EUROPRO 50TR User manual

USER MANUAL

THREE-PHASED COMPRESSORS

EUROPRO 50TR & 100TR

Ref. 90469 & 90284

EUROPE PROJECTION - 228, avenue Olivier Perroy 13790 ROUSSET

Tél : +33 (0)4 42 29 08 96 – Fax : +33 (0)4 42 53 44 36

SAS au capital de 400 000€ - SIREN 394 961 510 – NAF 2892 Z

Edition of 18/06/2019

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP2

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P3

SUMMARY

1. INTRODUCTION...........................................................p. 4

2. USER MANUAL ...........................................................p. 5

2.1. Importance of the manual .................................................p. 5

2.2. Receivers of the manual ..................................................p. 5

3. WARNING.................................................................p. 6

3.1. Safety ...................................................................p. 6

3.2. Electric connection .......................................................p. 8

3.3. End-of-life of the product ..................................................p. 8

4. YOUR COMPRESSOR .....................................................p. 9

4.1. Description ..............................................................p. 9

4.2. Technical characteristics ..................................................p. 9

4.3. Identication of the components EUROPRO 50TR ..........................p.10

4.3. Identication of the components EUROPRO 100TR .........................p.11

5. USE OF THE MACHINE....................................................p.12

5.1. Prerequisites.............................................................p.12

5.2. Starting up ...............................................................p.12

5.3. Stopping of the compressor ...............................................p.12

6. MAINTENANCE AND SERVICING ..........................................p.13

6.1. Once per week ...........................................................p.13

6.2. Every 200 working hours ..................................................p.13

7. DEFECTS AND REMEDIES ................................................p.14

8. DECLARATION OF CONFORMITY .........................................p.15

9. WARRANTY...............................................................p.17

9.1. Warranty conditions ......................................................p.17

9.2. Warranty certicate .......................................................p.19

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP4

1. INTRODUCTION

You just acquired a three-phased compressor and all the team of Europe Projection thanks you for

the condence you have granted us.

Manufacturer of professional equipments for paint and llers, we have put our know-how for 20 years

at the service of the users of our machines.

Our technical and commercial team is at your disposal for any further information you may need about

the machine you just acquired.

EUROPE PROJECTION

228, avenue Olivier Perroy 13790 ROUSSET

Tél : +33 (0)4 42 29 08 96 – Fax : +33 (0)4 42 53 44 36

SAS au capital de 400 000€ - SIREN 394 961 510 – NAF 2892 Z

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P5

2. USER MANUAL

2.1. IMPORTANCE OF THE MANUAL

This manual is a key part for the use of your machine. It summarizes the procedures of starting-up,

cleaning and maintenance of the device and also the safety instructions you need to observe.

Read carefully all the working and safety instructions and the warnings included in this manual before

starting your machine.

Most of the accidents are caused by the non-compliance of the safety standards and rules.

This manual must be kept near the machine, within reach of the user and held in good condition until

the nal destruction of the machine.

In case of loss or deterioration of the manual, you can ask the machine manufacturer mentioned on

page 4 for a copy at any moment.

2.2. RECEIVERS OF THE MANUAL

This manual is intended to any staff which will manipulate the machine :

- people in charge of the transport of the machine

- people in charge of the use of the machine

- people in charge of the cleaning and maintenance of the machine

- people in charge of the nal destruction of the machine

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP6

3. WARNING

3.1. SAFETY

Using the machine in an incorrect way or in non-compliance of the safety instructions

indicated in this manual can cause death or serious injuries.

Read carefully all the working and safety instructions and the warnings contained in this

manual before starting your machine.

• Respect all the safety standards before running the equipment.

• Use the equipment only for the applications specied in the manual.

• Always remain alert when using the equipment.

• Transport the machine using the handles or the appropriate grips.

• During the breaks, disconnect electrically the machine.

• Run the equipment to its nominal voltage.

• Let at least 50 cm of free space between the equipment and any obstacle so that the air

ow is not blocked.

• Know how to quickly stop the equipment in case of necessity.

• Never use the equipment while it is running abnormally or it is defective.

• Do not direct a water jet or ammable liquid on the compressor.

• Never direct an air jet or product jet on a person or an animal.

• Do not touch warm surfaces of the equipment.

• Always wear adequate body protections (glasses, gloves, overall and mask) and pay

attention to long hair.

• Never touch moving parts.

• Do not insert any object or the hands inside the protection grids to avoid any accident or

damage to the machine.

• For any outside job, only use appropriate extension cords.

• Maintain the equipment carefully and clean it properly after every use.

• Disconnect the equipment before any intervention.

