MC608 SUMMARY 0

EUROMAG | MC608 | Ed. 10/2018

EUROMAG | MC608 | Ed. 10/2018

1 INTRODUCTION 5

1.1 MANUFACTURER’S STATEMENT............................................................................................... 5

1.2 PACKAGING VERIFICATION....................................................................................................... 5

1.3 PRELIMINARY NOTES ................................................................................................................ 6

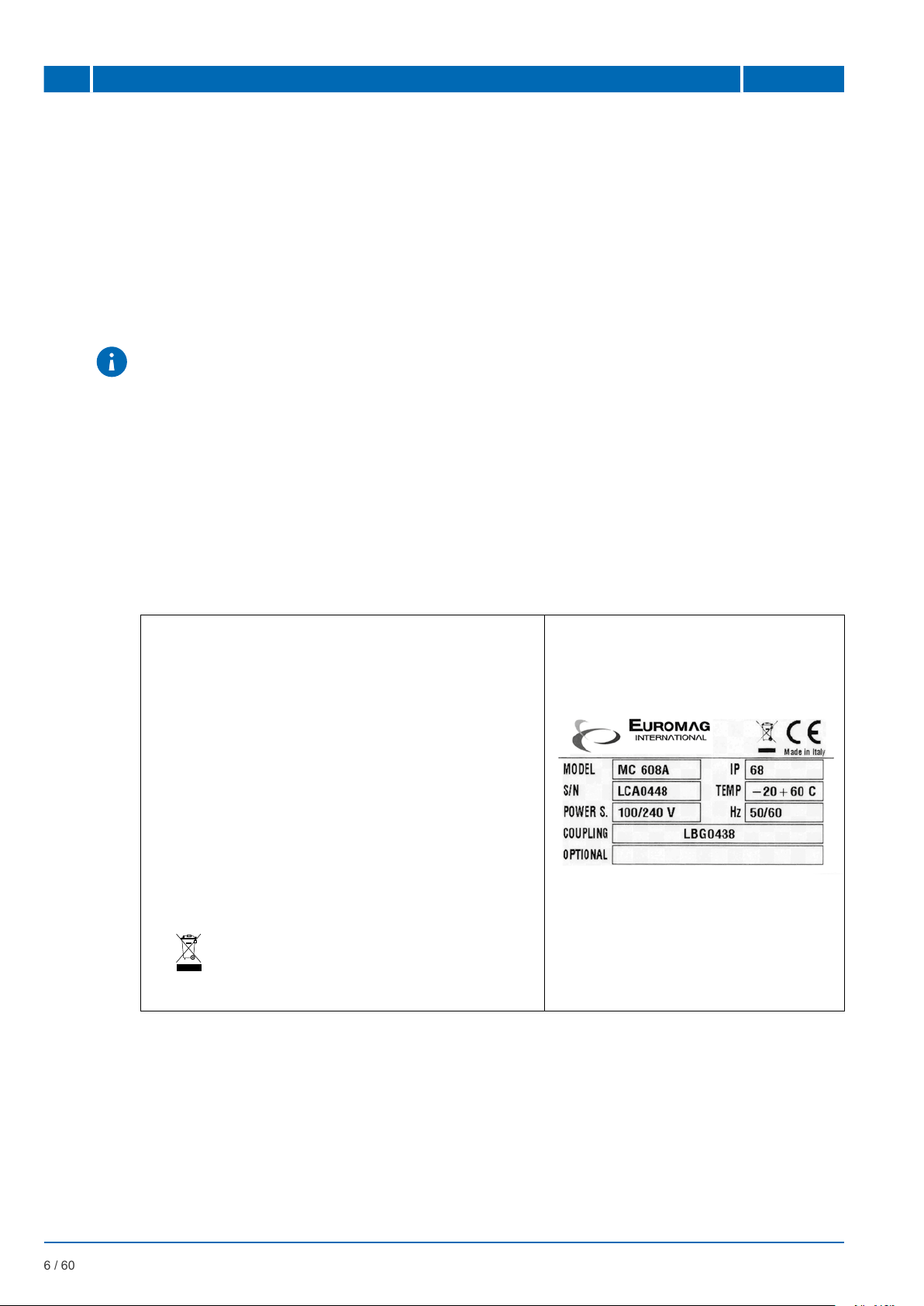

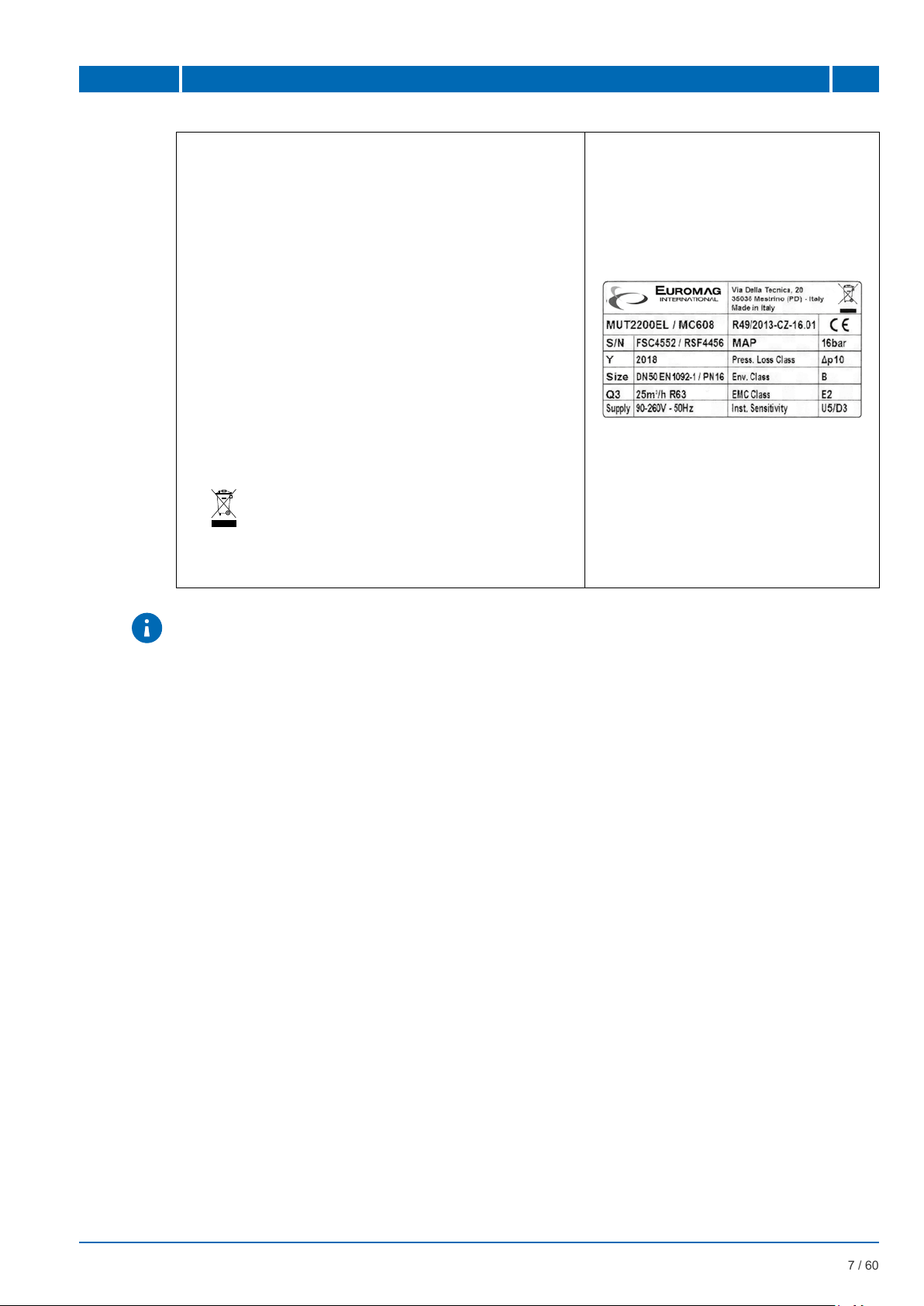

1.4 PRODUCT IDENTIFICATION....................................................................................................... 6

1.5 APPLICATIONS............................................................................................................................ 7

