Euromag MC608 Series User manual

MC608 Converter

Installation Manual

Vers. 6.0 and subsequent

PLEASE READ THESE INSTRUCTIONS

AND KEEP IN A SAFE PLACE

TD 210-1-ENG

IT IS VERY IMPORTANT THAT ALL THE STAFF WORKING WITH THE EQUIPMENT HAVE

READ AND FULLY UNDERSTOOD THE INSTRUCTIONS AND

INFORMATION PROVIDED IN THIS MANUAL AND FOLLOW AND APPLY THEM BEFORE

USING IT. THE MANUFACTURER IS NOT

LIABLE FOR ANY CONSEQUENCES RESULTING FROM MISUSE BY THE OPERATOR.

PLEASE READ AND KEEP THESE INSTRUCTIONS IN A SAFE PLACE

This manual can be downloaded from the internet www.euromag.com visiting the download area.

To ensure a proper and safe installation we strongly recommend thoroughly reading this operation manual.

IMPORTANT WARNING

The operator shall bear responsibility for the suitability of the device for the specific purpose:

Improper installation and operation of the devices (systems) will cause warranty to be void

• The manufacturer will not be liable for any kind of damage resulting from the use of its products,

including, but not limited to those deemed direct, indirect, incidental, punitive and consequential. The

installation, connection, commissioning and maintenance must be performed by staff specifically

qualified and authorized for that purpose.

• The installation personnel must ensure that the measuring system is correctly connected in accordance

with the wiring diagram.

For applications that require high working pressures or substances that may be hazardous to the

people, the environment, equipment or anything else if a pipe breakage occurs, Euromag International

recommends, that before installing the sensor the operator takes the appropriate precautions such as

precautions such as the correct location, protection or the mounting of a guard or safety valve.

The device contains live electrical components, thus the installation, monitoring and maintenance must

be carried out by qualified and experienced staff fully aware of all the necessary precautions. Before opening

any inner part, please disconnect the power supply.

The flow meter consists of metal and plastic parts, all of which must be in compliance with local rules and

requirements concerning waste disposal.

CE/EMC/Norme

CRUCIAL INFORMATION AND INSTRUCTIONS TO BE APPLIED.

PLEASE REFER TO THE ANNEXED DOCUMENTS .

CAUTION!

RISK OF ELECTRIC SHOCK!

ALL OPERATIONS MARKED WITH THIS SYMBOL SHOULD ONLY BE CARRIED OUT BY

QUALIFIED TECHNICIANS.

CAUTION!

INFORMATION AND INSTRUCTION

REQUIRING SPECIAL ATTENTION.

NOTE

The manual that describes this flowmeter conforms to the following safety rules:

• Directives EN 61326-1:2006, EN 55011:2009 + / A12010, EN 6100-3 (2/3), EN 6100-4 (2/3/4/5/6/8/11).

• Directive EN61010-1 (pending)

• Directive EN 60529 (pending)

• It is in class A.

In addition, it is essential to read the manual start-up that accompanies the flow meter and which is

contained in the package.

Manufacturer’s design and safety statement

• Responsibility for the choice of lining and electrode materials in regards to abrasion and corrosion

resistance lies with the purchaser. The effect of any change in fluid process during the operation of the

device must be taken into account. Incorrect selection of lining and/or electrode could lead to a failure

of the device.

• While designing the device stresses and loads possibly caused by earthquakes, traffic, strong winds and

fire damage were not taken into account.

• Do not install the device so that it acts as a focus for pipeline stresses. In the configuration of the device

please take into account any external loads.

• During operation do not exceed the pressure and/or temperature ratings indicated on the nameplate or

in this Operating Manual.

Battery Operation:

• Lithium batteries are primary power sources with high energy content. They are designed to meet the

highest possible safety standards. They may, however, pose a potential hazard if they are misused either

electrically or mechanically which may cause the generation of excessive heat and possible breakage

of the cell.

Thus the following basic precautions should be observed when handling and using lithium batteries:

- Do not short-circuit, recharge, overcharge or connect with incorrect polarity

- Do not expose to temperature beyond the specified temperature range or incinerate the battery

- Do not crush, puncture or open cells or disassemble battery packs

- Do not weld or solder to the body of the battery, or the battery packs

- Do not expose contents to water

Lithium batteries are regulated under United Nations Model Regulations on Transport of Dangerous goods

(UN document on transport of hazardous goods), UN ST/SGAC document. 10-1, 12th revised edition, 2001.

The UN document No. 3091

Class 9 covers the lithium batteries packed with the equipment or inserted into it. The UN document No.

3090 Class 9 only covers the transport of the batteries themselves.

Thus the following basic precautions should be followed when transporting lithium batteries:

- Transport only in special packaging with special labels and transportation documents.

- Use caution in handling, transporting and packaging in order to prevent short circuiting of the batteries.

- The gross mass of the package is limited according to the type of transportation. In general, a gross

mass of less than 5 kg is acceptable for all forms of transport

- The batteries comply with the requirements set out in “UN Manual of tests and criteria, Part III,

subsection 38.3” for transport by air and with the provisions of the ADR regulations for the transport by

truck/sea.

• Remove the battery from the transmitter before returning the flow meter to Euromag International for

possible service or warranty claim.