• Avoid absolutely to unscrew any connection while the machine is under pressure.

• Check the damaged parts.

• Do not clean the plastic parts with solvant.

• In case of damage of the electric cable or the plug, do not run the machine and contact a

licensed After-Sale Service to put genuine parts instead of the defective ones.

• In case of needed After-Sale Service, always specify the machine model and its serial

number.

• For any replacement of parts, only use genuine parts.

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P7

3. WARNING (continued)

3.1. SAFETY (continued)

• Do not cut or dismantle the protection grids.

• Do not transport the compressor when it is working or under pressure.

• Do not modify the machine. Especially puncture holes, weld and voluntarily deform the

compressed air reserve.

WORKSPACE

• Maintain the workspace clean and clear.

• Ambient operating temperature must be from 5°C and 35°C.

• Do not use the equipment in a potentially explosive area.

• Do not place any potentially inammable objects in close proximity to the machine.

• Take away every not qualied person from the working area of the machine, as well as children

and animals.

• In case of installation of the machine on scaffolding or a plan above ground level, attach the machine

to avoid any fall while operating.

• Do not install the equipment on an inclined surface to avoid the risks of unexpected moves or falls.

HOSES

• Always use hoses and connections adapted to the used product (genuine parts), do not try to x it.

• Do not walk on the hoses, do not bend them.

• Do not use the hoses to pull the machine.

• Do not use the hoses with other materials, especially materials with higher pressure.

STORAGE

• After every use of the compressor, drain the tank to empty the water inside of it.

• Keep the equipment in a clean and clear area in which the temperature does not exceed +35°C.

IN CASE OF NECESSITY, WE SAVE OURSELVES THE RIGHT TO MAKE ANY USEFUL

MODIFICATION WITHOUT ADVANCED NOTICE.

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP8

3. WARNING (continued)

3.2. ELECTRIC CONNECTION

The electric connection of the machine must be on a 16A - 400V plug (EUROPRO 50TR) or a

32A - 400V plug (EUROPRO 100TR) with a differential circuit breaker.

Before any intervention on the machine, make sure that every energy supply is cut (air and

electricity).

GROUND CONNECTOR

All the machines must be connected to the ground when they work to protect the operator from electric

shocks. Our machines are all equipped with standardized connection plugs.

Electric connection must be made by a qualied technician. It is fobidden to modify or dismantle the

machine, especially the electric box.

Repairs must be made by an authorized center or our After-sale Service.

During any intervention on the machine, make sure that the ground is well reconnected.

EXTENSION CORDS

During the use of an extension cord, make sure that it is not crushed or damaged and that it contains a

ground. Check that the section of the used extension cord is sufcient to support the machine when it

is working. A too thin extension cord can cause voltage drops or overheating of the machine.

In case of use of a cable reel, it is imperative to unwind it entirely, otherwise, the equipment can be

damaged. The section must be proportional to the length of the cord.

3.3. END OF LIFE OF THE PRODUCT

At its end-of-life, the machine must not be eliminated with the other household waste. The

uncontrolled elimination of waste can harm the environment or human health. Individuals are

invited to contact the distributor which sold them the product or to inquire with their city hall

to know where and how to get rid of the product so it can be recycled while respecting the

environment.

Under the regulation of Waste of Electrical and Electronic Equipments (WEEE), we undertake

to process the used EEEs according to the following provisions: applicable only to products on

the market since 08/13/05, under the brands EUROPE PROJECTION or VOLUMAIR, products

of other brands sold by our company (upon presentation of the corresponding invoices),

products that operate using electrical energy (for example, thermal washers or compressors

do not fall into this category).

Treatment modality

WEEE returns collected by our clients/distributors at their own expense to our collection points

in Antony (92) or Rousset sur Arc (13). Upon receipt, the products are sorted by our employees

and directed to the most appropriate processing channels.

For any further information, contact our hotline +33 4 42 29 08 96 or conseil@euromair.com.

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P9

4. YOUR COMPRESSOR

4.1. DESCRIPTION

The EUROPRO 50TR and 100TR compressors are machines designed for intensive use on all types

of jobs.

They operate on a three-phase electrical supply. They are equipped with a phase inverter, an automatic

valve that controls the pressure in the tank, an air outlet with quick-connect half-coupling and 4 folding

transport arms.

Uses: sprayer, sander, pneumatic paint-stripper, slurry and paint spray-gun, inator, stapler, etc.

Do not use the compressors for dietary or medical applications. In certain applications,

the addition of an air dryer and/or oil separator can be necessary.

