Eurocryor COMFORT MAXI Operating instructions

COMFORT

Refrigerated display unit

USER AND MAINTENANCE MANUAL

2

SAFETY WARNINGS

This symbol, affixed to the counter, indicates that it uses a flammable

refrigerant.

CAUTION: keep the ventilation openings in the appliance casing free from obstructions.

CAUTION: do not use mechanical devices or other means to accelerate the defrosting

process other than those recommended by the manufacturer.

CAUTION: do not damage the refrigerant circuit.

DO NOT STORE EXPLOSIVE SUBSTANCES SUCH AS PRESSURISED CONTAINERS WITH FLAMMABLE

PROPELLENT INSIDE THE DISPLAY UNIT.

It IS FORBIDDEN TO DISPLAY PHARMACEUTICAL PRODUCTS.

CAUTION: DO NOT USE ELECTRICAL APPLIANCES INSIDE THE COMPARTMENTS OF THE APPLIANCE

USED TO STORE FROZEN FOODS IF THESE ARE NOT OF THE TYPE RECOMMENDED BY THE

MANUFACTURER.

GUARDS OR PANELS WHICH REQUIRE THE USE OF TOOLS TO BE REMOVED MUST ONLY BE REMOVED

BY QUALIFIED PERSONNEL.

DO NOT PUSH OR DRAG THE APPLIANCE BY THE SIDES OR THE GLASS SURFACES.

DO NOT LEAVE THE APPLIANCE EXPOSED TO ATMOSPHERIC AGENTS.

NEVER USE DIRECT OR INDIRECT JETS OF WATER ON THE CABINET. DO NOT TOUCH THE APPLIANCE

WITH WET OR DAMP HANDS AND FEET. DO NOT USE THE APPLIANCE BAREFOOT.

THE APPLIANCE IS NOT INTENDED FOR USE BY PEOPLE (INCLUDING CHILDREN) WITH REDUCED

PHYSICAL, SENSORIAL OR MENTAL ABILITIES, OR WITH LACK OF EXPERIENCE OR KNOWLEDGE

UNLESS THEY HAVE BEEN SUPERVISED OR RECEIVED INSTRUCTIONS ON THE APPLIANCE FROM A

PERSON RESPONSIBLE FOR THEIR SAFETY. CHILDREN MUST BE SUPERVISED SO THEY DO NOT PLAY

WITH THE APPLIANCE.

ENSURE THAT THE POWER VOLTAGE CORRESPONDS TO THE RATING PLATE OF THE CABINET.

IT IS OBLIGATORY TO GROUND THE CABINET.

IT IS FORBIDDEN TO USE ADAPTER PLUGS.

THE OPERATIONS THAT INVOLVE THE COOLING CYCLE OR ELECTRICAL SYSTEM MUST BE

PERFORMED EXCLUSIVELY BY QUALIFIED STAFF AND BEFORE EACH ACTIVITY THE COUNTER MUST

BE UNPLUGGED FROM THE ELECTRICAL POWER SOCKET.

ANY OTHER USE NOT EXPLICITLY INDICATED IN THIS MANUAL IS CONSIDERED HAZARDOUS AND

THE MANUFACTURER CANNOT BE HELD LIABLE FOR ANY DAMAGE DERIVING FROM IMPROPER,

INCORRECT AND UNREASONABLE USE.

The manual is available in digital format from EPTA S.p.A. Local Unit of Solesino. Contact

+39.0429.707311 or send a request to the following e-mail:

sales@eurocryor.it

3

SEZIONI

/

SECTION /

DIMENSIONS

/

ABMESSUNGEN /

DIMENSIONES

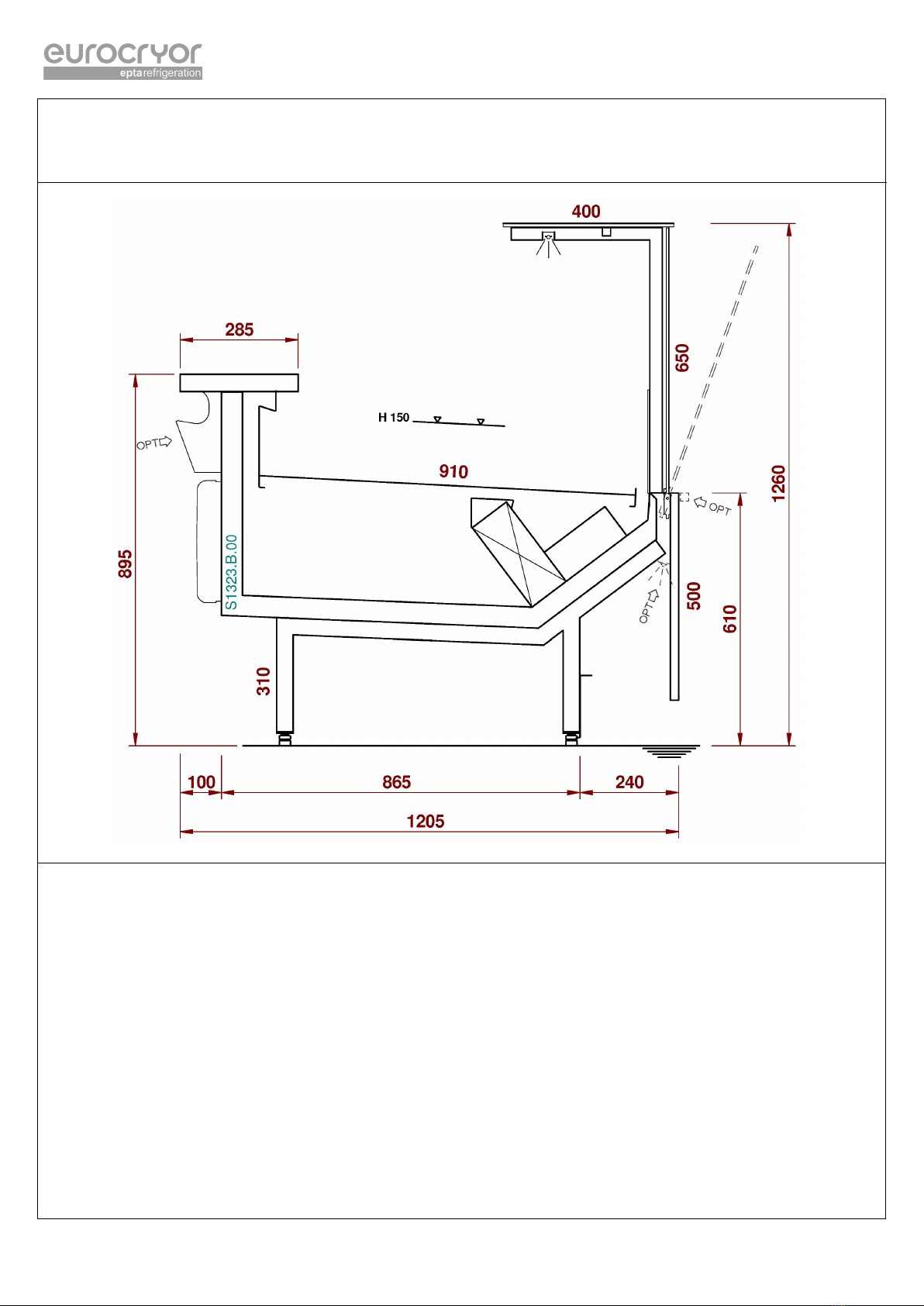

COMFORT MAXI

4

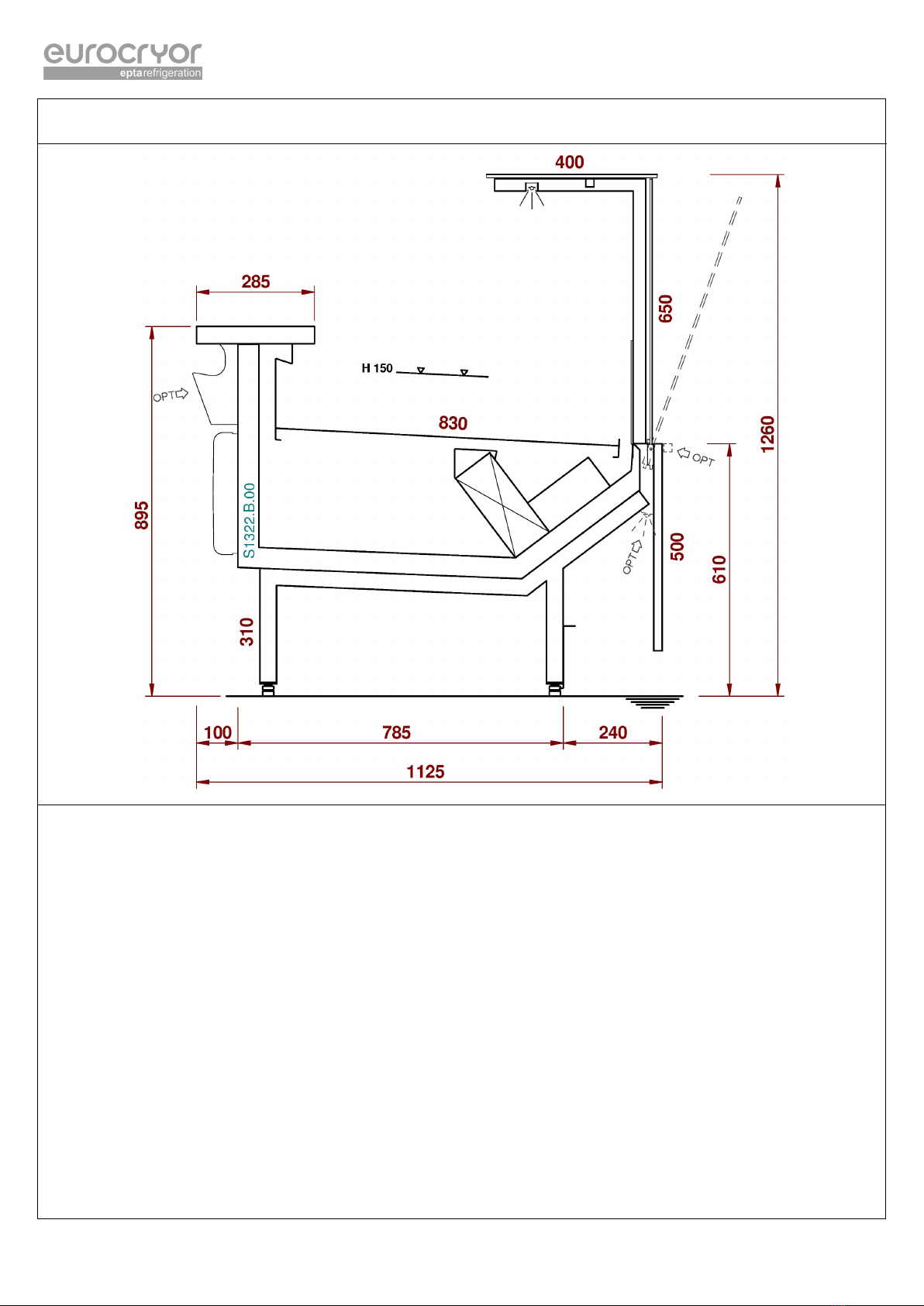

COMFORT MIDI

5

1

.INTRODUCTION

1.1 CLAUSES

THIS INSTRUCTION MANUAL IS AN INTEGRAL PART OF THE PRODUCT AND MUST BE KEPT UNTIL THE

PRODUCT IS DISMANTLED.

THE MANUAL MUST BE HELD BY A PERSON RESPONSIBLE FOR THAT PURPOSE, IN A SUITABLE PLACE

AND KNOWN TO ALL THE INTERESTED PARTIES, SO THAT IT IS ALWAYS AVAILABLE FOR

CONSULTATION.

1.2 CONTENT OF THE MANUAL

The manual contains information on the installation, use and maintenance of the product.

It also contains the information on the technical characteristics and on the safe use of the product.

1.3 PURPOSE OF THE MANUAL AND INTERESTED PARTIES

The information contained in the instruction manual indicates the use of the product and the technical

characteristics as well as its movement, installation, assembly, regulation, and use. It also contains the

information related to the instructions to be given to operators in charge of use, as regards the

maintenance work and to protect the safety of the workers directly.

This instruction manual is addressed to:

OPERATOR: qualified person, in charge of the operation, regulation, cleaning and regular maintenance

of the display unit.

SPECIALIST TECHNICIAN: person with the technical training and experience required to make them

aware of the risks they are exposed to in carrying out the work and putting them in the condition of

being able to adopt the necessary measures required to minimise the damage to self or to others,

authorised to carry out extraordinary maintenance, repairs, replacements, overhauls.

The person to whom the chapter refers is specified beside the title of each

paragraph (OPERATOR or SPECIALIST TECHNICIAN).

No specification next to the title means that the chapter refers to both people

defined above.

1.4 STRUCTURE OF THE MANUAL AND LEGEND

IMPORTANT: This symbol is used to report recommendations, rules, warnings, and

the communications, which any person interested in use of the product (each for their

own expertise) must bear in mind during all phases of the life of the same

(installation, use, maintenance, dismantling, etc).

CAUTION: This symbol is used in safety messages of the manual to report hazards

which, if neglected, may cause small or moderate injuries or damage. The message

may also be used only to report conditions that may cause damage to the product.

HAZARD: This symbol is used in safety messages of the manual, to indicate behaviour

that is to be absolutely avoided during use of the machine, in the maintenance phases

or when potential for danger and the likelihood of serious injury or death exists.

TO AVOID ACCIDENTS, read, understand and follow all the precautions and the warnings contained in

this manual and those set out on the plates attached to the product.

