EUROPRO 0701AREN30MAS User manual

EUROPE PROJECTION - 228, avenue Olivier Perroy 13790 ROUSSET - Tél : +33 (0)4 42 29 08 96 – Fax : +33 (0)4 42 53 44 36

SAS au capital de 400 000 € - RCS Aix-en-Provence B 394 961 510 - NAF 2892 Z - Intracom : FR 54 394 961 510

User manual

Edition of 07/04/2020

Mini-Sandblaster 30L

INSTRUCTIONS AND MAINTENANCE MANUAL

2

INDEX

THANKS.................................................................................................................................................... 2

1. MANUAL AIMED TO............................................................................................................................. 3

2. INFORMATION REMARK..................................................................................................................... 3

3. GUARANTEE........................................................................................................................................ 4

4. WASTE PRODUCTS AND ENVIRONMENT........................................................................................ 4

5. EQUIPMENT DESCRIPTIONS ............................................................................................................. 4

5.1. GENERAL DESCRIPTION.............................................................................................................................4

5.2. MAIN COMPONENTS....................................................................................................................................5

5.3. IDENTIFICATION PLATE...............................................................................................................................6

5.4. TECHNICAL FEATURES ...............................................................................................................................7

5.5. REGULATION ................................................................................................................................................7

5.6. SAFETY SYSTEMS........................................................................................................................................8

6. EQUIPMENT INSPECTION WHEN RECEIVED................................................................................... 8

7. USE INSTRUCTIONS ........................................................................................................................... 9

7.1. PRIOR OPERATIONS....................................................................................................................................9

7.2. TANK LOADING.............................................................................................................................................9

7.3. WORKING PRESSURE REGULATION .........................................................................................................9

7.4. ABRASIVE PRODUCT OUTLET REGULATION..........................................................................................10

7.5. CONTROL OF THE ABRASIVE OUTLET ON LEAVING SANDING............................................................10

8. COMPONENTS DISMANTLE............................................................................................................. 11

8.1. TIPS DISMANTLE ........................................................................................................................................11

8.2. PRODUCT HOSE DISMANTLE ...................................................................................................................11

8.3. TANK TOP DISMANTLE ..............................................................................................................................11

9. PIECES OF ADVICE TO AVOID INAPPROPIATE AND DANGEROUS PRACTICES..................... 12

10. COMPLETE SPARE PARTS DISMANTLE...................................................................................... 14

TROUBLESHOOTING ............................................................................................................................ 17

12. EQUIPMENT STORAGE................................................................................................................... 18

13. EQUIPMENT WITHDRAW................................................................................................................ 18

14. INSPECTIONS AND PERIODICAL TESTS...................................................................................... 18

CONFORMITY DECLARATION ............................................................................................................. 19

THANKS

EUROPE PROJECTION wants to thank the confidence shown in the acquired

precision sandblaster.

This trust motivates us to keep working daily for the consecutions of the highest quality

criteria of our products, to such an extent that they have became a reference on reliability and

exigencies fulfilling in the market aimed to.

Hoping the acquired product is of your complete satisfaction and being at your entire

disposition to assist any consultation or suggestion, please receive again our most sincere

thanks.

SANDBLASTER 0701AREN10MAS

3

1. MANUAL AIMED TO

EUROPE PROJECTION has elaborated the here shown Instructions manual and

maintenance as a document recommended to be attached to the precision sandblaster

for its whole useful life, considering it as other component of this one.

The Manual is aimed to the end user and technical assistant of the equipment and it

contains every useful information on safety related to:

Assembly

Fine tuning

Use

Manteinance, including testing by the end user

Dangers caused by an inappropiate use

2. INFORMATION REMARK

This document must be at disposal of the staff using and maintaining the equipment.

In order to assure that equipment features are the same as the ones specified in your

order, please, revise it when received and contact the authorized TAS (Technical Assistance

Service) in case you find any disagreement.

For these reasons, it is recommended that every repairing or substitution of

components into the equipment is done directly by specialized staff (Consult the manufacturer

for local Technical Service)

ATTENTION:

Any modification in the original configuration of the equipment or its components, as

well as its use to a different aim for which it has been designed, will imply the

immediate invalidation of the product homologation. This will free EUROPE PRO-

JECTION from any responsibility as manufacturer enterprise of the commercialized

equipment.

Moreover, the homologation invalidation will be caused by:

Welding operations on the pressure device.

Mechanization operations (drills, cuts, etc.)

Different assemblies to the original one

Substitution of elements different to the original ones

Safety valve manipulation

The following actions will cause a breakdown which is be covered by the guarantee:

To work with wet abrasives or with measures higher to recommended.

To put the machine in horizontal position with the tank full of abrasive

To fill the tank with abrasive till the very top.

To use the equipment near of the air compressor

INSTRUCTIONS AND MAINTENANCE MANUAL

4

3. GUARANTEE

The acquired equipment counts on a two years guarantee from the Invoice date. The

guarantee covers manufacturing defects and faults in components.

Elements repairs and substitution are only guaranteed if made by technical staff of

EUROPE PROJECTION or Official Technical Service.

Defectives pieces will be sent carriage paid.

The guarantee does not cover direct or indirect damages caused by our machine on

people or things, neither repairing operations made directly by the client or third people.

Guarantee does not cover:

Breakdowns or damages caused by an inappropiate use of the equipment.

Breakdowns or damages caused by spare parts different to the original ones

or recommended by EUROPE PROJECTION.

Breakdowns or damages caused by a wrong conservation.

Components subject to wear (tips, filters, hoses, etc.).

Guarantee is null:

When repairs and components substitutions are done in the equipment, without prior

authorization from EUROPE PROJECTION.

When the serial number identifying unequivocally every equipment is manipulated or

removed.

When breakdown is proved to be caused by an inadequate use of the equipment, by

a fall or a hit, or by causes not due to normal working conditions.

When the equipment is dismantled, manipulated or repaired without the authorization

of EUROPE PROJECTION.

Repair operations made on guaranteed equipments will not mean stop or extension of

guarantee period.

4. WASTE PRODUCTS AND ENVIRONMENT

5. EQUIPMENT DESCRIPTIONS

5.1. GENERAL DESCRIPTION

The bought equipment is a precision sandblaster aimed to small and medium precision

workings on decoration, metal or wood industry; based in the application of abrasive products

on the surface to be treated.

Amongst the possible applications we can find:

Wall cleaning

Wood stripping

REMEMBER:

To get rid of pollutant and dangerous products, of packages, of equipments and

tools into disuse and in general of any type of waste produced by its activity, please

go to the Selective Collection and Treatment points suitable for each case.