6

EUROMAG | MC608 | TD210-1

www.euromag.com

SUMMARY

MANUFACTURER’S DESIGN AND SAFETY STATEMENT 5

BATTERY OPERATION 5

1. PRELIMINARY NOTES 10

2. GENERAL PRECAUTIONS 10

3. SENSOR INSTALLATION 12

3.1 IDENTIFICATION NAMEPLATE 12

3.2 BIDIRECTIONAL READING 12

3.3 INSTALLATION INSTRUCTIONS 13

3.3.1 POSITIONING IN RELATION TO THE PLANT 13

3.3.2 POSITIONING IN RELATION TO THE FLOW 14

3.3.3 IMPORTANT INSTRUCTIONS ON MOUNTING 15

3.3.4 CHARTS OF MAXIMUM ALLOWABLE TORQUES 15

3.3.5 IMPORTANT GUIDELINES FOR CORRECT INSTALLATION 17

3.3.6 IMPORTANT GENERAL INFORMATION FOR A PROPER INSTALLATION 20

3.3.7 INSTALLATION EXAMPLE OF WAFER METER (MUT1000EL – MUT1100J) 21

4. POTENTIAL EQUALIZATION 22

5. NEGATIVE PRESSURE IN THE PIPE 24

6. INSTRUCTIONS FOR DIAMETER REDUCTION 24

7. INFORMATION CONCERNING THE MC608R CONVERTER 25

8. INSERTION METERS 26

8.1 INTRODUCTION 26

8.1.1 FEATURES AND BENEFITS 26

7

8.1.2 SYSTEM DIAGRAM 27

8.1.3 MECHANICAL INSTALLATION 27

8.2 INSTALLATION 28

8.2.1 MEAN AXIAL VELOCITY POINT (1/8 OF THE INTERNAL DIAMETER) 29

8.2.2 ALIGNMENT 29

8.2.3 PROGRAMMING 29

9. MC 608 CONVERTER 30

9.1 INSTALLATION 30

9.1.1 IDENTIFICATION NAMEPLATE 30

9.1.2 COMPACT VERSION 30

9.1.3 REMOTE VERSION 31

9.1.4 ELECTRICAL CONNECTIONS 34

9.1.5 MODBUS RS485 OUTPUT 37

9.1.6 ELECTRICAL GROUNDING OF THE COVERTER CASE 37

9.1.7 CONNECTION TO THE POWER SUPPLY 38

9.2 MC608 CONVERTER PROGRAMMING 38

9.2.1 PROGRAMMING 41

10. DESCRIPTION OF THE MENU 44

10.1 OPTIONS 44

10.1.1 TECHNICAL UNITS 44

10.1.2 MEASUREMENT FREQUENCY 45

10.1.3 DISPLAY 45

10.1.4 VIEW OPTIONS 46

10.1.5 FULL SCALE FLOW RATE 46

8

EUROMAG | MC608 | TD210-1

www.euromag.com

10.1.6 LANGUAGE 46

10.2 COUNTERS 46

10.3 PARAMETERS 47

10.3.1 KA SETUP 47

10.3.2 DIAMETER SETUP 47

10.3.3 FILTERS SETUP 48