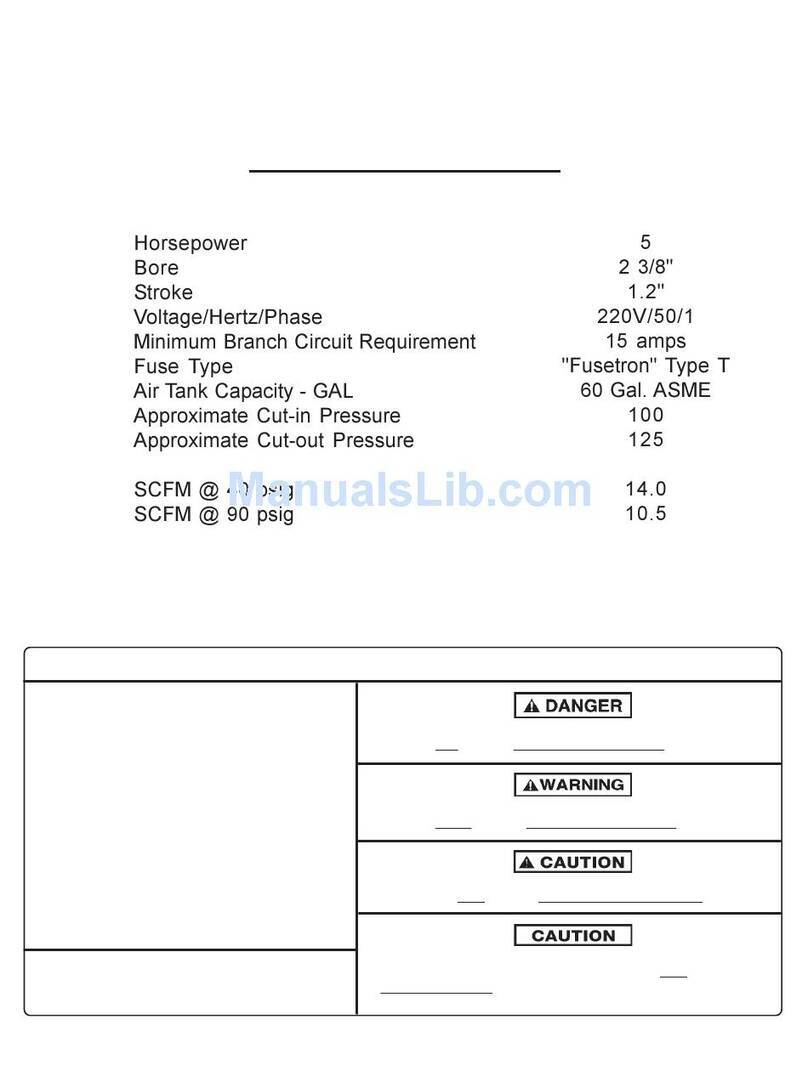

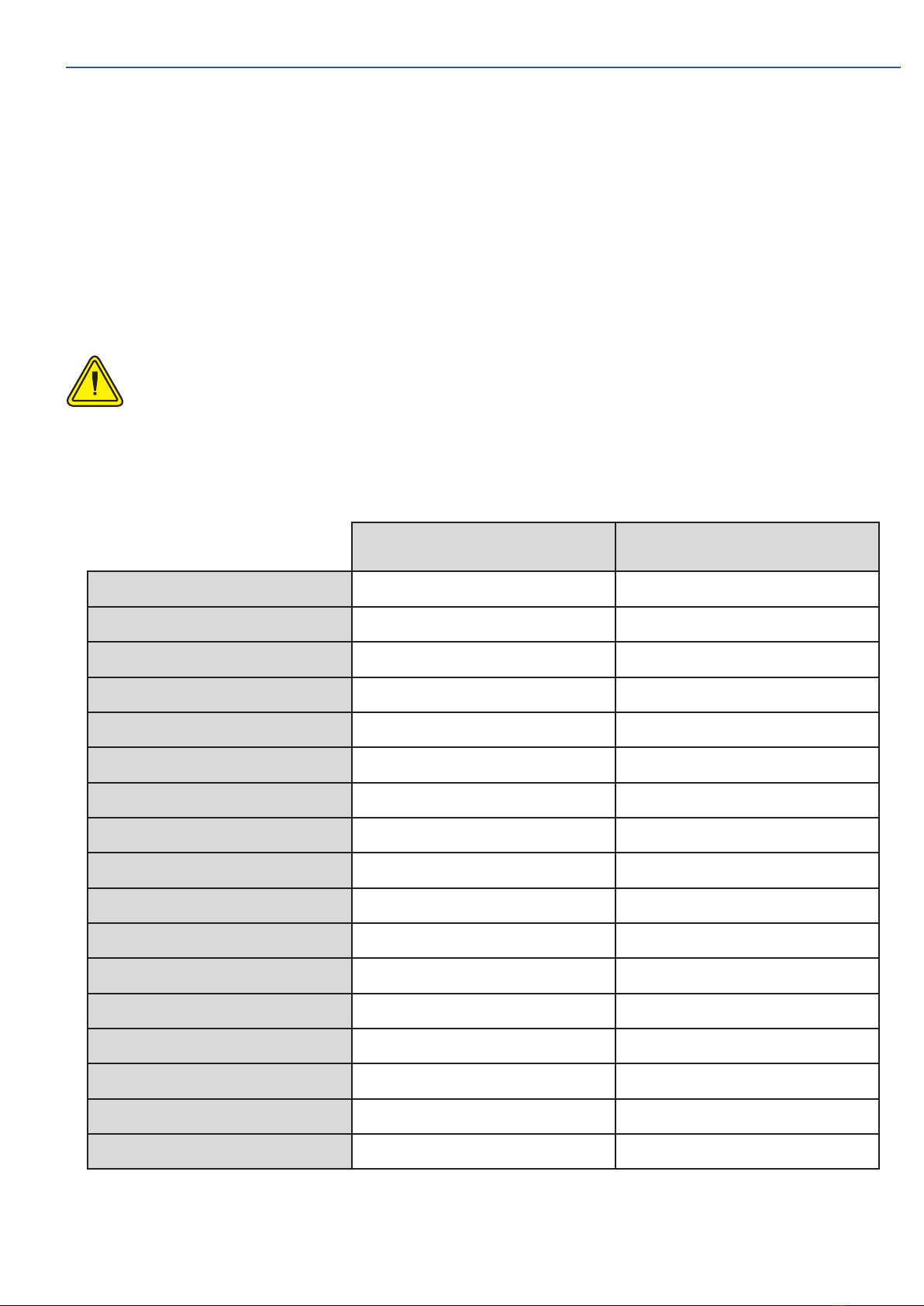

4.2. TECHNICAL CHARACTERISTICS

EUROPRO 50TR EUROPRO 100TR

Rotation speed 1215 RPM 1300 RPM

Flow-rate of air absorbed 820 L/min (49 m3/h) 1080 L/min (65 m3/h)

