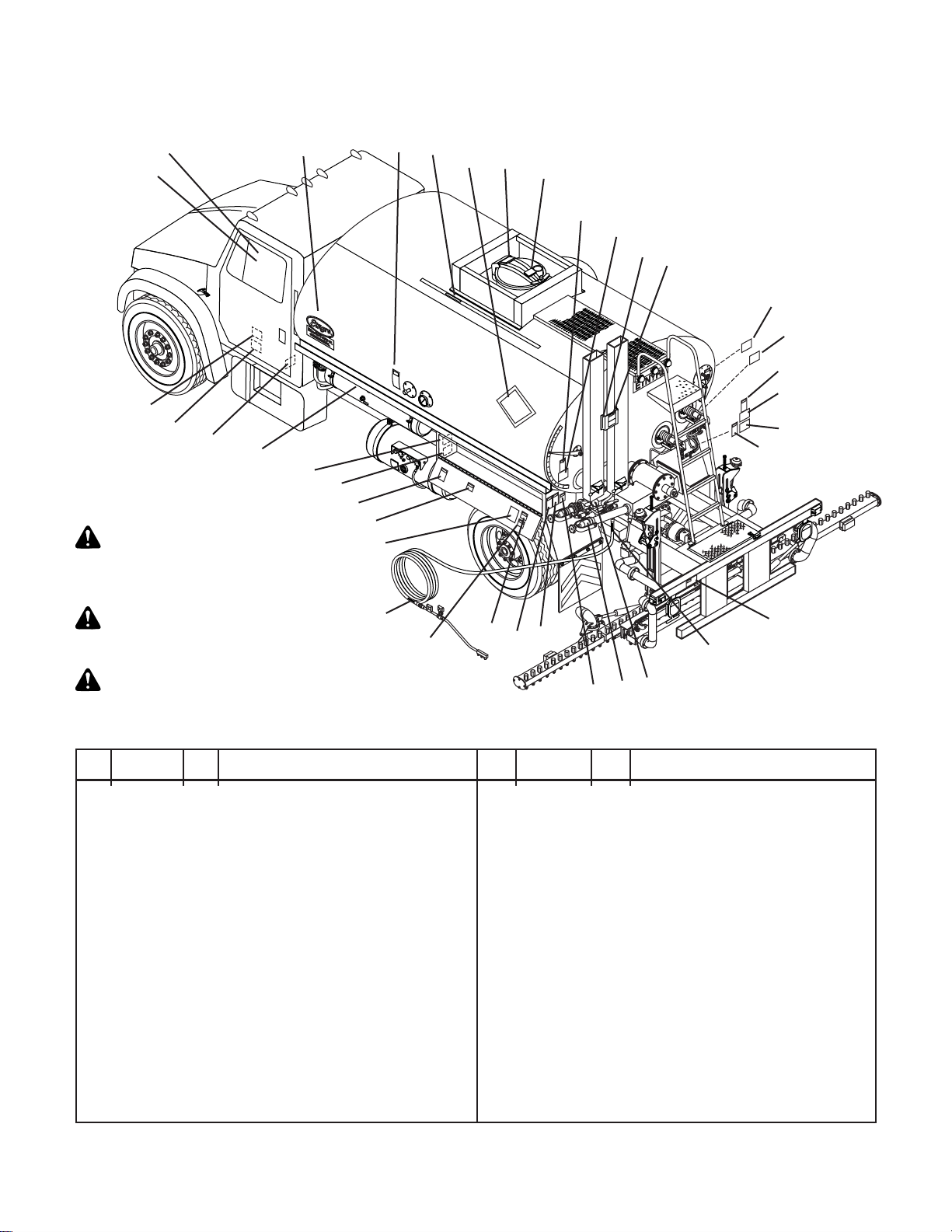

Component Location And Identification .......... 12

Rear and Side Components............................ 12

Spray Bar Components................................... 13

Hydraulic Tank Components ........................... 13

Cab Control Panel........................................... 14

Rear Control Panel ......................................... 17

Preparing for Operation ............................... 19

Setting Up the Computer ................................ 19

First Screen..................................................... 19

Second Screen ............................................... 19

Third Screen ................................................... 19

Fourth Screen ................................................. 20

Fifth Screen..................................................... 20

Sixth Screen.................................................... 20

Seventh Screen .............................................. 20

Eighth Screen ................................................. 20

Engaging Pump on PTO Equipped Distributors .... 21

Manual Transmissions .................................... 21

Automatic Transmissions ................................ 21

Spraying Operations ....................................... 22

Setting the Digital Memory Presets ................ 23

Adjusting the Spray Bar Nozzle Angle ............ 23

Adjusting the Spray Bar Height....................... 23

Operation ....................................................... 25

Tank Capacity ................................................. 25

Operation Screens .......................................... 25

First Operating Screen.................................... 25

Second Operating Screen............................... 25

Third Operating Screen................................... 26

Information Messages..................................... 26

Loading ........................................................... 28

Loading Through the Manhole........................ 28

Loading Through the Load Line Connections

and Preliminary Checks .................................. 29

Check Strainers .............................................. 29

Using the Measuring Stick .............................. 29

Loading Through the Load Line...................... 29

Circulating in the Tank..................................... 31

Circulating Product in the Bar ......................... 33

Spraying (Auto) ............................................... 35

Hand Spraying ................................................ 36

Bar Suck Back Override.................................. 37

Spray Bar Suckback ....................................... 38

Flushing Operations........................................ 40

Bar Flush (Auto).............................................. 40

Bar Flush (Manual) ......................................... 41

Unload Operations with External Pump.......... 42

Unload Operations with Distributor Pump....... 44

Transfer Operations ........................................ 46

Heating Product in Distributors .................. 48

Heating with Liquid Propane Gas (LPG) Burners .. 48

LPG Supply Tank Requirements..................... 48

Manual Control Burners .................................. 49

Burner Operation ............................................ 49

Burners With Outfire Controls......................... 50

Burners with Automatic Ignition and

Temperature Limiting Control........................ 53

Burner Operation with Auto Ignition &

Temperature Control ..................................... 53

Electric Driven Burner Diesel Operation ......... 54

Troubleshooting............................................ 55

Maintenance .................................................. 57

Electrode Assembly Adjustments.................... 57

Burner Air Band Settings................................. 57

Check Ignition Transformer Spark .................. 58

Fire Burners .................................................... 58

Replacing Speed Pickup................................. 58

Servicing the Etnyre P-15 Pump..................... 59

Vacuum Check................................................ 59

Impeller Installation And Pump ....................... 59

General Fuel Data and Heating Terminology.. 60

Fuel Data ........................................................ 60

Approximate Burner Fuel Consumption.......... 60

Heating Terminology ....................................... 60

Hydraulic Fluid Requirements......................... 61

General Information ........................................ 61

Hydraulic Fluid Requirements......................... 61

Viscosity & Temperature Requirements.......... 61

Contamination Levels ..................................... 62

Lubrication Chart............................................. 64

Etnyre Spraybar Nozzles ................................ 65

Decimal Equivalent Chart ............................... 66