10.3.4 ZERO FINDER 50

10.3.5 FLOW RATE ALARMS 50

10.3.6 EMPTY PIPE THRESHOLD 50

10.4 I/O 51

10.4.1 PULSE OUTPUT 51

10.4.2 FREQUENCY OUTPUT 52

10.4.3 PROGRAMMABLE OUTPUT 52

10.4.4 PROGRAMMABLE INPUT 53

10.4.5 BATCHING 53

10.4.6 PROGRAMMABLE OUT LOGIC 54

10.5 OTHERS 54

10.5.1 SYSTEM INFO 54

10.5.2 TIME/DATE 54

10.5.3 RESERVED 54

10.5.4 GRAPH 54

10.5.5 SIMULATION 54

10.5.6 COMMUNICATIONS 54

10.5.7 DATA CONNECTION (RS485/IRCOMM) 54

9

10.6 MEMORY 55

10.6.1 LOAD USER COPY 55

10.6.2 SAVE USER COPY 55

10.6.3 FACTORY SETTINGS 55

10.6.4 DATALOGGER 55

10.6.5 PASSWORD SETUP 57

11. TECHNICAL DATA 58

11.1 GENERAL FEATURES 58

11.2 CERTIFICATES AND APPROVALS 59

11.4 ACCURACY 60

12. RETURN OF THE FLOW METER FOR ANY CHEK OR REPAIR 61

13. APPENDIX - TROUBLESHOOTING 62

REPAIR APPLICATION FORM 65

NOTE 66

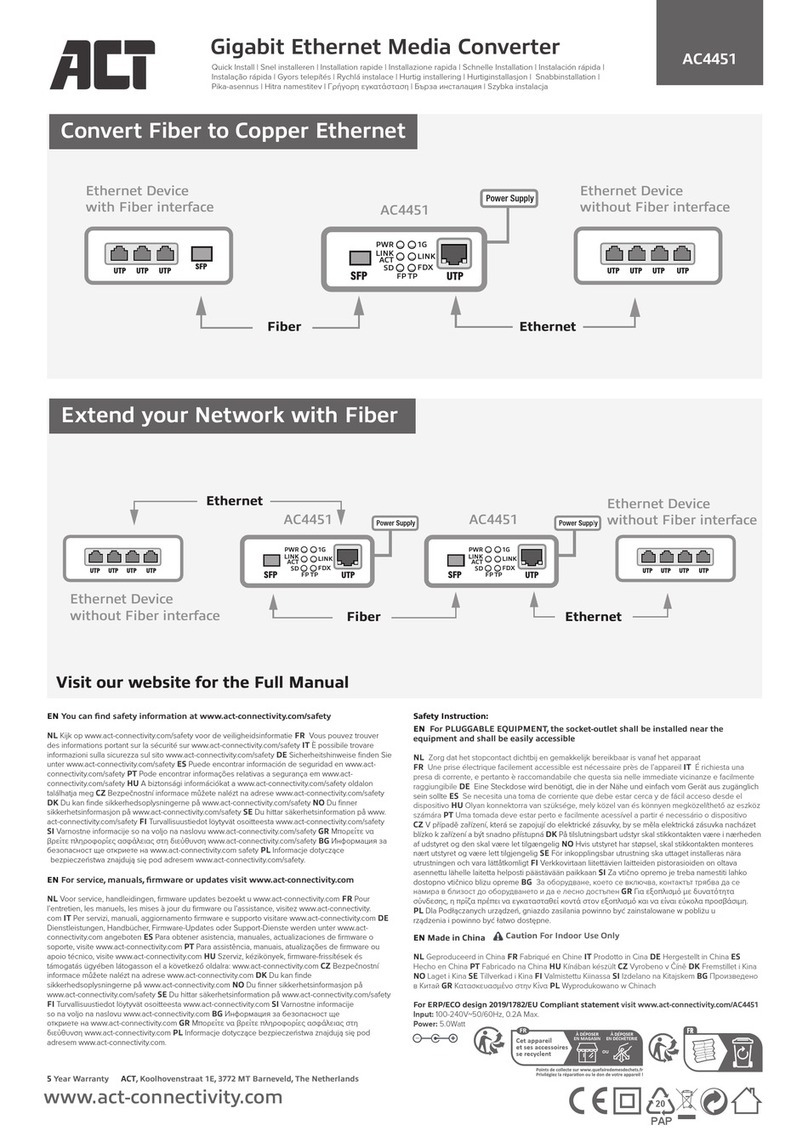

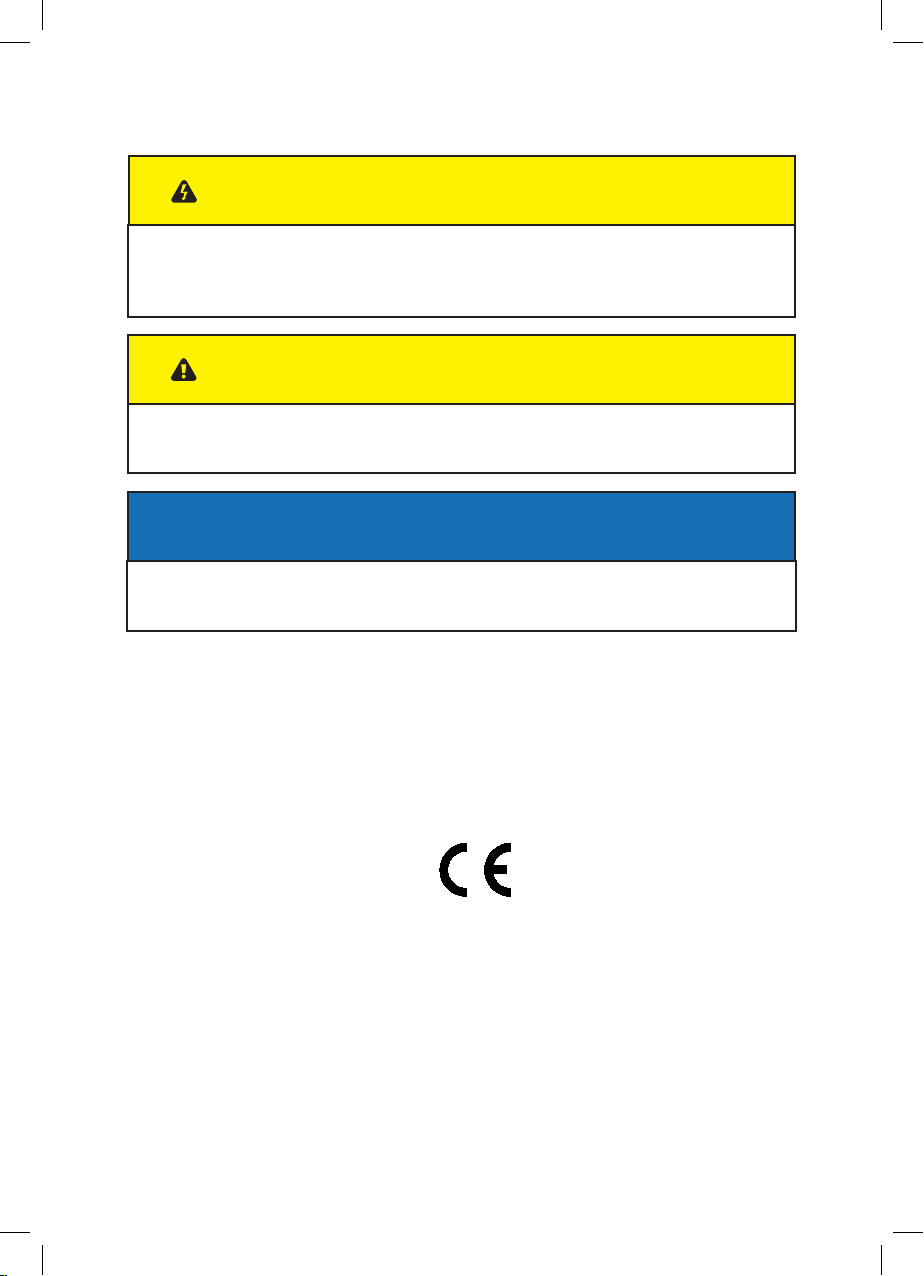

fig_2_1 fig_2_2

10

EUROMAG | MC608 | TD210-1

www.euromag.com

1. PRELIMINARY NOTES

The main parts composing the electromagnetic flow meter consists of:

A. The sensor – is installed in the pipes using flanges or threaded attachments or clamp attachments

B. The converter – may be installed on the sensor (in compact version), or nearby (in remote version)

connected via two cables.

Electromagnetic flow meters have many important advantages with respect to relevant mechanical

counterparts, including among the others: outstanding long term stability, maximum process reliability, no

need for maintenance. Consequently, these sensors can deliver accurate and reliable measurements for

many years.

Please see the paragraphs below for more detailed instructions on correct installation.

ELECTROMAGNETIC FLOW METERS ARE SPECIFICALLY DESIGNED

TO WORK UNDER FEW BASIC CONDITIONS:

1. LIQUID MUST BE CONDUCTIVE

2. THE PIPE MUST ALWAYS BE COMPLETELY FILLED

3. INLET AND OUTLET DISTANCES MUST BE THOSE RECOMMENDED

NOTE

2. GENERAL PRECAUTIONS

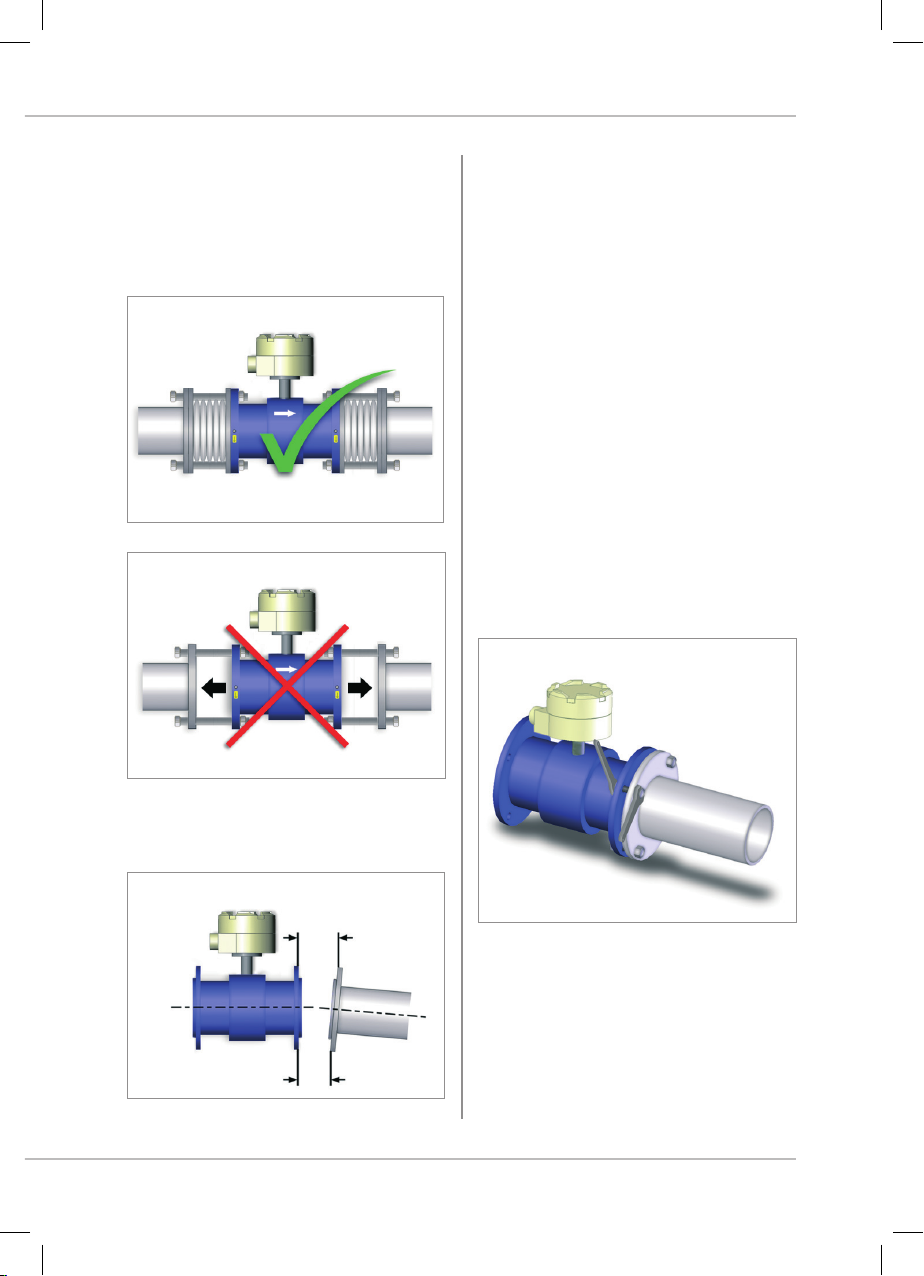

The proper lifting method is shown in Figure fig_2_1, while it must be avoided that shown in Figure fig_2_2; to

be noticed, do NOT raise the flow meter gripping the converter, but always holding it on the sides.

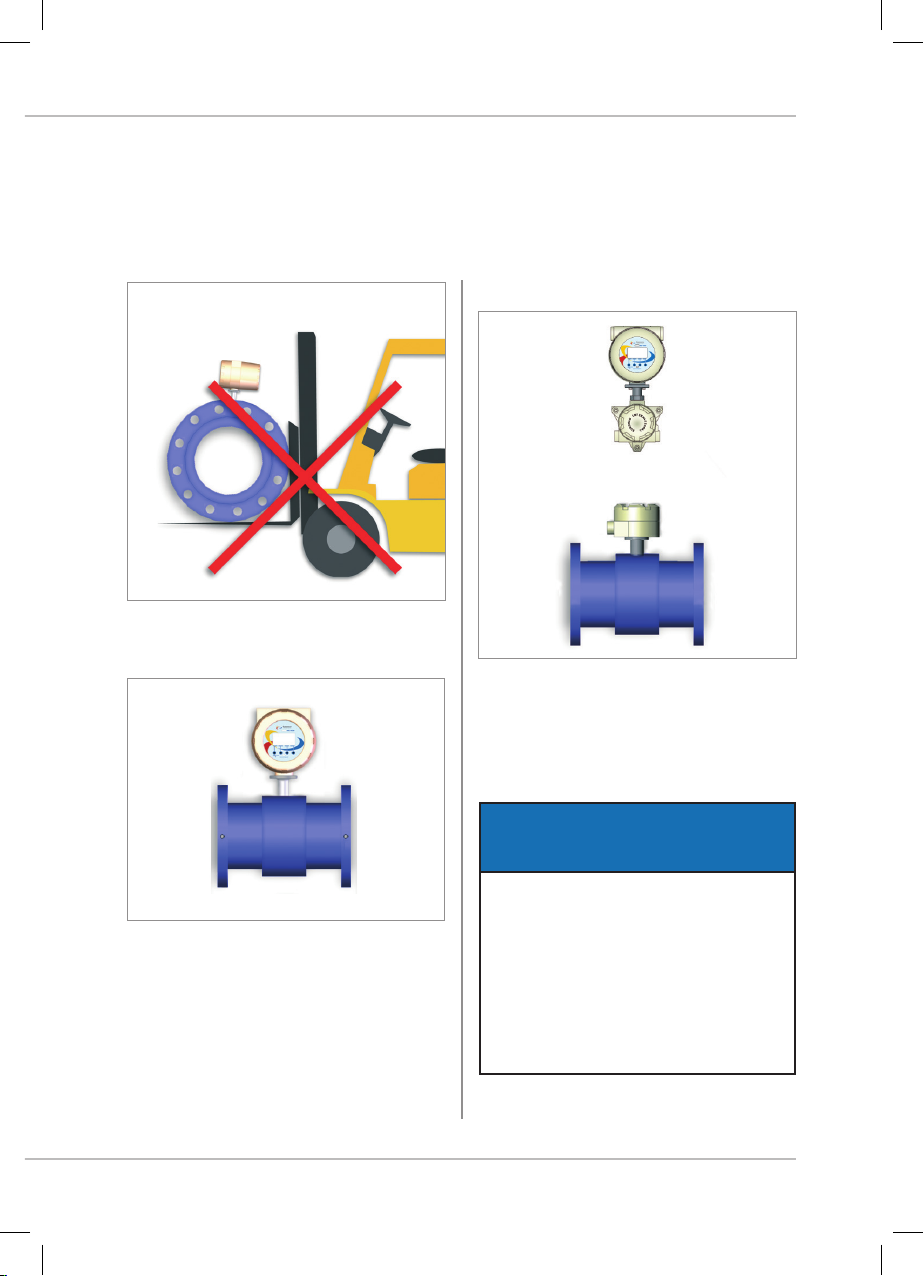

fig_2_3

fig_2_4

fig_2_5

11

Moreover:

DO NOT move the flow meter with the lifting device without the original packaging or without the help

of an appropriate support, ensuring the required stability.

2. GENERAL PRECAUTIONS

THE JUNCTION BOX ON THE

SENSOR IS DESIGNED TO BE IP68

PROTECTED ONLY WHEN PROPERLY

CLOSED AND FULL TIGHTENED.

THE MANUFACTURER ACCEPTS NO

LIABILITY FOR IMPROPER CLOSING

CARRIED OUT BY THIRD PARTIES.

