ETS-Lindgren OMS User manual

www.fmgrupotec.com fmgrupotec@fmgrupotec.com 0034.903.360.306 Calle Algepser n16 Parque Empresarial Tactica- 46980 Paterna (Valencia)- España

Sample Draw

Oxygen

Monitoring System

(OMS)

User Manual

www.fmgrupotec.com fmgrupotec@fmgrupotec.com 0034.903.360.306 Calle Algepser n16 Parque Empresarial Tactica- 46980 Paterna (Valencia)- España

ETS-Lindgren Inc. reserves the right to make changes to any product described

herein in order to improve function, design, or for any other reason. Nothing

contained herein shall constitute ETS-Lindgren Inc. assuming any liability

whatsoever arising out of the application or use of any product or circuit

described herein. ETS-Lindgren Inc. does not convey any license under its

patent rights or the rights of others.

© Copyright 2013 by ETS-Lindgren Inc. All Rights Reserved. No part of this

document maybe copied byany means without written permission from

ETS-Lindgren Inc.

Trademarks used in this document: The ETS-Lindgren logo and OMS are

trademarks of ETS-Lindgren Inc.; NEMA is a registered trademark of NEMA;

3M and Scotch-Brite are trademarks of 3M.

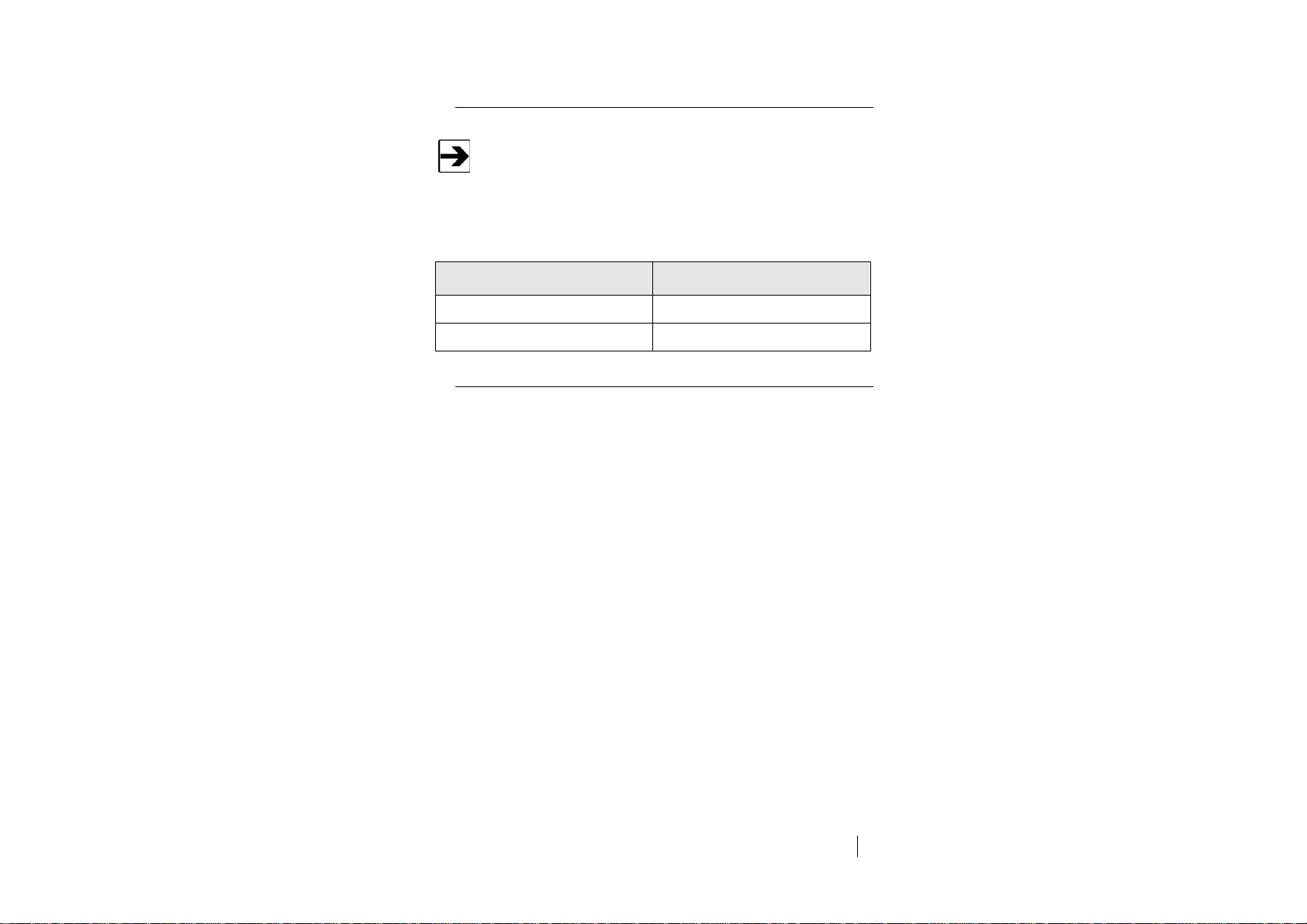

Revision Record

MANUAL,OXYGEN DEFICIENCY MONITOR | Part #399374, Rev. B

Revision

Description

Date

A

Initial Release

August, 2013

B

Updated Introduction; added

installation location information;

added Sample Draw Sensor

Tubing

December, 2013

www.fmgrupotec.com fmgrupotec@fmgrupotec.com 0034.903.360.306 Calle Algepser n16 Parque Empresarial Tactica- 46980 Paterna (Valencia)- España

Table of Contents

Notes, Cautions, and

Warnings..............................................vii

1.0

Introduction..........................................................................9

Technology................................................................................................. 9

Long-Life Zirconium Oxide Sensor Cell............................................... 9

Smart Electronics.............................................................................. 10

Standard Configuration............................................................................. 10

Optional Remote Display.......................................................................... 10

Other Optional Items................................................................................. 11

ETS-Lindgren Product Information Bulletin ............................................... 11

2.0

Maintenance ....................................................................... 13

Recommended Routine Maintenance....................................................... 14

Every 6-12 Months............................................................................ 14

Annually............................................................................................ 14

Replacement and Optional Parts .............................................................. 15

Service Procedures .................................................................................. 15

3.0

Specifications..................................................................... 17

Electrical Specifications ............................................................................ 17

Physical Specifications ............................................................................. 17

Performance Specifications ...................................................................... 18

Gas Detection System Specifications........................................................ 18

Signal Outputs.......................................................................................... 19

Default Factory Settings............................................................................ 19