If you need any information related to this, please go to the Environmental ministry

in your regional government or to the nearest city hall

SANDBLASTER 0701AREN10MAS

5

Paper and adhesive removing

Swimming pool stripping

Graffiti removing

Concrete cleaning and fitting

Plastic cleaning

Paving and flooring mark removing

Metallic surfaces preparation

Tank and metallic container clearing and stripping

This sansblaster allows us the application of the following types of abrasives: corindon,

metallic grain, glass, aluminium silicate, garnet, calcium carbonate and silica sand (grit).

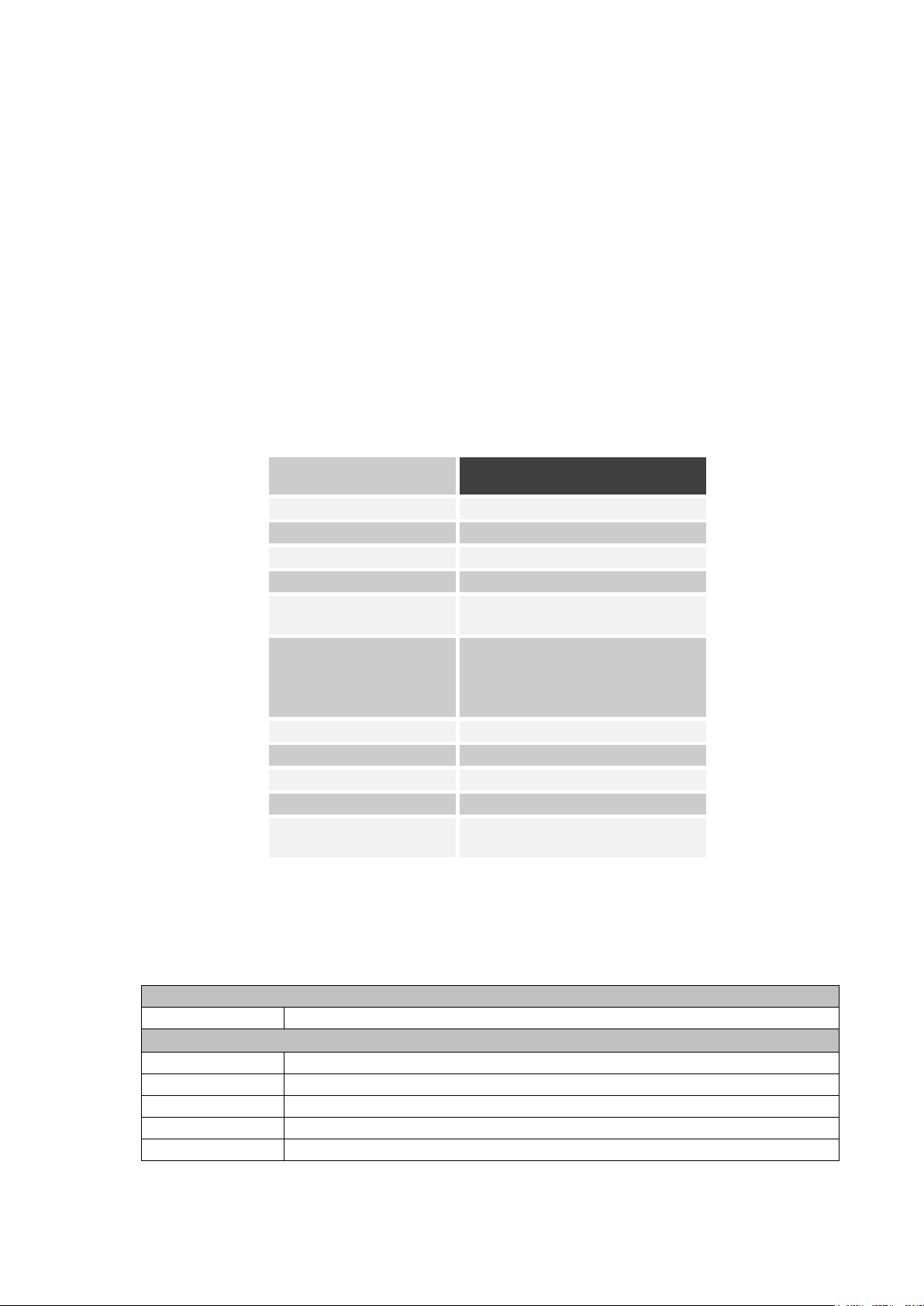

Next, it is attached a table which will help the end user to choose the abrasive size

according to tip diameter.

Tip (mm)

Abrasive Granule Diam. (mm)

Minimum

Maximum

2,0

0,25

0,40

2,5

0,25

0,50

3,0

0,25

0,60

4,0

0,25

1,00

Table 1

The reference of the precision sandblaster model acquired is 0701AREN10.