NOTE

Compact version

Separate version

IP67 (Nema 4X)

• possibility of immersion 1 meter;

• maximum immersion time 12 hours. Separate

version

IP67 Electronics (Nema 4x)

IP68 Sensor (Nema 4x)

• possibility of continuous immersion in 1.5

metres water column.

fig_3_1

12

EUROMAG | MC608 | TD210-1

www.euromag.com

3. INSTALLATION OF

THE SENSOR

3.1 IDENTIFYING DATA PLATE

The plate located on the sensor carries the

following data:

• MODEL:

• PART No.: the part number identifying the

device (identification number for tracing the

identity)

• DN: nominal diameter [inches or mm]

• PN nominal pressure [bar/s]

• Temp.: maximum process temperature

• IP: international degree of protection

• ELECTRODES: composition of the material

making up the electrodes

• LINING: internal lining material

• KA: calibration coefficients

• ART.: other special guidelines

3.2 BIDIRECTIONAL READING

In the sensor, if the liquid flows:

• in the same direction of the arrow (enter by – and exit by +), the flow is positive and the display will

show a reading with no sign;

• in the opposite direction to that indicated by the arrow (enter by + and exit by –), the flow is negative

and the display will show a reading with negative sign;

FLOW direct flow -> figure without signnegative figure-> reverse flow

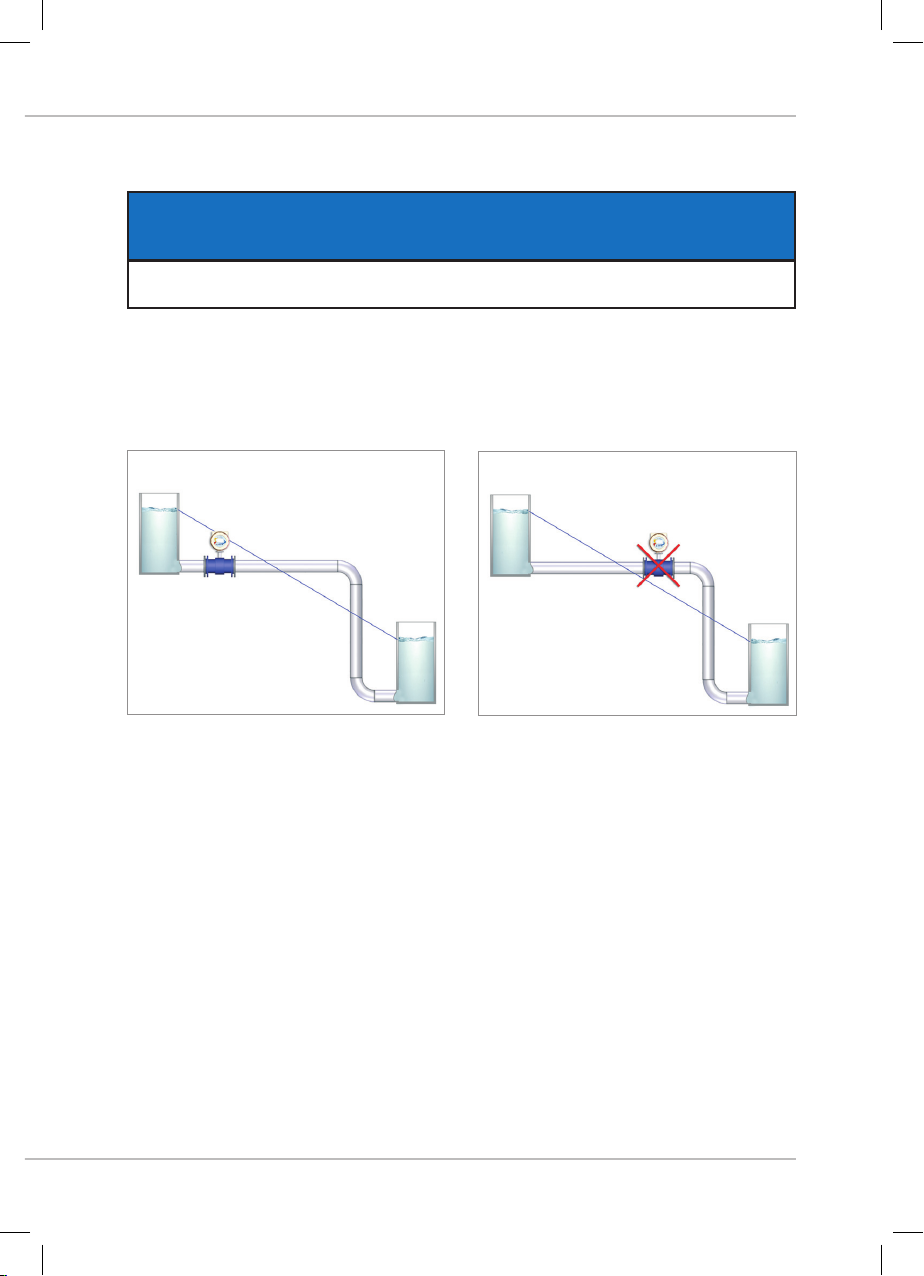

fig_331_2

fig_331_1

13

3.3.1 POSITIONING IN RELATION TO THE PLANT

For efficient working conditions, please carefully follow the instructions in figure 3_3_1.

The flow meter must remain below the hypothetical blue line (piezometric level line) which connects the

two levels of fluid to be measured.

3. INSTALLATION OF THE SENSOR

THE SENSOR MUST ALWAYS BE COMPLETELY FULL WITH LIQUID!

