Euroboor ADG.2S User manual

1

WARRANTY AND SERVICE

We (the manufacturers) warrant all products we sell to be free from defects in materials

and workmanship for a period of 360 days from the original purchase date. This warranty

does not apply to effects due directly or indirectly to abuse, misuse, negligence, normal

wear and tear down or improper maintenance, nor shall it apply to any product that has

been repaired or altered outside of our facilities. Should any product fail to provide

satisfactory service, call your distributor for return authorization but to be accompanied

with proof of purchase and an explanation for

the return.

We make no other warranty, expressed and/or implied. We shall in no event be liable for

death, injuries to persons or property, or for incidental, consequential, indirect or special

damages of any nature arising from the sale or use of the products, excepting only the cost

or expense of repair and replacement as describedabove.

This warranty gives the customer specific legal lights. Other legal rights may vary from state

to state.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

HOW TO GET SERVICE

The product or part must be returned to the distributor or sales agent for examination. You

must provide proof of initial purchase date and an explanation of the complaint must

accompany the merchandise. If our inspection discloses a defect, we will repair or replace

the product, or refund the purchase price, at our option. We will return the repaired

product or replacement at our expense unless it is determined by us that there is no

defect, or that the defect resulted from causes not within the scope of our warranty in

which case we will, at your direction, dispose of or return the product. In the event you

choose to have the product returned, you will be responsible for the shipping and handling

costs for the return.

SAFETY INFORMATION

Please read and understand this entire manual before attempting to assemble , operate

or install the product. If you have any questions regarding the product, please contact

the distributor or sales agent.

&WARNINGS

IMPROPER OPERATION OR MAINTENANCE OF THIS PRODUCT COULD

RESULTINSERIOUS INJURY ANDPROPERTY DAMAGE. READ ANDUNDERSTAND ALL WARNINGS AND

OPERATION

INSTRUCTIONS BEFOREUSINGTHISEQUIPMENT. WHEN USING AIR TOOLS, BASIC SAFETY

PRECAUTIONS SHOULD ALWAYS BE FOLLOWED TO REDUCE THE RISK OF PERSONAL INJURY.

2

!RISKOFEYE OR HEAD INJURY

WHAT COULD HAPPEN

HOW TO PREVENT IT

•

Airpoweredequipmentandpowertoolsarecapable of

propelling materials such asfasteners, metal

chips,sawdust andotherdebrisathighspeedwhich

could result in serious eye injury.

•

AlwayswearANSIapprovedZ87.1safetyglasses with

side shields.

•Never leave operating tool unattached. Disconnect

air

hose when tool is not in use.

•

Compressed air canbehazardous. Theair system

cancauseinjurytosoft tissue areassuchaseyes, ears,

etc. Particles or objects propelled by the stream can

cause injury.

•

Foradditionalprotectionuseanapprovedfaceshield

in addition to safety glasses.

•

Toolattachments canbecomelooseorbreakandfly

apart propelling articles at the operator and others

in the work area.

•

Make sure that any attachments are securely

assembled.

!RISK OF FIRE OR EXPLOSION

WHAT COULD HAPPEN

HOW TO PREVENT IT

•

Abrasive toolssuch as sanders and grinders,

rotatingtools suchasdrills,andimpacttoolssuch as

nailers, staplers, wrenches, hammers and

reciprocating saws are capable of generating

sparks,whichcouldresultinignitionofflammable

materials.

•

Never operate tools near flammable substances

such as gasoline, naphtha, cleaning solvents, etc.

•

Work inaclean,well-ventilatedareafreeof

combustible materials.

•

Never use oxygen, carbon dioxide orother bottled

gases as a power source for air tools.

•

Exceeding themaximum pressure rating oftoolsor

accessoriescouldcauseanexplosionresultingin

serious injury.

•

Use compressed air regulated to amaximum

pressure atorbelowtheratedpressureofany

attachments.

•

Neverconnect toanairsource thatiscapable of

exceeding 200 psi.

•

Always verify prior tousing the tools that the air

sourcehasbeenadjustedtotheratedairpressure

range.

!RISK OFLOSS OF HEARING

WHAT COULD HAPPEN

HOW TO PREVENT IT

•Long term exposure to noise produced from the

operationofairtoolscanlead topermanent hearing

•

Always wear ANSI S3.19 hearingprotection.

!

INHALATION

HAZARD

WHAT COULD HAPPEN

HOW TO PREVENT IT

•

Abrasive tools,suchasgrinders,sandersandcut-off

toolsgeneratedustandabrasivematerials,which can

be harmful to human lungs and respiratory system.

•

Always wearproperly fittingfacemask orrespirator

when using such tools.

° Some materials such as adhesives and tar contain

chemicalswhosevapourscouldcauseseriousinjury

with prolonged exposure.

