Preface

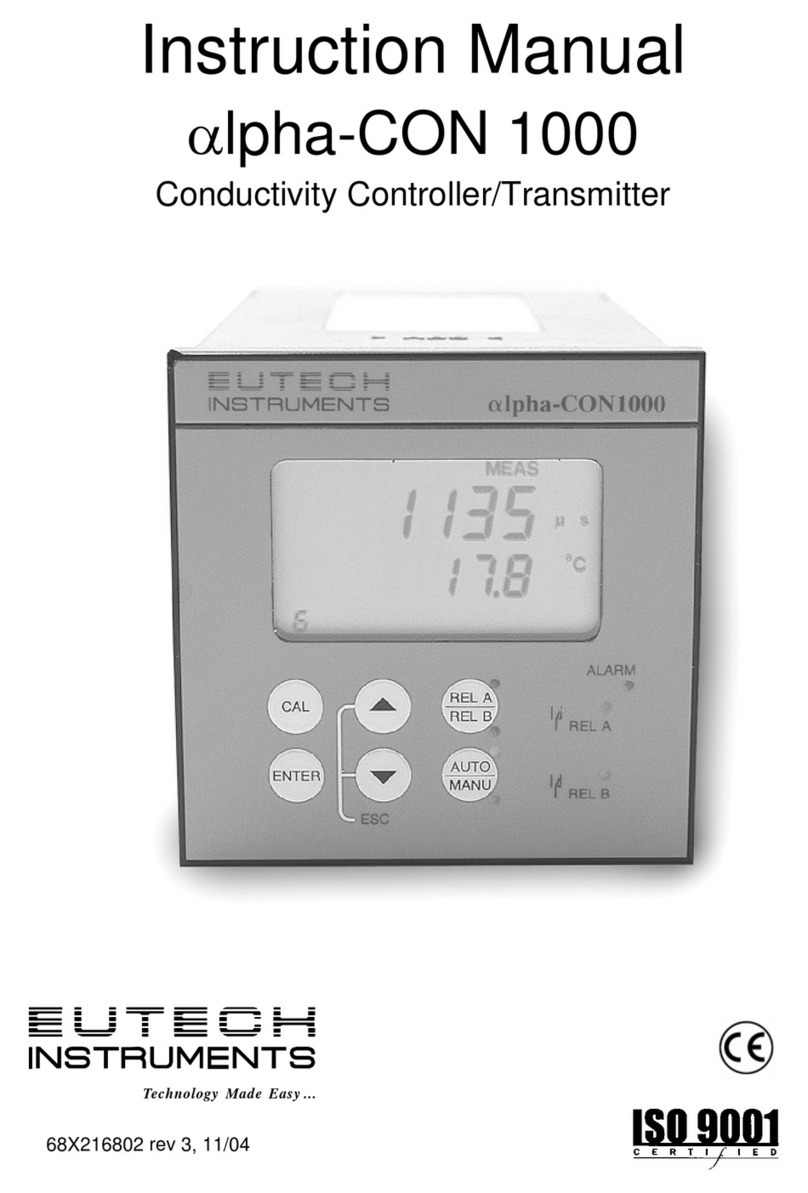

This manual serves to explain the use of the αlpha-CON1000 series Conductivity

controller/transmitter. The manual functions in two ways:firstly as a step by step guide to help the

user operate the instrument. Secondly, it serves as a handy reference guide. This instruction

manual is written to cover as many anticipated applications of the αlpha-CON1000 Conductivity

controller/transmitter. If you have doubts in the use of the instrument, please do not hesitate to

contact the nearest Eutech Instruments’ Authorised Distributor.

The information presented in this manual is subject to change without notice as improvements are

made, and does not represent a commitment on part of Eutech Instruments Pte Ltd.

Eutech Instruments cannot accept any responsibility for damage or malfunction of the unit due to

improper use of the instrument.

Copyright 1998 Eutech Instruments Pte Ltd. Version 1.0. All rights reserved.

EUTECH INSTRUMENTS PTE LTD

Blk 55 Ayer Rajah Crescent, #04-16/24, Singapore 139 949. Tel: (65) 778 6876; Fax: (65) 773 0836

TABLE OF CONTENTS

1 Introduction........................................................................................................3

1.1 Description of Unit.................................................................................3

1.2 Applications...........................................................................................4

2Assembly and Installation...................................................................................5

2.1 Measurement and Control System...........................................................5

2.2 Unit Dimensions.....................................................................................5

3Electrical Connection.........................................................................................6

3.1 Connection Diagram...............................................................................6

3.2 Back Panel .............................................................................................7

4Overview.........................................................................................................8

4.1 Keypad and Display................................................................................8

4.2 Function Groups.....................................................................................9

4.3 Control Concept ...................................................................................10

5MEASUREMENT............................................................................................11

5.1 Display in Measurement mode..............................................................11

5.2 Security Codes......................................................................................11

6Calibration Mode.............................................................................................14

6.1 Conductivity Calibration.......................................................................14

7ADVANCED SET-UP MODE.............................................................................15

7.1 Temperature Coefficient sub-function...................................................15

7.2 Temperature calibration (ATC mode only)............................................16

7.3 Control Relay A/Control Relay B (SP1/SP2) sub-function.....................17