Quantity of oil (crankcase) 1,4 L 1,6 L

Oil consumption 1,5 g/h 1,2 g/h

Motor power 5,5 kW 7,5 kW

Transmission by belt by belt

Electrical supply 400 V 400 V

Frequency 50 Hz 50 Hz

Current 12,2 A 16,8 A

Thermal protection yes yes

Safety valve yes yes

Tank capacity 1,64 L 2,64 L

Maximum pressure 10 bar 10 bar

Air coupling quick-connect quick-connect

Dimensions (L x w x h) 98 x 69 x 73 cm 109 x 70 x 85 cm

Weight 118 kg 177 kg

Noise level 99 Lwa 101 Lwa

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP10

4. YOUR COMPRESSOR (continued)

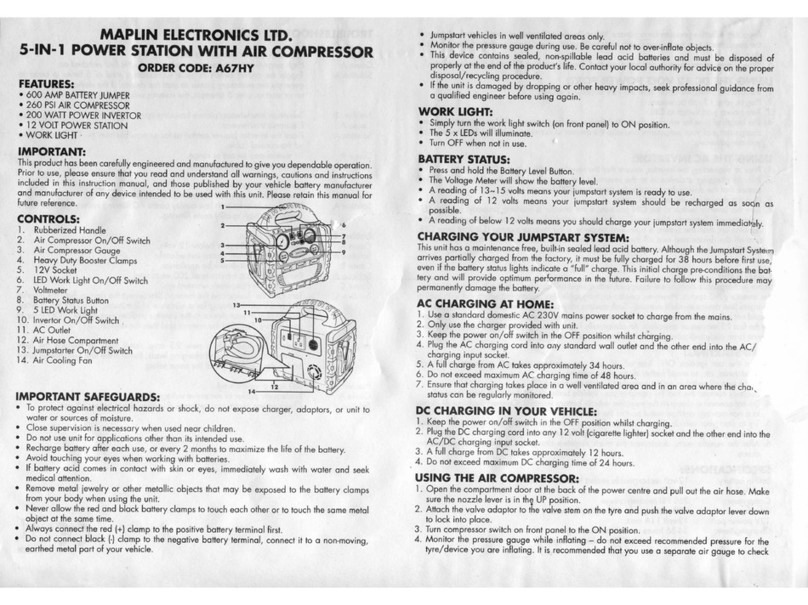

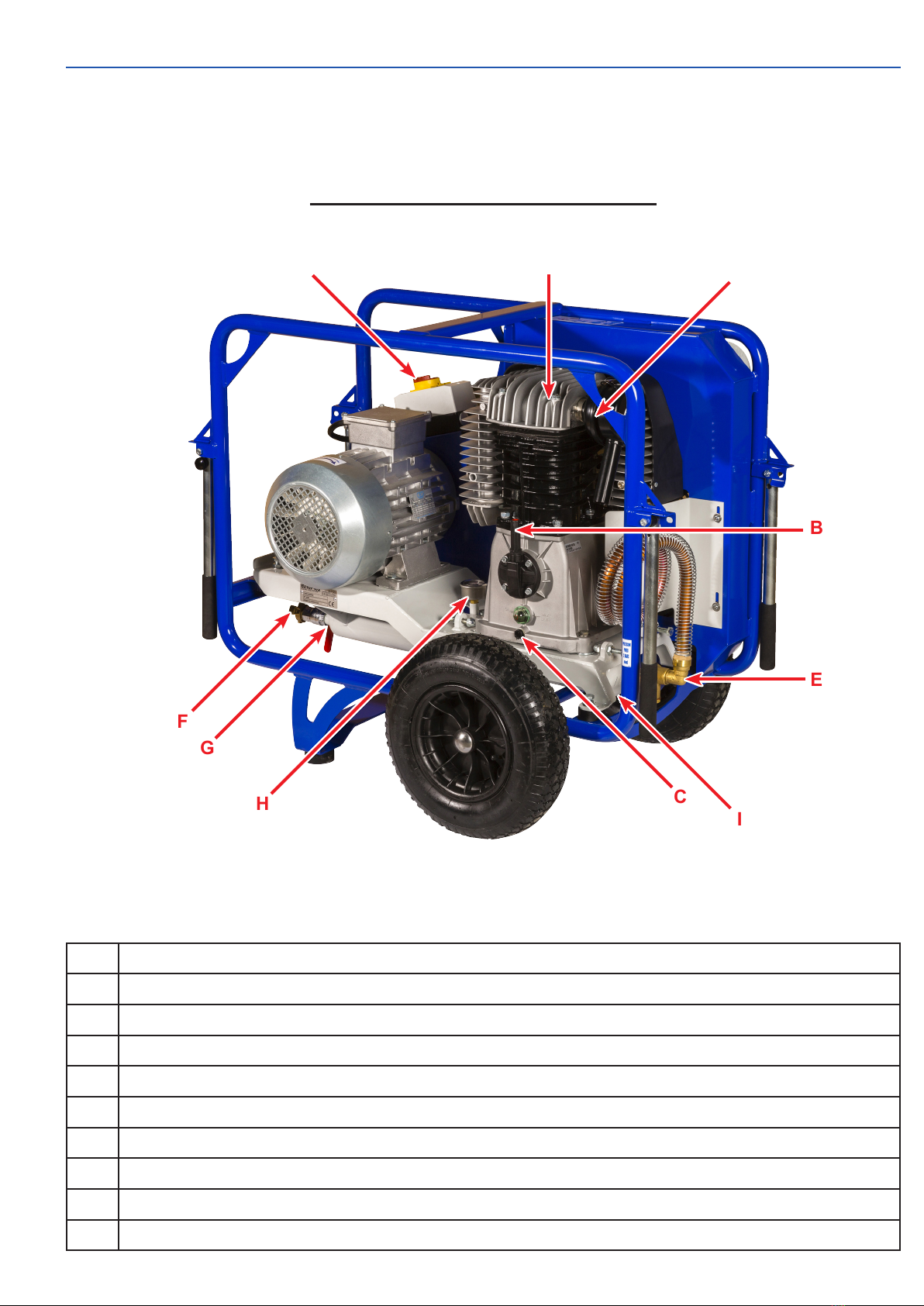

4.3. IDENTIFICATION OF THE COMPONENTS

EUROPRO 50TR

ACompressor head

BOil dipstick

CDrain plug

DAir lter

EAutonomous valve

FQuick-connector

GAir valve

HTank pressure manometer

IDrain screw

JBox and interrupter

A

B

E

C

H

FG

I

J

D

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P11

4. YOUR COMPRESSOR (continued)

4.3. IDENTIFICATION OF THE COMPONENTS

EUROPRO 100TR

ACompressor head

BOil dipstick

CDrain plug

DAir lter

EAutonomous valve

FQuick-connector

GAir valve

HTank pressure manometer

IDrain screw

JBox and interrupter

JAD

B

E

I

C

H

G

F

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP12

5. USE OF THE MACHINE

5.1. PREREQUISITES

• For the EUROPRO 50TR: the electric connection has to be 400 V - 16 A - 50 Hz with a 4 x 2,5 mm

cable reel of 40m maximum, completely unreeled.

