Euroboor AGR.1400 User manual

MANUAL

AGR.1400

Euroboor Angle Grinder

Euroboor Angle Grinder –AGR.1400

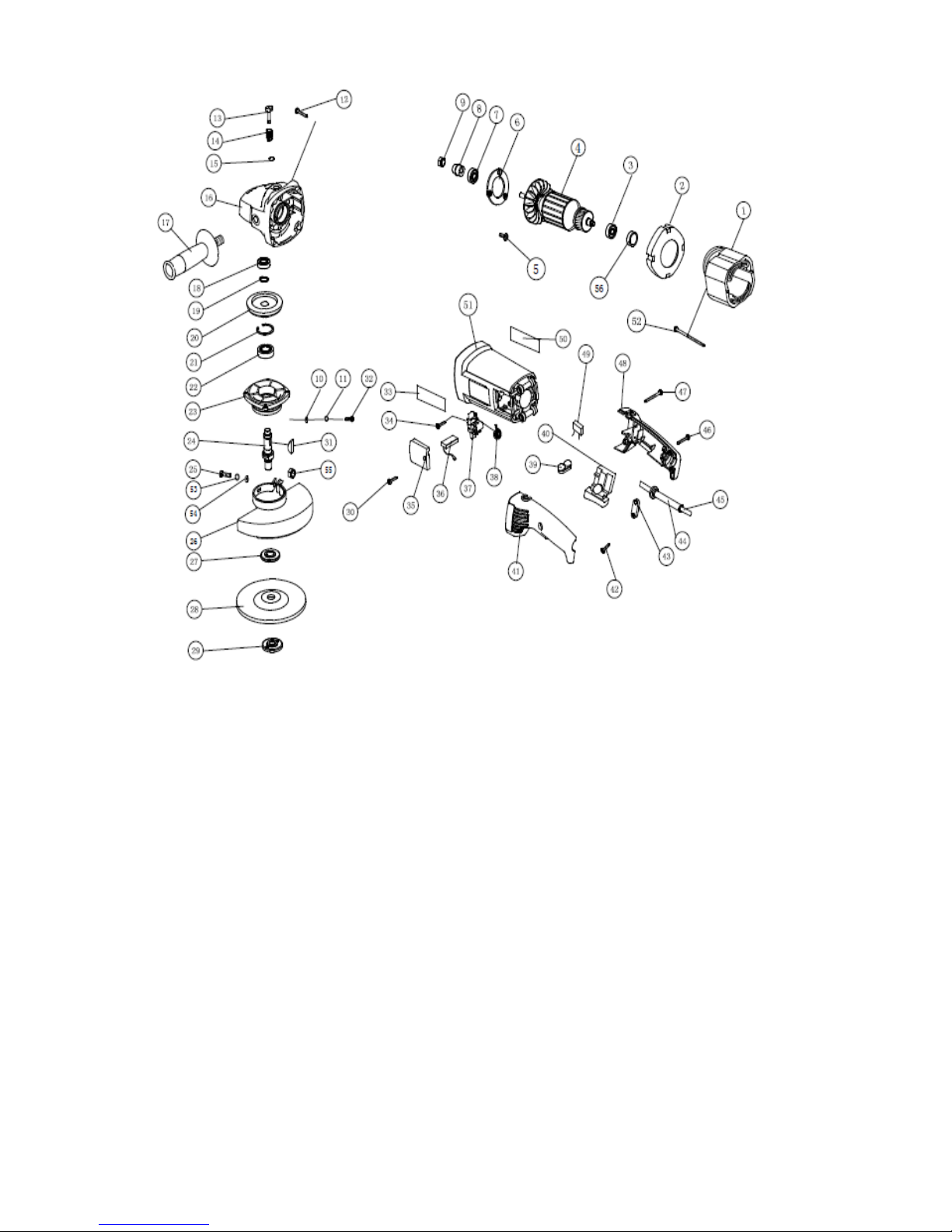

Overview

1. switch trigger

2. Drive shaft

3. Side handle

4. Gear box

5. Housing handle

6. Protective cover

7. Lock button

8. External flange spanner

9. External flange with thread

10. Internal flange

11.Lock off button

General Safety Instructions for Electric Tools

This device is exclusively for private use! It is not fit for commercial use!

WARNING! Read all instructions. Failure to follow all instructions listed below may result in electric shock, fire and/or serious injury :

SAVE THESE INSTRUCTIONS

1)Work area

• Keep work area clean and well lit. Cluttered and dark areas invite accidents

• Do not operate machines in explosive atmospheres, such as in the presence of flammable liquids, gases or dust. Machines create sparks

which may ignite the dust or fumes.

