Euroboor ERM.100/3 User manual

User manual – version 1.0.2 EN

Serial no.: _______________________

Date of purchase: _______________________

Core drill grinding machine

ERM.100/3

1

TABLE OF CONTENTS

1. Product description 2

1.1 ntended use 2

1.2 Function description 2

1.3 Technical data 2

2. Safety instructions 3

2.1 Care obligation of customer 3

2.2 Explanation of the used safety signs 3

2.3 Basic safety measures 4

2.4 Operating staff requirements 4

2.5 Special types of dangers 4

3.1 Environmental preconditions for installing the machine 5

3.2 Remove the transportation locking screws 5

3.3 nstructions on disposal of packaging material 5

4. Start up 6

4.1 Controls before the first start up: 6

5. Operation 7

5.1. Description of the operating elements 7

5.2 Adjusting and installing the machine 7

5.2.1 Replacing the index plate 7

5.2.2 Aligning a core drill 9

5.3 Operating the machine 10

5.3.1 Grinding the core drill teeth 11

5.3.2 Grinding stretched surfaces 13

5.4 Replacing the grinding disk 15

6. Maintenance 16

6.1 Cleaning and lubrication 16

6.2 Repairs 16

7. Accessories 17

8. Warranty 18

2

1. Prod ct description

1.1 Intended se

The Euroboor core drill grinding machine ERM.100/3 is exclusively intended for grinding

core drills (annular cutters) of HSS-Co and TCT core drills.

The machine is not intended for any type of use other than the one specified here, and any

such use will be seen as improper. Safe operation of the machine cannot be guaranteed if

the core drill grinding machine is not used properly. n such cases, the customer will be

responsible for all damages to material or person.

Please read this operating instructions document carefully, particularly the safety

instructions.

1.2 F nction description

The core drill grinding machine can be used to sharpen the core drill in the simplest possible

manner. ts robust and precise construction, low power requirement and ergonomic design

enable instant operation. The machine was designed in such a way that anyone can

familiarize himself with the machine's operation in a short period of time, and core drills can

be sharpened with maximum precision. Adjustment and grinding are undertaken manually.

1.3 Technical data

Dimensions L X B X H 410mm x 412mm x 390mm (without optics)

410mm x 412mm x 460mm (with optics)

Net weight 29 kg

Power supply 230 Volts, 50 / 60 Hz

Motor 230 Volts, 0.12 kW, 2,800 rpm

Travel path Motor carriage

Guidance carriage

75mm

215mm

For cutter sizes Max. Ø 60 mm

Max. DoC 55 mm

Noise emission dBa <70

Grinding discs Ø 125 mm, hole Ø 10 mm

Standard:

ERM3.0001 CBN grinding disc (flutes)

ERM3.0002 SDC grinding disc (teeth)

Optional:

ERM3.0011 CBN grinding disc (flutes)

Cutter holder 19,05mm ( ¾” ) (Weldon shaft) standard

31,75mm (1 ¼”) (Weldon shaft) on request

(part number ERM3.0003)

Technical specifications subject to change without prior notice.

3

2. Safety instr ctions

2.1 Care obligation of c stomer

The core drill grinding machine ERM.100/3 was designed and produced after giving due

consideration to danger analysis and after careful analysis of appropriate harmonized

standards, as well as the further technical specifications. t conforms to the status of the

latest technology and guarantees maximum possible safety.

However, the specified safety level can only be achieved if the necessary measures are

taken during operation. The care obligation of the customer includes planning these

measures and controlling their execution.

The customer must especially ensure that:

-The machine is used properly according to the specification (please refer chapter 1.

Production description)

-The machine should only be operated in faultless and functionally sound condition.

n particular the safety devices are to be checked for proper functioning regularly

-These original instructions need to be available in full and legible condition at the

location where the machine is operated.

-Personnel handling the machine need to be provided with adequate instructions on

work safety and environment protection on a regular basis. The operator needs to

have read and understood the operating instructions document and the safety

measures defined in them in particular.

-All the safety and warning signboards near the machine are not to be removed and

are maintained in readable condition.