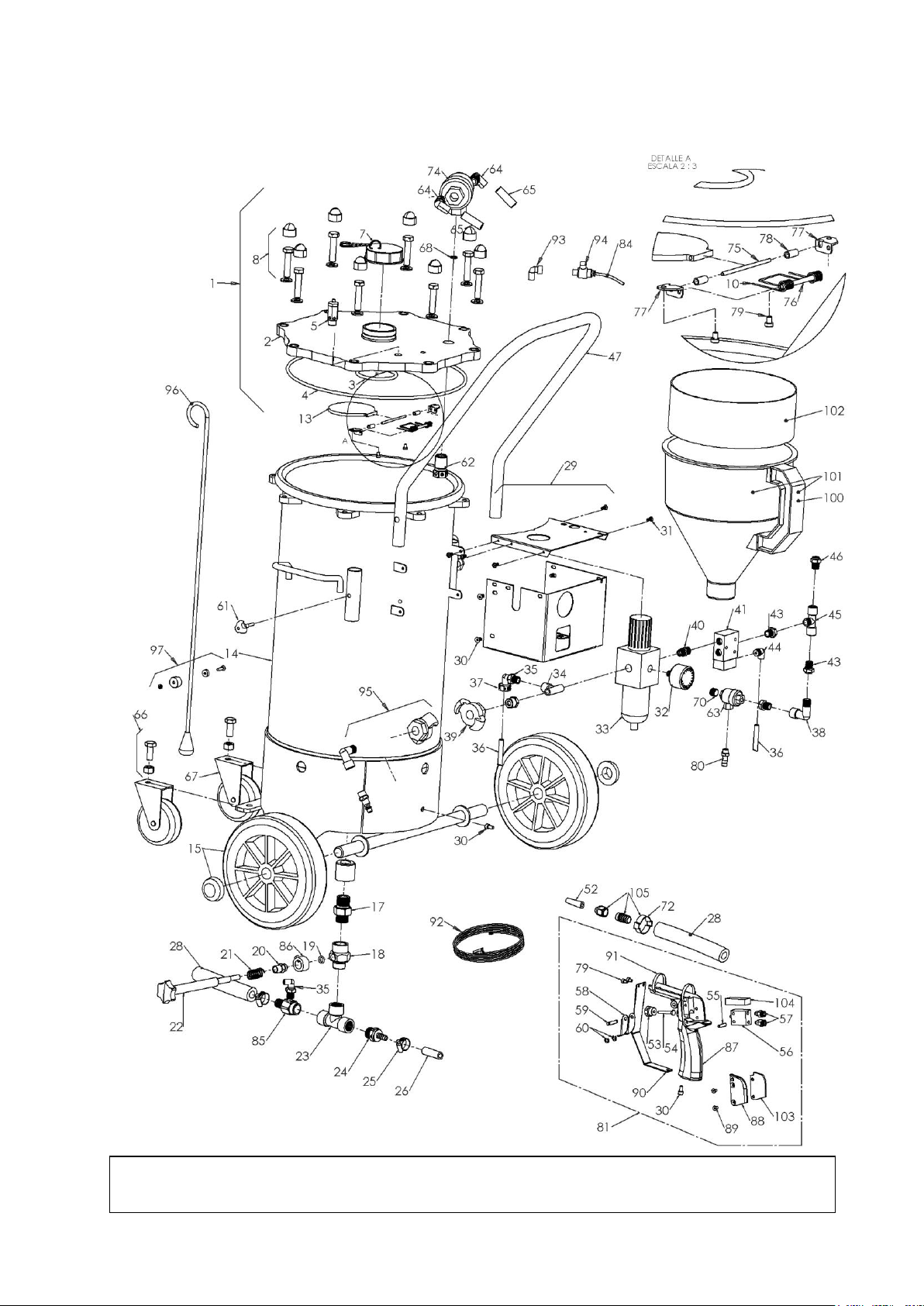

5.2. MAIN COMPONENTS

Main components in the equipment are here shown graphically and listed.

Posit.

Denomination

1

Tank with wheels

2

Top

3

Product inlet

4

Regulation box and system

5

Working pressure regulador

6

Abrasive product outlet

7

Product outlet flow rate regulator

8

Product hose

9

Remote control circuit (pneumatic)

10

Safety valve

11

Air inlet to equipment

12

Gun

13

Carriage handle

14

Handle clamp

15

Handle clamp housing

16

Air inlet to tank

17

Cap

18

Purifier filter

INSTRUCTIONS AND MAINTENANCE MANUAL

6

19

Manometer

20

Air tank release

Table 2

5.3. IDENTIFICATION PLATE

Spare parts 1 –Main components

SANDBLASTER 0701AREN10MAS

7

The equipment is fitted with a identification plate that, under any case, can´t be

removed or manipulated.

The identification plate provides the following information:

Manufacturer name

Serial number and manufacturing date.

Main characteristics.

Other compulsory data, according to application regulation.

To make any enquiry to EUROPE PROJECTION, related to the equipment, it will

be neccessary to refer to the serial number on the identification plate.

5.4. TECHNICAL FEATURES

The precision sandblaster technical features are shown in the

table as follows:

0701AREN30MAS

Weight

31,5 kg

Tank capacity

30 l.

Min. working pressure

2 kg/cm2

Max. working pressure

6 kg/cm2

Optimal working

pressure

4 –5,5 kg/cm2

Required air flow rate

(compressor)

250 –450 l./min. (Boquilla 2)

350 –600 l./min. (Boquilla 2,5)

700 –1000 l./min. (Boquilla 3)

1200–1400 l./min.(Boquilla 4)

Safety pressure

6 kg/cm2

Air inlet connection

CR 3/8 / Racor Expres Din 3489

Working temperatura

de 0 a 50º C

Tip material

Carburo de tungsteno

Size

500x430x940 mm (with carriage

handle)

Table 3

5.5. REGULATION

The precision sandblaster has been designed, manufactured, inspected, tested and

commercialized, under the compliance of the following regulation:

EUROPEAN DIRECTIVE

97/23/CE

Relative to pressure equipments

HARMONIZED EUROPEAN REGULATION

EN 13445-1:2002

Pressure tank not subjected to flame action. General issues.

EN 13445-2:2002

Pressure tank not subjected to flame action. Materials

EN 13445-3:2002

Pressure tank not subjected to flame action. Design

EN 13445-4:2002

Pressure tank not subjected to flame action. Fabrication

EN 13445-5:2002

Pressure tank not subjected to flame action. Inspection and testing

Table 4

INSTRUCTIONS AND MAINTENANCE MANUAL

8

5.6. SAFETY SYSTEMS

5.6.1. SAFETY VALVE

The sandblaster is fitted as standard with a safety valve [Spare parts 1 –Posit.10] installed

on the top of the tank [Spare parts 1 –Posit.2], in order to never exceed the maximum working

pressure for which it has been designed (6 kg/cm2). If it exceeds the safety pressure, the valve

will unload the pressure excess.

No manipulation in safety valve or its seal may be done. Any valve alteration can

cause serious damages to user and alter the correct functioning of the equipment.

EUROPE PROJECTION is free from any responsibility derived from any

manipulation in valve by the user, which will support this responsibility.

5.6.2. DEPRESSURE SYSTEM

The sandblaster is fitted with a three via with piloting [Spare parts 2 –Posit.41] placed in

the inside of the regulation box [Spare parts 1 –Posit.4]. The pneumatic remote control system

[Spare Parts 1 –Posit.9] has been designed so that with no piloting signal (gun trigger [Spare parts 2

–Posit.58] released), the air inlet via to tank gets closed, so at the same time it is depressurized

through the exhaust of the antireturn valve installed on the top of the equipment [Spare parts 1 –

Posit.20].

6. EQUIPMENT INSPECTION WHEN RECEIVED

Before using the equipment, we have to ensure that it has not suffered any damage

during the carriage or storage. Moreover, we must check that every component and

accessories composing the equipment are into the package.

