MANUAL

PARALLEL SLIDE RAIL SYSTEM EG-PV

2

These instructi ns f r use must be presented t the building site pers nnel.

1. General purp se f use

Extremely solid slide-rail system with a pipe culvert height of up to 1.80 m. When the system is used as di-

rected, the shoring can be performed with the occurrence of virtually no settling.

2. Specificati ns EG PV 400

Max. pipe culvert height: 1,800 mm

Rail length: 4,000 mm

Rail weight: 4 4 kg

Slide weight: 1 7 kg

Extension weight: L= 00 29.2 kg

L=1000 0. kg

L=1 00 71.8 kg

L=2000 93.1 kg

Max. bending moment: 210.3 kNm

3. Safety regulati ns

We refer to the fact that the above shoring system is only for the intended use and may only be assmebled,

installed, dismantled and unmounted in the sequence listed under points 4 - 7, exclusively with the use

of all relevant ”original construction elements”.

The shoring panels used are slide-rail panels of the KRA/KRI VS 100 type (plate thickness 10 mm) and

A/KRI VS 120 (plate thickness 12 mm). If this is not observed, the manufacturer’s liability and warranty

are invalid. Observe the load-bearing capacity of the shoring elements.

N te:

All of the requirements of BG-Bau (the professional association) as well as DIN 4124 ”Excavations and

trenches, embankments, workroom widths, shoring” are applicable. In the event of conditions deviating

from the standard conditions, construction site statics must be prepared.

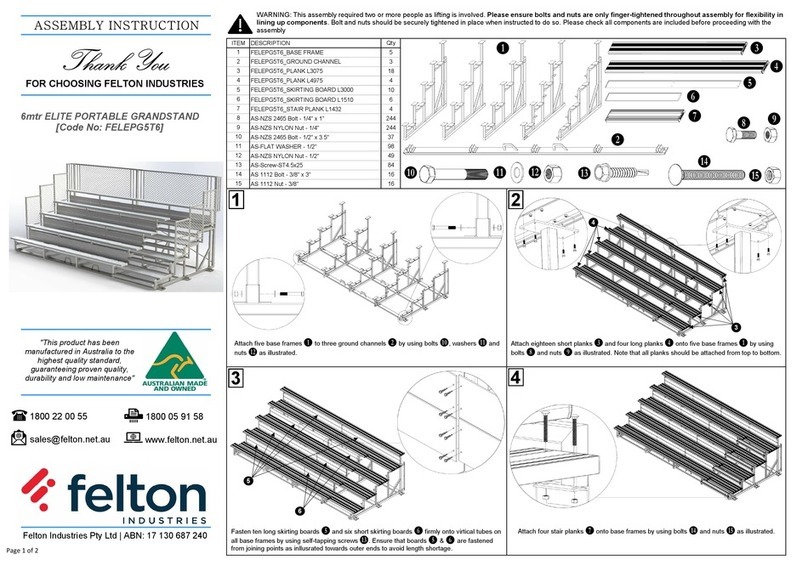

4. Assembly:

Sufficiently tighten the sliding frame consisting of

two slides, and the extension beams required for

the trench width, according to Fig. 2, with screws

DIN 6914 M24x8 -10.9 HV, nuts DIN 69 1 M24-10

and discs DIN 6916. All screw connections must be

checked after each dismantling of the shoring ele-

ments and retightened if necessary. The screw

tightening torque is 7 0 Nm and the width across

flats of the HV screws is 41 mm. Thread the sliding

frame according to Fig. 2 into the guide with the

rail lying flat. Only an appropriate lifting device

may be used. Existing lifting eyes must be used.

After threading, insert the securing bolts into the

corresponding apertures pos. 2 and pos. 7 in the

rail and secure them by rotating 180°. Then thread

a second rail into the sliding frame using the lif-

ting eyes on the back of the rail and secure with

bolts in pos. 2 and pos. 7 as described above. After

erecting the rails, check the securing effectiveness

of the bolts.

WARNING

Image 2

Trench shoring equipment

Production - Sales - Rental - Service

Snug bolts in

Pos. 7 secure by

rotating 180°

Snug bolts in

Pos. 2 secure by

rotating 180°