•

Always work in aclean, dry, well-ventilated area.

3

!

RISKOFINJURY

WHAT COULD HAPPEN

HOWTO PREVENTIT

•

Atoolleftunattended, orwiththeairhoseattached,

canbe activatedbyunauthorizedpersonsleadingto

theirinjury orinjury to others.

•

Remove airhose when toolisnotinuseandstore

toolinsecure location away fromreach ofchildren.

and untrained users.

•

Airtoolscanpropelfasteners orothermaterials

throughout the workarea.

•Use only parts, fasteners andaccessories

recommendedbythemanufacturer.

•

Keep workareacleanandfreeofclutter.Keepchildren

and

othersawayfromtool whileitisinoperation.

•

Keep work area wellIit.

•

Awrench orakeythatisleft attached to arotating

part of the tooI increases the risk of personal injury.

•

Remove adjusting keysand wrenches before turning

the tool on.

•

Using inflator nozzles fordusterapplicationscan

cause serious injury.

•

DO NOT use inflator nozzles for duster applications.

•

Air tooIs canbecomeactivatedbyaccidentduring

maintenance or tooIchanges.

•

Remove air hose to lubricate or add grinding

attachments, sandingdiscs, drills,etc.to the tool.

•

Never carry the tool by hose.

•

Avoid

unintentional

.

starting.

Don't

carry

hook-up

tool

with

finger

.

on

trigger.

•

Only an authorized servicerepresentativeshoulddo

repair servicing.

•

Air tools can cause the workpiece to move upon

contact: leading to injury.

•

Use

damps

or

other

devices

.

to

prevent

movement.

•

Lossofcontrolofthetoolcanleadtoinjury toself

or others.

•

Never use tool while using drugsoralcohol.

•

Don’t overreach.Keepproperfooting and balance.

.• Keep handles dry, clean and free from oiI/grease.

•

Stayalert.Watchwhatyouaredoing,Use common

sense.Donotoperatetoolwhenyouare tired.

•

Poorquality,improper ordamaged toolssuchas

grinding

wheels,

.

chisels

,

sockets,

drills,

nailers,

staplers,

etc., can

fly apart during operation, propelling particles

throughout the work area causing serious injury.

•

Alwaysusetool attachment ratedforthespeedof

the power tool.

•

Never use tools, which have been dropped, impacted o

r

damaged byuse.

•

Use onlyimpactgrade sockets onanImpact wrench.

•

Donotapplyexcessiveforcetothetools;letthetool

perform thework.

•

Fastenerscouldricochetorbepropelledcausing

serious

injury

or

property

.

damage:

•

Neverpointdischarge oftoolatselforothers.

•

Donotpulltriggerunlesstoolcontactsafety deviceis

against work surface.

•

Never attempttodrivefastenersintohardsurfaces

such as steel, concrete, or tile.

•

Avoiddrivinga fastenerontopofanotherfastener.

•

Positiontool carefullysothatfasteners willbe

delivered to the proper location.

•

Improperly maintained toolsandaccessories can

cause serious injury.

•

Maintain the tool withcare.

•

Keep a cutting tool sharp and clean. A properly

maintained tool, with sharp cutting edges, reduces

the

risk of binding and is easier to control.

*There is a risk: of bursting if the tool is damaged.

•

Check for misalignment or binding of moving parts,

breakage of parts and any other condition that

affects

the

tool’s

operation.

If

damaged,

have

the

tool

serviced before using.

•

Useonlyaccessories.identifiedbythemanufacturer

to be used with specific tools.

•

Useofanaccessory notintended forusewiththe

specific tools increase the risk of injury to persons.

4

!

RISK OF ELECTRIC SHOCK

WHAT COULD HAPPEN

HOW TO PREVENT IT

•

Using air tools to attach electrical wiring can result in

electrocution or death.

•

Never use nail/staplers to attachelectrical wiring

while energized.

•This tool is not provided with an insulated gripping

surface. Contact with a "live" wire will also make

exposed metal parts of the tool "live" and can result

in electrocution or death.

•

Avoid body contact with grounded surfaces such as

pipes, radiators, ranges and refrigerators. There is

an increased risk of electric shock if your body is

grounded.

•

Fasteners coming in contact with hidden electrical

wiring could cause electrocution or death.

•

Thoroughly investigate the workpiece forpossible

hidden wiring before performing work.

!

RISK OF ENTANGLEMENT

WHAT COULD HAPPEN

HOW TO PREVENT IT

•TooIs which contain moving elements, or drive other

moving parts, such as grinding wheels, sockets, sanding

discs, etc., can become entangled in hair, clothing,

jewelry andotherloose objects, resulting in severe injury.

