Unit 6, St Martin’s Park

Moorend Farm Avenue

Cabot Park, Avonmouth

Bristol, BS11 0RS

Tel: +44 (0)1179 381800

Fax: +44 (0)1179 381801

Web: www.sdsdrives.com

formerly now

then

For correct operation, A, /A, B and /B must be connected as shown. If any is left unconnected, the HTTL speed feedback

technology box will not operate.

Note: The M and H inputs are not normally connected - these are for use with future versions of drive software.

M: For connection to the once-per-revolution marker output from the encoder to verify correct operation of the encoder.

H: For where the encoder has provision for a `health’ output.

Take special care wiring the encoders to the option due to the low level of the signals.

All wiring to the HTTL Speed Feedback Technology Box should be made in screened cable. Use cable with an overall screen and a

screen over each individual pair. To ensure compliance with the EMC Directive the overall cable screen should be connected to the

encoder body and to the terminal block, pin 11.

Recommended cable (pairs individually screened):

Belden equivalent 8777

SSD Drives Part Number CM052666

Terminal Block (TB1) Connections

3

HTTL Speed Feedback Technology Box

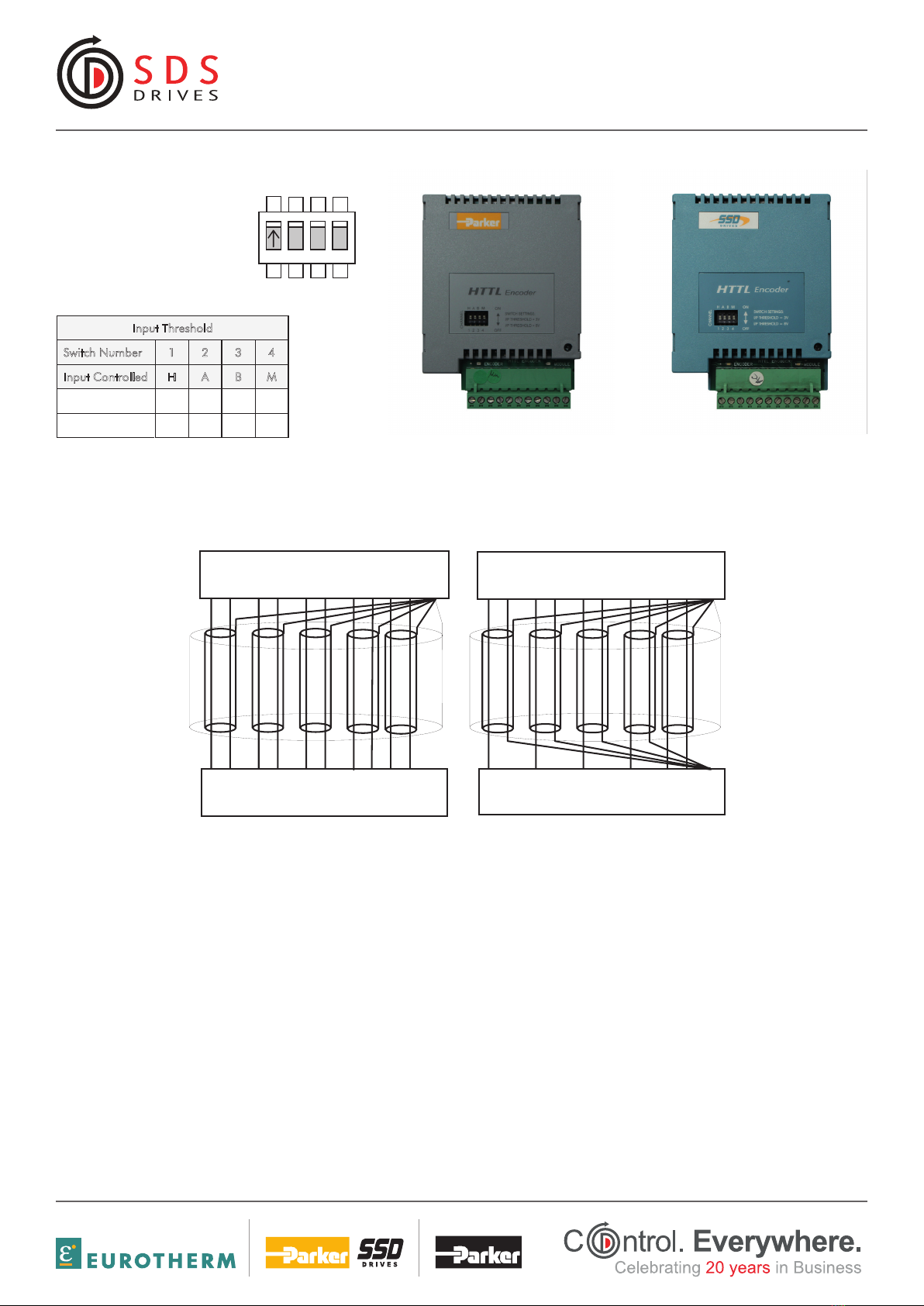

DIP Switch Settings

The DIP switch can be seen

through the casing of the

HTTL Speed Feedback

Technology Box.