The basic equipment includes the following components:

Sandblaster unit (tank with wheels, top, regulation and safety valve systems)

Carriage handle

Gun

Tungsten carbide tip 3 mm

5 m product hose

10 m pneumatic remote control circuit (5 m to gun+ 5 m return)

Hopper with extension

Identification plate

Instructions and maintenance manual

Gloves

Basic protection mask

Disposable celulose hood (2 unit.)

Hearing protection, ear plugs

You must check that Serial number in the equipment coincides with the one appearing

in the delivery document.

WARNING:

Once the gun trigger is released of finger action [Spare parts 2 –Posit.58], we must wait

about 10 seconds to assure that tank depressurization has been completed.

SANDBLASTER 0701AREN10MAS

9

7. USE INSTRUCTIONS

7.1. PRIOR OPERATIONS

Before starting the equipment, we must do the following operations:

To drain the air feeding hose to eliminate possible water condensations.

To check that compressor is capable to supply the air flow rate required. The air flow

rate depends on the type of work to be done (working pressure), that can be between

700 –1000 l/min for the tip standard 3.

To check that every hose are in good condition (with no cracks no folds).

To check that connection of air feeding inlet is in good condition.

To check that water purifier filter [Spare parts 1 –Posit.18]is not full. As drain in not

automatic, you should drain it regularly.

To place the carriage handle [Spare parts 2 –Posit.47] which is received dismantled.

To fix the handle, slide the handle [Spare parts 2 –Posit.47] through the tubes welded to to

the body of the boiler and place the handle clamp [Spare parts 2 –Posit.61] .

To connect the air feeding hose to equipment.

7.2. TANK LOADING

To load the tank, you must follow the following steps:

To assure that tank is depressurized (manometer view [Spare parts 1 –Posit.19]).

To disconnect the equipment from compressor.

To unscrew the plastic cap [Spare parts 1 –Posit.17] located in the product inlet [Spare

parts 1 –Posit.3].

To introduce the hopper with extension in the loading hole [Spare parts 1 –Posit.3]

pressing into the inner product lid [Spare parts 2 –Posit.13], and so, it will be opened.

To pour the abrasive product inside the tank until reach the wanted fill level.

To remove the hopper, allowing the inner product lid [Spare parts 2 –Posit.13] locks

automatically thanks to the spring system.

To check that there is no abrasive product on the loading hole causing lack of air

tightness on the locking or unnecessary joint wear [Spare parts 2 –Posit.3].

To screw plastic cap [Spare parts 1 –Posit.17] into the original position.

To connect again the equipment to compressor.

The type of abrasive product (sand, metallic grain, glass, corindon, etc.) to be used, as

well as the granule diameter, depends on the type of work. To help to choose the abrasive

size according to tip diameter, please check Table 1.

7.3. WORKING PRESSURE REGULATION

Working pressure can be adjusted operating manually the regulator [Spare parts 1 –

Posit.5], located in the regulation box [Spare parts 1 –Posit.4].

The regulator can be operated with the equipment on.

To activate the regulator you must follow the following steps:

To raise the regulator control

To turn the control until reaching the appropiate working pressure which is shown

in the manometer.

INSTRUCTIONS AND MAINTENANCE MANUAL

10

To push the control again down to click the regulator.

Working pressure must never exceed 6 kg/cm2(max. pressure on safety valve).

Optimal pressure range is considered from 3,5 to 5,5 kg/cm2.

Working pressure depends on the type of work we want to do.

7.4. ABRASIVE PRODUCT OUTLET REGULATION

The abrasive product outlet can be regulated by operating manually the regulation

control of the product outlet [Spare parts 1 –Posit.7], placed in the lower part of the tank.

The beginning of the adjusting must be done with the regulator completely closed

(control totally tight), and you must open slowly and gradually until reaching the flow rate

suitable for the type of work to do. The adjusting process must be done with the gun trigger

[Spare parts 2 –Posit.59] pushed.