6

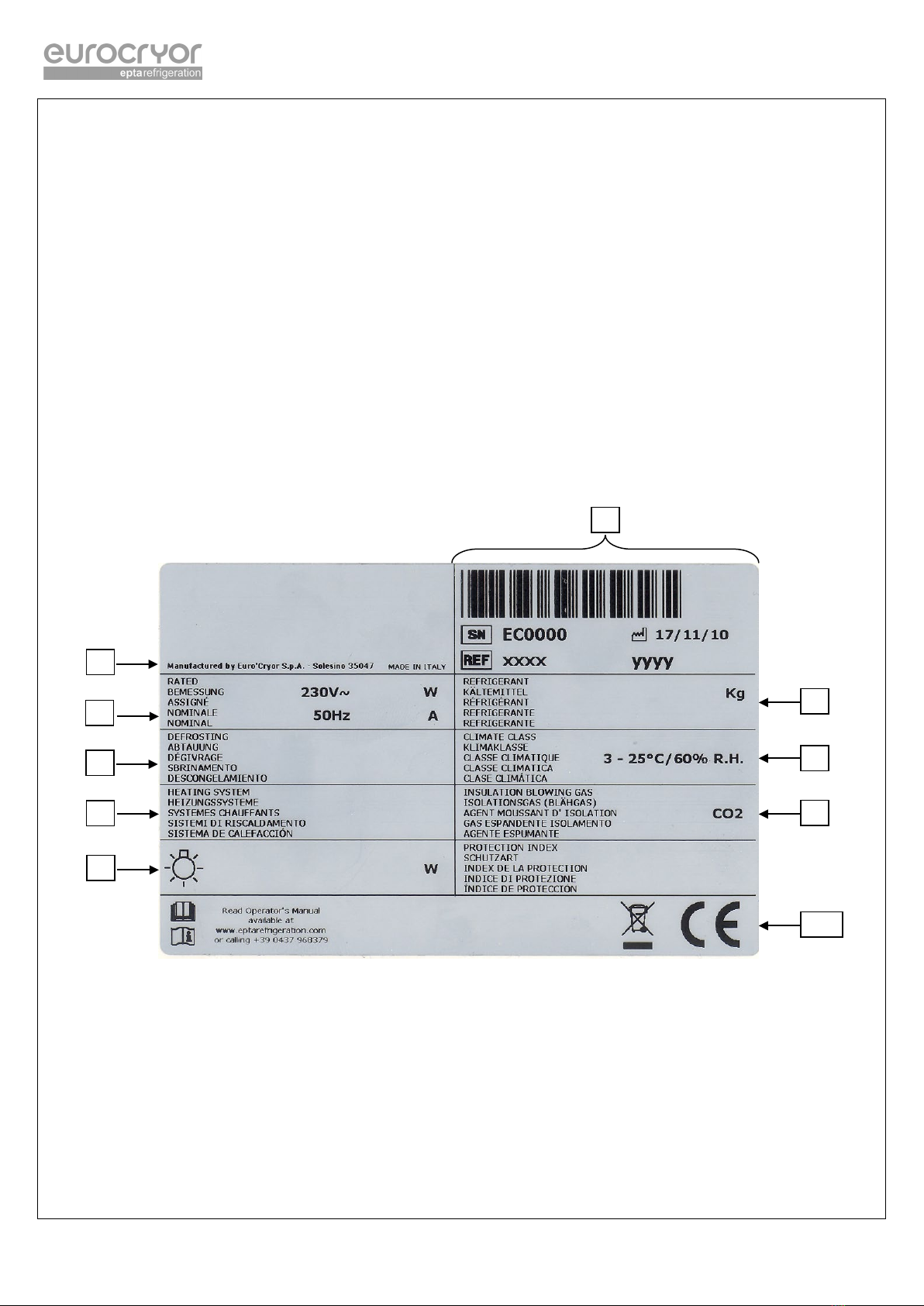

2. RATING PLATE DATA

This product is accompanied by documentation that certifies its conformity to the directive in force and

lists its essential characteristics.

It provides the following information:

1.Identification data of the product (series number, date, product code)

2. Name of manufacturer

3. Rated electrical characteristics (Voltage, frequency, current, power)

4. Power – defrosting current (if electrical defrosting)

5. Power of auxiliary heating systems.

6. Power of lamps

7. Number and weight of refrigerant

8. Climate class, temperature, and relative humidity of the reference climate class.

9. Insulation foam blowing glass

10. CE marking and any other marks

The rating plate must remain unchanged over time and contain the necessary details to be provided to

Epta when some need arises.

The A-weighted sound pressure level emitted by the appliance is lower than

70dB(A).

The display unit does not cause harmful vibrations.

2

3

4

5

6

7

8

9

10

1

7

3. RESPONSIBILITY

THE INSTRUCTION MANUAL IS AN INTEGRAL PART OF THE PRODUCT AND MUST BE KEPT

UNTIL THE END OF THE PRODUCT’S LIFETIME.

The manufacturer is released from any liability arising from:

▪improper, incorrect, or unreasonable use of the product.

▪use contrary to national regulations.

▪incorrect installation of the product.

▪power supply faults.

▪lack of planned maintenance.

▪unauthorised modifications or interventions.

▪use of non-original or model-specific spare parts and products.

▪non-compliance with the instructions contained in this manual.

4. VALIDITY AND COPYRIGHT

4.1 GENERAL INFORMATION

This user and maintenance manual complete with all attachments, is the only documentation of the

appliance provided and accompanies it throughout its working life.

In case of loss or deterioration, the replacement documentation must be requested directly from Epta.

4.2VALIDITY OF THE MANUAL

The user is reminded that this manual reflects the state of the art and of the technology, used in

manufacturing the appliance, valid at the time of marketing of same and cannot be therefore considered

unsuitable or obsolete if it has been subsequently updated according to new experience.

4.3RIGHTS ON THE MANUAL

EPTA reserves the right to update its production and, consequently, the applicable user and maintenance

manual, without the obligation to inform the Client of the changes made.

4.4COPYRIGHT

This manual is the exclusive ownership of EPTA. The delivery of this manual to third parties must be

authorised by the management of EPTA.

It is strictly forbidden to copy, reproduce by any means, even partially, the drawings and documents

contained in the manual.

All the violations are punishable by law and provide for damages under the commercial rights of

protection.

8

5. INTENDED USE

The product is intended for use by qualified staff, personnel who has been instructed and trained by the

employer in the use of the product and on the risks that such use may entail.

Read this manual with extreme care before use and instruct the operator on the use of the cabinet

according to the instructions in this manual.

What is set out in this manual is also valid for staff in charge of the transportation, installation,

maintenance and dismantling of the product, each within their own area of expertise.

The product must be used exclusively for the purpose for which it was designed, as set out in the

manual.

The Cabinet is suitable exclusively for the display of refrigerated

foods/beverages with a storage temperature above 0°C/4°C

The cabinet is NOT suitable for lowering the temperature of the product but only

for storing it.

The goods placed inside the cabinet MUST already be at the storage

temperature.

It is absolutely forbidden to display pharmaceutical products.

In normal use, the front windows of the cabinet must remain closed; it is only possible to open them fully

during maintenance or cleaning. Intermediate positions are forbidden.

It is forbidden to remove any guard or panel that requires the use of tools to be removed.

Any tampering or alteration of the product is totally forbidden.

Any other use not specifically indicated in the manual is considered hazardous so

EPTA shall not be held liable for any damage due to an improper and unreasonable

use.

Do not store explosive substances such as pressurised containers

with flammable propellent in the display unit.

