Table of Contents

1. Introduction ...........................................................................................................1

1.1 Before You Begin................................................................................................................... 1

1.2 Intended Use.......................................................................................................................... 1

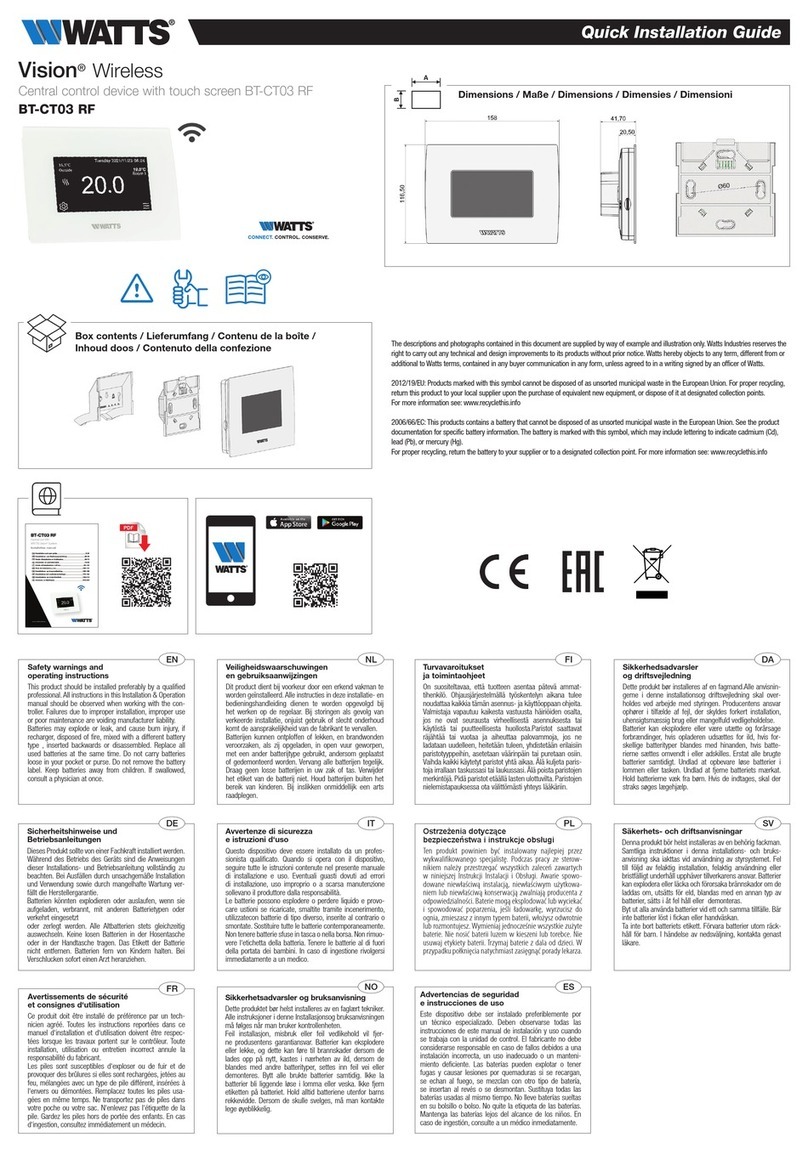

1.3 Safety Instructions.................................................................................................................. 2

1.4 Taking Out of Service / Correct Disposal of the Unit ............................................................. 2

2. Getting Started ......................................................................................................3