« Neverwear loose fitting clothes orapparelthat

contains loose straps or ties, etc., which could

become entangled inmoving parts ofthetools.

•

Remove any jewelry, watches, identifications,

bracelets,necklaces, etc.,whichmightbecome

caught by the tool.

•

Keep hands away from moving parts.Tie up orcover long

hair.

•

Always wear proper fittingclothingandothersafety

equipment when using the tool.

!

RISK OF CUT OR BURNS

WHAT COULD HAPPEN

HOW TO PREVENT IT

•TooIs that cut, shear, drill, staple, punch, chisel, etc.

are capable of causing serious injury.

•

Keep theworking part of the tool away from hands

and body.

•

Replace warning labels if they become obscured orremoved.

•

Do not use this tool for other than its intended use.

•

Excessive air pressure or too much free rotation will decrease the life of the

tool and may cause a hazardous situation.

•

Check air hosefor wear,and keep themaway from heatand sharp edges. Do not

carry the tool by the air hose.

•

Slip / trip/ fall isa major causeof serious injuryor even death.Be aware of

excess hose left on your walking way or on the working surface and be aware

of the whipping air hosetoo.

•

Continuous operation and bad

working

condition

will

injure hands. Once hand

numbs oraches, operator shall stop the toolfora while

for relaxing and

re-start the

work after recovery. Operator shall immediately see a doctor if

such a serious

symptom

occurs.

5

•

Keep

visitors

a safe

distance from the work

area. keep

children

away.

•

This product may contain one or more chemicals known to

cause cancer

and birth defects or other reproductive harm. Wash hands after handling.