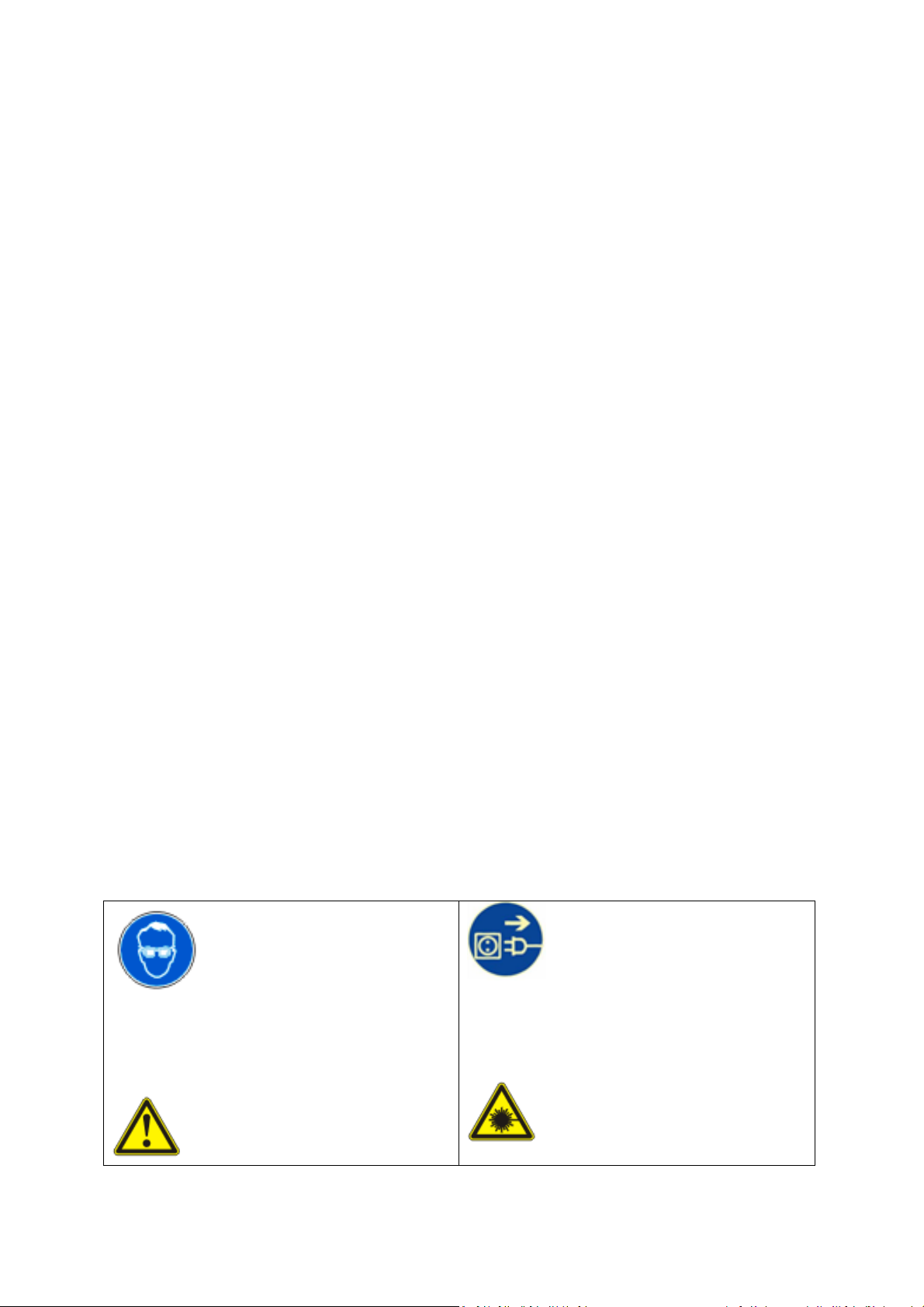

2.2 Explanation of the sed safety signs

The following safety signs have been used in the present operating instructions document:

These signs are supposed to attract the attention of the reader to the text of the adjacent

safety instruction. These signs indicate that there is danger to the life and health of persons.

Use eye protection

Protection to eyes against

flying particles during the

grinding process

General danger

Please pull the power plug

out before replacing the disk

or changing the location of

the machine

Danger of laser rays

4

2.3 Basic safety meas res

Use eye protection

Wear protective glasses without exception

while performing grinding jobs with the

ERM.100/3. Dust from the grinding

operation can damage your eyes seriously.

Remove the grinding disk protection only

while replacing the grinding disk. Otherwise,

the protection should always be there on

the machine. The ERM.100/3 has a laser

beam generating device. Eyes should never

be exposed to the laser rays, as they may be

damaged seriously. Avoid exposing the

optical system directly to sunrays to avoid

the danger of fire.

Please pull the power plug out of the mains

socket before replacing the grinding disk or

changing the location of the machine.

