Chapter 1 General Description

1 - 1 582/583/5831

Chapter 1 General Description

The Eurotherm Drives Inverters described in this manual are suitable for the speed control of

standard 3-phase induction motors.

The Inverters use advanced microprocessor based technology to generate a variable frequency

variable voltage output, the control algorithm combining unique space Vector Pulse Width

Modulation control strategy with quiet pattern operation. The Inverters' control terminals are

galvanically isolated from power circuits to allow easy system interconnection. The controller is

protected against both phase to phase and phase to earth short circuits, overloads, and excessive

voltages via an intelligent monitoring strategy, thus avoiding nuisance tripping and giving trouble

free operation.

The Inverters require either a single phase 2 wire supply of 220/240 Volts, 50/60Hz or a 3-phase

3 wire supply, at 220/240V, 50/60Hz.

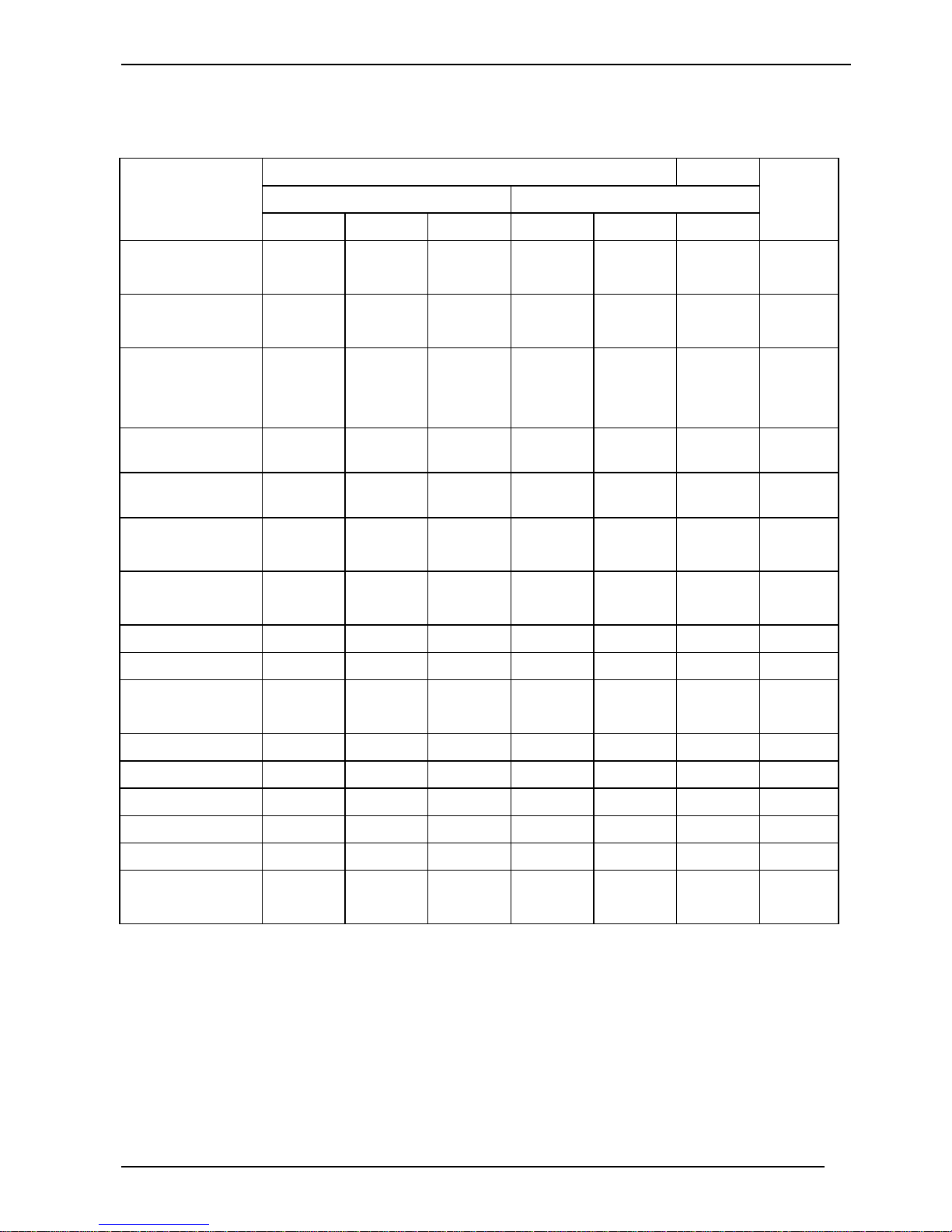

The 582 is available in two versions:

i)0.37/0.55kW single phase supply only

ii) 0.55/0.75kW single or 3-phase supply possible

The 583 is available in two versions:

i)1.1/1.5kW single or 3-phase supply

ii) 1.5/2.2kW single or 3-phase supply

The 5831 is available in two versions:

i)0.37/0.55/0.75kW single or 3-phase supply

ii) 1.1/1.5kW single or 3-phase supply

All versions feature power derating by simple switch selection. Note that all controllers are

shipped with the switches set to the lower rating.

The Inverters' output frequency ranges from 0 - 100/120Hz with varying voltage/frequency

characteristics suitable for either constant torque applications or efficient operation of fans and

centrifugal pumps.

The 582/583 Inverters are available in either IP00 or IP20 enclosures. The IP20 version can be

supplied with the basic operator controls of speed demand, direction and start/stop, requiring

only the power connections to be made to give a working system.

The 5831 is the IP54 version of the Inverter family. It can be supplied as a simple enclosed

version or with basic operator controls.

An option card is also available which can be fitted in the inverter to allow use of a current

reference instead of the standard voltage reference.

The inverters are fully compliant with the requirements of the EMC directive. As standard they

meet the industrial immunity requirements of the draft generic standard prEN50082-2 (1992),

and with the addition of filters, and correct installation meet the ‘residential, commercial and

light industrial’ emission requirements of the generic standard EN50081-1 (1992).

WARNING

Dangerous voltages remain present in the drive for a few minutes after power is removed, as

indicated by the link charge LED. Allow 5 minutes after the power is removed for the link

capacitors to discharge before working on the drive or ancillary equipment.

***** DO NOT CONNECT TO 415V SUPPLY. USE ONLY 220/240V *****