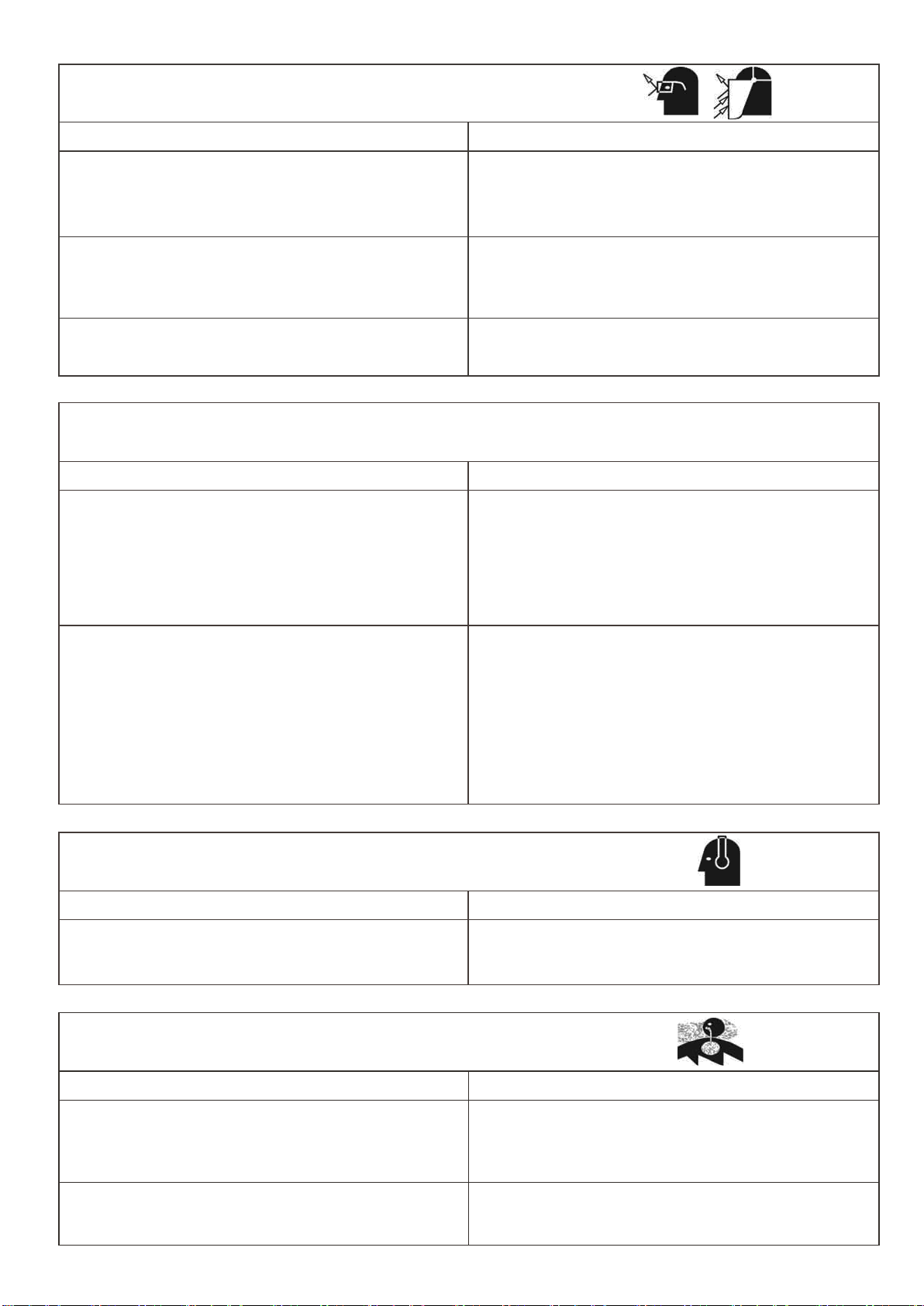

AIR SUPPLY

Please refer to the diagram below.

1.

Make surethat the aircompressor being usedfor the airtool operation supplies

the correct output (CFM).

2.

Have the tool in the “off” position when connecting the tool to the air supply.

3.

Use normal 90 psi (or ranging from 6.0 to 8.0 kg.) air pressure while running the tool.

High pressure and unclean air will shorten the tool’s life due to faster wear and also may

create a hazardous situation.

4.

Drain water from air compressor tank daily, as well asany condensation inthe air lines.

Water in the air line may enter the tool and damage the tool mechanisms at operation.

5.

Clean the air inlet filter cartridge weekly. The recommended hook-up procedure can be

viewed in the diagram below.

6.

Line pressure should be increased accordingly to make up for extra-long air hoses (usually

over 8meters). The minimum hose diameter should be 1/4”

I.

D. and the

fittings should have the same inside dimensions. But usually a 3/8” l.D. air hose is

recommended for air supply to get the best function of air tool operation.

7.

Use proper hoses and fittings. We do not suggest connecting quick change couplings

directly to the tool since they may ca use failure due to vibration. Instead, add a

leader hose and connect coupling between air supply and hose whip.

8.

Check hosesfor wear before individual use. Makecertain that allconnections are in

security.

SPECIFICATIONS

Item number......................................................................... ADG-2S

Capacity ................................................................................ 1/4 INCH (6 MM)

Free speed (unloaded speed) ............................................... 20,000 RPM

Average air consumption ...................................................... 5 SCFM

Working pressure ................................................................. 90 PSI (6.3 BAR)

Air inlet ................................................................................. 1/4 INCH

Air hose ................................................................................ 3/8 INCH (inside diameter)

Length x height ..................................................................... 6.81 x 2.36 INCH (173 x 68 MM)

Weight .................................................................................. 0.39 KGS (0.86 LBS)