4.0 Component

Views

..............................................................21

Front View Exterior................................................................................... 21

Front View, Cover Removed..................................................................... 23

Transmitter Interior ................................................................................... 25

Alarm Relay Board.................................................................................... 26

5.0 Before You Begin

Installation...........................................27

Site Requirements.................................................................................... 27

Connect to 24 VDC Regulated Power....................................................... 28

Connect OMS and Sensor Before Powering............................................. 28

www.fmgrupotec.com fmgrupotec@fmgrupotec.com 0034.903.360.306 Calle Algepser n16 Parque Empresarial Tactica- 46980 Paterna (Valencia)- España

Do Not Exchange the Sensor Electronics.................................................. 28

Use Proper Calibration Steps.................................................................... 28

Keep Away From Silicone Compounds..................................................... 29

Keep Away From High Air Flow ................................................................ 29

Keep Away From a Water Stream............................................................. 30

6.0

Installation..........................................................................

31

Mounting the OMS.................................................................................... 31

Transmitter and Sensor..................................................................... 32

Enclosure Mounting Feet .................................................................. 33

Dust Filter......................................................................................... 34

Sample Draw Sensor Tubing.................................................................... 35

Using an Available Waveguide.......................................................... 36

Using Kit 551060 to InstallWaveguide.............................................. 37

Wiring....................................................................................................... 39

Installing the Optional Remote Display...................................................... 40

Connecting a Remote Horn and Strobe to OMS........................................ 42

Connecting a Remote Fan Contactor to OMS........................................... 43

Initial Startup............................................................................................. 44

7.0

Operation ............................................................................

47

Joystick Operation.................................................................................... 47

Main Operation Mode ............................................................................... 48

Internal Sample Flow Rate........................................................................ 48

Signal Outputs.......................................................................................... 48

Instrument Faults...................................................................................... 49

Loss of Power Indicator ............................................................................ 50

Alarm Reset.............................................................................................. 50

8.0 Programming the

OMS

......................................................