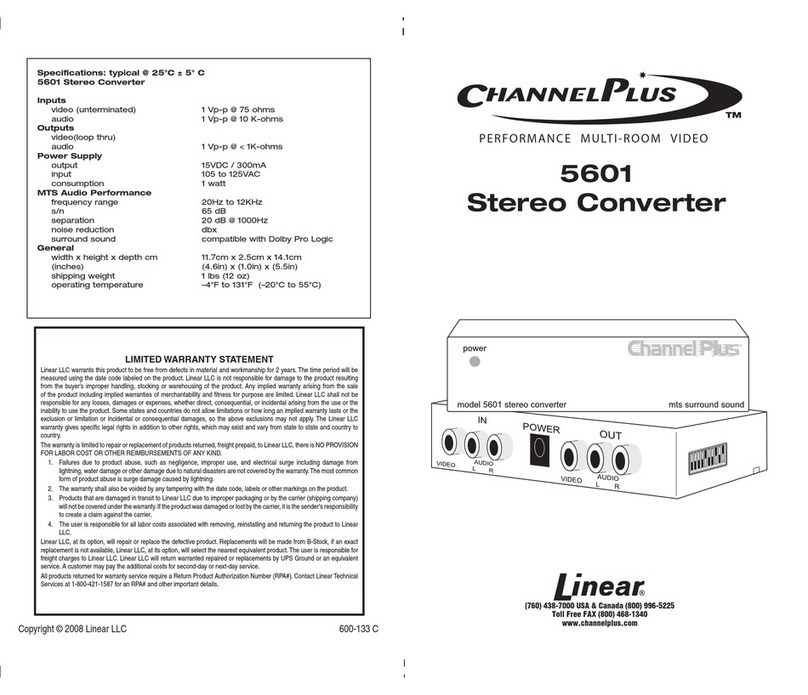

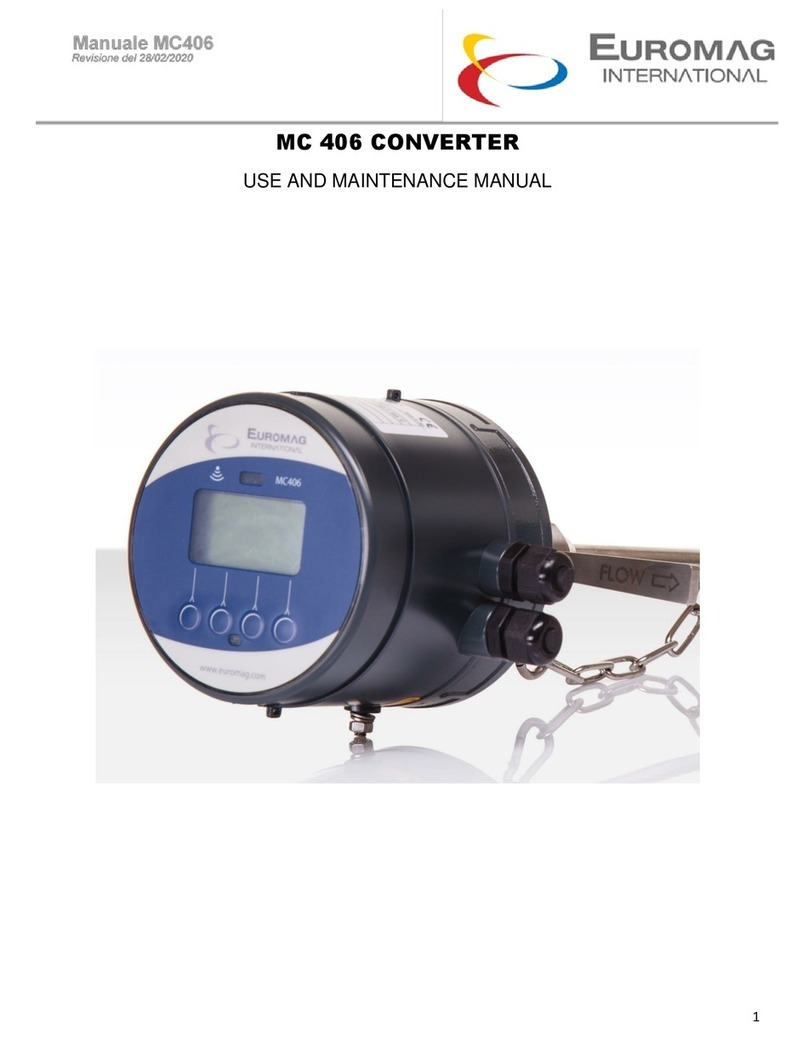

2 PRODUCT DESCRIPTION 8

2.1 OPERATING PRINCIPLE ............................................................................................................. 8

2.2 AVAILABLE VERSIONS ............................................................................................................... 8

2.3 CONVERTER INSTALLATION TYPES ...................................................................................... 10

2.4 CASING ...................................................................................................................................... 10

2.5 POWER BATTERIES.................................................................................................................. 10

2.6 DATA SAFETY ............................................................................................................................ 11

2.7 REMOTE DATA READING ......................................................................................................... 12

2.8 OPTIONAL MODULES ............................................................................................................... 12

2.8.1 Hart protocol available for MC608A............................................................................................ 12

2.8.2 Optional module Pression/Temperature for MC608A. ................................................................ 12