PACKAGING CONTENTS

PREPARATION

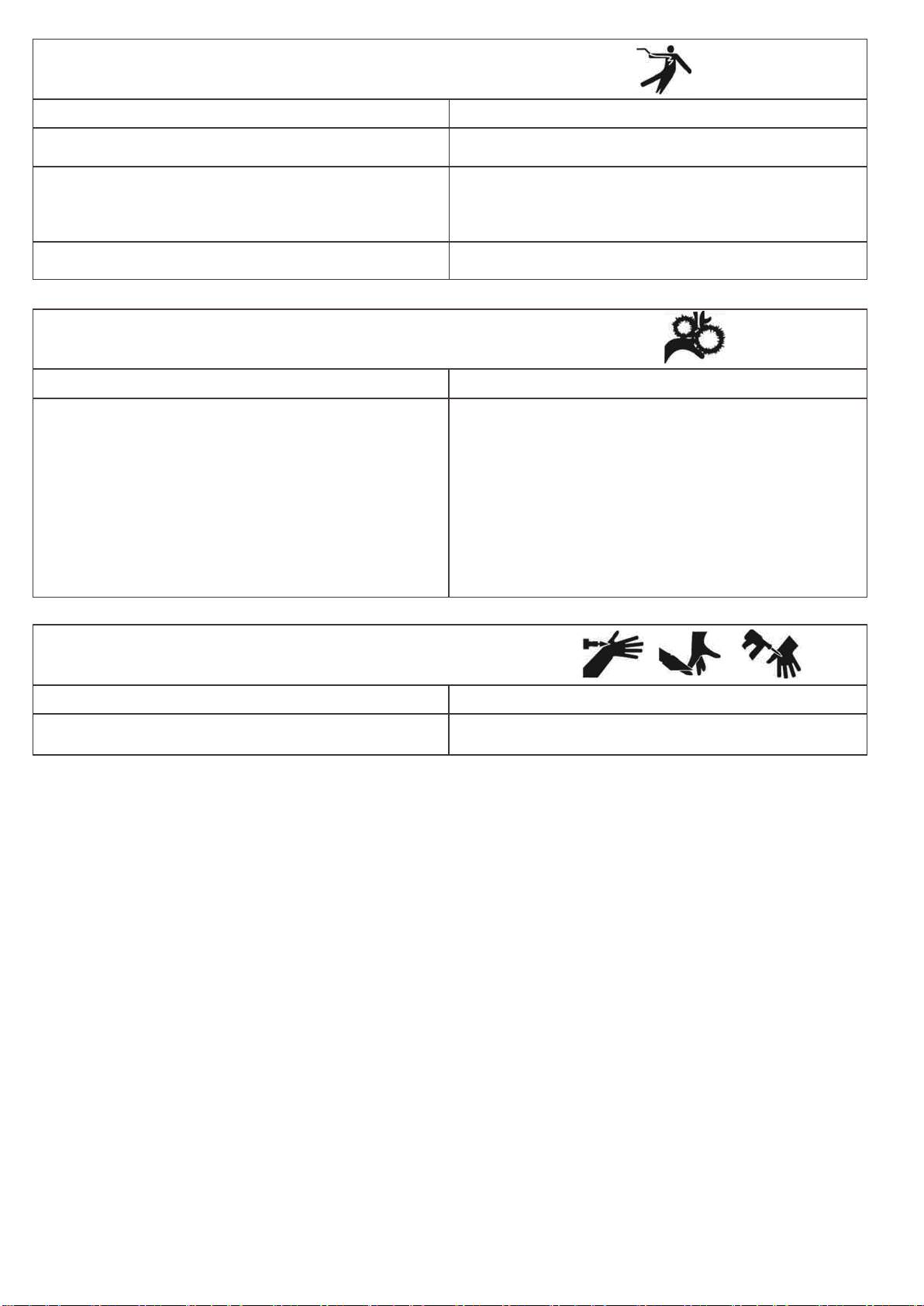

Figure 1

Before beginning assembly or operation of the product, make sure that all parts are

present. Compare the parts with the package contents list. If any part is missing or

damaged, do not attempt to assemble, install or operate the product. Contact the

distributor or sales agent for replacement.

OPERATING INSTRUCTIONS

1.

Lubricate thetool before operating. See “CARE AND

MAINTENANCE” section for oilinginstructions.

2.

Loosen the collet fixing cap (Part #31) counterclockwise with

one wrench while holding the other wrench on the flats of

the collet base (Part #27). (See Figure 1)

3.

Insert a grinding accessory like a grinding stone (not

provided) into the collet hole. (See Figure 2)

4.

Tighten the collet fixing cap clockwise with one wrench while

holding the other wrench on the flats of the collet base. Make

sure the collet fixing cap is securely tightened. (See Figure 3)

!

Only use grinding accessories that

have an RPM

rating equal to or greater than the

tool itself.