51

Program Flowchart ................................................................................... 52

Passwords................................................................................................ 57

Enter Password ................................................................................ 57

Change Password............................................................................. 58

Enable/Disable Password Function................................................... 59

Main Menus and Submenus ..................................................................... 60

Set 4–20 mA Loop............................................................................ 60

www.fmgrupotec.com fmgrupotec@fmgrupotec.com 0034.903.360.306 Calle Algepser n16 Parque Empresarial Tactica- 46980 Paterna (Valencia)- España

Set Formats...................................................................................... 61

www.fmgrupotec.com fmgrupotec@fmgrupotec.com 0034.903.360.306 Calle Algepser n16 Parque Empresarial Tactica- 46980 Paterna (Valencia)- España

Set Alarm Threshold Parity............................................................... 63

Set Latching...................................................................................... 65

Reset Latching Alarm........................................................................ 66

Set Alarm Delay................................................................................ 67

Set Zero Suppression....................................................................... 67

Set Alarm Thresholds ....................................................................... 68

Set Alarm Hysteresis ........................................................................ 70

Set Sensor Adjust............................................................................. 72

9.0 Sensor

Verification ............................................................

73

Required Gas and Equipment................................................................... 74

Sensor Verification Procedure .................................................................. 74

Sensor Verification to Nitrogen.................................................................. 75

Sensor Verification to Known Concentration of Oxygen ............................ 76

Appendix A:

Warranty.............................................................

77

www.fmgrupotec.com fmgrupotec@fmgrupotec.com 0034.903.360.306 Calle Algepser n16 Parque Empresarial Tactica- 46980 Paterna (Valencia)- España

This page intentionally left blank.

vii

www.ets-lindgren.com

Notes, Cautions, and Warnings

Note: Denotes helpful information intended to

provide tips for better use of the product.

Caution: Denotes a hazard. Failure to follow

instructions could result in minor personal injury

and/or property damage. Included text gives proper

procedures.

Warning: Denotes a hazard. Failure to follow

instructions could result in SEVERE personal injury

and/or property damage. Included text gives proper

procedures.

See the ETS-Lindgren Product Information Bulletin for safety,

regulatory, and other product marking information.

This page intentionally left blank.

1.0 Introduction

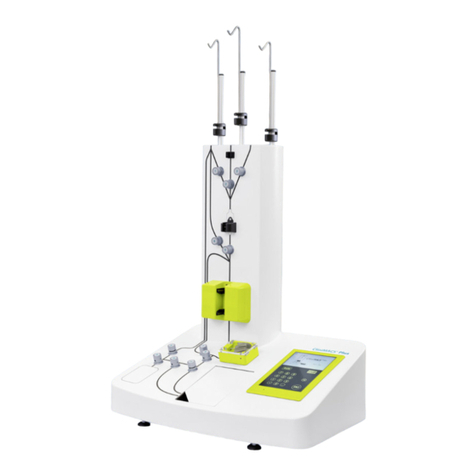

The ETS-Lindgren Sample Draw Oxygen Monitoring System (OMS™) is a

self-contained oxygen deficiency detection system suitable for remote sampling

of confined spaces; this single-point monitor is designed for the continuous

detection and measurement of ambient oxygen concentration levels.

As a compact gas monitoring system, the OMS is ideal for the continuous

monitoring of the air in MRI rooms, labs, freezers, confined spaces, and other

shielded enclosures where inert gases may displace the oxygen and create a

danger for patients and staff. The OMS is suitable for indoor and outdoor use,

and is intended to be installed outside of the shielded enclosure.

Each system consists of a long-life zirconium oxide sensor cell and 3-wire

transmitter. Unlike electrochemical sensor cells, the zirconium oxide sensor cell

provides stable oxygen readings even in areas where temperature and humidity

levels are changing. The OMS may be used as a standalone gas detector or

connected to your own centralized control and surveillance system.

Technology

L

ONG

-L

IFE

Z

IRCONIUM

O

XIDE

S

ENSOR

C

ELL

The heart of the monitoring system is a zirconium sensor, which responds to low

oxygen conditions within seconds and provides accurate measurements over a

wide temperature and humidity range. The zirconium sensor will operate

continuously for eight or more years, requiring minimum maintenance. There are

no zero or span calibration pots to adjust, and when compared to disposable

sensors, the long-life zirconium sensor can save hundreds of dollars in annual

maintenance.

Unlike concentration cells, the zirconium sensor does not need an oxygen

reference gas for proper operation. The OMS can detect low oxygen levels in

confined spaces and process tools without the need of a reference gas.

S

MART

E

LECTRONICS

The OMS incorporates a special electronic circuit that continuously monitors

sensor operation.With the addition of the alarm relay option, any cell degradation

or complete failure will be detected immediately. This smart circuitry alerts the

user to sensor faults and other electrical problems that may interrupt surveillance

through the standard mA signal output signal or through the optional fault relay

option.