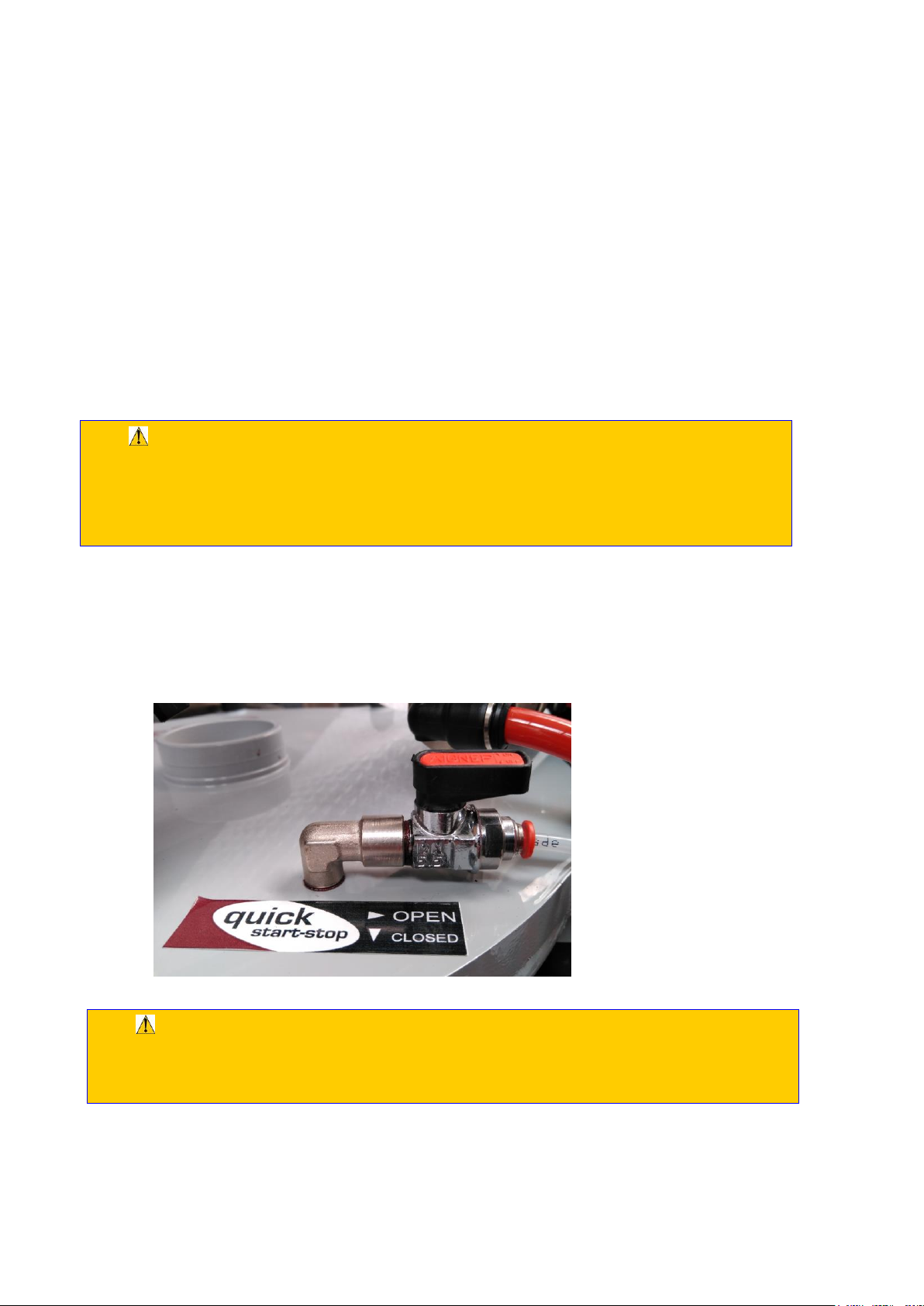

7.5. CONTROL OF THE ABRASIVE OUTLET ON LEAVING SANDING

The sandblaster has a valve in the tank cover [Exploded View 2 - Posic.94] to control

the abrasive outlet when the trigger is released.

In normal operation, the valve must be open to prevent the appearance of abrasive jets

when starting to sand and at the end.

WARNING:

Do not dismantle the regulation screw with the equipment on. Once the maximum

flow rate is reached, you must not keep turning the regulation screw [Spare parts 1 –

Posit.7] to opening, as it could be accidentally dismantled.

WARNING:

If for safety, it is necessary that the abrasive stops immediately when the trigger is

released. It is necessary, lock the key on the tank cover [Exploded view 2 - Posic.94].

SANDBLASTER 0701AREN10MAS

11

8. COMPONENTS DISMANTLE

Next, we describe how to procceed to tasks related with dismantling or substitution of

equipment components that, to EUROPE PROJECTION´s discretion, are considered

usual and can be made by the user.

To do other types of dismantling actions, it is neccessary to count on your SAT- Official

Technical Service

8.1. TIPS DISMANTLE

To dismantle the tip of the gun [Spare parts 2 –Posit.28]to clean it or substitute, you must

proceed as follows:

To disconnect the equipment from the air pressure feeding.

To unscrew the tip nut [Spare parts 2 –Posit.51]out of the adaptor [Spare parts 2 –

Posit.50] attached to the product hose.

To quit the tip [Spare parts 2 –Posit.52] out of the tip nut [Spare parts 2 –Posit.51].

To place the tip, you must do the steps below vice versa.

8.2. PRODUCT HOSE DISMANTLE

To dismantle the product hose [Spare parts 2 –Posit.28], to clean it or substitute it, you

must do the following.

To disconnect the equipment from the air pressure feeding.

To loose the clamp [Spare parts 2 –Posit.25]which fix the hose [Spare parts 2 –Posit.28] to

coupling nut [Spare parts 2 –Posit.24].

To separate the hose from the coupling nut.

To assemble again the hose, you must do the steps below vice versa.

8.3. TANK TOP DISMANTLE

This operation must be only done for maintenance and periodical cleaning. Abrasive

product loading must be done through the product loading cap [Spare parts 2 –Posit.13] and not

through the tank top [Spare parts 2 –Posit.2].

To dismantle the tank top [Spare parts 2 –Posit.2], you must do as follows:

To disconnect the equipment from the air pressure feeding.

INSTRUCTIONS AND MAINTENANCE MANUAL

12

To assure of tank is depressurized by checking manometer [Spare parts 1 –Posit.19]

placed in the regulation box of the equipment [Spare parts 1 –Posit.4].

To unscrew and remove the screws [Spare parts 2 –Posit.8] joining the top to the body

tank.

To disconnect the air feeding tube to the tank of the swivel elbow [Spare parts 2 –

Posit.64] placed on the tank top [Spare parts 2 –Posit.2] and the air tube [Despiece 2 –

Posic.84] of the valve [Despiece 2 –Posic.94] located on the tank cover [Despiece 2 –

Posic.2].

To remove the top [Spare parts 2 –Posit.2].

To assemble again the tank top, you must do the steps below in contrary sense,

paying attention to contact surfaces between the tank top and upper border are clean and free

or particles causing lack of air tightness on the locking or unnecessary joint wear [Spare parts 2 –

Posit.4].

9. PIECES OF ADVICE TO AVOID INAPPROPIATE AND DANGEROUS

PRACTICES

You must follow attentively the following warnings in order to avoid risk which can be

dangerous for people, animal or goods.

WARNING:

Do not use the equipment in the presence of other people not wearing protection

equipment and suitable clothing. The user and other people near working areas must

protect themselves from impact of abrasive product.

WARNING:

An inappropriate application of the jet of abrasive product can be dangerous. Never

point the gun to people, animals, electricity system or sandblasting equipment.

WARNING:

Never use the equipment to treat a piece hold by other user.

WARNING:

Do not make pressure against the product inlet top whereas the tank is pressurized.

To avoid accidental opening, the plastic cap [Spare parts 1 –Posit.17] must be always

placed.

WARNING:

Before doing any operation on the equipment (repairs, maintenance, elements

substitution), you must disconnect the equipment from the air pressure feeding.

WARNING:

While the equipment is working, the plastic top on the lid [Spare parts 1 –Posit.17]

must be always removed as if during the loading process, some abrasive remains on

the loading inlet (see point 7.2 “TANK LOADING”), the pressurization would be

correct and the compressed air could take out the top of the loading inlet [Spare parts

1 –Posit. 3] strongly.

SANDBLASTER 0701AREN10MAS

13

The equipment user must wear a protection screen and safety gloves. Any part of the

body must be exposed to the impact of abrasive product on the treated surface. If required

due to the sound level conditions on the working area, the user must wear hearing

protection.

The equipment must be as far as possible from working area.

The equipment can only be used by staff knowing the content of this manual.

The equipment can not be used by children or non qualified staff.

You must take special care of the abrasive product hose (no fold, no step on, no scratch

no contact with sharp objects).

Do not start the equipment without assure that hose connections to equipment and

compressor are correct.

Do not operate, fix or block the pneumatic remote control.

Use exclusively original spare parts.