9

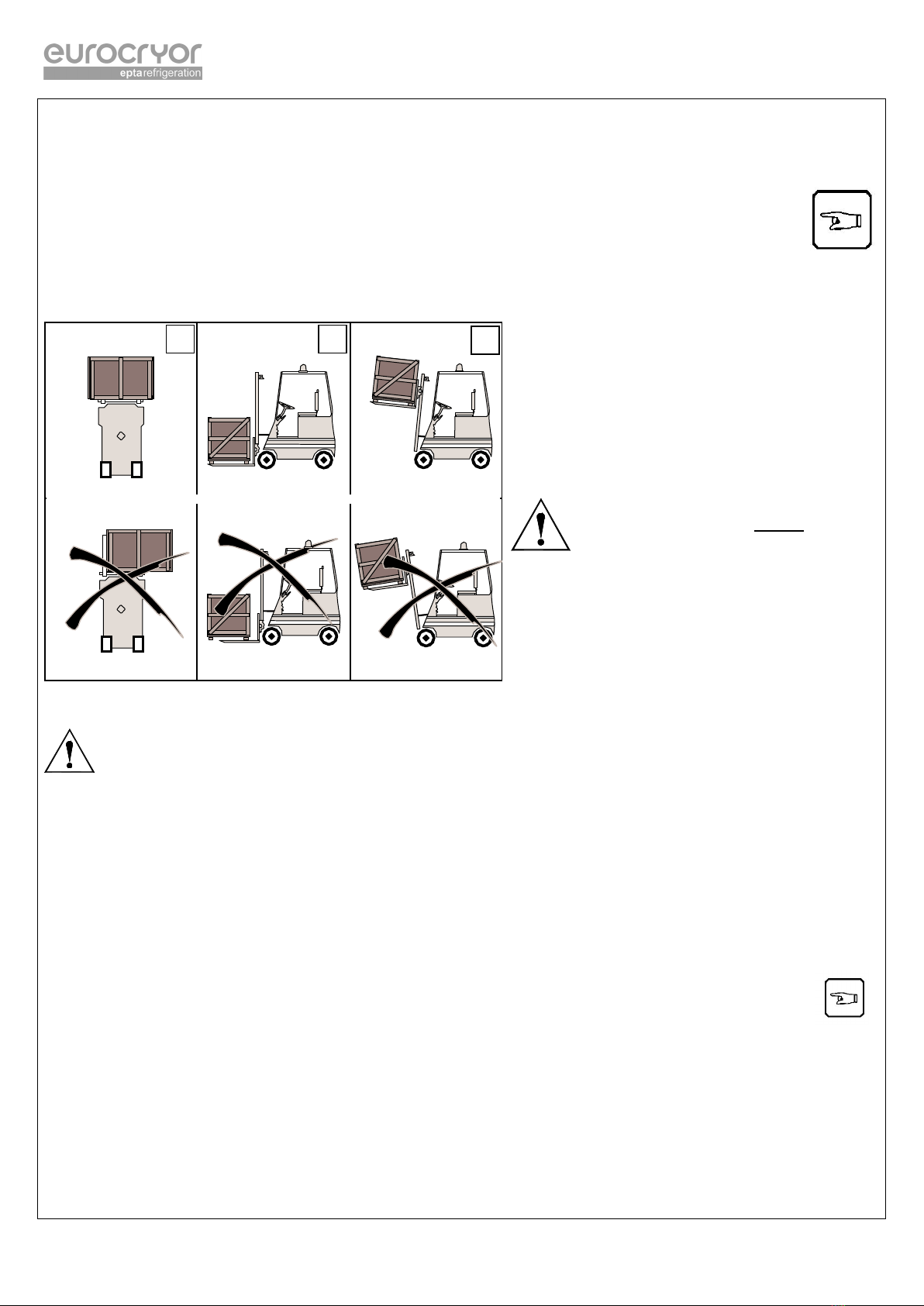

6. TRANSPORT AND STORAGE (SPECIALIST TECHNICIAN)

6.1 TRANSPORT

The loading and unloading operations must be performed by qualified staff, who will verify the

weights and the exact lifting points; they will use lifting equipment of adequate capacity and

safety. No outsiders should be near the lifting point.

•Load handling on pallet or cage

Thepackage must be lifted by fully inserting

the forks of the lift truck into the space

between the feet of the pallet or cage,

distributing the weight of the appliance in such

a way as to keep the centre of gravity of the

package balanced (Fig. 1-A). Do not overturn

the appliance.

Before inserting the forks of

the lift truck check that these

cover the entire depth

of the

package (Fig. 1-B). Otherwise

install suitable extensions.

It is totally forbidden to drag or push the cabinet by its sides.

PROHIBITED LIFTING EQUIPMENT

Lifting equipment or systems must not be used that do not respond to the safety features

required, namely:

•lifting capacity lower than the weight of the appliance.

•unsuitable lift truck construction features (e.g., short forks).

•construction features altered by use.

•non-compliant ropes or cables.

•worn ropes or cables.

Any other transport procedure different to that described in this chapter is not

allowed.

Fig. 1

A

B

C

10

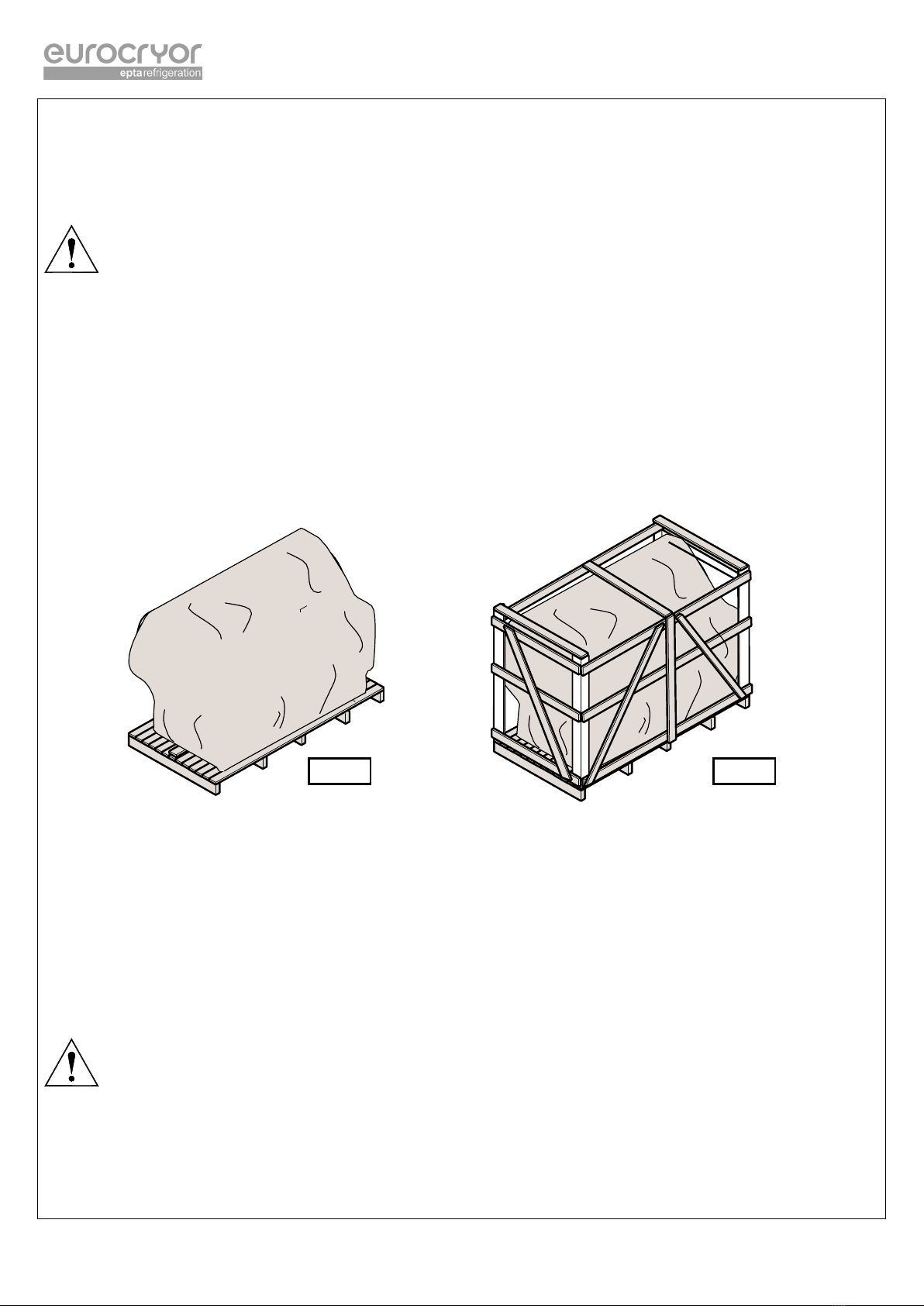

6.2STORAGE

Theappliance must be stored in a dry and moisture-free environment.