Figure 2

Figure 3

Description

Quantity

1/4" (6 mm) Mini Air Die Grinder

1

Wrench

2

Male Plug

1

Manual

1

7

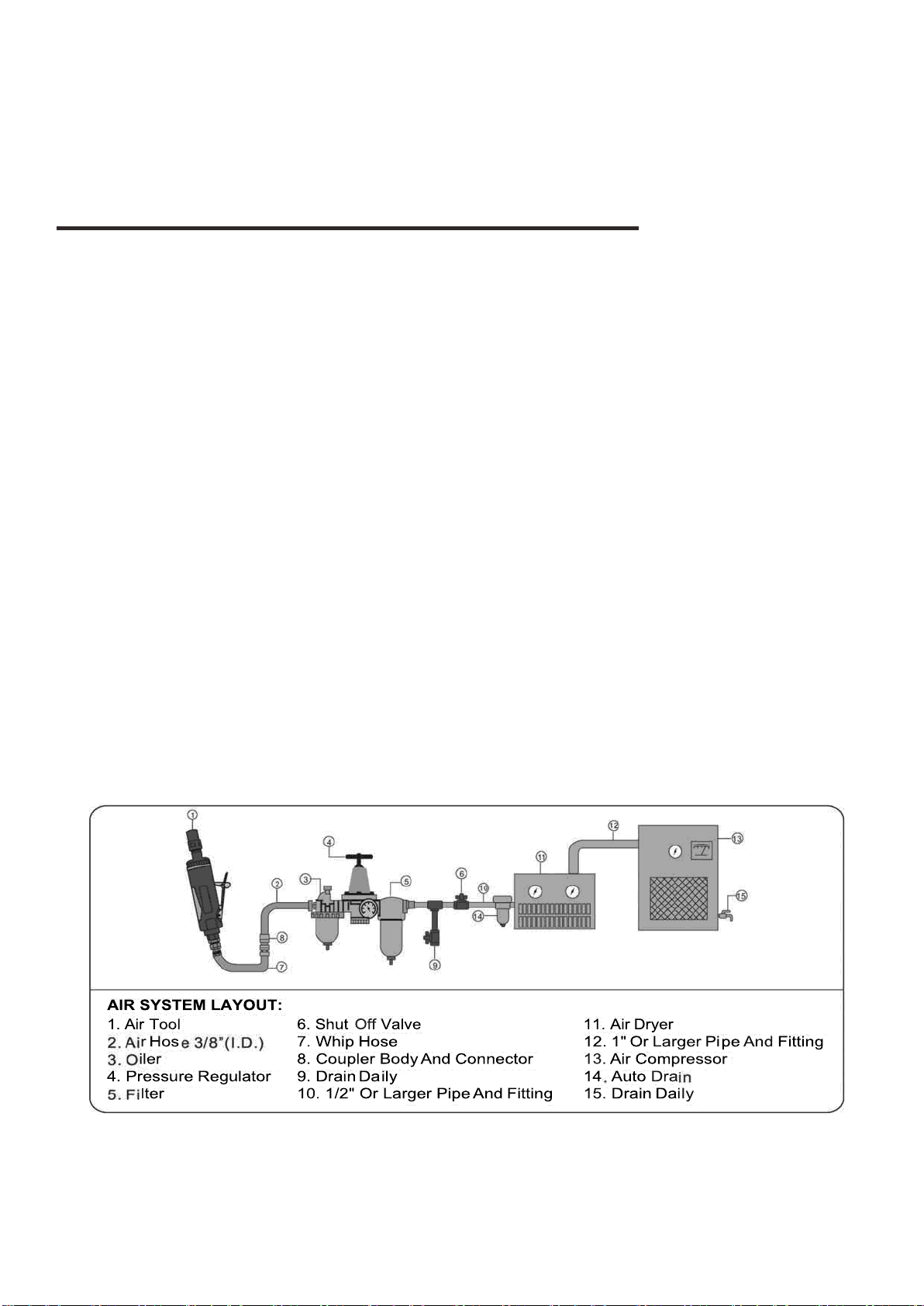

5.

Remove the air cap from the tool air inlet and connect the air

supply hose to the tool. Set the air pressure at 90 PSI.(See Figure

4)

6.

Push forward the lever block (Part #4)and press down on the

lever trigger (Part #3). How far the lever trigger is pressed

determines the tool rotation speed. Then the tool starts to

work. (See Figure 5)