3 TECHNICAL SPECIFICATIONS 13

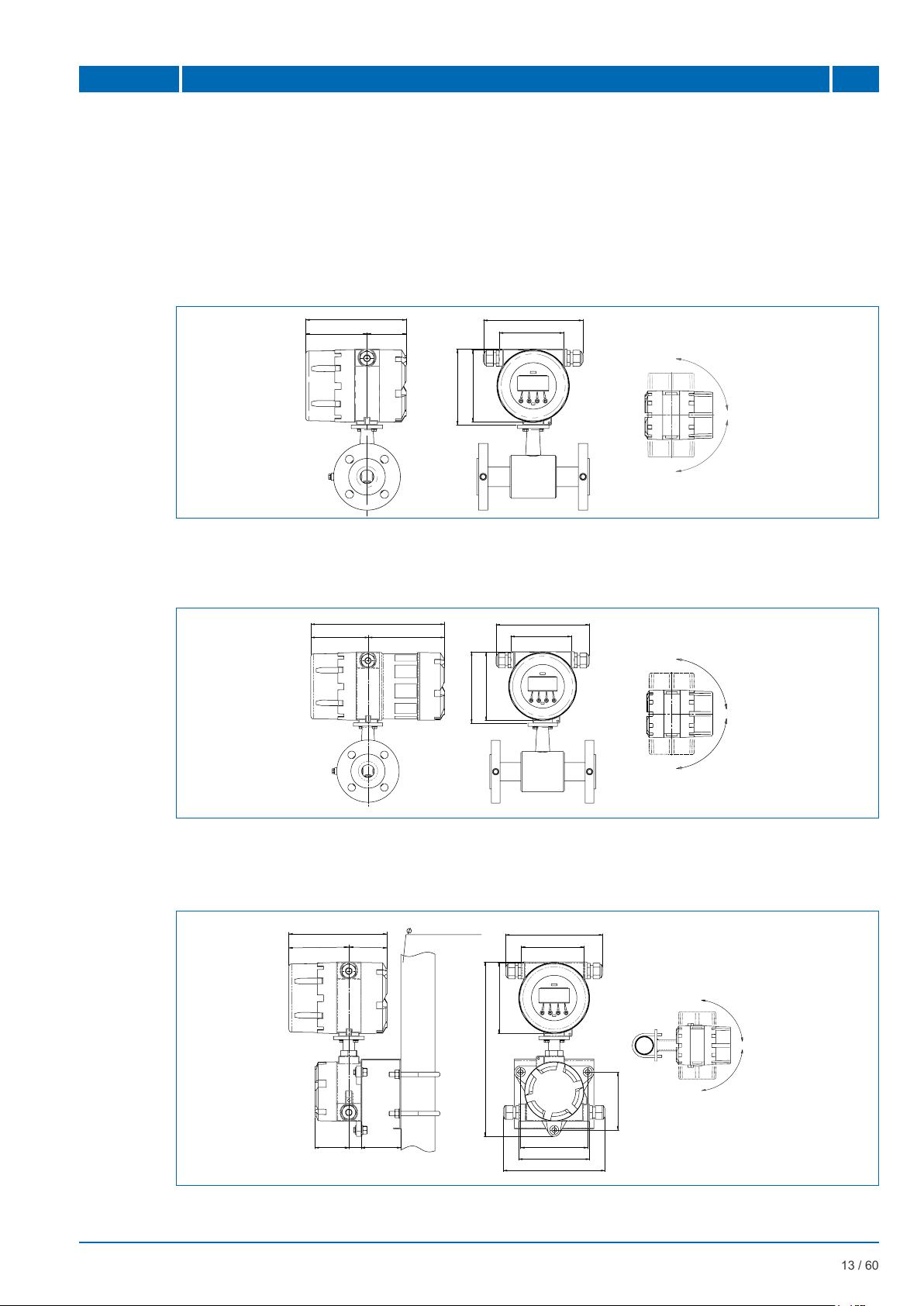

3.1 OVERALL DIMENSION .............................................................................................................. 13

3.1.1 Version MC608A (COMPACT) .................................................................................................... 13

3.1.2 Version MC608B/R (COMPACT) ................................................................................................ 13

3.1.3 Version MC608A (REMOTE) ...................................................................................................... 13

3.1.4 Version MC608B/R (REMOTE)................................................................................................... 14

3.1.5 Version MC608P (REMOTE) ...................................................................................................... 14

3.1.6 Version MC608I (REMOTE)........................................................................................................ 14

