OPERATION

POWER TROWELS ST62L

ELECTRIC MOTOR

ST 62L -9- JUNE. 2005

ENGLISH

Operating the trowel

NOTE

Always operate the trowel using the Dead Man Control Handle.

Assembly of the float disc

1. Place the trowel on to the float disc.

2. Rotate the blades so that the blades move

underneath the 4 L shaped brackets.

3. Rotate the blade adjustment knob so that

the blades rise.

4. Ensure that there is sufficient pressure on

the blades and that the disc is tightly

attached to the trowel.

NOTE

The trowel is to be used only by experienced operators and they must have the

knowledge of when the concrete is ready to be troweled and the angle of the

blades.

These instructions should be used as general guidance only.

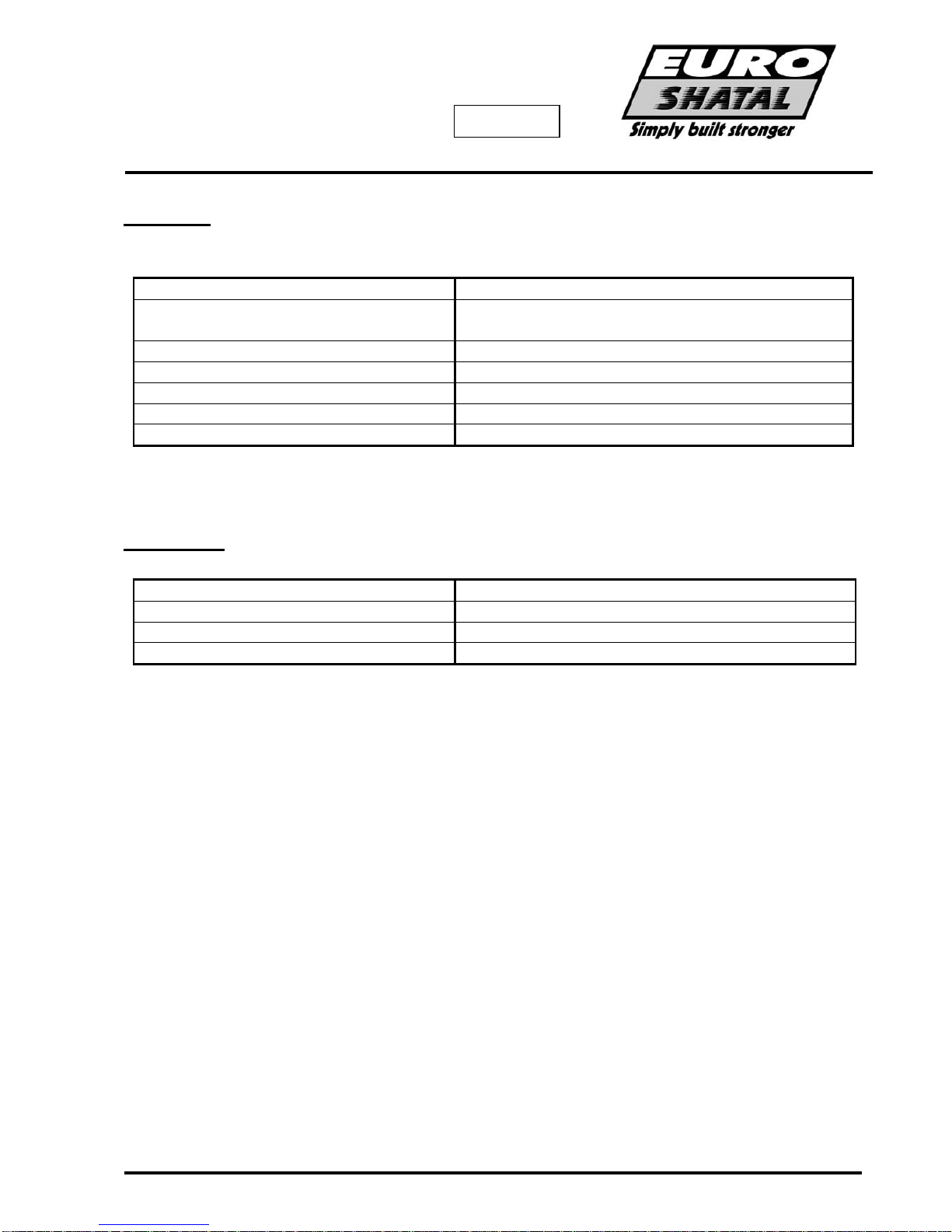

Ref. B = Working condition of concrete C = Suggested working pitch

1 Wet surface working stage Flat (no pitch)

2 Wet to plastic working stage Slight pitch (5º)

3 Plastic working stage Additional pitch (10º)

4 Semi-hard working stage to hard finishing stage

(burnishing) Maximum pitch (15º)

Floating concrete

Use the float disc or the blades set at a small angle for floating.

The concrete should be sufficiently set before the floating operation takes place.

This must be determined by the operator.

To have the machine move to the right bear down slightly on the handle. Lift

gently on the handle to have machine move to the left.

Do not operate machine in one spot but keep it moving over the surface for

eitherfloating or finishing of concrete. If machine is allowed to stand in one spot

while not operating , lift up on the handle to break loose the suction on the trowels

and move to a new spot before starting to operate the machine.

Finishing concrete

The finishing operation is carried out with the blades set at a large angle.