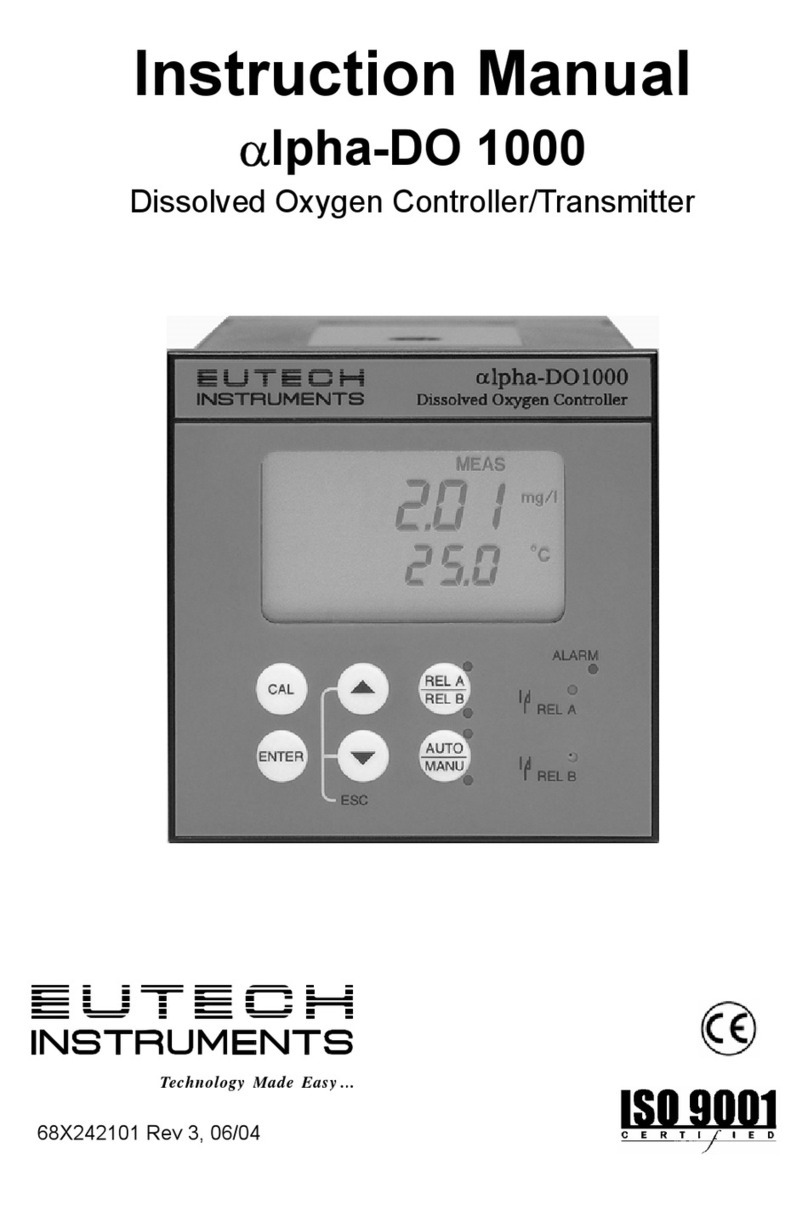

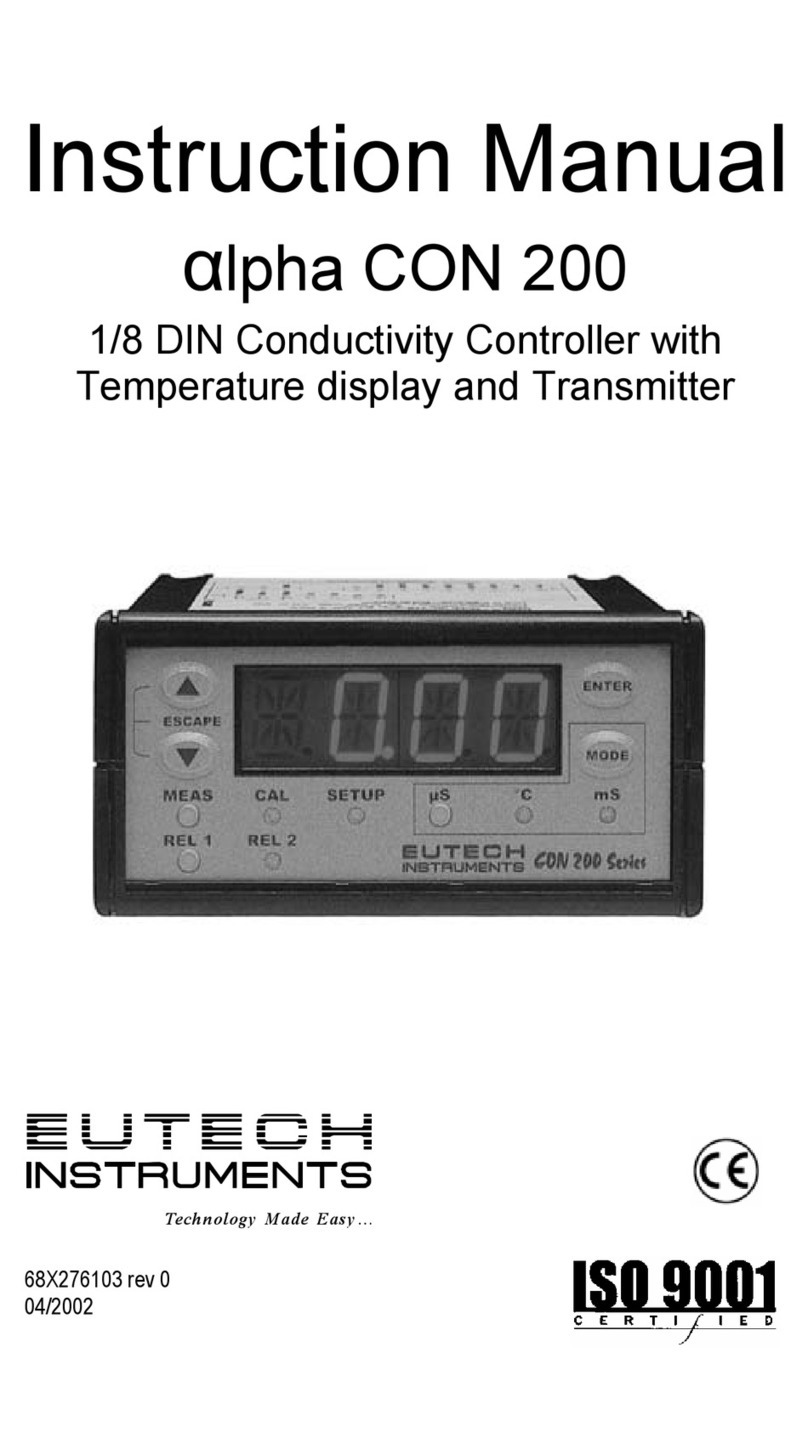