• For the EUROPRO 100TR: the electric connection has to be 400 V - 32 A - 50 Hz with a 6 x 2,5 mm

cable reel of 40m maximum, completely unreeled.

• The compressor is equipped with a thermal circuit breaker which stops the engine when it has

reached a temperature which is too high.

If the compressor fuse has blown, the power switch (K) turns to "OFF". Wait several minutes to let

it cool down, then reset the main circuit breaker (K) onto position "ON".

Reduce the length of the electrical cord or use a cable with a bigger cross-section.

If the defect persists, contact our After Sales Service

Before use, it is imperative to connect and start the compressor, to verify that the direction

of rotation of the motor helix is in accordance with the direction of the arrow (photo 1).

Otherwise, stop the compressor, disconnect it, then invert the phases in the plug by using

a screwdriver (photo 2).

5.2. STARTING UP

Before every utilization, verify the oil level with the dipstick (B). Rell if needed with

the oil ISO 68INH (ref. 80043) until you reach the level "Max" of the dipstick.

1. Drain the air in the tank using the drain screw (I).

2. Connect the compressor electrically.

3. Close the drain screw.

4. Turn the (K) interrupter to the "ON" position and start the compressor.

5. Wait until the pressure of the manometer (H) reaches 8 bars. Once this maximum pressure has

been reached, the autonomous valve will decompress.

6. Connect the equipment (spraying machine, scraper, etc…) to the compressor on the quick connector (F),

then open the valve (G). The exact setting of the outlet pressure will be done on the connected equipment.

7. Start to use your equipment.

5.3. STOPPING OF THE COMPRESSOR

1. Close the valve (G), then purge the air remaining in the hose.

2. Detach the equipment linked to the compressor.

3. Open the drain screw and let the compressor for about 2 minutes to evacuate all the condensation

which was created in the tank.

4. Turn the (K) interrupter to the "OFF" position to shut down the compressor.

5. Close the drain screw (I).

6. Disconnect electrically the compressor

Photo 1 Photo 2

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P13

6. MAINTENANCE AND SERVICING

Disconnect the plug of the machine from the electrical network before any intervention..

6.1. ONCE PER WEEK

Blasting air lter

EUROPRO 50TR : unscrew and unclip the air lter (D) and blast it with help of a pressure cleaner.

EUROPRO 100TR : unclip the air lter (D) and blast it with help of a pressure cleaner.

6.2. EVERY 200 WORKING HOURS

Replace the air lter

Unscrew and/or unclip the air lter (D) and replace it.

Oil change

Contact our After-Sale Service : +33(0) 4 42 29 08 96.

Used oil must not be spilled into the environment or the sewage system, but into a

specialized collection site.

In case of the intensive utilization of the compressor, repeat the above mentioned

operations more regularly.