Laser protection clauses: The laser source

corresponds to the Laser Protection Class

according to D N EN60825-1/94. No

additional protection measures are

therefore necessary.

2.4 Operating staff req irements

The machine should be operated only by staff who have read this operating instructions

manual, and who observe them in practice.

2.5 Special types of dangers

You must perform the following activities before each start up:

-Check the machine for visual damages and repair any identified defects immediately

-The machine should only be operated in faultless condition

Check electrical fittings regularly:

-Reattach or tighten loose connections

-Ask an electrician to replace damaged wires or cables without any delay

- Never clean electrical fittings with water or similar liquids

Modifications to the machine:

-For security reasons, do not make any modifications in the machine on your own.

-Use only original spare parts consumables and accessories as they are designed

specifically for the machine.

5

3. Installation

3.1 Environmental preconditions for installing the machine

-Use the core drill grinding machine only in dry rooms.

-Ambient temperature should be between 5

o

C and 50

o

C (4

o

F - 122

o

F)

-Humidity should be lower 90%, no condensation allowed

-The core drill grinding machine is a table top machine.

Please ensure that the machine stands stable on a workbench.

The place must guarantee a vibration-free operation of the machine.

3.2 Remove the transportation locking screws

Transportation lock

After removing the packaging and installing the machine at the workplace, please remove

the transportation locking screws (refer to above image).

3.3 Instr ctions on disposal of packaging material

The carton packaging material can be recycled. The remaining packaging material must be

disposed of as garbage.

6

4. Start p

The following points must be observed and followed fully during start up, to avoid damage

to the machine and potentially fatal physical injuries to the human body.

-Before undertaking the first start up, please check that all auxiliary tools and external

parts have been removed from the machine.

-Check the direction of rotation of the motor before the start up

-Direction of rotation of grinding disk should always be downwards

-Please also read the chapter 2. Safety nstructions.

