DSA3xx-A.DOC 08/09 1

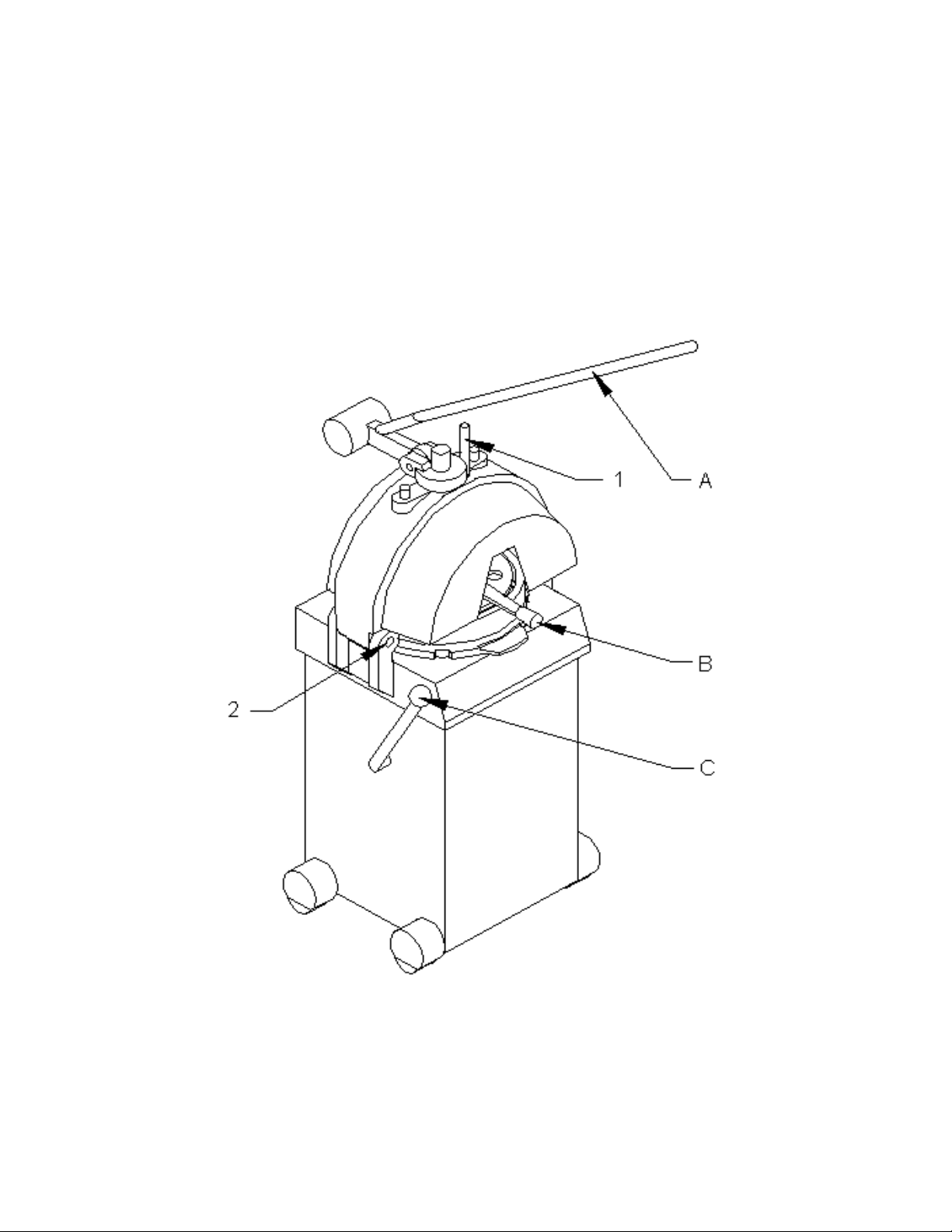

DOYON SEMI-AUTOMATIC DIVIDER ROUNDER

INTERCHANGABLE PRESS PORTION

DSA315 / DSA322 / DSA330 / DSA336

TABLE OF CONTENTS

TO GET THE BEST PERFORMANCE FROM YOUR MACHINE, PLEASE READ THIS

MANUAL CAREFULLY.

CHAPTER 1 - RECEPTION OF THE MERCHANDISE . . . . . . . . . . . . . . . . . . . 2

- NAMEPLATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

CHAPTER 2 - GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CHAPTER 3 - THE USE OF THE DIVIDER ROUNDER

3.1 - General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.2 - Machine’s characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.3 - Improper use of the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

CHAPTER 4 - TECHNICAL DATA

4.1 - General dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.2 - Technical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.3 - Electric specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.4 - Electric installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.5 - Security system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CHAPTER 5 - ELECTRIC CONNECTION AND INSTALLATION

5.1 - Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

5.2 - Electric installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

CHAPTER 6 – OPERATING AND REPLACEMENT OF PRESS

6.1 - Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

6.2 – Replacement of the press . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

CHAPTER 7 - MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

LIMITED WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21