Before storage it must be protected with a sheet to protect it against

deposits of dust or other deposit.

The maximum storage temperature is 55°C.

In case of storage of the appliance (only packages with cages)

overlap a maximum of 1 package (Fig. 2).

7.AMBIENT CONDITIONS OF INSTALLATION

The display unit must be installed in a closed environment, covered and protected

from atmospheric agents.

The display unit must not be installed in environments with the pr

esence of

explosive substances.

Position the appliance far from draughts (fan-coil, fans, windows, air vents). Avoid direct exposure of the

counter to sun rays, to concentrated lighting units or to heat sources such as radiators, heaters, ovens.

Ensure that there is sufficient air circulation on all sides of the display unit.

It is totally forbidden to position objects around the counter which in some way can obstruct air circulation

on the condensing unit.

Failure to respect the requirements may

result in, as well as rapid deterioration of

the materials making up the counter,

incorrect operation of the counter itself,

namely:

•Greater energy consumption.

•Formation of condensation on the cold

surfaces (glass or worktop).

•Incorrect storage of the foods of the

counter and therefore risk of damage

to the goods on display.

Theclimatic conditions of the

environment must fall within the

temperature limits established by the

appliance class (25 °C - 60% of

humidity), outside these environmental

conditions, lower performance must be

accepted from the equipment.

Fig. 2

25°C

60%

11

8.INSTALLATION (SPECIALIST TECHNICIAN)

INCORRECT INSTALLATION OF THE PRODUCT CAN CAUSE INJURY TO PEOPLE OR DAMAGE

PROPERTY.

THE MANUFACTURER CANNOT BE HELD LIABLE FOR THIS.

Any variation or modification of the installation conditions must be authorised in

advance by EPTA. The operations described in this chapter must be carried out by

qualified staff.

To guarantee that people assigned to installing the product work in the appropriate safety situations, we

suggest that you carefully follow the installation procedure described here. In every case, it is

recommended to use suitable equipment or clothing: safety shoes, safety gloves, spirit level.

We also suggest you use all the tools or protective clothing required by legislation, or by the laws in force

in the country of installation.

8.1 OPENING THE PACKAGE

The cabinet is provided in one of the following ways:

♦Platform or pallet (fig. 1)

♦Crate (fig. 2)

The protective wooden packaging (crate) is opened using suitable tools: it is recommended to cover

exposed parts and in particular hands, with safety gloves because wood splinters may become detached

from the packaging. It is recommended to remove the nails, starting from the top part, until the

appliance is uncovered but still attached to the pallet (packaging platform).

Therefore:

•Remove protective cover with which the appliance is wrapped.

•Visually check that the appliance has not been damaged during transport.

CAUTION: inside the appliance there are components that must be assembled.

Be very careful not to break or lose them during unpacking operations.

Slowly remove the protective film from the various components, without tearing it to avoid adhesive

sticking. If this should happen, remove the residues of glue using appropriate solvents.

During handling operations, it is forbidden to drag or push the display unit using the

glass.

Fig. 1

Fig. 2

12

8.5 ELECTRICAL CONNECTIONS

The operations described in this chapter must be carried out by specialist personnel.

The customer is responsible for providing the electrical supply line up to the connection point of the

counter.

The power supply line must be sized according to the power absorbed by the appliance (see technical data

table).

Check the supply voltage and frequency reflect the values defined in the label or if they differ by a

maximum 5% the first and by 2% the second.

The display unit is equipped with a power cable complete with SCHUKO-type plug.

Comply with the rules listed below for a correct connection.

•Provide a suitable wall socket.

•It is forbidden to use adaptor plugs.

•After installation, the plug must be easy to access.

•The power cable must be well stretched, in a position that is not exposed to any knocks, and it

must not be close to liquids or heat sources.

The systems must be carried out in accordance with the rules governing their

construction, installation, use and maintenance. EUROCRYOR decli

nes any

responsibility vis-à-vis the user and vis-à-vis third parties for any damage that may

be caused by malfunction or fault of the systems upstream of the product

and for

damage which may be caused by the product due to causes that depend directly on

the malfunction of the electrical system.

THIS APPLIANCE IS IN CLASS 1: GROUNDING IS OBLIGATORY. The

manufacturer declines any responsibility for failure to observe this

requirement.

It is recommended to install an overvoltage category III thermal-magnetic circuit

breaker upstream of the power supply socket with a flow rate suitable for the power

/current values defined in the technical data table.

Instruct the operator on the position of the switch so that it can be easily reached in case of

emergency.

In case of damage to the

power cable, to prevent any type of risk, the replacement

must only be carried out by the manufacturer’s service personnel or by an experienced

person (see MAINTENANCE chapter)