-Wear protective glasses

4.1 Controls before the first start p:

-Check electrical elements for damages

-Check that the guides run smoothly

-Check the fixed parts

7

5. Operation

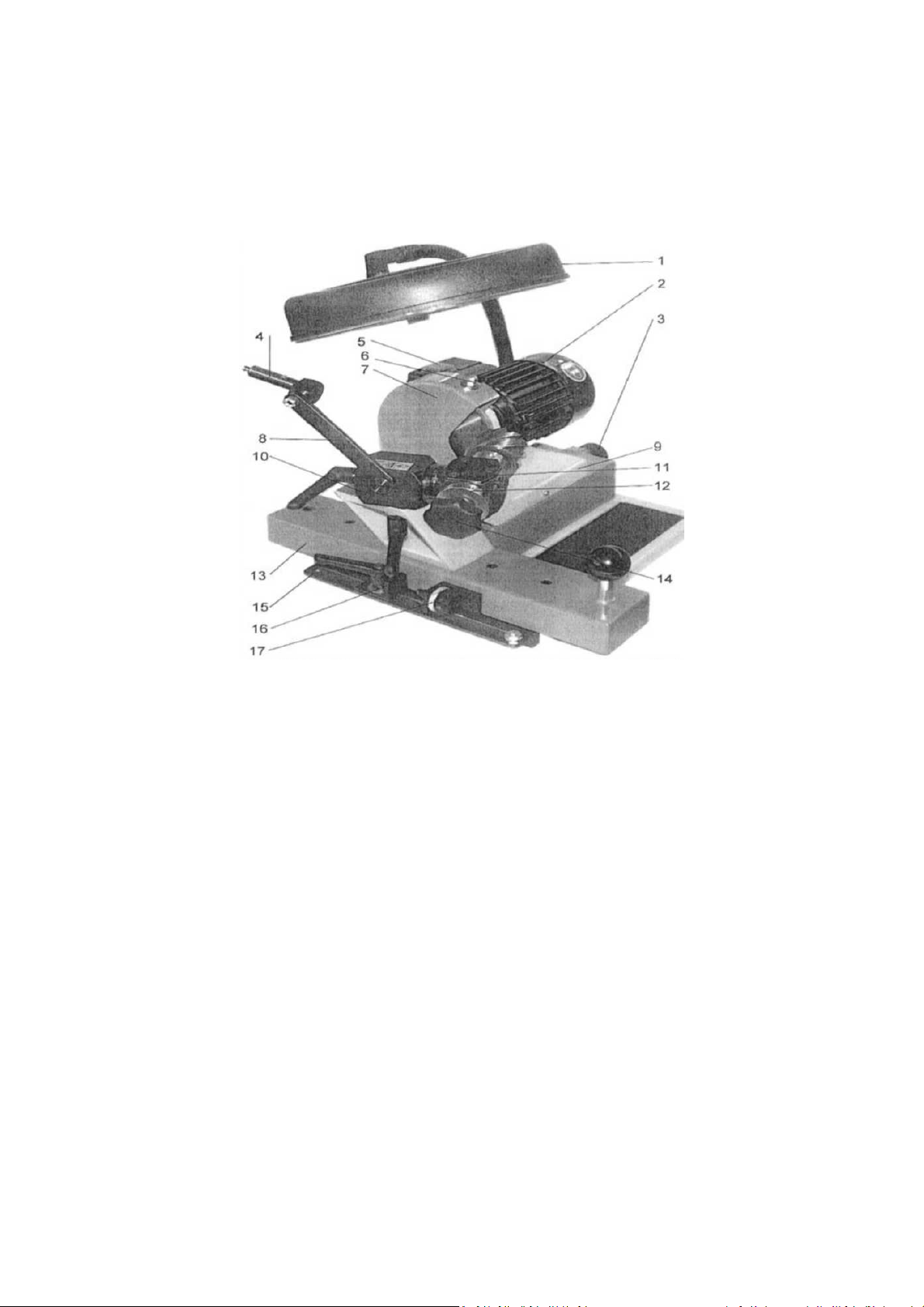

5.1. Description of the operating elements

1. Precision optics (optional) 10. Grinding head support

2. Motor 11. Core drill holder

3. Motor feed 12. Section disk

4. Laser source 13. Guidance carriage

5. Switch 14. Philips-head screw

6. Grinding disk protection fastening 15. Stop rail

7. Grinding disk protection 16. Quick adjusting angle

8. Laser guidance rod 17. Fine tuner

9. Motor angle

5.2 Adj sting and installing the machine

5.2.1 Replacing the index plate

The index plate of the core drill grinding machine determines the precision of the grinding of

core drills with various numbers of teeth.

As standard the machine is supplied including index plate 8/10 for use with cutters with 4, 5,

8 and 10 teeth. See chapter 7. Accessories for optionally available index plates.

8

Replacing the index plate

Select the appropriate index plate for your core drill. To replace the index plate turn the

knob in the clockwise direction until the grub screw in the index plate is facing upwards.

Tighten the edge screw (refer to Figure a). Turn the knob in anti-clockwise direction. Loosen

the grub screw (Allen key 2.5) and remove the index plate.

Inserting the index plate

Place the selected index plate on the shaft. Make sure one of the grooves on the side you

want to use is placed against the spring-loaded selector.

Tighten the grub screw lightly and turn the knob in the clockwise direction and tighten it.

Then fully tighten the grub screw on the index plate.

9

5.2.2 Aligning a core drill

While performing the adjustments, please note that the drill cutters are very

sharp and you can suffer physical injuries easily. Always wear safety gloves.

1) Set the core drill holder at 90 degrees.

2) Switch on the laser beam with the red button on top of the laser beam housing

3) Direct the laser beam with the help of the laser guidance rod to align it above one of

the teeth.

4) Rotate the core drill in the holder until the laser beam only just touches the tip of the

selected tooth.

5) MARK THE F RST AL GNED TOOTH

10

SPECIAL NOTE:

While adjusting the core drill in the holder, please ensure that the grub screw is not in

contact with a flat position of the Weldon shank of the cutter. To prevent the slightest of

unintended movement of the cutter the grub screw must lie on the rounding of the cutter

shank.

5.3 Operating the machine

Use eye protection

Always wear protective glasses while working with the Euroboor core drill grinding machine