Do not use the equipment under alcohol, narcotics or medicines influence.

Never open the equipment tank whereas it is pressurized.

Do not use safety valve to depressurize the tank. To depressurize, you only have to stop

acting the gun trigger.

In order to keep the air compressor in good conditions, it must be located far enough from

the sandblaster and always out of the working area.

INSTRUCTIONS AND MAINTENANCE MANUAL

14

10. COMPLETE SPARE PARTS DISMANTLE

You can here find a table and graphical scheme of the components you can acquire as

original spare parts:

Model: 0701AREN30MAS

Posit.

Reference

Denomination

1

52205

MANTLED TOP

2

52097

FINISHED TOP

3

550571B

LOADING CAP TORIC JOINT

4

52080B

TOP JOINT

5

55021B

SAFETY VALVE

7

52093

COMPLETE CAP

8

52095

COMPLETE SCREWS KIT (8 Units)

10

52004B

SPRING (2 Units)

13

52026MB

MECHANIZED LOADING CAP

14

52CUERAREN30MASB

WELDED BODY ARENADORA

15

55041B

FIX WHEEL (2 Units)

17

52052B

SWIVEL NUT ½

18

52187B

REGULATOR BODY

19

52184B

JOINT (1 Unit)

20

52188B

MEDIUM PIECE

21

52019B

SPRING

22

52189B

PRODUCT OUTLET REGULATOR

23

52049B

“T” 1/2H-1/2H-1/2H

24

52020B

COUPLING NUT 1/2M DOWEL 9

25

30151B

CLAMP (2 Units)

26

52106B

HOSE 8 x 15 BLACK

28

52218

HOSE 13X25 (5m)

29

52060

COMPLETE BOX

30

52011B

ALLEN SCREW (4 Units)

31

52010B

METAL SHEET SCREW (4 Units)

32

52181B

MANOMETER 0-10 BAR 4

33

52180B

PURIFIER REGULATOR FILTER 1/4H

34

52178B

“T” 1/4M-1/4H-1/4M

35

52013B

SWIVEL ELBOW 1/4 A 4

36

52108

POLIAMIDE DOUBLE PIPE 2X4

37

52065B

PLASTIC CLAMP (10 Units)

38

55051B

ELBOW 90º 1/4M –1/4H

39

52177B

EXPRES COUPLING NUT

40

55009

COUPLING NUT 1/4M (5 UD.)

41

52014B

VALVE 3/2

43

11051/41/4H

REDUCTIÓN 1/4M –1/4H

44

52015B

SWIVEL ELBOW 1/8 A 4

45

52012B

CENTRAL “T” 1/4H-1/4M-1/4H

46

52090B

COUPLING NUT 1/4 A 10

47

52190

CARRIAGE HANDLE WITH CLAMP

52

520243B

TIP 3

53

52043B

MEDIUM NUT

54

52044B

PUSHER

55

52022B

VALVE

55

52045B

MEDIUM PIN

56

52022B

VALVE

SANDBLASTER 0701AREN10MAS

15

57

52023B

COUPLING NUT M5 TO PIPE 4

58

50068B

TRIGGER

59

50067

TRIGGER PIN ASSEMBLY (10 Units)

60

50006

SEJER RING ASSEMBLY (10 Units)

61

52207

HANDLE CLAMP

62

52103B

AIR DISTRIBUTOR

63

52073B

FAST DISCHARGE VALVE 1/8

64

52088B

SWIVEL ELBOW 1/2 A 10

65

52089B

POLYURETHANE PIPE 8x10

66

55313B

COMPLETE SCREWS KIT FOR ROTATING WHEEL (2UD)

67

55042B

ROTATING WHEEL (1UD)

68

52104B

52104B

70

55258B

CAP 1/8

71

10M91BLISTER

ADAPTATOR 1/4H (2 UD.)

72

52168B

CLAMP 25 x 28

74

52087B

FAST DISCHARGE VALVE 1/2

75

52115B

FILLING LID AXLE

76

52116B

SPRING AXLE FILLING LID

77

52113B

FILLING LID BRACKET KIT

78

52117B

FILLING LID BUSHING

79

52114B

SCREW M4X6 (2 U.)

80

10M92BLISTER

ADAPTATOR 1/8M (2 Units)

81

52110

COMPLETE GUN SET

84

52214

POLYAMIDE TUBE 2x4 (1,5 m.)

85

52166B

COUPLING CONNECTOR ½ SPIKE 13

86

52172B

TOP REGULATOR PRODUCT+SCREW

87

52JAFEARENCUERPOB

SANSBLASTER GUN BODY

88

52JAFEARENTAPAB

SANDBLASTER GUN BODY CAP

89

52169B

STAINLESS COUNTERSUNK HEAD SCREW M4x8

(2 Units)

90

52167B

SANDBLASTER GUN PROTECTOR

91

23VAKRT556011

50 PLASTIC CLAMP 250x5

92

52215

GROUND WIRE + CLAMP (PIN)

93

52179B

ELBOW 1/8

94

52182B

VALVE 1/4 TUBE 4

95

52210

ADAPTATOR EXPRES CR 3/8

96

52195

LOAD METER

97

52211

SUPPORT FOR LOAD METER

100

50160ASA

HANDLE

101

52062

FUNNEL

102

52TAMIZ

SIEVE

103

52231B

COVER FOAMS

104

52233B

VALVE FOAMS

105

52236B

TIP HOUSING SET

Table 5

INSTRUCTIONS AND MAINTENANCE MANUAL

16

Spare parts 2 –Repairing components (0701AREN30MAS) (Rev1)