Ideal for continuously monitoring oxygen levels in confined spaces or areas

where inert gases are used, the OMS does not drift or lose sensitivity with

weather or temperature changes. The electronics are housed in a

NEMA Type 4X enclosure.

Standard Configuration

The OMS must be installed outside of the shielded enclosure.

•Oxygen Monitoring System

•Power supply

•Dust filter

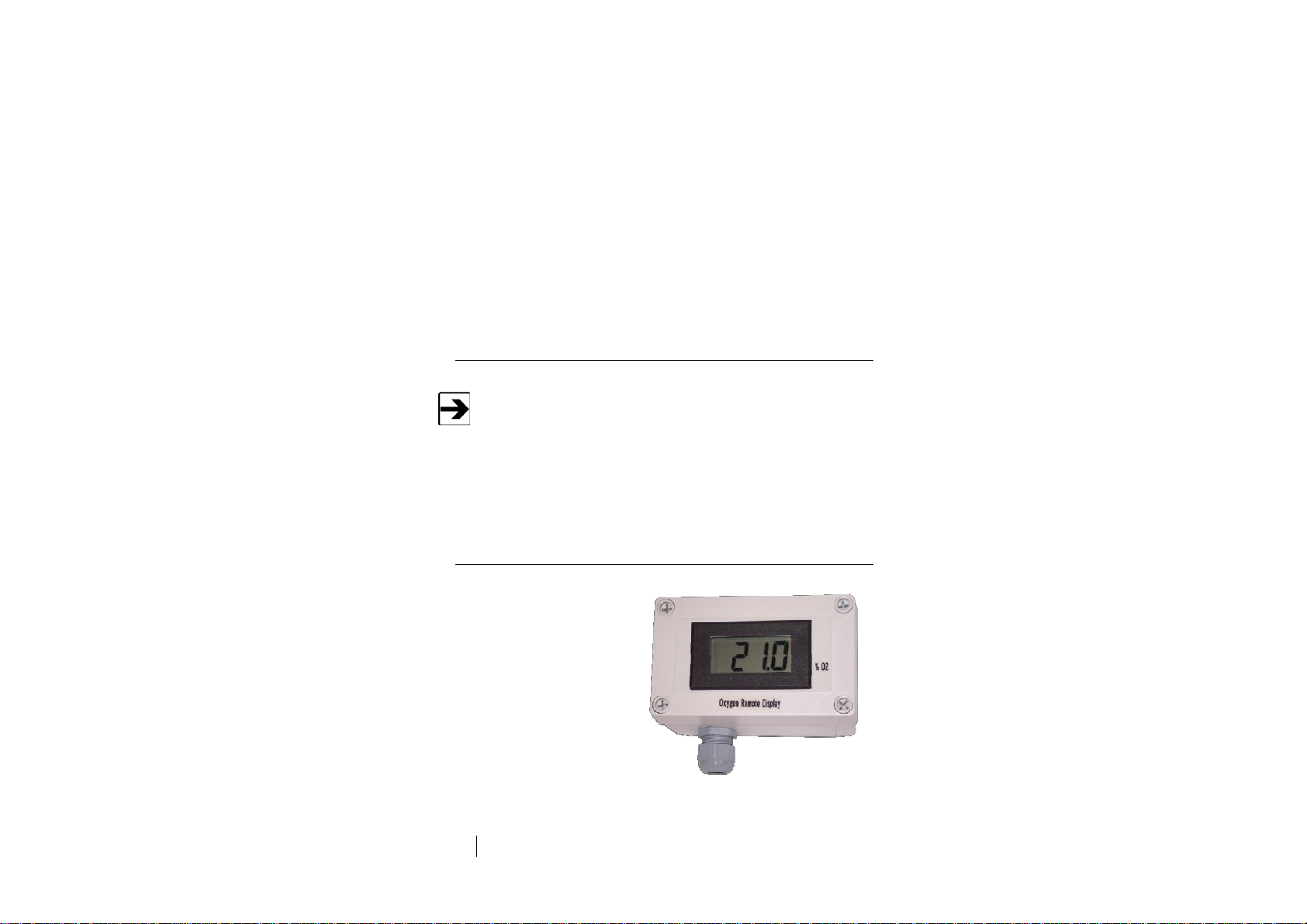

Optional Remote Display

The remote display receives oxygen

concentration information from

the OMS. Up to two remote displays

can be connected. See page 40 for

installation information.