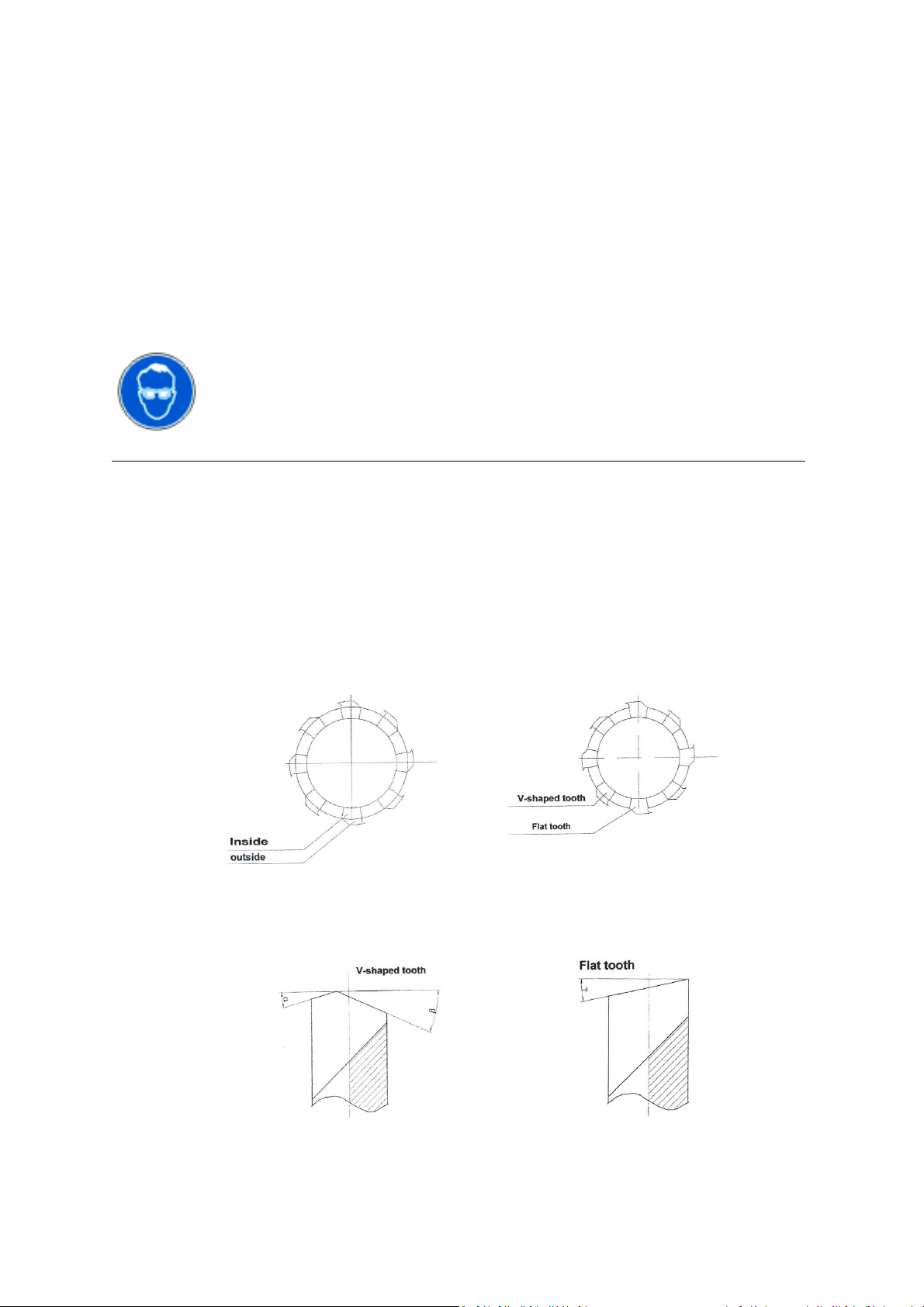

Core drills come in different variations. The variations with matching grinding order are:

1) Only V-shaped teeth

a. nner surface

b. Outer surface

2) Alternating flat & V-shaped teeth

a. nner surface V-shaped teeth

b. Outer surface V-shaped teeth

c. Flat teeth

11

5.3.1 Grinding the core drill teeth

Different manufacturers produce different variations of core drills with different diameters.

f you have the manufacturer provided grinding instructions of your core drill, use the data

specified in the document. f you do not have grinding instructions provided by the

manufacturer of your core drill, we recommend the following general base settings:

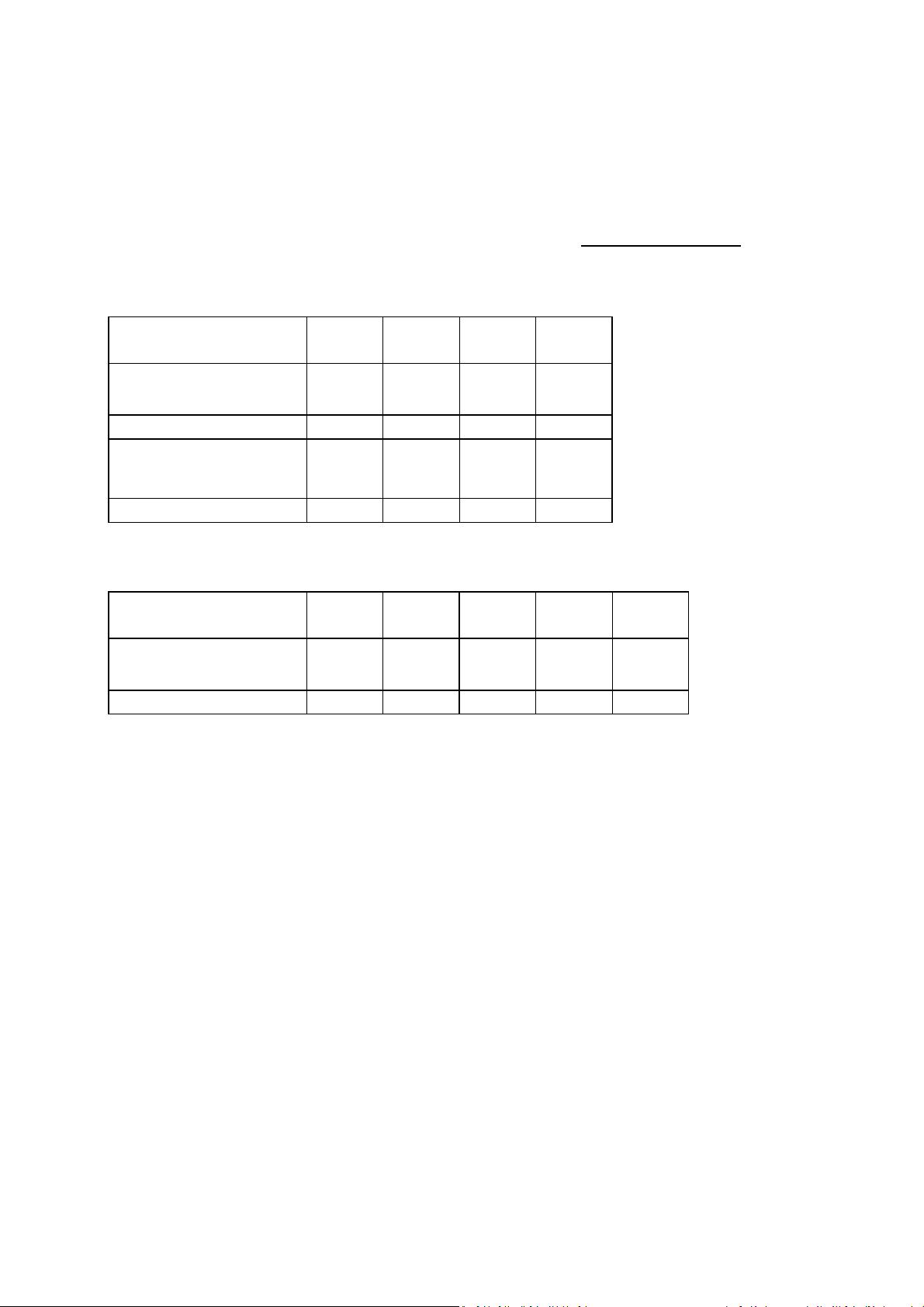

STANDARD CORE DRILLS

Shape of teeth Column

Scale

Column

Scale

Cutter

Holder

Cutter

Holder

V-Shaped teeth nside Outside nside Outside

All dividing disks 20° 7.5° 5° 22°

Flat teeth Column

Scale

Arbor

Holder

All dividing disks 6° 15°

TCT CORE DRILLS

Shape of teeth Cutter

Holder

Column

Scale

Column

Scale

Cutter

Holder

Cutter

Holder

Teeth Outside nside Outside nside Outside

All dividing disks 22° 20° 7.5° 7.5° 17.5°

FOLLOWING INSTRUCTIONS ARE SPECIFIED AS BASE GUIDELINE FOR STANDARD

EUROBOOR HSS ANNULAR CUTTERS. ALWAYS CHECK MEASUREMENTS AND ANGLES AND

FINE-TUNE WHEN NECESSARY.

FOR ALTERNATIVE CUTTERS, USE MANUFACTURER PROVIDED SPECIFICATIONS OR REVERT

TO THE SETTINGS PROVIDED ON THIS PAGE.

