Spray Bar Suck Back

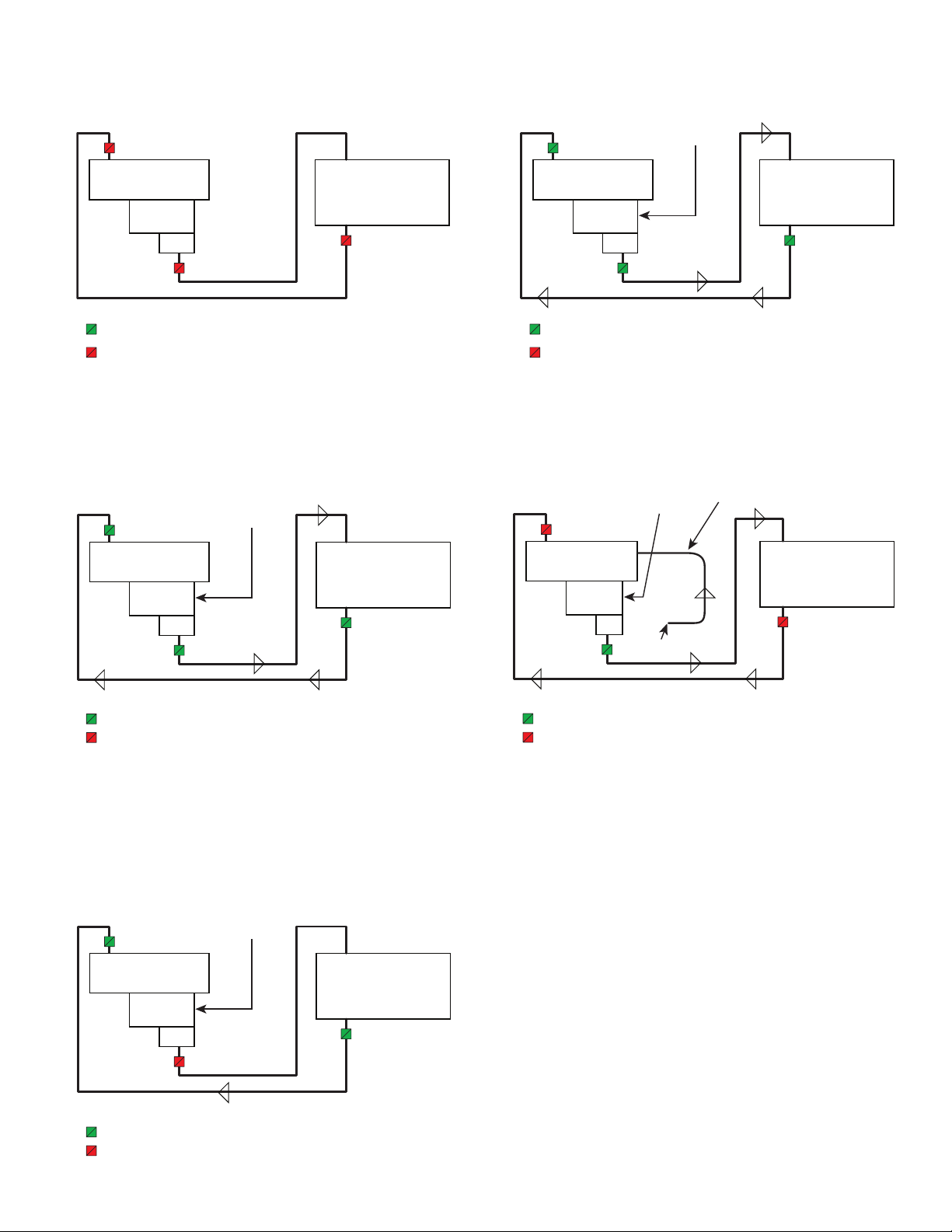

Refer to Figure 1 for the following procedures.

1. Park the Distributor and set the parking brake.

The Engine must be running and the optional

transmission PTO must be engaged.

2. Turn the MASTER SPRAY switch OFF.

3. Turn the cab POWER switch ON and turn the rear

EMERGENCY STOP ON.

4. At the rear of the distributor, set or conrm the

following:

• Return valve open

• Tank Valve closed

• Master hand spray valve closed

• Transfer line suck back valve closed

• Transfer line valve closed

• Flush valve closed

• Load and transfer line caps are in place

and secured

5. Increase truck RPM over 1000 RPM

6. Go to suck back on the screen

7. Move pump to auto if not already there (200 GPM

default)

8. Tap start pump button

9. Raise spray bar and fold wings

10. Let pump suck back for a sufcient period of

time to allow all the product to be pulled from

the spray bar and circulating system as dened

by the pump (noise/load). Do not open any

spray valve or air into the system at this time.

11. When condent that the product pump is not

pulling any material from the circulating system,

turn on the wash down pump (if equipped) or

open the ush valve on the side of the load line

to introduce release agent into the system.

NOTE: Without a wash down pump it will be

a calculated guess as to how much release

agent is going into the system due to the nature

of the condition of the wash down system (this

may take extra time). With the wash down pump

running, open the ush valve for a period of

time (20 to 30 seconds, depending on material

in the circulating system) to allow release agent

NOTE: The pump can be stopped and the auto-mat-

ic tank valve can be closed immediately at any time

during operation by turning the EMERGENCY STOP

switch OFF.

For asphalts like AC it is recommended that this

procedure be repeated a second time, after which

adding solvent such as diesel fuel through each

bleeder will quickly ush the spray bar.

If not equipped with an electric pump, it is helpful to

pour some diesel fuel down the ll line after all op-

erations are completed. The diesel fuel will remain

in the pump overnight to keep the pump free for the

next morning’s operation.

Ensure that the self ush valve is closed at the

end of this function, or before loading or circulating

asphalt to eliminate chances of inducing asphalt into

the self ush fuel tank.

Suck Back Operation Mode

to migrate into the strainer box and over to the

asphalt pump.

12. At this time while the wash down pump is running

and suck back is in auto, change the pump con-

trol from auto to manual, and increase the pump

speed slider about ¾ of the way and start the

pump again.

Adjust the pump GPM to around 60 GPM for

another 10 seconds then turn the pump dial

counterclockwise to the 0 GPM position for

approximately another 10 seconds.

13. Turn the ush valve to the off position, shut off

the wash down pump then hit the power button

to turn off the system.

4