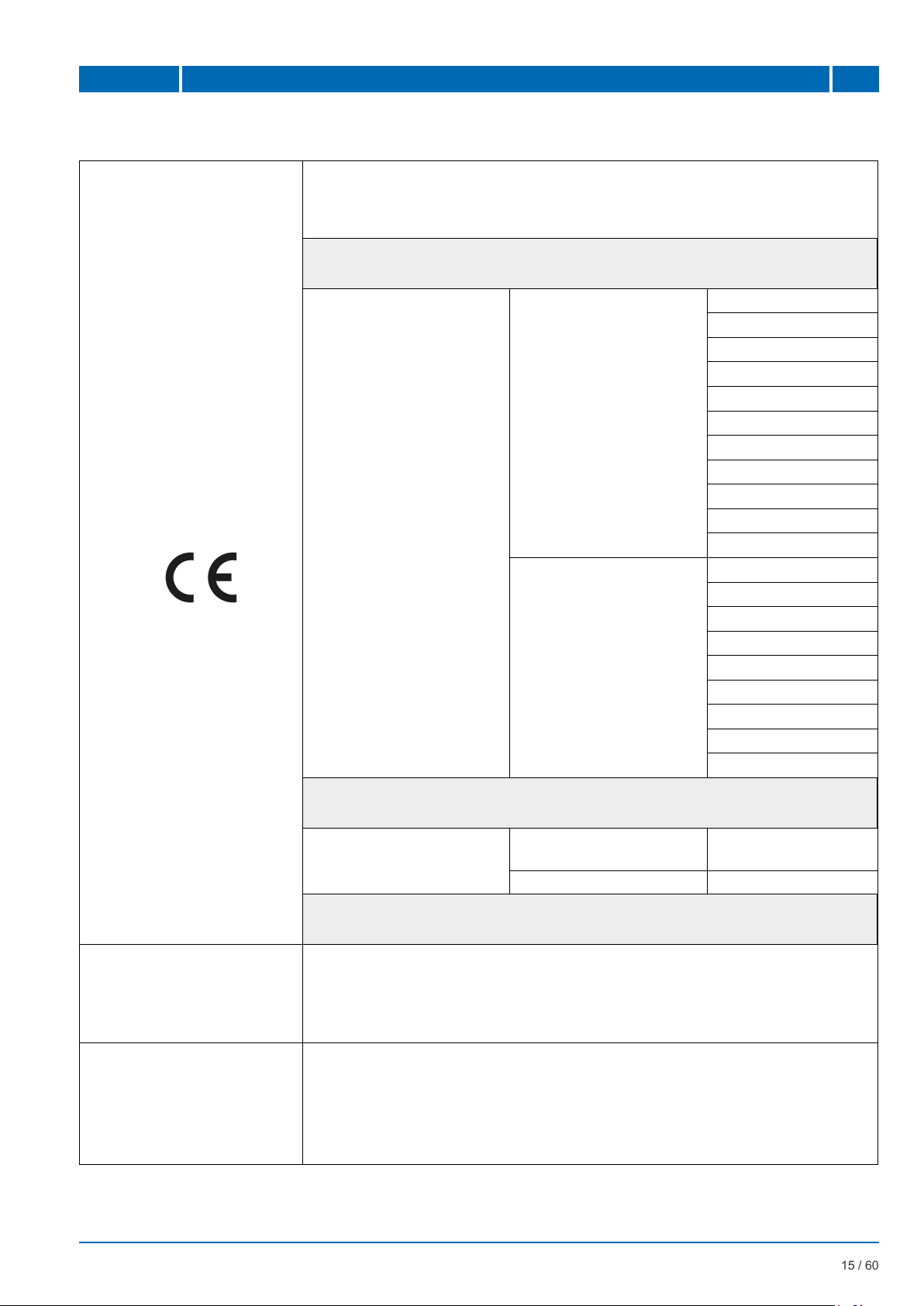

3.2 CERTIFICATES AND APPROVALS............................................................................................ 15

3.3 GENERAL TECHNICAL FEATURES.......................................................................................... 16