13

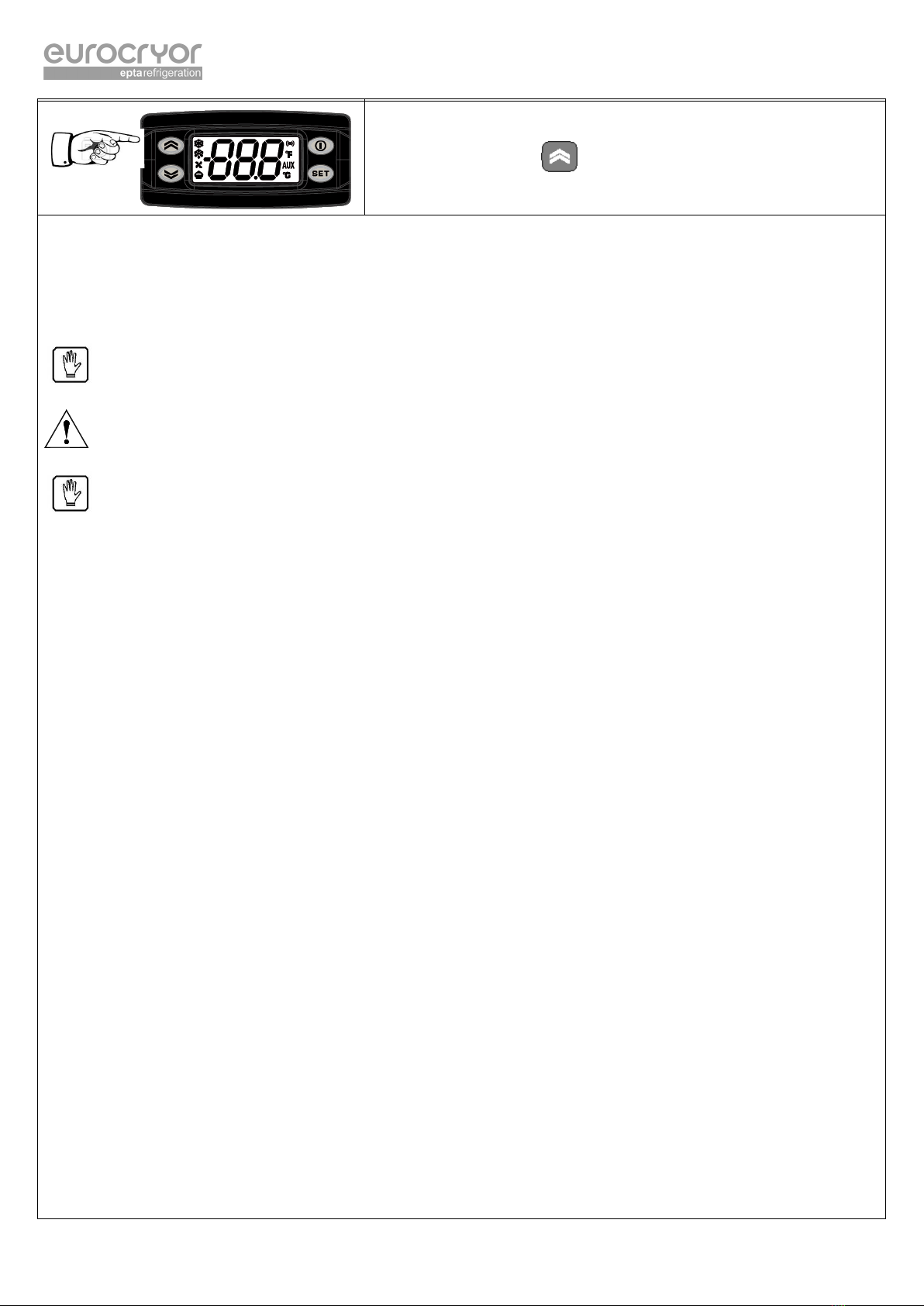

9FIRST START-UP (OPERATOR)

9.1 FIRST CLEANING

Clean the display unit thoroughly before putting it into operation.

The cleaning procedures are specified in the chapter on “CLEANING”.

9.2 FIRST START-UP

9.2.1 COUNTER WITH CONDENSING UNIT

•Plug in

•Press of the controller to put the display unit into operation.

•Check that:

oThe controller display lights up.

oThe compressor turns on.

oThe interior fans operate (check to see that air circulates).

oSwitch on the lights using.

Fig. 1: panel with condensing unit

9.2.1 COUNTER WITHOUT CONDENSING UNIT

•Plug in

•Press the switch to put the display unit into operation; check that the controller display lights

up and that the fans turn on (check to see that air circulates)

•Switch on the lights by pressing .

Fig.2: panel without condensing unit

To carry out the operations of this chapter wear safety gloves.

14

The display unit functions (defrosting, refrigeration) are controlled by the electronic controller.

The interval and duration of the defrosting activity are set according to standard environmental values. If

the environmental conditions should be unfavourable, we recommend increasing the number and duration

of defrosts.

The screen of the electronic controller shows the interior temperature of the display unit.

The goods must be entered into the display unit only when the set temperature has been

reached.

10 USE OF CABINET (OPERATOR)

10.1 PERFORMANCE OF DISPLAY UNIT

The Cabinet is suitable exclusively for the display of refrigerated foods/beverages

with a storage temperature above 0°C/4°C

The cabinet is NOT suitable for lowering the temperature of the product but only

for storing it.

The goods placed inside the cabinet MUST already be at the storage temperature.

It is absolutely forbidden to display pharmaceutical products.

10.2 LOADING THE PRODUCT

During loading of the goods and throughout their stay pay the utmost attention:

•Not to exceed the maximum load lines

•Not to obstruct the air outlet and air intake slots.

•Not to obstruct the flow of refrigerated air

•To respect the load limits (in kg) expressed in the technical specification.

10.3 CHANGE OF SETPOINT: Controller ELIWELL mod. EWplus974EO

TO CHANGE THE SETPOINT

1. Press and instantly release the SET key (figure at the

side).

2. SET will appear on the screen.

3. press SET key again and the value of the SETPOINT will

appear on the screen

1. to change the value, press the keys (to increase)

or (to decrease) within 15 seconds to choose the

new value.

Any showcasing of fresh foods NOT PACKAGED, is to be carried out in conformity

with the local regulations.

Before placing the goods control the correct position of the display shelves.

The goods must be placed inside the display unit only when it has reached the set

temperature.

Attention: do not place the goods directly on top of the painted display surface.

It is recommended to check the consistency of the packaging before showcasing

packaged products containing liquids which could damage the counter if leaked.

Otherwise insert the packaged product in a container.

15

TO START A MANUAL DEFROSTING CYCLE

1. press the key (figure at side) for 5 seconds. If

defrosting conditions do not exist, the screen flashes 3

times.

For changes to parameters that modify the operation of the display unit, it is advisable to contact the

installer or a specialised technician.

11.CLEANING

To perform the cleaning operations, wear safety gloves

It is totally forbidden to use jets of water to clean the counter.

Caution: in the cabinets with condensing unit, the condensation water evaporates

only when the counter is in operation.

The liquid collection tray has a limited capacity; do not pour large quantities of water

during cleaning

11.1 ORDINARY CLEANING (OPERATOR)

Thevisible surfaces of the display unit (painted parts, steel, plastic, rubber, etc) must be cleaned using

neutral detergents and non-abrasive sponges, dry with a soft cloth.

It is forbidden to use flammable products or aggressive products such as alcohol or various solvents.

Use specific products to clean the glass.

Beware of hot parts (marked with dedicated symbol); wait for them to have cooled down.

•Cleaning stainless steel parts

Some situations are listed below, not necessarily of an extraordinary nature, which may lead to oxidation

phenomena:

1. Iron residues left to settle on damp surfaces (not dried), brought into circulation by water or foods.

2. limestone.

3. chlorine or ammonia-based detergents not appropriately rinsed.

4. incrustations or food residues.

5. salt, salt solutions (brine).

6. dry residues of evaporated liquids.

Methods of cleaning

Rust and stains on the stainless-steel surfaces, can be easily removed – if of recent formation – with

neutral shampoos and detergents using a sponge or a cloth. After cleaning, carefully remove every trace

of detergent or soap, rinse with plenty of water and dry the surface.

In case of old stains and rust of a brown colour with well-defined contours, chemical substances can be

used for stainless steel containing 25% nitric acid or other similar substances.

If the rust deposit resists this type of chemical substances, resort to sanding or polishing with a stainless-

steel brush. Immediately after having polished the deteriorated parts of the surface, wash with detergent

products. Please note, however, that scratches may occur on the surface due to the abrasive cleaning

techniques.

16

After every cleaning operation rinse with plenty of water and dry.

The following must be avoided at all costs:

1. chlorine-based detergents such as bleach or similar products normally on the market because they

produce serious effects of corrosion unless abundantly, quickly and properly rinsed.

2. The contact or only the vapours from acid (muriatic acid/chloric acid) or alkaline (sodium

hypochlorite/bleach) products or ammonia, used directly or contained in common detergents, to

clean and sanitise floors, tiles and washable surfaces as they can have an oxidising/corrosive effect

on stainless steel.