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP14

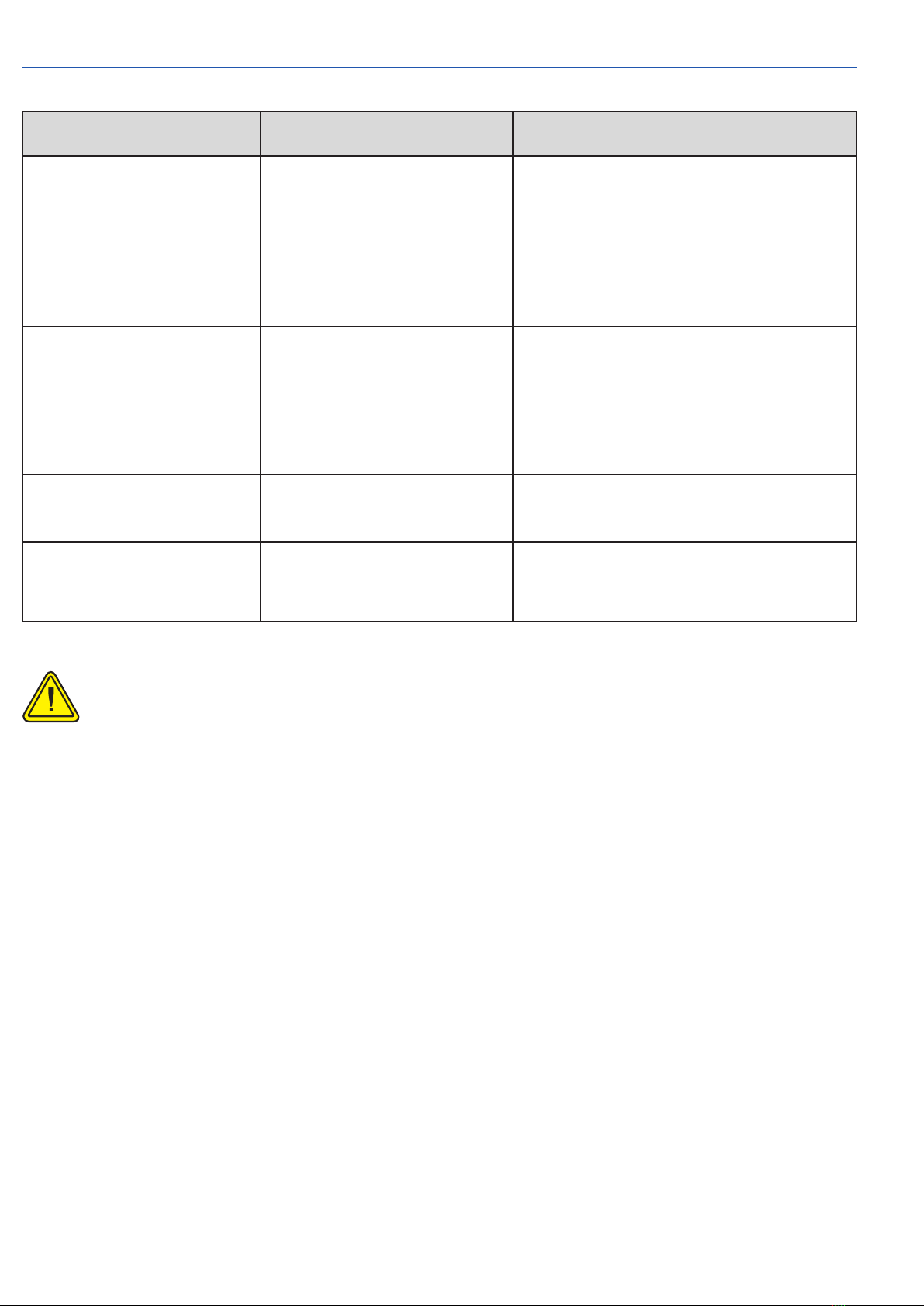

7. DEFECTS AND REMEDIES

Defect Cause Remedy

The compressor short

circuits cuts out

• Bad power supply

• Defective circuit breaker

• Defective circuit cutout

• Reset the circuit breaker (replace if

necessary)

• verify the current, change the plug on

the site

• Verify the cross-section of the

extension cable

The pressure of the

compressor does not go up

• Filter is clogged up

• Drain screw is open

• Air leakage

• Broken valve plate

• Replace the lter

• Screw up or replace the drain screw

• Verify that there is no leakage

• Replace the regulator lter

• Contact the After-Sale Service

The engine roars but does

not start

• Blown condenser

• Lack of oil

• Replace the condenser

• Verify the oil level

The compressor loses

pressure

• Suction lter is clogged

up

• Clean the lter or replace it if it is

damaged

In case of an unknown defect or a doubt on the good running of the machine, do not try to

repair it by yourself or to dismantle it.

Contact an authorized After-Sale Service or our hotline : +33 4 42 29 08 96.

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P15

8. DECLARATION OF CONFORMITY

THE MANUFACTURER : EUROPE PROJECTION

228, avenue Olivier Perroy

13790 ROUSSET

DECLARES THAT THE EQUIPMENT DESIGNATED BELOW :

Trademark : EUROPE PROJECTION

Type : Compressor

Model : EUROPRO 50TR or EUROPRO 100TR

COMPLIES WITH THE ARTICLE:

• the R.233-73 article of the Labour Code

THE DIRECTIVES :

• Machines 2006/42/CE

• Low voltage 2014/35/UE

• CEM 2014/30/UE

• ROHS 2011/65/UE

• Noise emissions 2005/88/CE

AND WITH THE STANDARDS:

• NF EN ISO 12100

• NF EN 60204-1

• NF EN ISO 13857

ROUSSET, APRIL 21th 2019

Patrick BOREL

President

Distributed by : EUROMAIR DISTRIBUTION

228, avenue Olivier Perroy 13790 ROUSSET

Tél : +33 (0)4 42 29 08 96 – Fax : +33 (0)4 42 53 44 36

SAS au capital de 400 000€ - SIREN 394 961 510 – NAF 2892 Z

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP16

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P17

9. WARRANTY

9.1. WARRANTY CONDITIONS

Each product is delivered inspected and tested.