SANDBLASTER 0701AREN10MAS

17

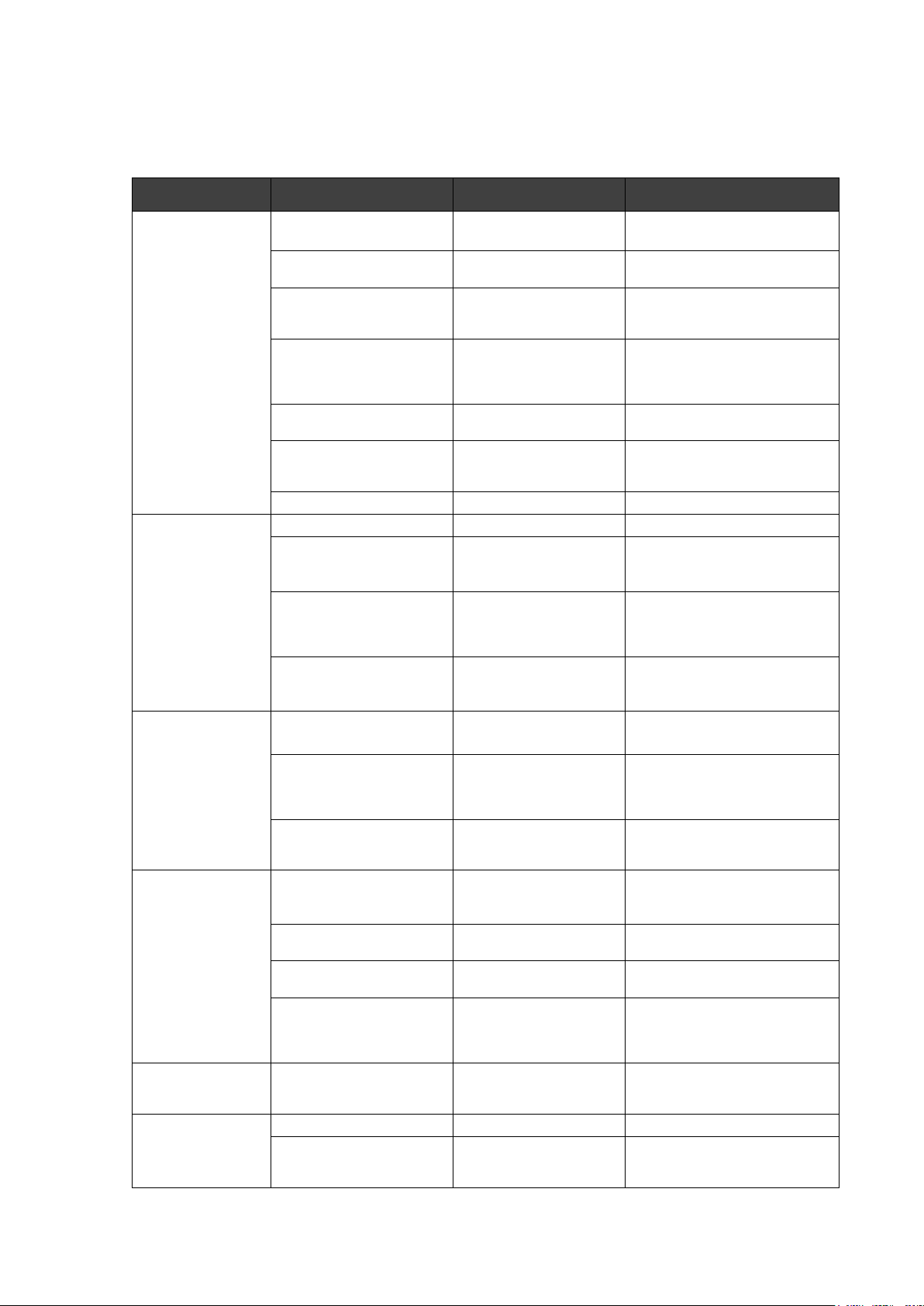

TROUBLESHOOTING

ANOMALY

POSSIBLE CAUSE

CHECKING POINTS

SOLUTION

I. No air through the

tip

A) Compressor unplugged or

switched off

Feeding compressor

To connect the compressor to

sandblaster and start it

B) Tip clogged up

Tip

To dismantle gun tip and blow it to

remove obstruction

C) Sand flow rate regulator

too open

Outlet product regulator

To close the regulator until reach

the appropiate opening level. To

blow the hose and the tip.

D) Excessive granule

diameter of used abrasive

Abrasive

To empty the tank and fill it with

abrasive with sutiable diameter. To

blow the hoses to remove residual

abrasive.

E) Product hose clogged up

Product hose

To dismantle product hose and

clean

F) Three via valve placed in

regulation box doesn´t

work

Three via valve

Substitute

G) Gun valve doesn´t work

Gun valve

Substitute

II. No abrasive

through gun (only

air)

A) Tank without abrasive

Tank

To load tank with abrasive product

B) Outlet abrasive clogged up

Product outlet

To operate regulation handle to

increase flow rate

To clean tank outlets piping

C) Excessive granule

diameter of used abrasive

Abrasive

To empty the tank and fill it with

abrasive with suitable diameter. To

blow the hoses to remove residual

abrasive.

D) Outlet abrasive reguladtor

closed

Outlet product regulator

To operate regulation handle to

increase flow rate

III. Non uniform

abrasive flow

A) Wet abrasive or foreign

particles

Tank interior

To empty tank and load it with dry

and filtered abrasive.

B) Excessive granule

diameter of used abrasive

Abrasive

To empty the tank and fill it with

abrasive with suitable diameter. To

blow the hoses to remove residual

abrasive.

C) Sand flow rate regulator

too open

Outlet product regulator

To operate the regulator until reach

the appropiate opening level.

IV. The result of the

application is not

satisfactory

A) Inappropiate tip for the

application

Tip

To substitute the tip (according to

Table 1)

B) Lack of air tightness of the

hoses

Hoses

To substitute the hoses

C) Inappropiate working

pressure

Pressure regulador

To operate on the air regulator until

get the resulted wanted

C) Inappropiate abrasive to

the work to be done

Abrasive

To ask for information to your

abrasive supplier about the most

recommended product for each

work

V. Air exhaust by

safety valve

A) Excessive air pressure of

the compressor feeding

the sandblaster

Manometer of the

compressor

To regulate outgoing air pressure

on compressor up to a maximum 6

kg/cm²

VI. Inadequate air

going out through

tip

A) Purifier filter clogged up

Purifier filter

To clean purifier filter

B) Tip clogged up in the part

of the hose

Tip - hose

To disconnect the hose from the

sandblaster and blow from tip to

unblock it.