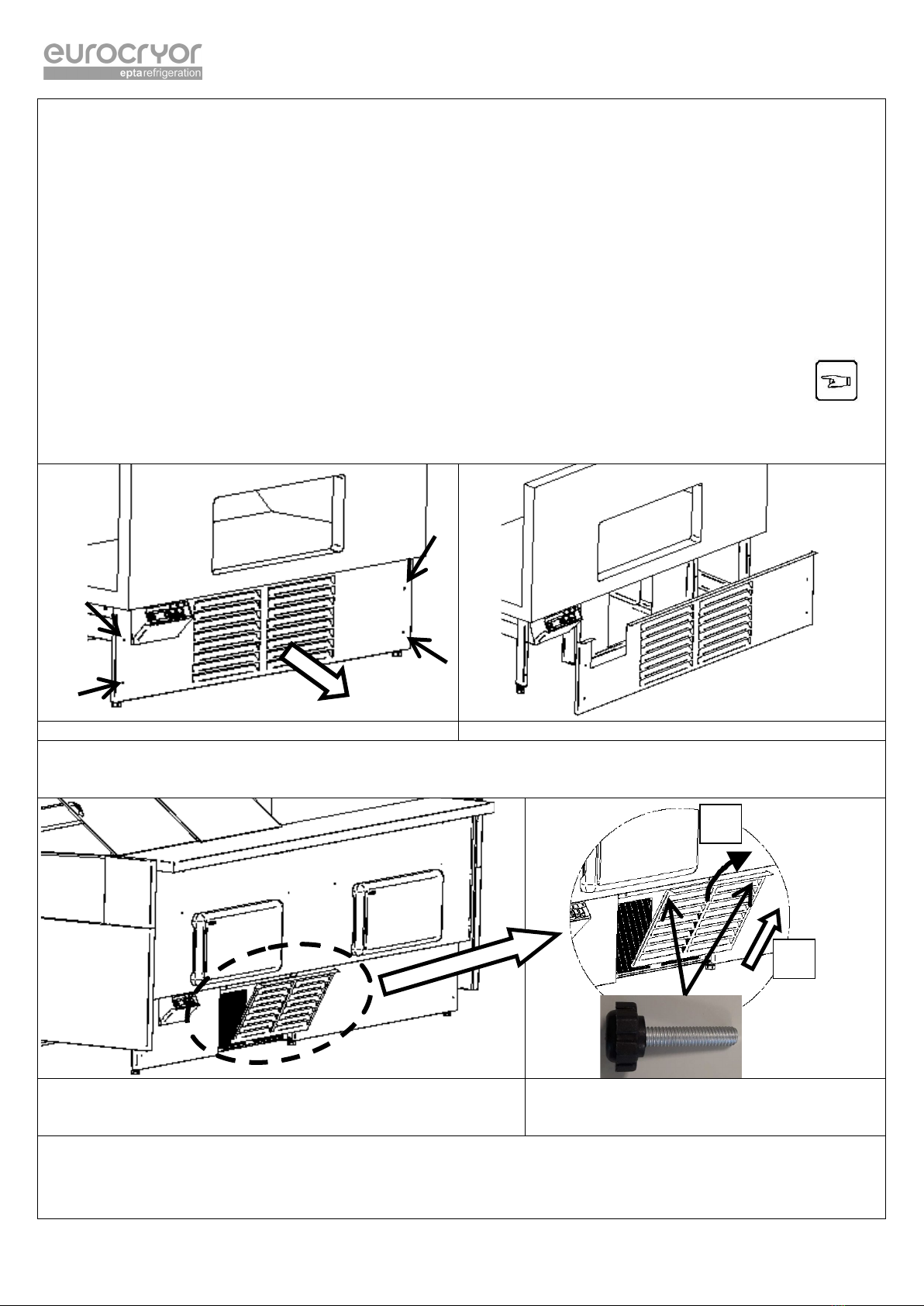

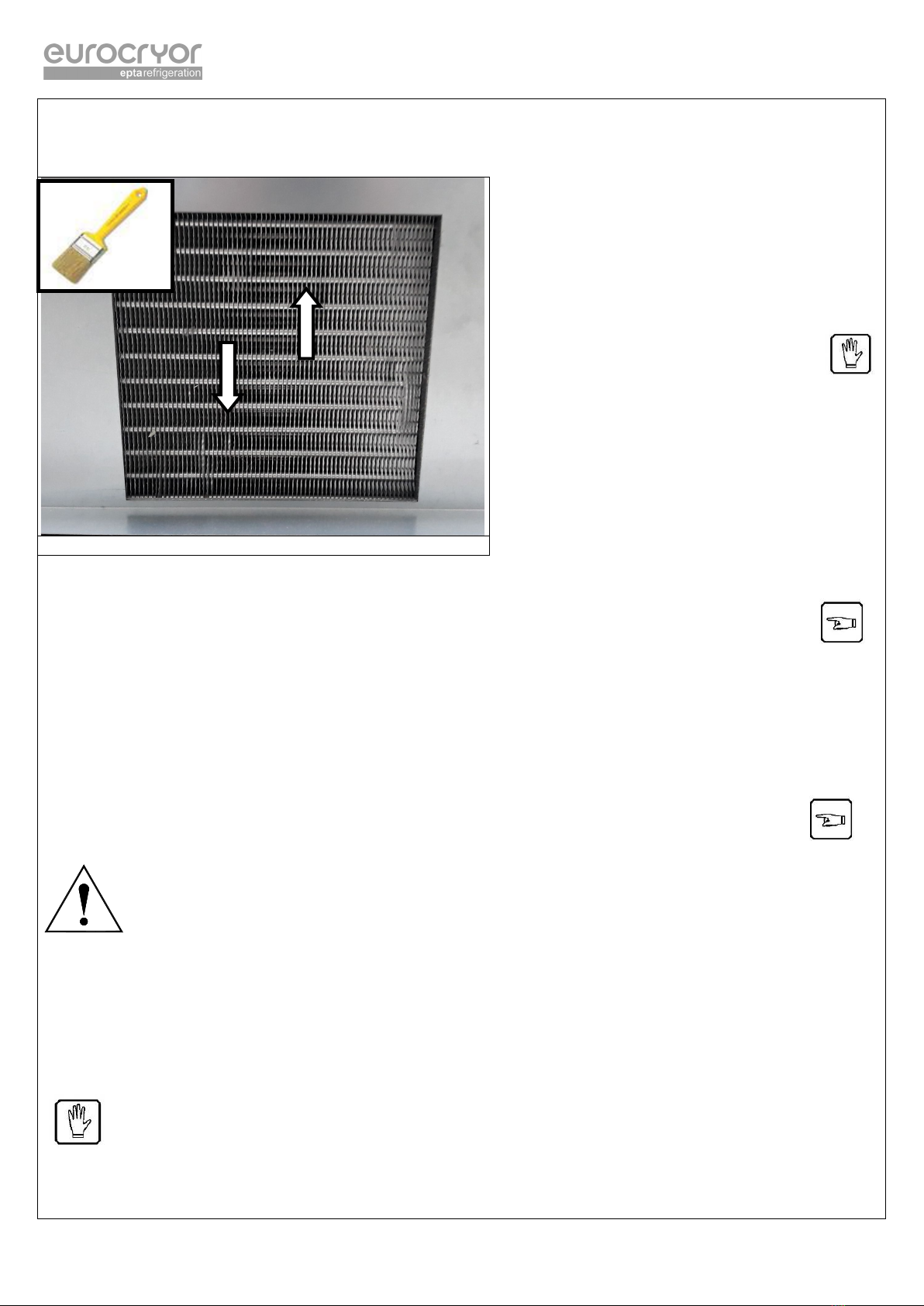

11.1.2 CLEANING THE CONDENSING UNIT (OPERATOR)

It is recommended to clean the condensing unit condenser every month.

•Only for counters L.938 – 1250 - 1563

Fig. 1: remove protection panel.

Fig. 2: clean the condenser

•For all other lengths of the counter.

Fig. 3: removing the condenser grille

Fig. 4: remove the knobs that secure the

grille then pull the upper part outwards

(1) and remove it completely (2)

After cleaning the condenser install the protection panel

Regular cleaning of the condensing unit is important for proper counter operation

and electrical saving.

2

1

17

Clean the condensing unit with a brush or a hoover by acting in the direction of the fins so as not to bend

or deform them.

After cleaning install the protection panel

11.2 EXTRAORDINARY CLEANING (SPECIALIST TECHNICIAN)

All the operations described in this chapter must be carried out in the absence of

voltage.

Before any work on the cabinet switch off the power by disconnecting the main wall

switch.