The switch settings control

the following inputs:

Usually the switches will be set to give a threshold of 3V when using a differential encoder, and

to 8V when using a single-ended encoder. (Factory default is with switches 1 & 2 set in the ON

position - 3V).

Terminal Block (TB1) Connections

For correct operation, A, /A, B and /B must be connected as shown. If any is left unconnected,

the HTTL speed feedback technology box will not operate.

Note: The M and H inputs are not normally connected - these are for use with future versions

of drive software.

M: For connection to the once-per-revolution marker output from the encoder to verify

correct operation of the encoder.

H: For where the encoder has provision for a `health’ output.

Take special care wiring the encoders to the option due to the low level of the signals.

All wiring to the HTTL Speed Feedback Technology Box should be made in screened cable.

Use cable with an overall screen and a screen over each individual pair. To ensure compliance

with the EMC Directive the overall cable screen should be connected to the encoder body and to

the terminal block, pin 11.

Recommended cable (pairs individually screened):

Belden equivalent 8777

Parker SSD Drives Part Number CM052666

1234

ON

OFF

DIP SWITCH

TB1

DIP

Input Threshold

Switch Number 1 2 3 4

Input Controlled H A B M

3V±1 On On On On

8V±1 Off Off Off Off

2

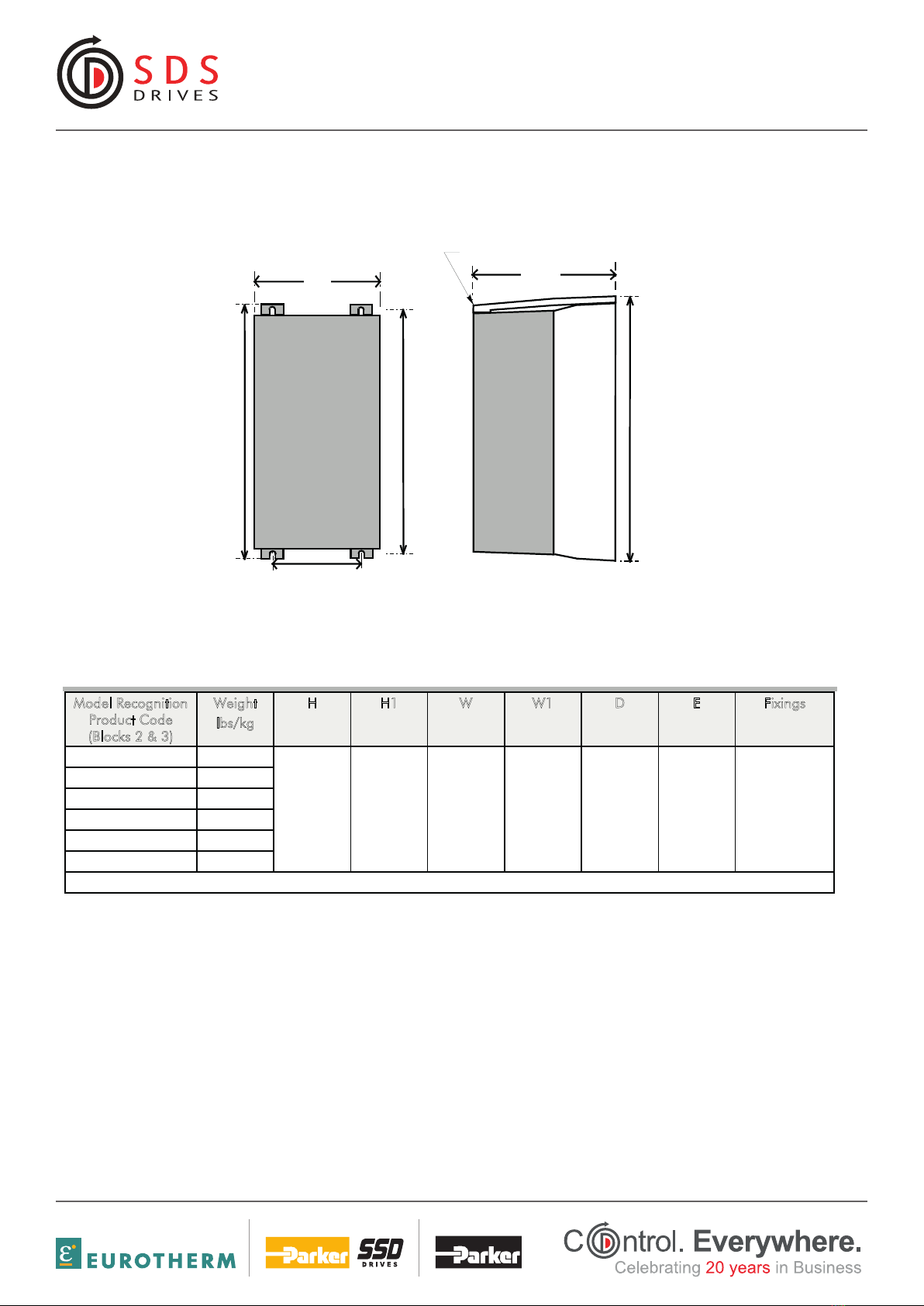

134 56 78910 11

TB1 - TECHNOLOGY BOX

GND

M /MH /H A /A B /B +-

supply

0V

M

HA B+-