• Keep children and bystanders away while operating a machine. Distractions can cause you to lose control.

2)Electrical safety

• Machine plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs with earthed (grounded) machines.

Unmodified plugs and matching outlets will reduce risk of electric shock.

• Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges and refrigerators. There is an increased risk of electric

shock if your body is earthed or grounded.

• Do not expose machines to rain or wet conditions. Water entering a machine will increase the risk of electric shock.

•Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the machine. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

• When operating a machine outdoors, use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of

electric shock.

3)Personal safety

• Stay alert, Watch what you are doing and use common sense when operating a machine. Do not use a machine while you are tired or under

the influence of drugs, alcohol or medication. A moment of inattention while operating machines may result in serious personal injury.

• Use safety equipment. Always wear eye protection. Safety equipment such as dust mark, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

•Avoid accidental starting. Ensure the switch is in the off position before plugging in. Carrying machines with your finger on the switch or

plugging in machines that have the switch on invites accidents.

•Remove any adjusting key or wrench before turning the machine on. A wrench or a key left attached to a rotating part of the machine may

result in personal injury.

•Do not overreach. Keep proper footing and balance at all times. This enables better control of the machine in unexpected situations.

• Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves away from moving parts. Loose clothes, jewellery

or long hair can be caught in moving parts.

• If devices are provided for the connection of dust extraction and collection facilities, ensure these are connected and properly used. Use of

these devices can reduce dust related hazards.

4)Machine use and care

• Do not force the machine. Use the correct machine for your application. The correct machine will do the job better and safer at the rate for

which it was designed.

•Do not use the machine if the switch does not turn it on and off. Any machine that can not be controlled with the switch is dangerous and must

be repaired.

•Disconnect the plug from the power source before making any adjustments, changing accessories, or storing machines. Such preventive safety

measures reduce the risk of starting the machine accidentally.

• Store idle machines out of the reach children and do not allow persons unfamiliar with the machine or these instructions to operate the

machine. Machines are dangerous in the hands of untrained users.

• Maintain machines. Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the

machines operation. If damaged, have the machine repaired before use. Many accidents are caused by poorly maintained machines.

•Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting edges are less likely to bind and are easier to control.

• Use the machine, accessories and tool bits etc., in accordance with these

instructions and in the manner intended for the particular type of machine, taking into account the working conditions and the work to be

performed. Use of the machine for operations different from intended could result in a hazardous situation.

5)Service

• Have your machine serviced by a qualified repair person using only identical replacement parts. This will ensure that the safety of the machine

is maintained.

Safety warning specific for grinding operations:

1. use only wheel types that are recommended for your power tool and the specific guard designed for the selected wheel. Wheels for which

the power tool was not designed can not be adequately guarded and are unsafe.

2. the guard must be securely attached to the power tool and positioned for maximum safety, so the least amount of wheel is exposed

towards the operator. The guard helps to protect operator from broken wheel fragments and accidental contact with wheel.

3. wheels must be used only for recommended applications. For example: do not grind with the side of cut-off wheel. Abrasive cut-0off wheels

are intended for peripheral grinding, side forces applied to these wheels may cause them to shatter.

4. always use undamaged wheel flanges that are of correct size and shapes for your selected wheel. Proper wheel flanges support the wheel

thus reducing the possibility of wheel breakage. Flanges for cut-off wheels may be different from grinding wheel flanges.

5. do not use worn down wheels from larger power tools. Wheel intended for larger power tool is not suitable for the higher speed of a samller

tool and may brust.

Hearing protection

• In case of a sound pressure greater than 85.0 dB(A) wear hearing protection to avoid damage to your hearing!

Switch action

This model is safety switch, this means the switch can’t be locked on, and need two action to power on.

If you need power on, press the lock off button (11), then press the switch trigger (1). If you need power off, just release the switch trigger (1)

Mounting the Side Handle

During operation, keep one hand on the housing handle (5) and the other on the side handle (3). In order to mount the side handle, screw it into

the screw hole of the gear box (4).

Correct Fitting of the Protective Device

Ensure that the protective cover (6) is fitted correctly and that the fixing screws have been tightened! Before tightening the fixing screws, switch

off the machine and remove the mains plug!

Grinding and Surface Processing

In order to grind surfaces you should use a coarse abrasive disk with a sunken centre. You can use abrasive disks with diameter of 125mm. The

maximum thickness is 6mm.

Inserting the Wheels/Disks

Please proceed as follows when inserting the wheel/disk:

1. Before mounting, remove the mains plug from the socket release the switch trigger (1) to power off the tool ! Ensure that the protective

device is correctly installed.