11.2.1 INTERNAL CLEANING

At least once a month, it is recommended to clean the zone under the shelves, operating as follows:

•Empty the counter completely by placing the goods into other refrigerators.

•Wait for the counter to reach the ambient temperature.

•Remove the shelves

Caution: in counters with CONDENSING UNIT the condensation water evaporates only

when the counter is in operation.

The liquid collection tray has a limited capacity; do not pour large quantities of water

during cleaning

Fig. D: detail of the condenser, cleaning direction.

Be careful not to cut

yourself with the slim

evaporator fins or with

edges or corners of adjacent

sheet metal. Once the

cleaning operations are

completed it is obligatory to

install the rear closure.

Regular cleaning of the condenser is important for proper operation of the counter and

for electricity saving.

The operations described in this chapter must be carried out by qualified personnel.

18

•After cleaning, check the water has drained away correctly; remove any residues from the drain

hole.

•Re-assemble in the reverse order. For proper operation of the cabinet, put the shelves back correctly

in their place.

•Put the counter back into operation. Before re-inserting the goods, check the working temperature

has been reached (see chapter “FIRST START-UP”).

12. MAINTENANCE (SPECIALIST TECHNICIAN)

The operations described in this chapter must be carried out by a specialist

technician.

Any maintenance work must be carried out in the absence of voltage.

Act on the main wall switch to switch off the power supply.

Caution: all power circuits must be disconnected before accessing the terminals.

12.1 REPLACEMENT OF POWER CABLE

In case of damage to the power cable, to prevent any type of risk, the replacement must only

be carried out by the manufacturer’s service personnel or by an experienced person

12.2 REPLACEMENT OF LED MODULES

Caution: to replace a LED lighting fixture it is obligatory to contact the display unit dealer. Do

not install alternative components.

It is recommended to have a specialist technician carry out a general check of the

cabinet (gas springs, refrigeration circuit, …) every year.

19

13. DISPOSAL (SPECIALISED OPERATOR)

Different laws apply in different countries, therefore the requirements of the laws and authorities of the

countries where the demolition takes place must be observed.

In general, it is necessary to redeliver the appliance to the specialist collection/demolition centres.

Dismantle the appliance, grouping the components according to their chemical nature.

The components of the appliance are waste similar to urban waste.

The dismantling operations must be carried out by qualified personnel.

The materials used in manufacturing the cabinet are:

•steel pipe: transport bars.

•Aluminium pipe: frame.

•Galvanised sheet metal: closing panels.

•Stainless steel: internal parts of the cabinet.

•Expanded polyurethane (thermal insulation)

•copper: refrigeration circuit.

•PVC: various plastic material.

•Tempered glass: front glass.

NOTICE

This appliance is subject to the obligations declared in Legislative Decree n. 151 of 25 July

2005 “Implementation of the Directive 2002/95/EC, 2002/96/CE and 2003/108/EC, related to

the reduction in the use of hazardous substances in electrical and electronic appliances and

waste disposal” only if it is equipped with a built-in Condensing Unit at the time of purchase.

The manufacturer is obliged to dispose of an equivalent product when purchasing a new product (the

appliance is equivalent when the weight of the appliance returned is not greater than double the weight of

the appliance delivered). The rates for any additional components to dispose of or the excess weight of

non-equivalent appliances will be agreed each time. Pursuant to art. 13 of the decree, the symbol of the

barred bin on the appliance or on its package indicates that the product must be collected separately from

other waste at the end of its useful life.

The separate waste collection of the end-of-life appliance (if subject to the

obligations of the directive) is organised and managed by the manufacturer.

The user who wishes to dispose of this appliance should therefore contact

EPTA and follow the system it has adopted for separate collection of end-of-

life equipment.

Appropriate separate collection for subsequent recycling, treatment and

environmentally sound disposal of discarded equipment contributes to

avoiding possible negative effects on the environment and health and

promotes the reuse and/or recycling of the materials from which the

equipment is made.

Unauthorised disposal of the product by the holder will result in the application of administrative sanctions

as provided for by current legislation.

Information on the materials used to make the counter can be requested from EPTA.

The components of the refrigeration circuit must not be cut and/or separated but

they must be transferred intact to the specialised centres for the recovery of

refrigerant gas.

20

Rohs Declaration

EPTA, the undersigned party, declares under its responsibility that the refrigerated display unit object of

this manual, equipped with a built-in refrigeration unit, meets the requirements of the directive

2002/95/CE (RoHS). In the materials used to produce the cabinet, any presence of lead, mercury,

cadmium, hexavalent chromium, biphenyl, polybrominated (PBB) and diphenyl ether (PBDE) does not

reach 0.1% by weight; cadmium does not reach 0.01% by weight.

14.WARRANTY CONDITIONS

Article 5 - Returns

5.1 Unless special conditions exist related to the warranties, the appliances cannot be returned

without the prior written consent of EPTA: The returns will be made at the risk of the buyer. The

appliances returned without prior agreement of EPTA in writing shall remain available to the client,

at his risk with related costs payable by him.

Article 6 – Standard terms and conditions for the warranty

6.1.The appliances recognised as faulty and any manufacturing or design defects are covered by

warranty, except in the case that the manufacture or design has been specified by the buyer, for a

period of 12 months, starting from delivery of the appliances. It remains understood that the actions

carried out under warranty cannot extend its duration.

Until the expiry of this warranty period, EPTA undertakes to substitute, repair, at its discretion,

the appliances recognised as faulty by its technical offices.

6.2. The following are not included in the warranty: (i) normal wear and tear of the appliances during

the warranty period, (ii) abnormal wear or deterioration deriving from negligence originated from

inadequate supervision or maintenance of the appliance, or incorrect handling not attributable to

EPTA; (iii) defects caused by the decision of the buyer to carry out personally, or have carried out,

modifications or repair work; (iv) the glass parts and the refrigerant fluids are not covered by

warranty.

6.3 The company will remedy, by way of refund of the total or partial price (where relevant, as a

discount on an outstanding portion of the price), or, at its discretion, by way of repair or

replacement, the defects that emerge during the normal wear of the goods and due exclusively to

design defects (except when this is provided by or on behalf of the Client), materials and/or labour,

as long as:

a) the defect in question appeared within 12 months from the date in which the Client came into

possession of the goods, and it was readily communicated in writing to the company, and

b) the goods declared faulty, if requested by the company, have been immediately returned at

the risk and expense of the Client to the workshop of the company for inspection, and the

company, in its reasonable judgement, considers its faulty exclusively due to a defect of design,

materials and/or labour; and

c) no attempt has been made by the Client or third parties to remedy a defect before the goods

have been returned for inspection to the company, if it has requested this, and

d) correct technical assistance and maintenance of the goods has been carried out, in compliance

with the recommendations of the company, no spare parts, components and/or accessories

different to those manufactured or recommended by the company have been used, and

e) if this defect is due to a fault of spare parts, components, accessories and/or other parts of the

goods not manufactured by the company, the client will be entitled, vis-à-vis the company, only

to those remedies the company will have succeeded in obtaining from the relevant manufacturer

or supplier, and

f) the company shall not be liable for:

i) damage to glass or other materials after they have been fixed or positioned on site, or after

application of signature of receipt in good conditions.

ii) damage or defects of processing or materials due to causes that are out of the control of the

company, including:

a) small imperfections in the glass

b) imperfections caused by incorrect repairs or alterations by others

c) fluorescent tubes and/or lamps

This manual suits for next models

1

Table of contents

Other Eurocryor Commercial Food Equipment manuals