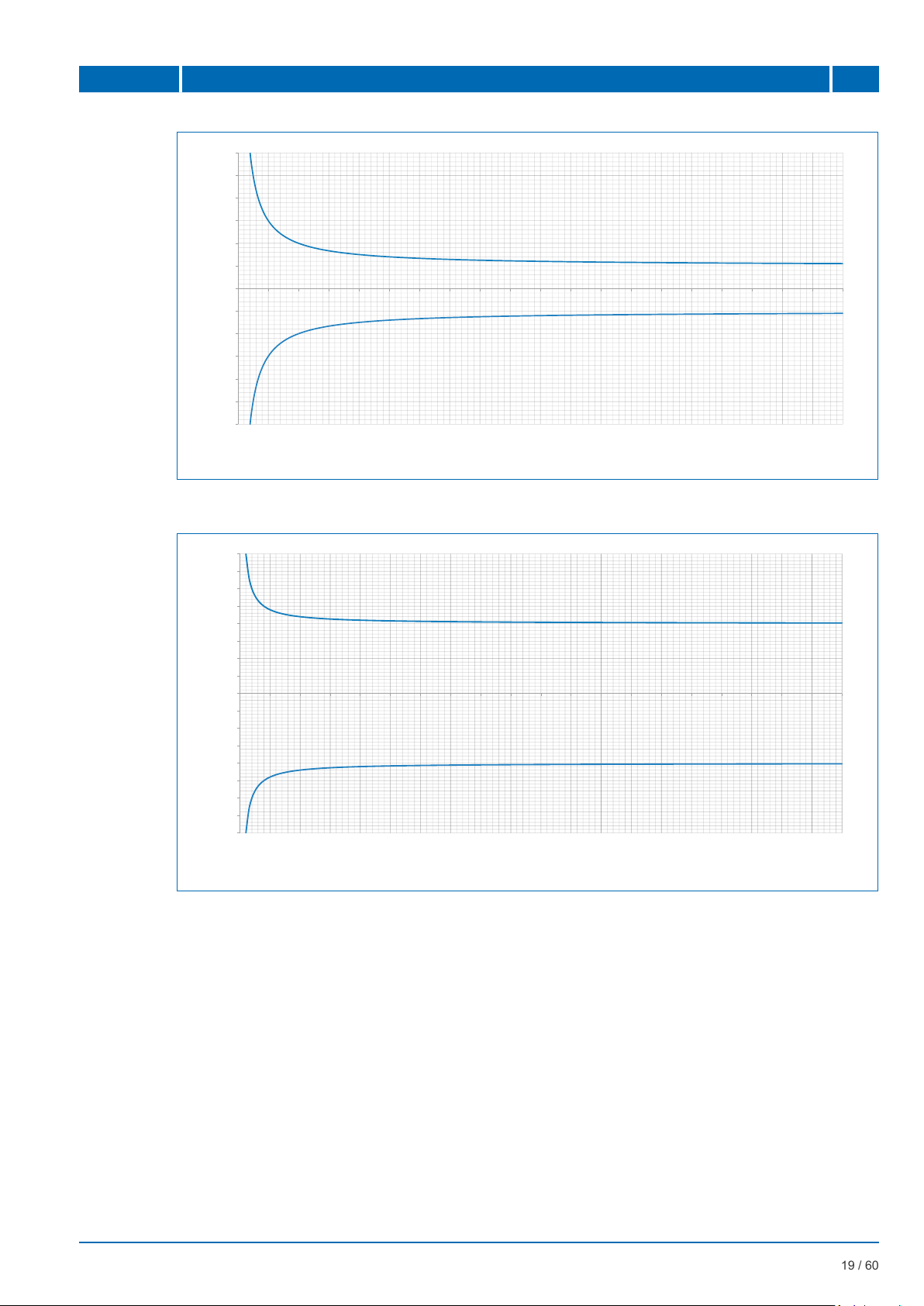

3.4 ACCURACY................................................................................................................................ 18

3.4.1 Reference conditions: ................................................................................................................. 18