Other Optional Items

•Remote Horn and Strobe

•Waveguide Installation Kit

ETS-Lindgren Product Information Bulletin

See the ETS-Lindgren Product Information Bulletin included with your shipment

for the following:

•Warranty information

•Safety, regulatory, and other product marking information

•Steps to receive your shipment

•Steps to return a component for service

•ETS-Lindgren calibration service

•ETS-Lindgren contact information

This page intentionally left blank.

13

2.0 Maintenance

WARRANTY

Calibrate or challenge the OMS ONLY outside

the MRI suite.

Before performing anymaintenance, follow the

safetyinformation in the ETS-Lindgren

Product Information Bulletin included with your

shipment.

Maintenance of the OMS is limited to the

procedures described in this manual, and

should be performed onlyby qualified

personnel.

Warranty may be void if non-authorized

procedures are performed, or if performed by

non-qualified personnel.

If you have any questions concerning

maintenance, contact ETS-Lindgren

Customer Service.

14

Maintenance

Recommended Routine Maintenance

The Sample Draw Oxygen Monitoring System (OMS™) is a continuous gas

detection system that measures and detects hazardous gas leaks in the

workplace, and therefore requires periodic maintenance to ensure proper

operation. The frequency with which this routine maintenance is performed

depends on your environment and company policies. Following are

recommendations intended as a general guideline.

E

VERY

6-12 M

ONTHS

•Visual checks: Check for power and proper operation. The OMS

should output a 17.34 mA signal when the oxygen level is at 20.9%.

Also, the display should indicate 20.9% oxygen when the oxygen is at

ambient levels.

•Sensor verification with nitrogen: The ambient oxygen level is

20.9%; therefore, under ambient conditions verification of the OMS to

20.9% oxygen is constantly performed. The OMS requires periodic

testing with nitrogen only to verify the cell response to low oxygen

levels. See Sensor Verification on page 73 for detailed steps.

A

NNUALLY

Depending on the environment, the filter should be replaced every 12 months; in

dusty environments, the filter may need to be replaced more frequently. If the

filter becomes completely blocked, the internal flow sensor will detect the loss of

flow and activate the fault relay and LED.

15

Replacement and Optional Parts

ETS-Lindgren may substitute a similar part or new part number with

the same functionality for another part/part number. Contact

ETS-Lindgren for questions about part numbers and ordering parts.

Following are the part numbers for ordering replacement or optional parts for

the OMS.