INSTRUCTIONS AND MAINTENANCE MANUAL

18

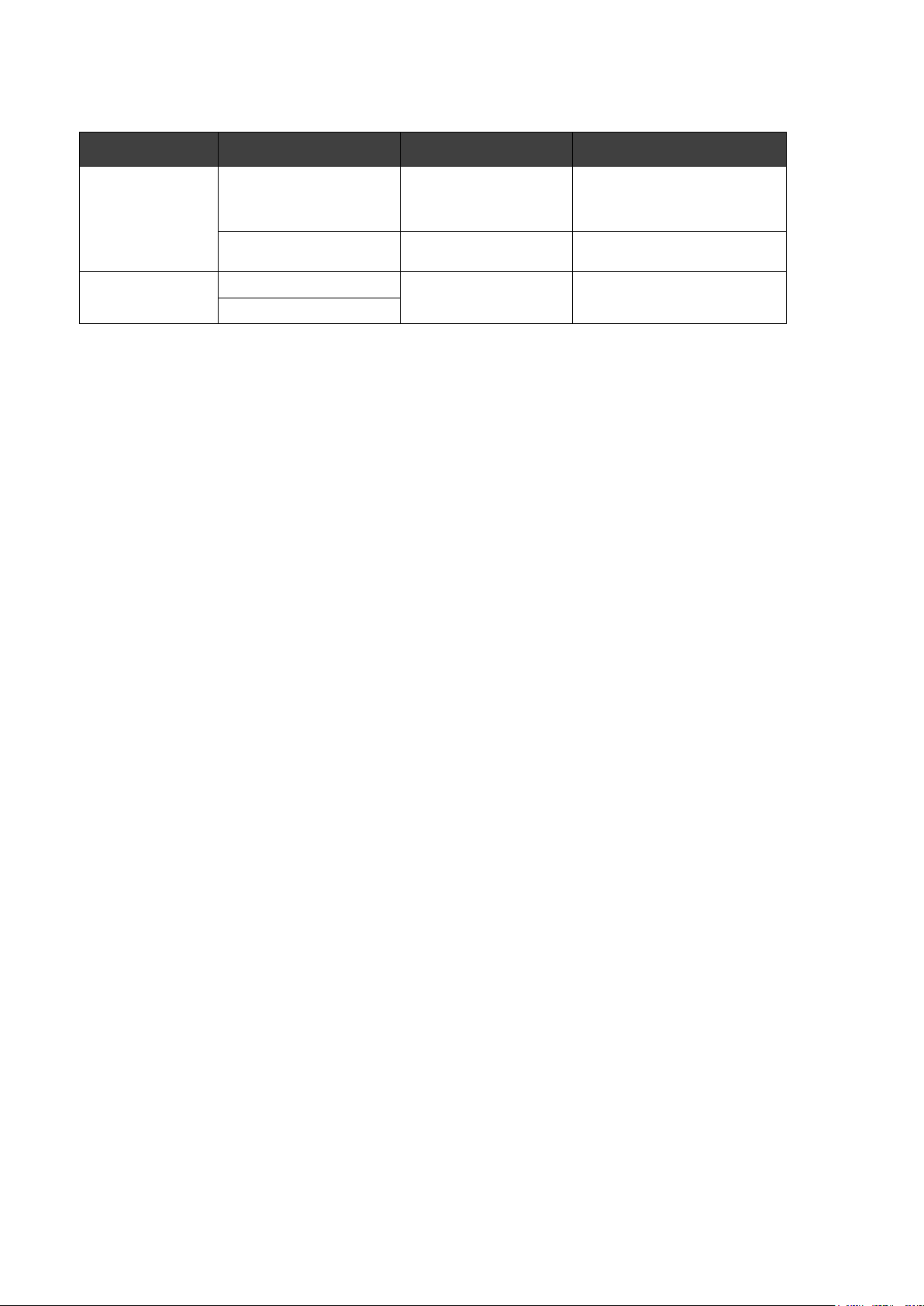

ANOMALY

POSSIBLE CAUSE

CHECKING POINTS

SOLUTION

VII. Lack o fair

tightness on tops

A) Existence of foreign

particles which hinders

the air tightness of those

ones

Tops

To clean surfaces in contact with

tops

B) Worn or damaged joints

Joints

To substitute

VII. Block of gun

trigger

A) Lack of lubrication

Gun trigger

To lubricate and clean the gun

trigger periodically

B) Lack of cleaning

Table 6

12. EQUIPMENT STORAGE

In case that the equipment is not going to be used for a long time, it is recommended

to store according to the following instructions:

To disconnect the equipment of any feeding source.

To empty the tank.

To clean completely the tank and remove any waste or sediment inside.

To cover the equipment with a waterproof package.

13. EQUIPMENT WITHDRAW

Once useful life of the equipment is ended, you must follow some basic rules of

behaviour to withdraw in a environment-friendly way.

The packages, the flexible pipes, the plastic components and non-metallic components

must be dismantled and removed separately.

14. INSPECTIONS AND PERIODICAL TESTS

According to current regulations on pressure equipments in the fabrication date, the

equipment must be subject every 10 years, at least, to a visual inside and outside inspection

and a pressure test.

Test and inspections must be done according to the specific regulation on pressure

equipment of the country where the equipment is used.

Annually the equipment will be cleaned thoroughly in the inside by the equipment user.

The safety valve will be subject, at least, to a checking every year, to be done by the

user.

However, once read the before exposed, it is responsibility of the user to be updated

on current regulations on pressure equipments for the useful life of the equipment and make

inspections and periodical tests specified on these ones.

DECLARATION OF CONFORMITY

AUTHORIZED REPRESENTATIVE:

EUROPE PROJECTION

228, avenue Olivier Perroy

13790 ROUSSET

DECLARES THAT THE EQUIPMENT DESIGNATED BELOW:

Model : MINI-SABLEUSE 30 L

Reference : 70475

COMPLIES WITH THE STANDARDS:

• UNE-EN 13445

ROUSSET, JANUARY 20th 2020

Patrick BOREL

President

EUROPE PROJECTION - 228, avenue Olivier Perroy 13790 ROUSSET

Tél : +33 (0)4 42 29 08 96 – Fax : +33 (0)4 42 53 44 36

SAS au capital de 400 000 € - RCS Aix-en-Provence B 394 961 510 - NAF 2892 Z - Intracom : FR 54 394 961 510

EUROPE PROJECTION - 228, avenue Olivier Perroy 13790 ROUSSET - Tél : +33 (0)4 42 29 08 96 – Fax : +33 (0)4 42 53 44 36

SAS au capital de 400 000 € - RCS Aix-en-Provence B 394 961 510 - NAF 2892 Z - Intracom : FR 54 394 961 510

Table of contents

Other EUROPRO Power Tools manuals

Popular Power Tools manuals by other brands

Labounty

Labounty MSD Series Safety, Operation & Maintenance

RED ROOSTER

RED ROOSTER RRI-60SA manual

GRAVEDA

GRAVEDA GRASPRESSO GP4-20 instruction manual

Trumpf

Trumpf TruTool F 300 (3B1) manual

Festool

Festool OF 2200 EB Supplemental user's manual

Powers Fasteners

Powers Fasteners P35s Operating instructions manual