4 INSTALLATION 20

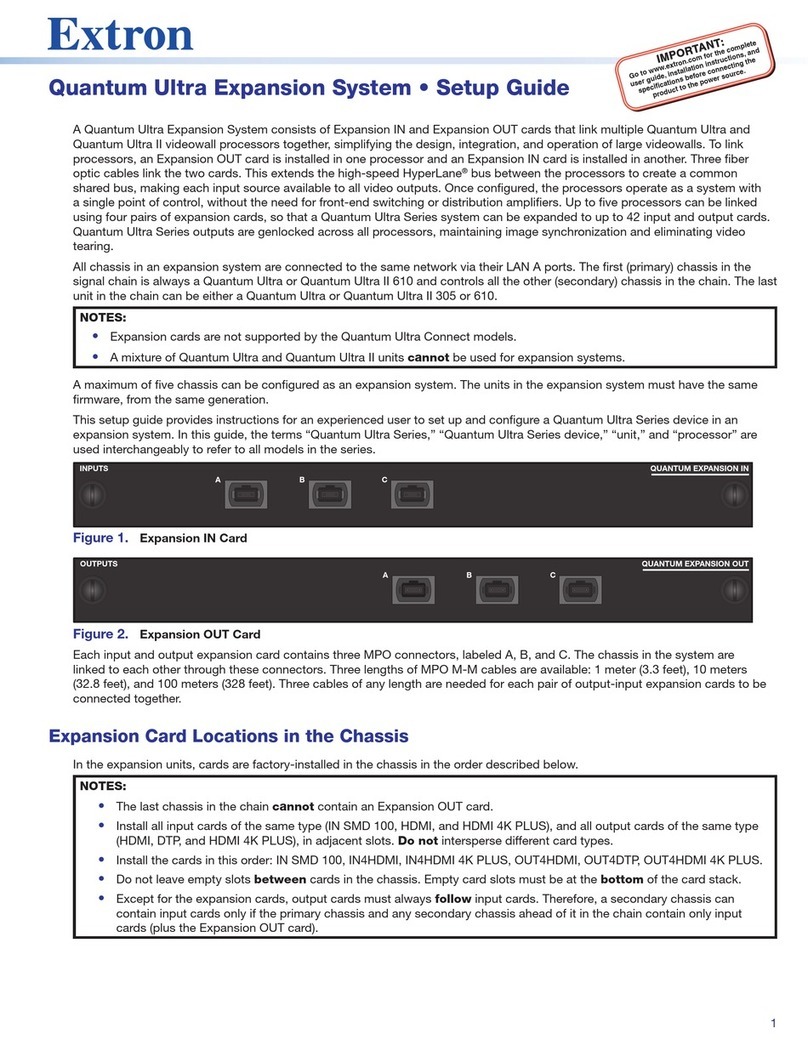

4.1 MOVING ..................................................................................................................................... 20

4.2 CONVERTER POSITIONINIG.................................................................................................... 21

4.2.1 Positioning/installation of the converter in COMPACT version ................................................... 21

4.2.2 Positioning/installation of the converter in REMOTE version...................................................... 22