IMPORTANT NOTE

INSTALLATION INSTRUCTIONS

Avoid placing the flow meter above the piezometric

level line

fig_332_5

fig_332_4

fig_332_3

fig_332_1

fig_332_2

14

EUROMAG | MC608 | TD210-1

www.euromag.com

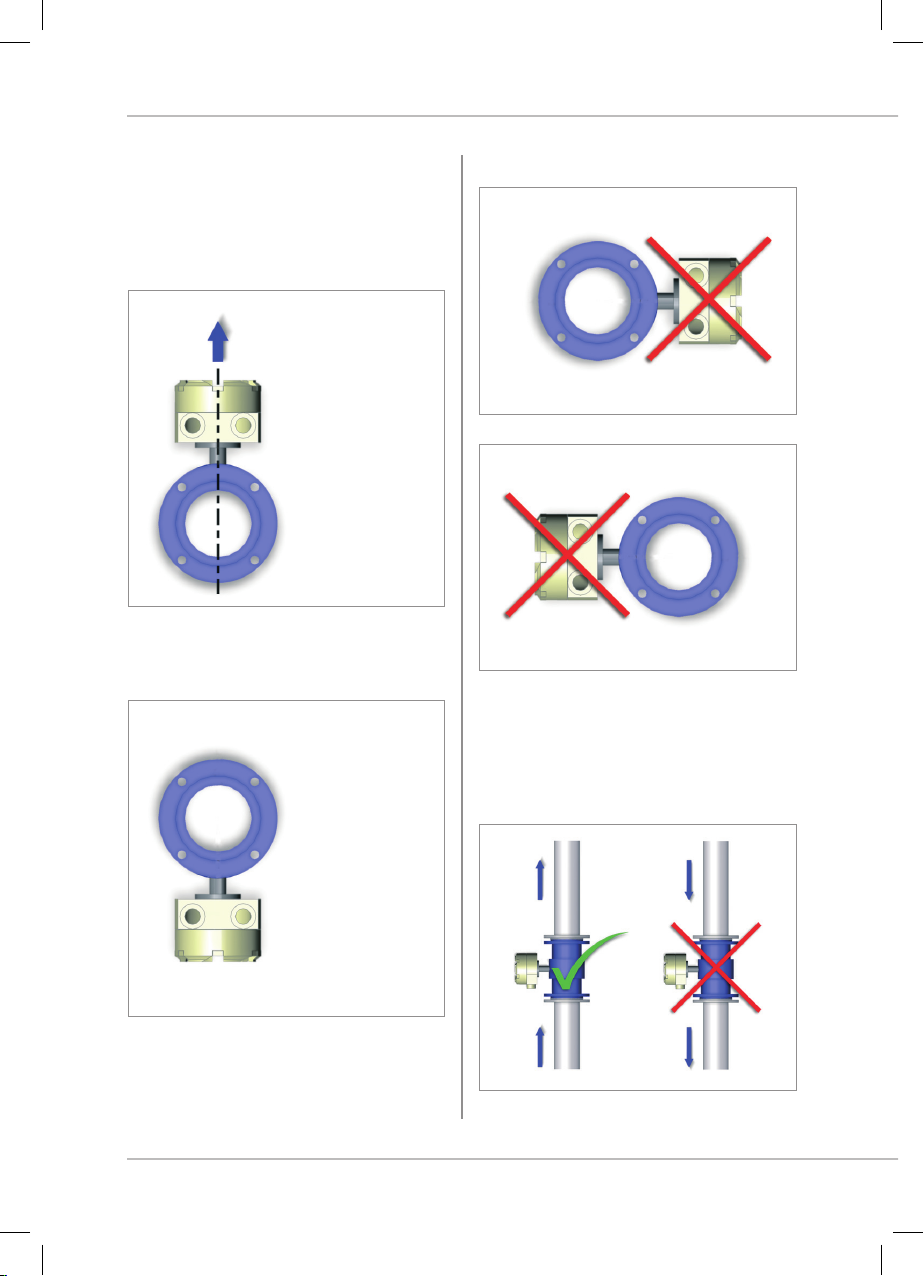

3.3.2 POSITIONING IN RELATION TO THE

FLOW

With installations on horizontal pipes, the converter

(or the junction box in the separate version) must

be placed upright to ensure the proper functioning

of the empty pipe detection.

In case of obstruction, follow the guidelines as

explained in the figures below.

Avoid following positions:

Recommended installation is on a vertical/inclined

pipe with upward flow direction, to minimize the

wear and deposits in the sensor. Avoid installation

in vertical pipes with free outlet.

The only position

that can assure

correct empty pipe

detection

Installation

NOT enabling

the empty pipe

detection

TOP

fig_333_3

fig_334_1

fig_333_2

fig_333_1

15

3.3.4 CHARTS OF MAXIMUM

ALLOWABLE TIGHTENING TORQUES

Standard bolts must be well lubricated and tightened

evenly around the gasket. If the bolts are tightened

excessively, they may result in leaks or damage to

the flow meter or to the pipe. Carefully follow any

instructions provided by the graphics, carefully check

the correct centring of the sensor before attaching the

flanges and then proceed by following the steps below:

Step 1. approx 50% of maximum tightening torque;

Step 2. approx 80% of maximum tightening torque;

Step 3 100% of the maximum tightening torque

provided in the chart.

All values are theoretical and were calculated

for optimum conditions and use with carbon steel

flanges.