supply

ENCODER

Figure 2 Single-Ended Encoder Outputs

2

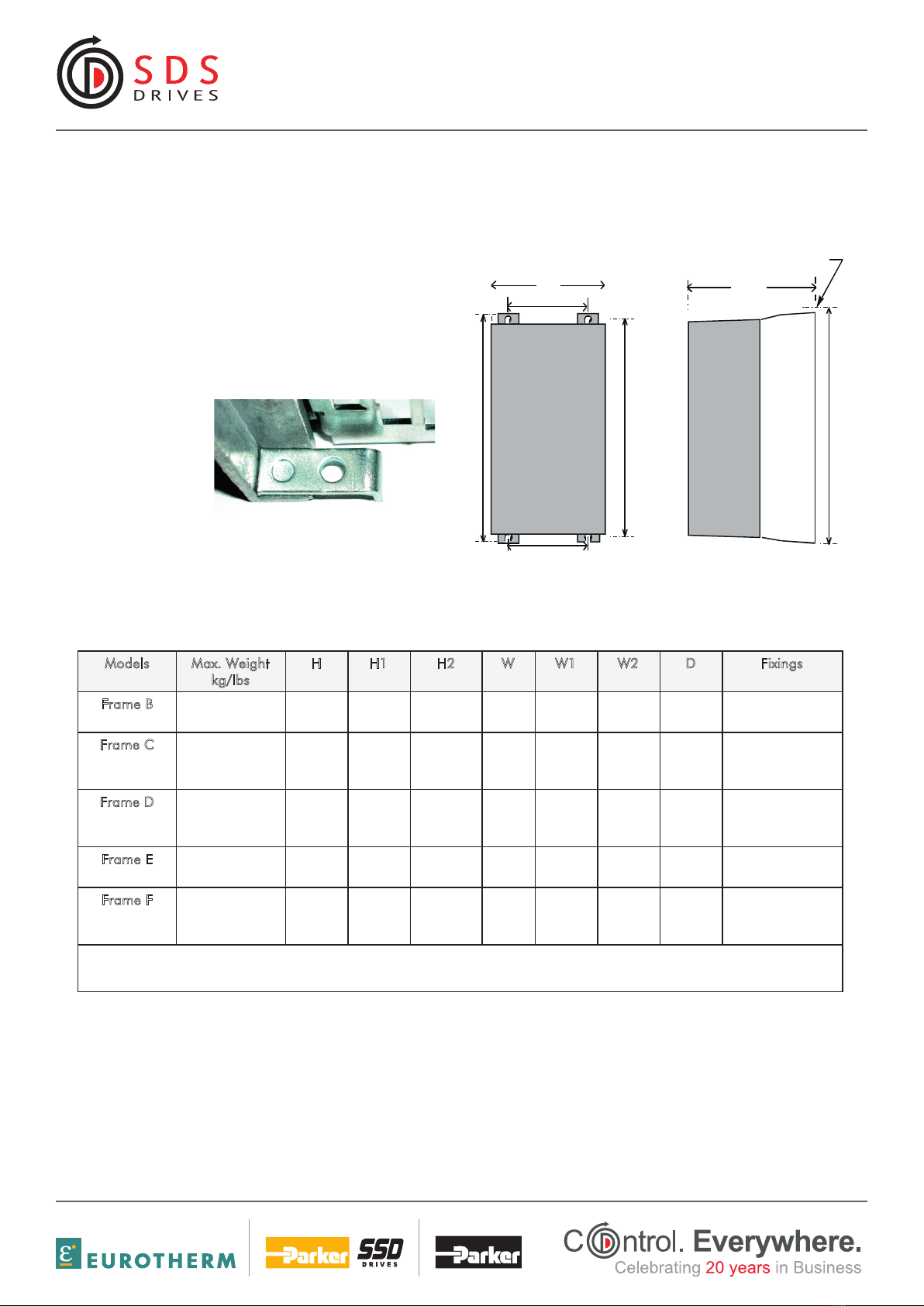

134 56 78910 11

TB1 - TECHNOLOGY BOX

GND

M /MH /H A /A B /B +-

supply

0V

M

HA B+-

supply

/M

/B/A

/H

ENCODER

Figure 3 Differential Encoder Outputs

This manual was downloaded at: www.sdsdrives.com

+44 (0)117 938 1800

Figure 3 Differential Encoder Outputs Figure 2 Single-Ended Encoder Outputs

DIP Switch Settings

The DIP switch can be seen

through the casing of the

HTTL Speed Feedback

Technology Box.

The switch settings control

the following inputs:

3

HTTL Speed Feedback Technology Box

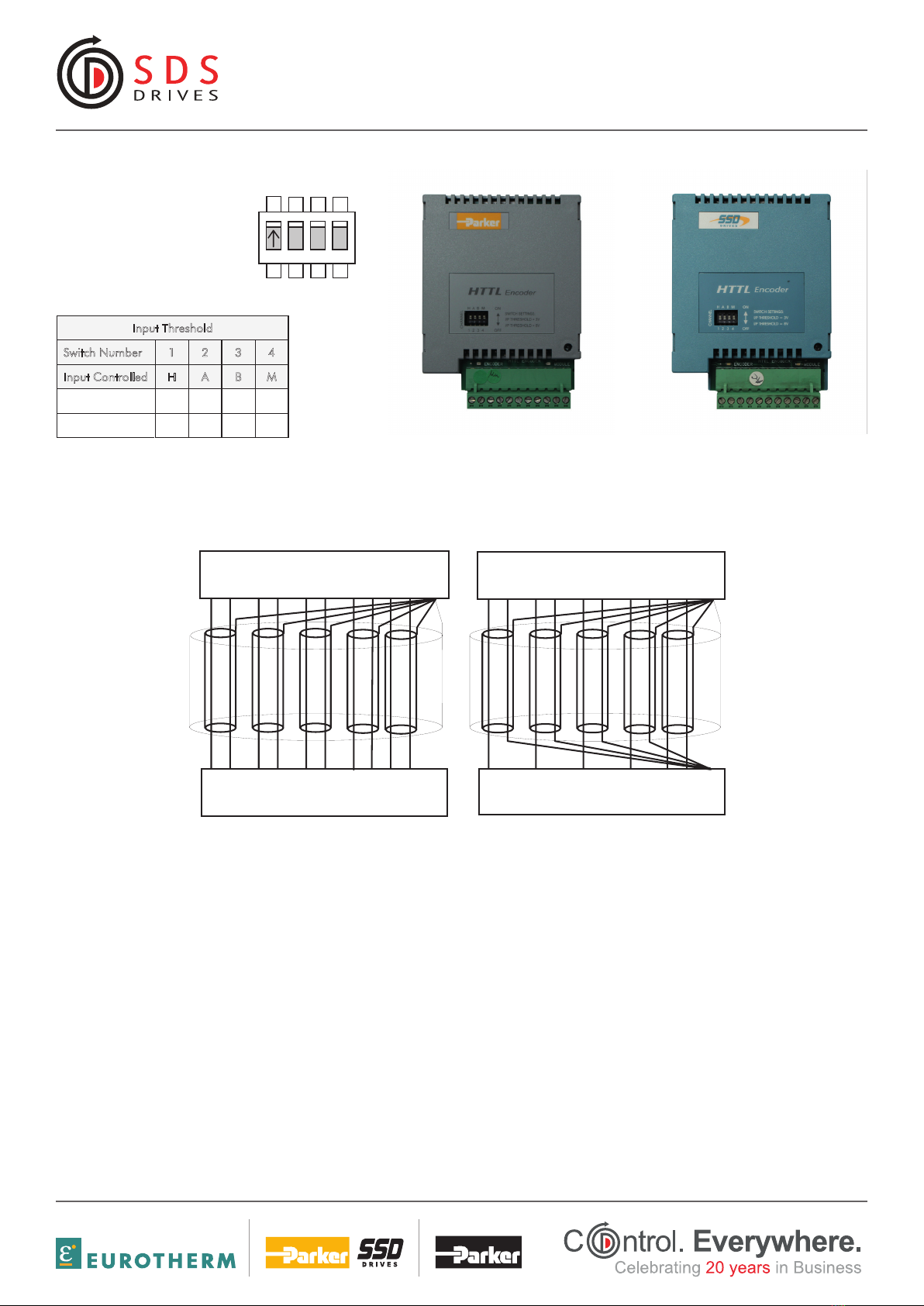

DIP Switch Settings

The DIP switch can be seen

through the casing of the

HTTL Speed Feedback

Technology Box.