12

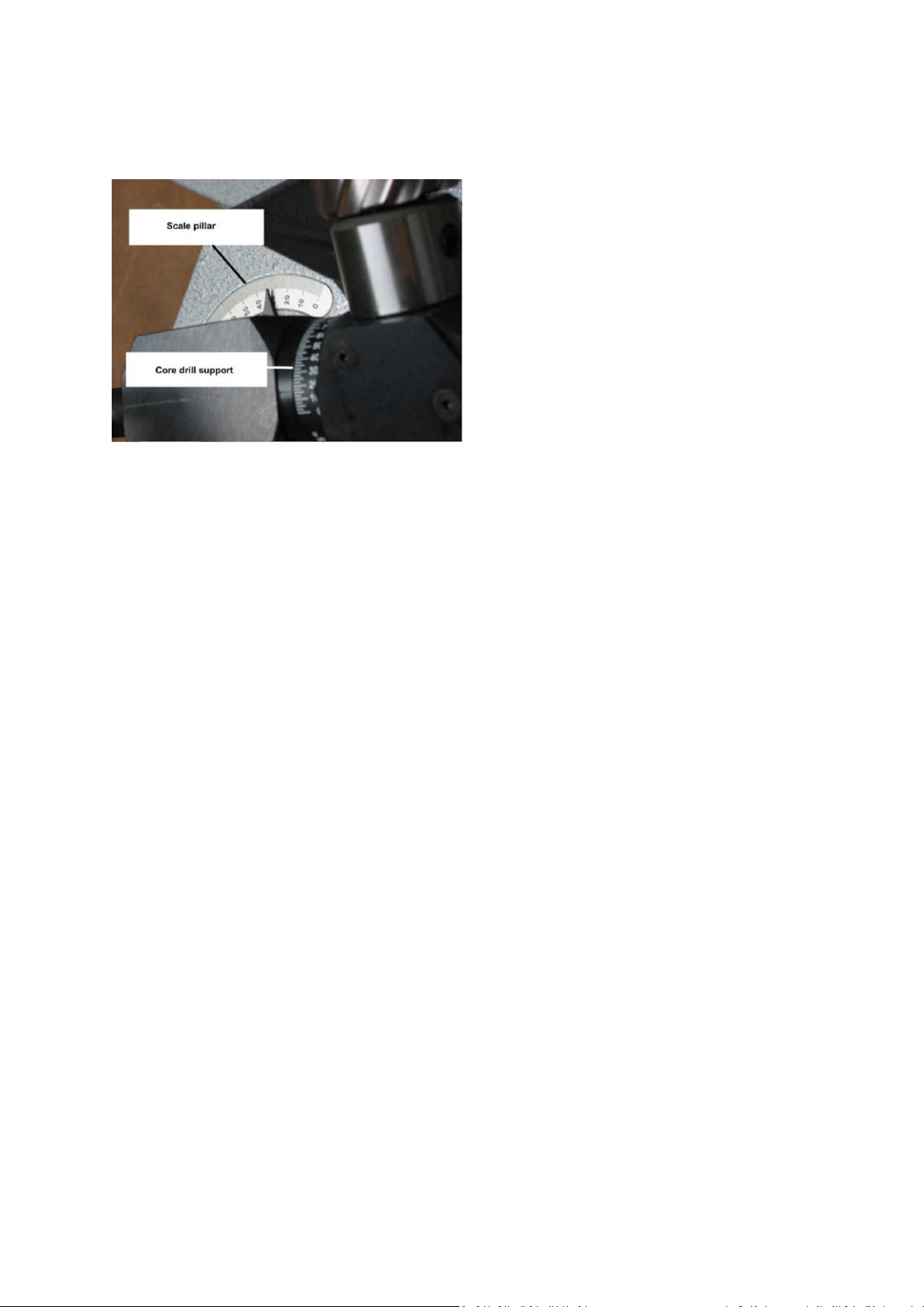

Grinding inner s rface

Mark the inner surface of the first tooth

Set the column scale to 27.5°

Set the cutter holder to 7.5°

1) After making these angular settings, move both the cutter holder slide towards the

grinding wheel, and grinding wheel towards the cutter.

SPECIAL NOTE

Grind the marked tooth as last. To start, first grind the next tooth.

2) Slide the core drill onto the stationary grinding disk and set its lateral stop on it (see

figure below). Fine-tune the setting by turning the adjusting screw of the stop in the

reverse direction till the next milling tooth is no longer in contact with the grinding

disk.

3) Now grind the outer free surface set by you by moving the guidance carriage to and

fro. The delivery from the motor feed should be low and it should remain constant

for all other cuts. This way you can ensure that the cuts remain at the same level.

4) After grinding the first cut, pull the guide carriage back and turn the star-shaped

screw head in the clockwise direction (direction of the arrow) till the next section is

reached. To position the next cut, do not change the motor feed. Repeat the grinding

operation till all the cuts have been ground.