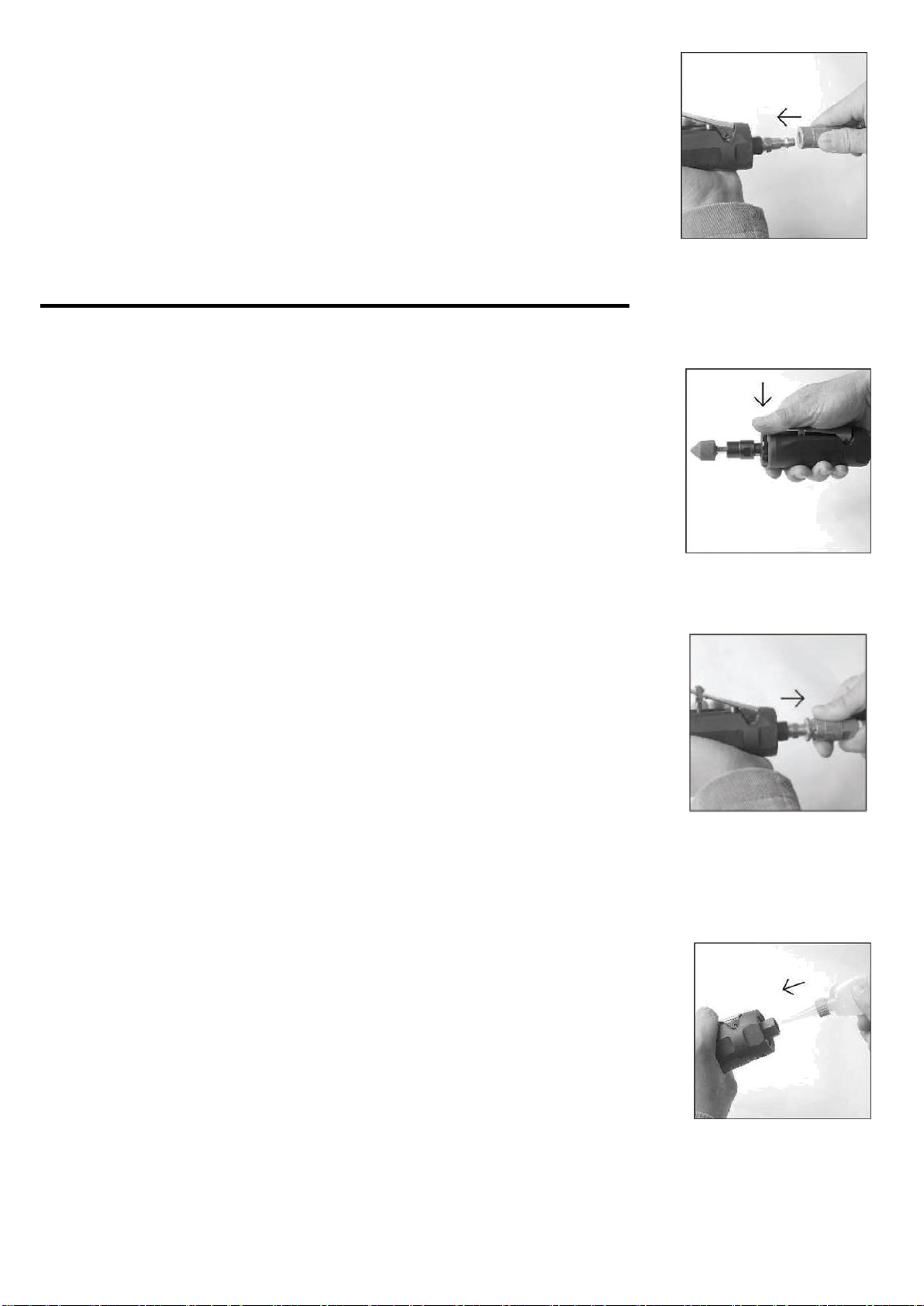

CARE AND MAINYENANCE

The tool shouldbe lubricated daily(or before eachuse) with air

tool oil (not included).

Air tool oil is available at major tool hardware stores. SAE

#10 weightoil or sewingmachine lubricant orany other

high grade turbine oil containing moisture absorbent,

rust inhibitors, metal wetting agents and an EP (extreme

pressure) additive may be used as a substitute. Do not

use detergent oil.

During continuous operation, the tool should be oiled

every 1 to 2 hours. This may be done using an in-line oiler,

or manually. If done manually, proceed as follows:

1.

Disconnect the tool from air supply. (See Figure 6)

2.

Place a few drops of air tool oil into the air inlet.

(See Figure 7)

Avoid the misuse of thicker oil which may lead to the reduced

performance or malfunction.

3.

Connect thetool to theair supply. Run thetool without load for

a fewseconds to distribute the oil through the tool.

Any excess oilmay be propelledfrom the exhaustarea. So

keep the tool away in a safedirection.

4.

After operating the tool and before storing the tool,

disconnect the airhose and place4 or 5drops of airtool oil into

the air inlet, then re-connect the air hose and run the tool to

evenly distribute the oil throughout the tool for 30 seconds

approximately. This will prolong thetool life.

5.

Avoid storing the tool in a humid environment which

promotes rusting of internal mechanisms. Always oil the tool

before storage.

6.

When thetool is seriously damaged or outof life, itshould be

left ina resource recyclingcan. Never dropit into fire.

Figure 4

Figure 5

Figure 6

Figure 7

8

TROUBLESHOOTING

Problem

Possible Cause

Corrective Action

Tool runs slowly

or will not

operate

1.

Grit orgum in tool.

2.

No oil in tool.

3.

Low airpressure.

4.

Air hose leaks.

5.

Pressure drops.

6.

Worn rotor blade.

7.

Moisture blowing out

of tool exhaust.

1.

Flush the tool with air-tool oil or gumsolvent.

2.

Lubricate the tool according to the lubrication

instructions in this manual.

3.

a. Adjust the regulator on the toolto maximum

setting.

b. Adjust the compressor regulator to tool

maximum of 90 PSIG.

4.

Tighten and seal hose fittings if leaks are found. Use

sealing tape.

5.

a. Besure the hose is the proper size. Long hose or

tools using large volumes of air may require ahose

with an

1.

D. of 1/2in. or largerdepending on the total

length of the hoses.

b. Do not use a multiple number of hoses

connec

ted together with quick-connect fittings.

This

causes additional pressure drops and reduces

the tool power. Directly connect the hoses

together.

6.

Replace rotor blade.

7.

Water in tank: drain tank. (See air compressor

manual). Oil tool and run until no water is evident. Oil

tool again and run 1-2 seconds.

Abnormal

vibration and/or

excessive heat

develops in

the tool.

Improper lubrication.

Follow proper lubrication procedures in this manual.

For any special troubles which cannot be settled down by the operator, contact the

distributor or sales agent from whom you purchase the tool.