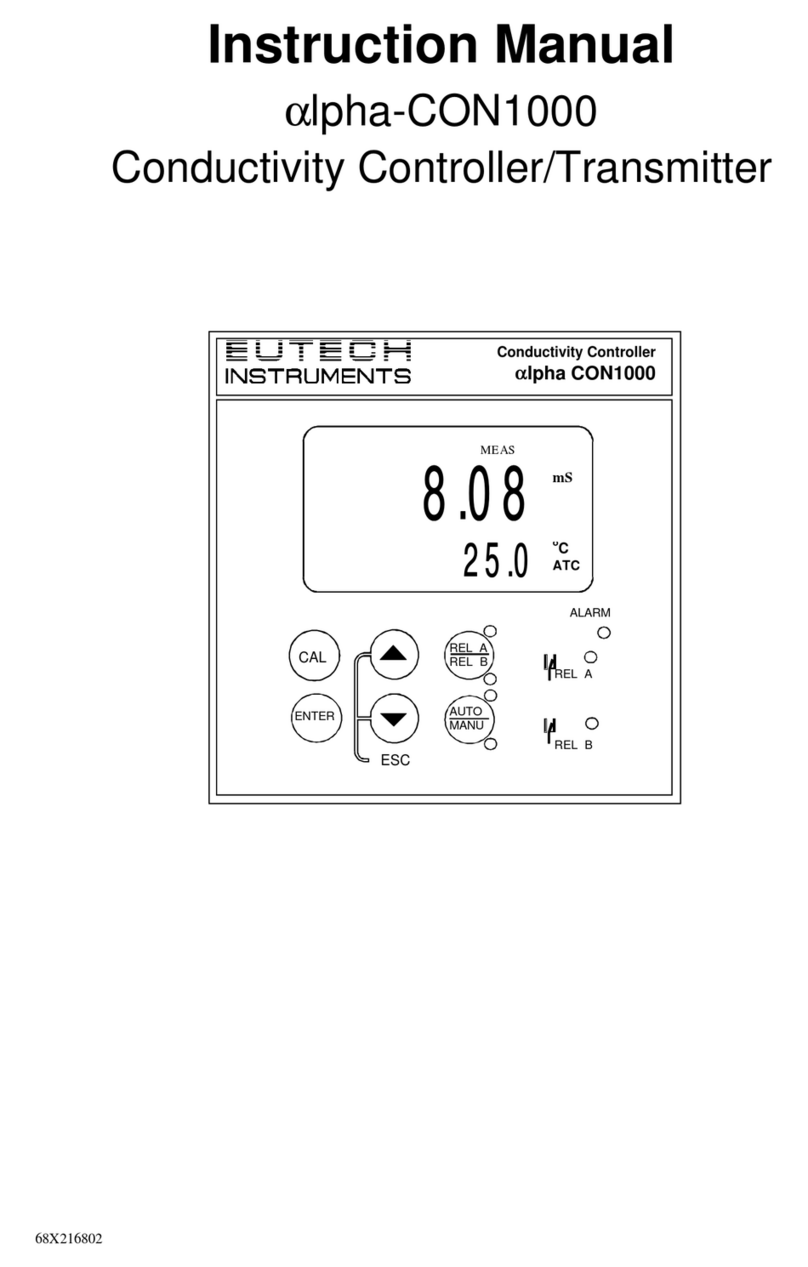

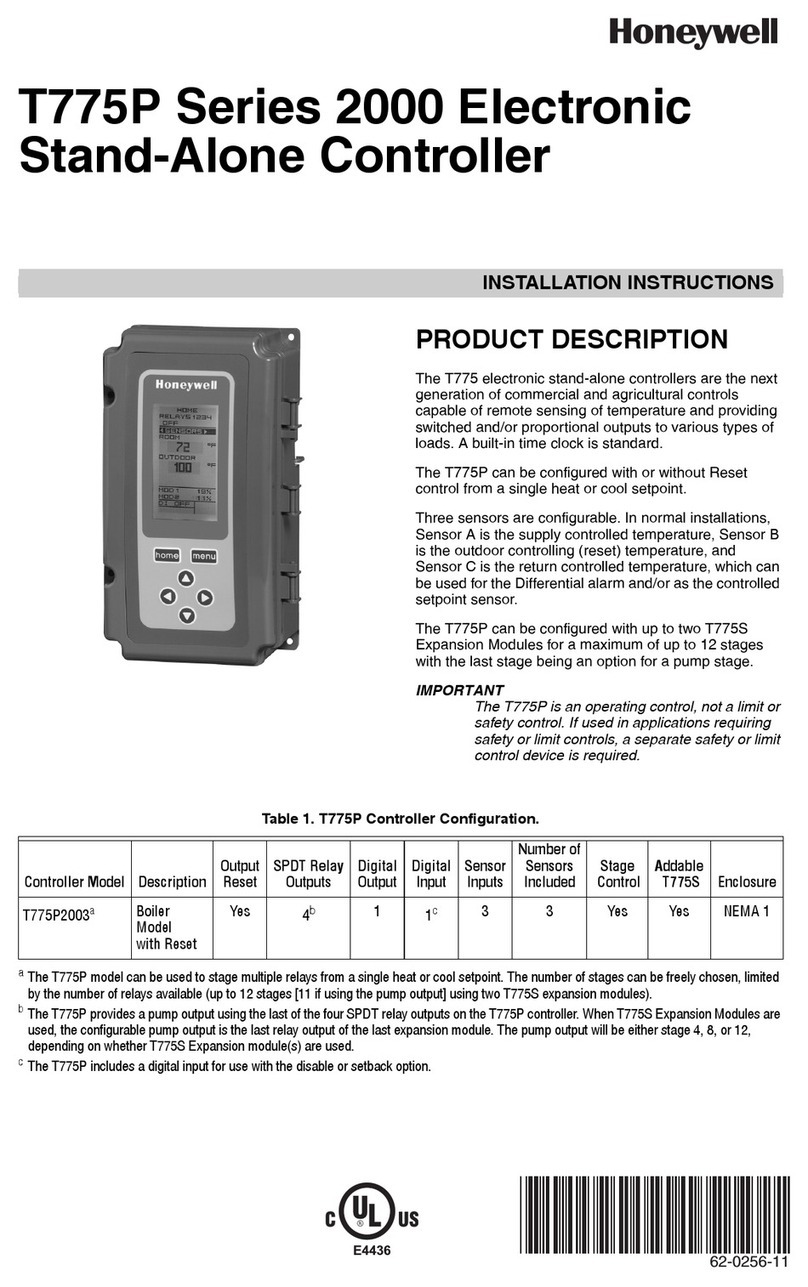

2.1 Description of Instrument .......................................................................................................3