The switch settings control

the following inputs:

Usually the switches will be set to give a threshold of 3V when using a differential encoder, and

to 8V when using a single-ended encoder. (Factory default is with switches 1 & 2 set in the ON

position - 3V).

Terminal Block (TB1) Connections

For correct operation, A, /A, B and /B must be connected as shown. If any is left unconnected,

the HTTL speed feedback technology box will not operate.

Note: The M and H inputs are not normally connected - these are for use with future versions

of drive software.

M: For connection to the once-per-revolution marker output from the encoder to verify

correct operation of the encoder.

H: For where the encoder has provision for a `health’ output.

Take special care wiring the encoders to the option due to the low level of the signals.

All wiring to the HTTL Speed Feedback Technology Box should be made in screened cable.

Use cable with an overall screen and a screen over each individual pair. To ensure compliance

with the EMC Directive the overall cable screen should be connected to the encoder body and to

the terminal block, pin 11.

Recommended cable (pairs individually screened):

Belden equivalent 8777

Parker SSD Drives Part Number CM052666

1234

ON

OFF

DIP SWITCH

TB1

DIP

Input Threshold

Switch Number 1 2 3 4

Input Controlled H A B M

3V±1 On On On On

8V±1 Off Off Off Off

2

134 56 78910 11

TB1 - TECHNOLOGY BOX

GND

M /MH /H A /A B /B +-

supply

0V

M

HA B+-

supply

ENCODER

Figure 2 Single-Ended Encoder Outputs

2

134 56 78910 11

TB1 - TECHNOLOGY BOX

GND

M /MH /H A /A B /B +-

supply

0V

M

HA B+-

supply

/M

/B/A

/H

ENCODER

Figure 3 Differential Encoder Outputs

This manual was downloaded at: www.sdsdrives.com

+44 (0)117 938 1800

Usually the switches will be set to give a threshold of 3V when using a differential encoder, and to 8V when using a single-ended

encoder. (Factory default is with switches 1 & 2 set in the ON position - 3V).

3

HTTL Speed Feedback Technology Box

DIP Switch Settings

The DIP switch can be seen

through the casing of the

HTTL Speed Feedback

Technology Box.

The switch settings control

the following inputs:

Usually the switches will be set to give a threshold of 3V when using a differential encoder, and

to 8V when using a single-ended encoder. (Factory default is with switches 1 & 2 set in the ON

position - 3V).

Terminal Block (TB1) Connections

For correct operation, A, /A, B and /B must be connected as shown. If any is left unconnected,

the HTTL speed feedback technology box will not operate.

Note: The M and H inputs are not normally connected - these are for use with future versions

of drive software.

M: For connection to the once-per-revolution marker output from the encoder to verify

correct operation of the encoder.

H: For where the encoder has provision for a `health’ output.

Take special care wiring the encoders to the option due to the low level of the signals.

All wiring to the HTTL Speed Feedback Technology Box should be made in screened cable.

Use cable with an overall screen and a screen over each individual pair. To ensure compliance

with the EMC Directive the overall cable screen should be connected to the encoder body and to

the terminal block, pin 11.

Recommended cable (pairs individually screened):

Belden equivalent 8777

Parker SSD Drives Part Number CM052666

1234

ON

OFF

DIP SWITCH

TB1

DIP

Input Threshold

Switch Number 1 2 3 4

Input Controlled H A B M

3V±1 On On On On

8V±1 Off Off Off Off

2

134 56 78910 11

TB1 - TECHNOLOGY BOX

GND

M /MH /H A /A B /B +-

supply

0V

M

HA B+-

supply

ENCODER

Figure 2 Single-Ended Encoder Outputs

2

134 56 78910 11

TB1 - TECHNOLOGY BOX

GND

M /MH /H A /A B /B +-

supply

0V

M

HA B+-

supply

/M

/B/A

/H

ENCODER

Figure 3 Differential Encoder Outputs

This manual was downloaded at: www.sdsdrives.com

+44 (0)117 938 1800