2. Place the internal flange (10) on the drive shaft (2). Ensure that it is in contact with the two flat areas.

3. Now place the abrasive disk on the drive shaft (2) and the internal flange (10). Ensure that it is correctly in place.

4. Now attach the external flange with the thread (9), ensuring that it is facing the right direction according to the type of disk/wheel used. In the

case of abrasive disks, the flange (9) is inserted with the higher side pointing towards the disk. In the case of cutting off wheels, the flange (9)

is inserted with the flat side pointing towards the wheel.

5. Depress and hold the lock button (7) so that cannot turn and then tighten the external flange (9) with the external flange spanner (8).

Abrasive Disks

• Ensure that the speed to which the machine is set is sufficient for the accessories chosen.

• Use only abrasive disks with a diameter of 125 mm!

• Before mounting the disk, remove the mains plug from the socket and push the on and release the switch trigger (1) to power off the tool

1. Place the internal flange (10) on to the drive shaft (2).

2. Place the abrasive disk on the drive shaft (2) and ensure that it is correctly in place.

3. Attach the external flange with the thread (9) and tighten it as described above with the external flange spanner (8).

NOTE: Expect a "rain of sparks" when the disk comes into contact with metal. While grinding, always maintain the correct angle between the

disk and the working surface of 15°. This produces ideal results and avoids overloads.

NOTE: After operation, always switch off the tool and wait until the wheel has come to a complete stop before putting the tool down.

Overload

The motor of your right angle grinding machine may be damaged when overloaded. This results from excessive working pressure over a

prolonged period. Therefore you should not try to accelerate your working speed by increasing pressure on your machine. The abrasive disks

work more efficiently if only slight pressure is exerted on the grinding machine, thus avoiding a drop in the grinding speed.

Maintenance

• The protective cover, air slits and motor housing should be kept as free of dirt and dust as possible.

• Rub off the device with a clean cloth or use compressed air at a low pressure to blow out any dust or dirt. Excessive amounts of metal dust

may result in electricity from the internal components being conducted on to exposed metal parts!

• Do not subject the grinding machine to any overload! Overloading will lead to a reduction in the speed and performance and cause the

machine to overheat! If this should happen, switch the grinding machine off and let it cool down for approximately 30 minutes or to room

temperature!

NOTE: Turning off the grinding machine while it is being subjected to a load will reduce the working life of the operating switch!

Cleaning and Care

• Before cleaning the machine, remove the mains plug from the socket andrelease the switch trigger (1) to power off the tool

• For cleaning purposes, only use a slightly damp but not wet cloth!

• Do not use any abrasive additives (petrol, turpentine etc) as these may damage the plastic housing!

• A mild soap is suitable for cleaning the machine!

• Ensure that no moisture is allowed to get inside the machine!

• After cleaning, wipe the machine with a dry cloth!

EC Conformity Declaration

We hereby declare that the angle grinder AGR.1400 fulfils the requirements of directive: 2006/42/EC, 2006/95/EC, 2004/108/EC

This appliance conforms to the CE directives for radio interference suppression and low voltage safety and has been built to meet current safety

requirements. Subject to technical changes without prior notice!

Technical Data

Model

AGR.1400

Rated input

230V~50Hz

Rated power

1400W

No load speed

8500/min

Disc size:

125mm

Class of tool

回

Sound pressure level(Lpa)

89dB(A) K=3 dB(A)

Sound power level(Lwa)

100dB(A) K=3 dB(A)

Vibration

4.53m/s2K=1.5 m/s2

ENVIRONMENTAL PROTECTION

Waste electrical products should not be disposed of with household waste.

Please recycle where facilities exist.

Check with your local authority or retailer for recycling advice.

Table of contents

Other Euroboor Grinder manuals

Euroboor

Euroboor EDG.600 User manual

Euroboor

Euroboor ADG.2S User manual

Euroboor

Euroboor ADG.2A User manual

Euroboor

Euroboor EDG.600 User manual

Euroboor

Euroboor AGR.1200 User manual

Euroboor

Euroboor ERM.100/3 User manual

Euroboor

Euroboor AGR.840 User manual

Euroboor

Euroboor ADG.2A User manual

Euroboor

Euroboor ADG.2E User manual

Euroboor

Euroboor AGR.2200/180 User manual

Popular Grinder manuals by other brands

Meterk

Meterk S1M-GW20-115 Translation of the original instructions

U.S.SAWS

U.S.SAWS SX65000C operating manual

Parkside

Parkside PWS 230 C3 Translation of the original instructions

SUHNER ABRASIVE

SUHNER ABRASIVE ASC 9 Technical document

PTA

PTA P1322 Operation manual

Craftsman

Craftsman CMCG400 instruction manual