13

Grinding o ter s rface

With the inside of the marked V-shaped tooth now ground, mark the outer surface of the

same tooth

Set the column scale to 17.5°

Set the cutter holder to 31°

Repeat steps 1 – 4 described under “Grinding inner surface”

5.3.2 Grinding stretched s rfaces

The use of Euroboor optional grinding disk ERM3.0011 (see also chapter 7. Accessories) is

recommended for grinding the stretched surfaces on standard Euroboor cutters.

For information on replacing the diamond disk, please refer to chapter 5.4 Replacing the

Grinding Disk.

14

Set the column scale to 50°

Set the cutter holder to 25°

SPECIAL NOTE

The value of this setting is not the same for all core drills.

1) Move the core drill along the grinding disk in stationary condition, and if necessary,

correct the angular setting (the angular setting can be in the 15 to 30 degree range).

2) After making the angular adjustments, bring the core drill with the guide carriage

and motor feed near the grinding disk. Grind the stretched surface with the radial

diamond disk provided for the purpose. Do not grind the tooth that was aligned

(marked tooth). nstead, grind the next stretched surface below it.

3) Move the core drill along the grinding disk in stationary condition until the stretched

surface touches the diamond disk. Set the lateral stop and the fine tuner in such a

way that the stretched surface can be ground.

4) Now grind the stretched surface set by you. Feed through the fine tuner should be

low, and it should be uniform for all the stretched surfaces. After grinding the first

stretched surface, pull the guidance carriage back and turn the knob in the clockwise

direction (direction of arrow) right up to the next section. You can position the next

stretched surface in this manner. Do not alter the motor feed and the fine tuner

position. Repeat the grinding process till all the stretched surfaces have been

ground.

15

5.4 Replacing the grinding disk

Always pull the plug out of the mains socket before replacing the grinding disk. No

core drill should be in the holder while replacing the grinding disk.

1) Unscrew the wing nut at the top

2) Remove the grinding disk cover

3) Loosen the nut bolt retaining the grinding disk with an Allen key and pull off the

grinding disk out of the motor shaft.

4) Assemble the appropriate grinding disk on the motor shaft. Make sure the grinding

wheel can rotate freely without touching any of the machine parts.

5) Fasten the retaining bolt

6) Reassemble the grinding disk cover on the machine

16

6. Maintenance

6.1 Cleaning and l brication

-The grinding dust in the core drill grinding machine must be cleaned at least once a

week with a soft brush

-Remove stubborn impurities with a usual commercial machine cleaner

-After cleaning, all moveable parts of the machine must be lubricated with a few

drops of machine oil

-To avoid corrosion of the blank parts, some oil should also be applied on these parts

and then a soft cloth should be used to wipe the oil off

-The motor carriages should be lubricated at least once in six months through the

lubricating nipples at the sides:

6.2 Repairs

For service and repair on assemblies like the grinding head or the guide carriage seek the

help of a specialized Euroboor repair point, to make sure the values and settings are

maintained or corrected.

17

7. Accessories

ERM3.0001 CBN Grinding wheel

ERM3.0002 SDC Grinding wheel

ERM3.0003 Cutter holder 31,75 mm (1 ¼”) Weldon

ERM3.0004 Lock wrench M8x15

ERM3.0005 Head support wrench M8x30

ERM3.0006 Laser beam generator

ERM3.0007 Head support wrench M8x75

ERM3.0008 ndex plate 6/7

ERM3.0009 ndex plate 8/10

ERM3.0010 ndex plate 9

ERM3.0011 CBN Grinding wheel (stretched surfaces)

18

8. Warranty

Euroboor warranty on ERM.100/3 covers material defects and manufacturing mistakes.

Wear and tear parts conditioned by operation, lack of maintenance, improper use of the

machine and damages caused by the use of force are excluded from warranty.

For additional details contact your point of sales.

Always provide the serial n mber of the machine when s bmitting for g arantee.

The machine can be returned only after obtaining prior approval from our side. We reserve

the right to charge transportation costs in case of unauthorized returns.

Other manuals for ERM.100/3

2

Other Euroboor Grinder manuals

Euroboor

Euroboor ADG.2S User manual

Euroboor

Euroboor ADG.2A User manual

Euroboor

Euroboor ADG.2A User manual

Euroboor

Euroboor AGR.1200 User manual

Euroboor

Euroboor EDG.600 User manual

Euroboor

Euroboor ADG.2E User manual

Euroboor

Euroboor AGR.840 User manual

Euroboor

Euroboor AGR.1400 User manual

Euroboor

Euroboor AGR.2200/180 User manual

Euroboor

Euroboor EDG.600 User manual