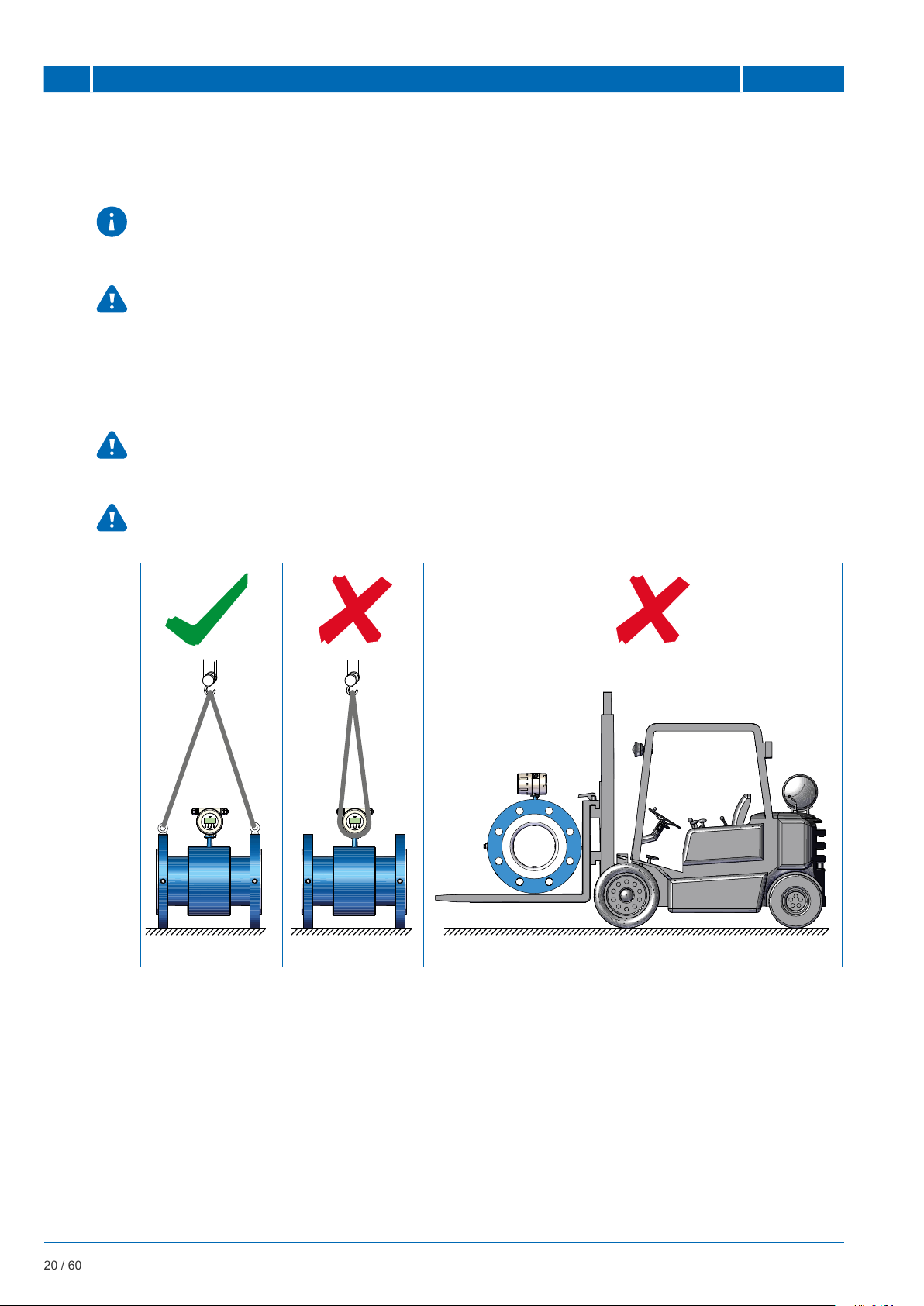

4.2.3 Relation between conductivity and cable length......................................................................... 23

4.2.4 Installation of the solar panel on MC608R in the COMPACT version......................................... 24

4.3 ELECTRICAL CONNECTION..................................................................................................... 25

4.3.1 Wiring diagram............................................................................................................................ 25

4.3.2 Connection to the sensor............................................................................................................ 27

4.3.3 Connection options I/O ............................................................................................................... 27

4.3.3.1 Pulse output................................................................................................................................ 27

4.3.3.2 Programmable output ................................................................................................................. 28

4.3.3.3 Output 4…20mA ......................................................................................................................... 29

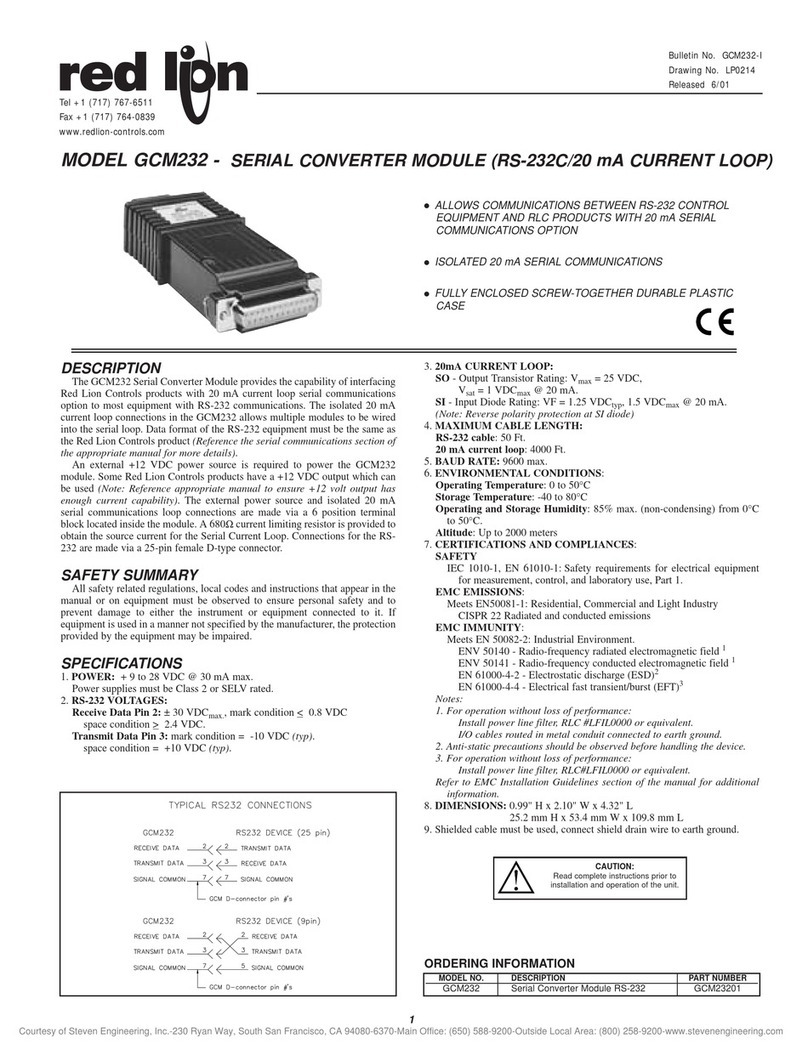

4.3.3.4 MODBUS RS485 interface ......................................................................................................... 29

4.3.4 Electrical grounding of the converter .......................................................................................... 30