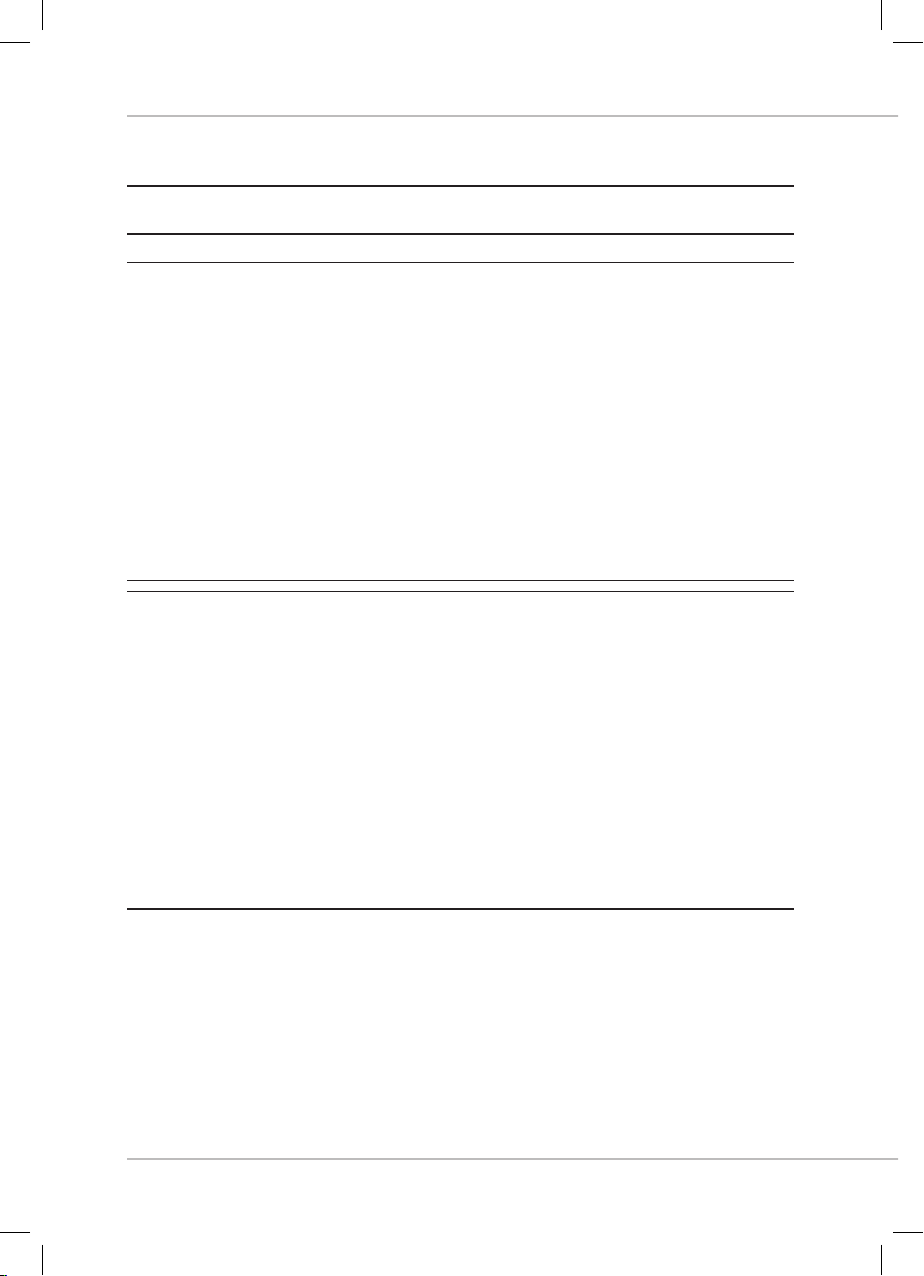

3.3.3 IMPORTANT INSTRUCTIONS ON

MOUNTING

Use elastic pipe fittings where there is not adequate

distance between the sensor and the pipe. Do not

attempt to bring the pipe to the sensor by tightening

the bolts.

Max. allowable deviation of pipe flange faces is

0.5mm

L max

L max. - L min. ≤5 mm

3. INSTALLATION OF THE SENSOR

16

EUROMAG | MC608 | TD210-1

www.euromag.com

PPBT+ MUT 1100J FIBREGLASS

Sensor Maximum operating pressure Pipe flange - Flange - Class Max. allowable tightening

torques

[bar] [psig] flange class [Nm] [ftlb]

DN 40 ≤10 ≤145 DN 40 PN 16/40 25 13

DN 50 ≤10 ≤145 DN 50 PN 16/40 35 19

DN 65 ≤10 ≤145 DN 65 PN 16/40 35 19

DN 80 ≤10 ≤145 DN 80 PN 16/40 35 19

DN 100 ≤10 ≤145 DN 100 PN 16/40 45 24

DN 125 ≤10 ≤145 DN 125 PN 16/40 65 35

DN 150 ≤10 ≤145 DN 150 PN 16/40 85 45

DN 200 ≤10 ≤145 DN 200 PN 16/40 100 53

1 1/2” ≤10 ≤145 1 1/2” 150/300 25 13

2” ≤10 ≤145 2” 150/300 35 19

2 1/2” ≤10 ≤145 2 1/2” 150/300 35 19

3” ≤10 ≤145 3” 150/300 35 19

4” ≤10 ≤145 4” 150/300 45 24

5” ≤10 ≤145 5” 150/300 65 35

6” ≤10 ≤145 6” 150/300 85 45

8” ≤10 ≤145 8” 150/300 100 53

fig_335_1 fig_335_3

fig_335_2

17

3.3.5 IMPORTANT GUIDELINES FOR

CORRECT INSTALLATION

For a correct working condition please follow

the important guidelines shown in the following

figures. Improper installation result in inaccurate

measurement.

To achieve the most accurate flow measurement

it is essential to have minimum straight lengths

of the inlet and outlet pipes as shown (DN: sensor

nominal diameter)

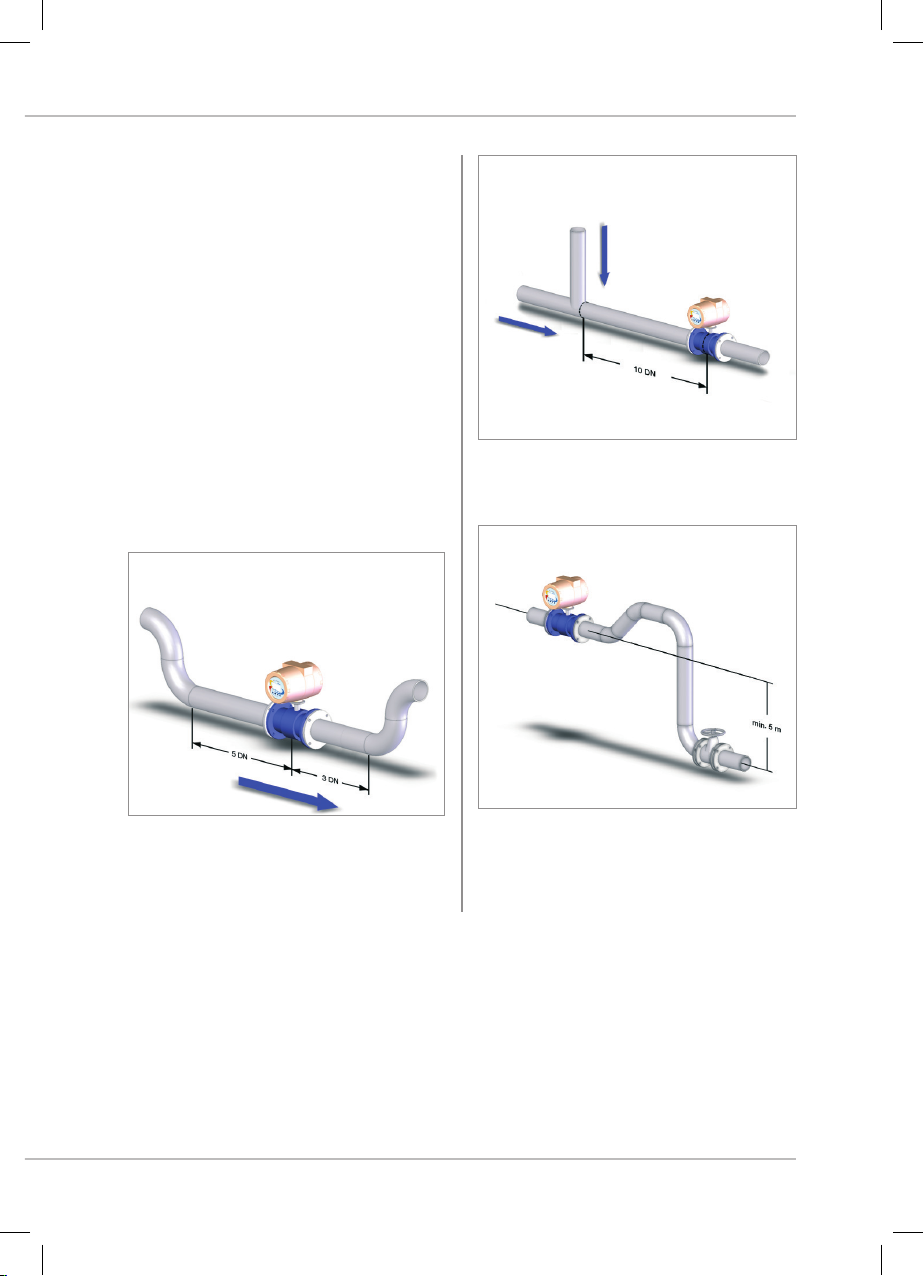

• For partially filled pipes or pipes with downward

flow and free outlet, the flow meter should be

located in a U-tube, respecting the upward and

downward lengths between the curves.