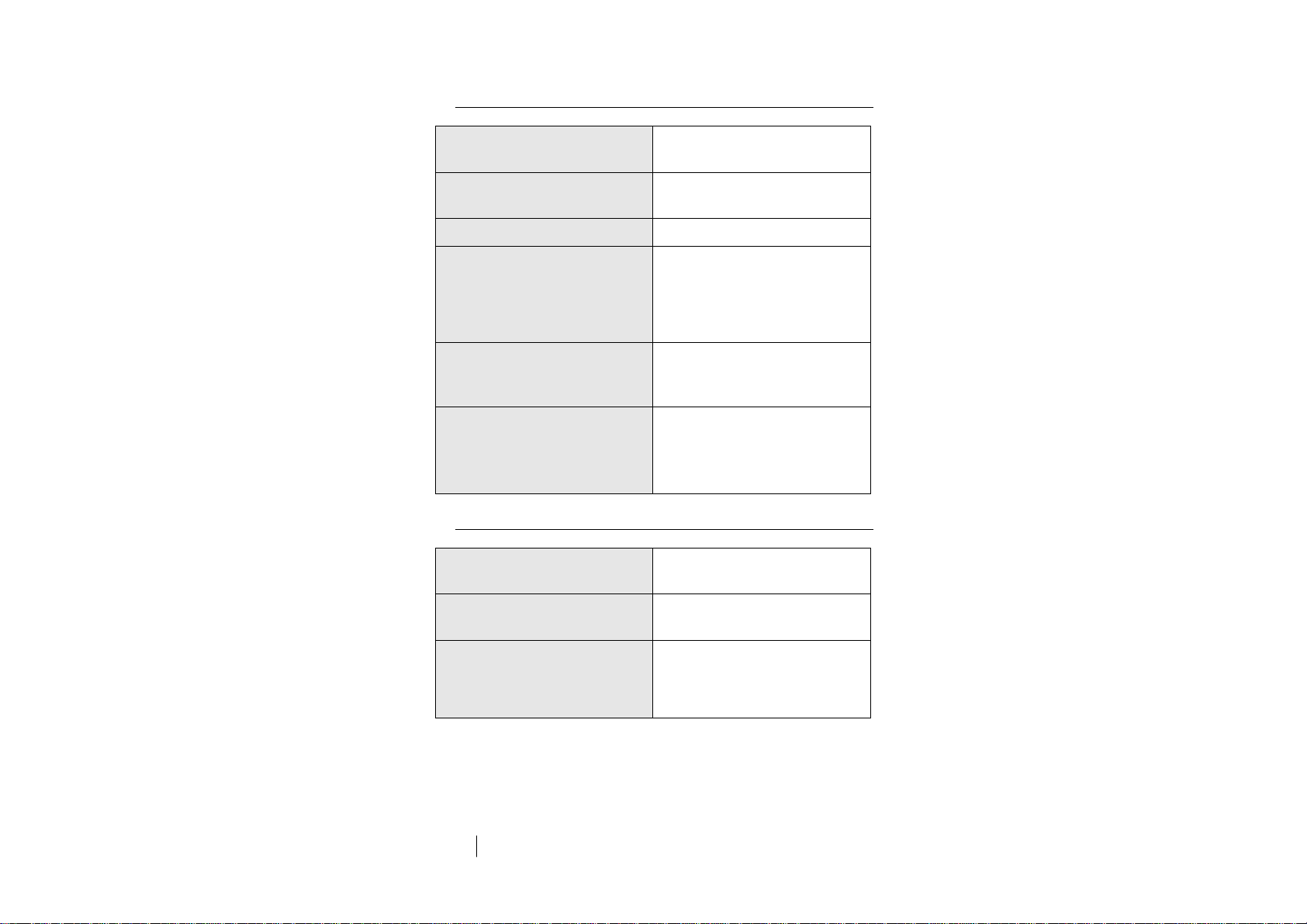

Part Description

Part Number

Optional Remote Display

250552

Filter Replacement

250551

Service Procedures

For the steps to return a system or system component to ETS-Lindgren for

service, see the Product Information Bulletin included with your shipment.

16

Maintenance

This page intentionally left blank.

17

3.0 Specifications

Electrical Specifications

A regulated 24 VDC power supply is required.

Power:

24 VDC external power

Consumption:

Approximately 700 mA

Physical Specifications

Height:

7.0 in (178 mm)

Width:

5.0 in (127 mm)

Depth:

5.0 in (127 mm)

Weight:

4.0 lb (2 kg)

Enclosure Type:

NEMA Type 4X wall mount general

purpose; not intended for explosive

atmospheres or

electrically-classified areas

18

Specifications

Performance Specifications

Sensor Type:

Long-life zirconium oxide

sensor cell, 0%–25%

Response Time:

Within 2 seconds of any change in

oxygen

Repeatability:

± 2% of reading

Fault Indicators:

•Loss of VDC power

(analog signal drops to 0 mA).

•Sensor cell failure: fault relay

activated

Operating Temperature:

-40°C to + 40°C (40°F to 104°F)

Contact ETS-Lindgren for lower or

higher operating temperatures

Humidity:

0% to 95% relative humidity (RH)

Contact ETS-Lindgren for sensors

which can operate in 100%

condensing RH environments

Gas Detection System Specifications

Type:

Long-life zirconium oxide

sensor cell, 0%–25%

Sensor Life:

8 to10 years, under normal

conditions

Transmitter:

•Microprocessor electronics with

built-in 3-digit backlit LCD display

•Joystick-operated menus

Other manuals for OMS

1

Table of contents

Popular Laboratory Equipment manuals by other brands

Hanil

Hanil Ultra 5.0 quick guide

Thermo Scientific

Thermo Scientific STANDARD Series manual

Swan Analytical Instruments

Swan Analytical Instruments AMI Turbiwell Operator's manual

Miltenyi Biotec

Miltenyi Biotec CliniMACS Plus System user manual

Thermo Scientific

Thermo Scientific HyPerforma 5.1 S.U.B. Hardware Integrator Guide

Thermo Scientific

Thermo Scientific Medifuge Instructions for use

Thermo Scientific

Thermo Scientific STANDARD Series instructions

Beckman Coulter

Beckman Coulter JA-25.50 Instructions for use

seward

seward STOMACHER 3500 Series Service and maintenance manual

LW Scientific

LW Scientific BVC-4k16-CMT3 instruction manual

Radleys

Radleys Carousel 12 Plus instructions

Parata

Parata Mini Customer guide