9

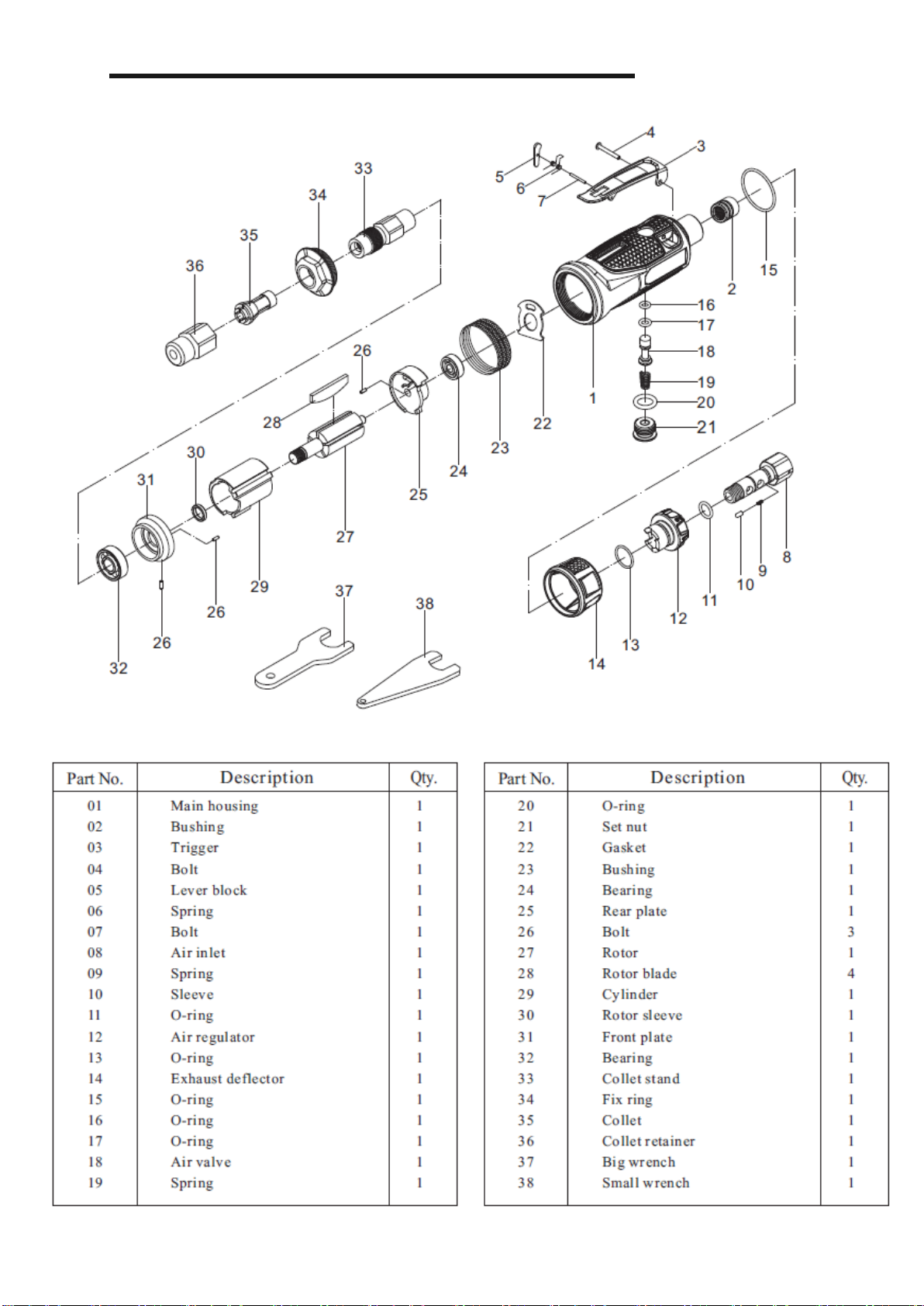

EXPLODED DIAGRAM AND PARTS LIST

10

•

Contact the distributor or sales agent from whom you purchase the tool for spare parts

ordering for any necessary replacement to get continuous use of tool and for extending

the toollife.

•

When ordering spare parts and components, give each part number and order

quantity.

Thank you.

Discover other pneumatic grinders on our website.

Table of contents

Other Euroboor Grinder manuals

Euroboor

Euroboor EDG.600 User manual

Euroboor

Euroboor AGR.2200/180 User manual

Euroboor

Euroboor ADG.2E User manual

Euroboor

Euroboor AGR.1200 User manual

Euroboor

Euroboor EDG.600 User manual

Euroboor

Euroboor ADG.2A User manual

Euroboor

Euroboor AGR.840 User manual

Euroboor

Euroboor AGR.1400 User manual

Euroboor

Euroboor ADG.2A User manual

Euroboor

Euroboor ERM.100/3 User manual