We exclude any warranty for visible defects for which the customer did not claim within 48 hours.

The sold equipments are covered by the warranty for the period dened by the manufacturer from the

purchase date, onwards the date on the original proof of purchase being valid.

This warranty covers any equipment against any manufacturing or material defect for normal use and

service.

The defects or deteriorations caused by natural wear, external accidents or a modication, use, storage

or treatment of equipments not planned by the manufacturer, nor specied by ourselves, are excluded

from any warranty.

Are expressly excluded from the warranty the defects coming from:

- a bad use

- the application of abrasive or corrosive products

- an inappropriate installation

- negligence

- an insufcient maintenance or cleaning

- chemical, electrochemical or electric inuences

- any change in the normal process of use

The following wearing parts are not covered by the warranty:

- rotors, stators, driving shafts, connecting rods, seals, cleaning balls

- spray guns, lance, nozzle, hose, needle kits

- cylinders, piston rods, prime/spray valve assy, seal kits, membranes, suction and delivery valves

- carding machine vanes

- lters, oils

The warranty also excludes the equipments:

- on which the serial number was erased or made illegible

- on which unauthorized people made attempts of repair

- which were totally or partially dismantled

Our equipments are covered by a warranty (parts and labour) of 12 months following the purchase.

The duration of this warranty can be extended by 6 months by completing the warranty extension form

on our website within 4 weeks after purchasing: www.euromair.com (section «Warranty»)

The defective equipments must be sent at the customer’s charge in the place we shall have specied

him. The warranty will be subject to the presentation of the invoice. Then we will be able to proceed,

free of charge, to the repair of the defective equipment.

The equipments repaired (under warranty) will be shipped free of charge to the customer during the

rst year of warranty.

Beyond this date, the transport of the repaired equipment will be chargeable to the customer.

In case of intervention of our services on a breakdown caused by the customer or a breakdown excluded

in the above-mentioned conditions, the costs of repair and transport will be charged to the customer.

We exclude any responsibility for any consequential damages suffered by the customer, such as, but

this without restriction, the losses of income, turnovers, loss of image, of whatever nature.

In any case, our responsibility will be limited to the amount paid by the customer for the defective

equipments.

Any action of the customer against us relative to the warranty of the equipments will be prescribed to

the deadline of 1 year from the day of the discovery of the cause of the action.

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP18

201906-381-ENG User manual - EUROPRO 50TR & 100TR compressors P19

9. WARRANTY (continued)

9.2. CERTIFICATE OF WARRANTY

IT IS COMPULSARY TO RETURN THIS DOCUMENT DULY COMPLETED

BY E-MAIL : contact@euromair.com OR BY FAX : +33(0)4 42 53 44 36

IMPERATIVE

The manual must be provided to the user of the equipment.

It must be read before starting up the machine.

For any intervention under warranty, the purchase invoice must be presented.

WARRANTY

Each product is delivered inspected and tested.

Moreover, it is guaranteed for 12 months from the date of purchase.

This guarantee only applies if the buyer respects the safety regulations, contractual and administrative

standards and if the use was in conformity with the instructions present in the user manual.

Based on this warranty, the manufacturer will repair or replace free of charge any part that can deteriorate

itself or be defective during this period.

The "nal judgment" rests solely with our After-Sale Service technicians.

The guarantee does not cover parts which, because of their specic use, are subject to wear and tear.

If the identied defects could not be attributed to our liability, costs will be charged to the buyer.

MODEL : EUROPRO 50TR or EUROPRO 100TR compressor

SERIAL NUMBER :

DELIVERY NUMBER :

Rousset, dated

Signature of the dealer Signature of the nal user Stamp of the nal user

Distributed by : EUROMAIR DISTRIBUTION

228, avenue Olivier Perroy 13790 ROUSSET

Tél : +33 (0)4 42 29 08 96 – Fax : +33 (0)4 42 53 44 36

SAS au capital de 400 000€ - SIREN 394 961 510 – NAF 2892 Z

User manual - EUROPRO 50TR & 100TR compressors 201906-381-ENGP20

EUROPE PROJECTION - 228, avenue Olivier Perroy 13790 ROUSSET

Tél : +33 (0)4 42 29 08 96 – Fax : +33 (0)4 42 53 44 36

SAS au capital de 400 000€ - SIREN 394 961 510 – NAF 2892 Z

Other manuals for 50TR

1

This manual suits for next models

1

Table of contents

Other EUROPRO Air Compressor manuals