• In the case of T-connection between two

different tubes, please keep a 10DN distance

upstream of the flow meter.

• Keep 5 meters between the axis of the flow

meter and those of the gate valve placed

downstream.

3. INSTALLATION OF THE SENSOR

fig_335_5

fig_335_7

fig_335_6

fig_335_4

18

EUROMAG | MC608 | TD210-1

www.euromag.com

RECOMMENDED INSTALLATIONS ( ) AND THOSE TO BE AVOIDED ( ):

• In this installation the sensor is full with liquid • The position on the left is correct, the other two

ARE NOT.

• DO NOT place the sensor close to any variation

in the path of the flow.

• This installation DOES NOT guarantee a full pipe

condition.

THE SENSOR MUST ALWAYS BE COMPLETELY FULL WITH LIQUID!

IMPORTANT NOTE

fig_335_12

fig_335_9

fig_335_10

fig_335_11

fig_335_8

19

• DO NOT install the sensor in vertical pipes with

free outlet or at the highest point in the pipe

system

• Always install the sensor downstream the pump

and NEVER upstream to avoid vacuum.

• DO NOT use the sensor as a support for the tube.

• The tube must act as a support for the flow

meter.

• DO NOT place any gate valve directly connected

upstream the sensor.

3. INSTALLATION OF THE SENSOR

fig_335_15

fig_336_2

fig_336_3

fig_336_1

20

EUROMAG | MC608 | TD210-1

www.euromag.com

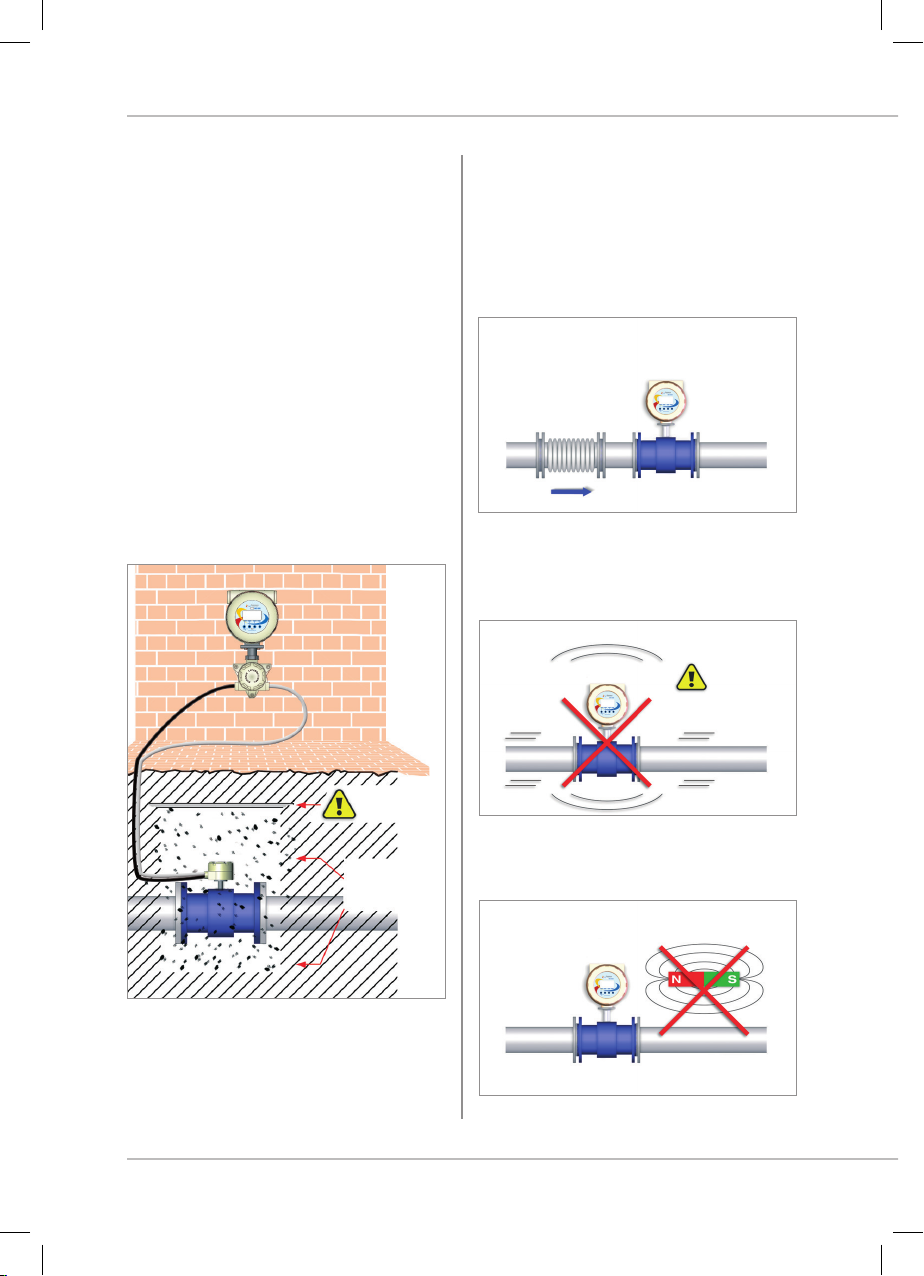

UNDERGROUND INSTALLATIONS

• The remote sensor is protected to IP68/NEMA

6P and can be positioned underground. We

recommend the use of gravel for at least

300mm (12 inches) around the sensor. This

provides certain drainage and prevents dirt from

solidifying on the sensor, in addition it facilitates

its location whenever new excavations are

required. Before covering the gravel with earth,

we suggest using electrical cable identification

tape above the gravel itself.The remote sensor

cable should pass through a conduit made of

plastic and of minimum 50mm (2 inches).

• It is recommended the junction box made of

steel in the case of underground installations.

3.3.6 IMPORTANT GENERIC INDICATIONS

FOR A CORRECT INSTALLATION

• Install a suitable anti-vibrational protection if

any vibration arise.

• DO NOT expose the flow meter to vibrations and/

or movement, which may affect its performance

and duration.

• AVOID exposing the flow meter to strong or

nearby magnetic fields.

Protective cover

Fill with an

adequate amount

of material

AVOID ANY

EXCESSIVE

VIBRATIONS

Other manuals for MC608 Series

1

This manual suits for next models

3

Table of contents

Other Euromag Media Converter manuals