2.2 Measurement and Control System......................................................................................... 4

2.3 Connecting Peripherals..........................................................................................................5

2.3.1 Connection Terminals.................................................................................................... 5

2.3.2 Switching Between Pt100 & Pt1000 Temperature Sensors.......................................... 6

2.3.3 Connecting Conductivity Probe..................................................................................... 7

2.3.4 Connecting Temperature Probe.................................................................................... 7

2.4 Installation.............................................................................................................................. 8

2.4.1 Mechanical Dimensions................................................................................................. 8

2.4.2 Wall Mount..................................................................................................................... 8

2.4.3 Panel Mount................................................................................................................... 9

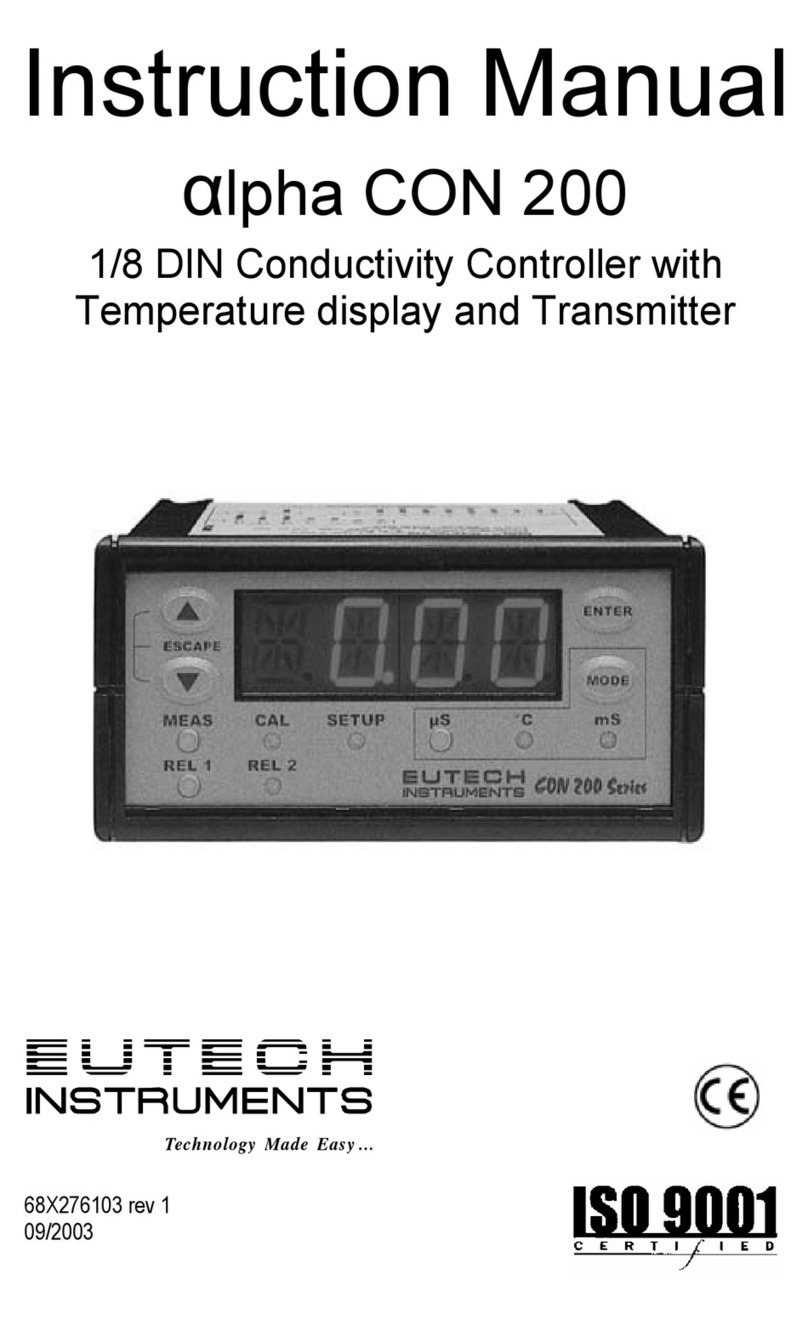

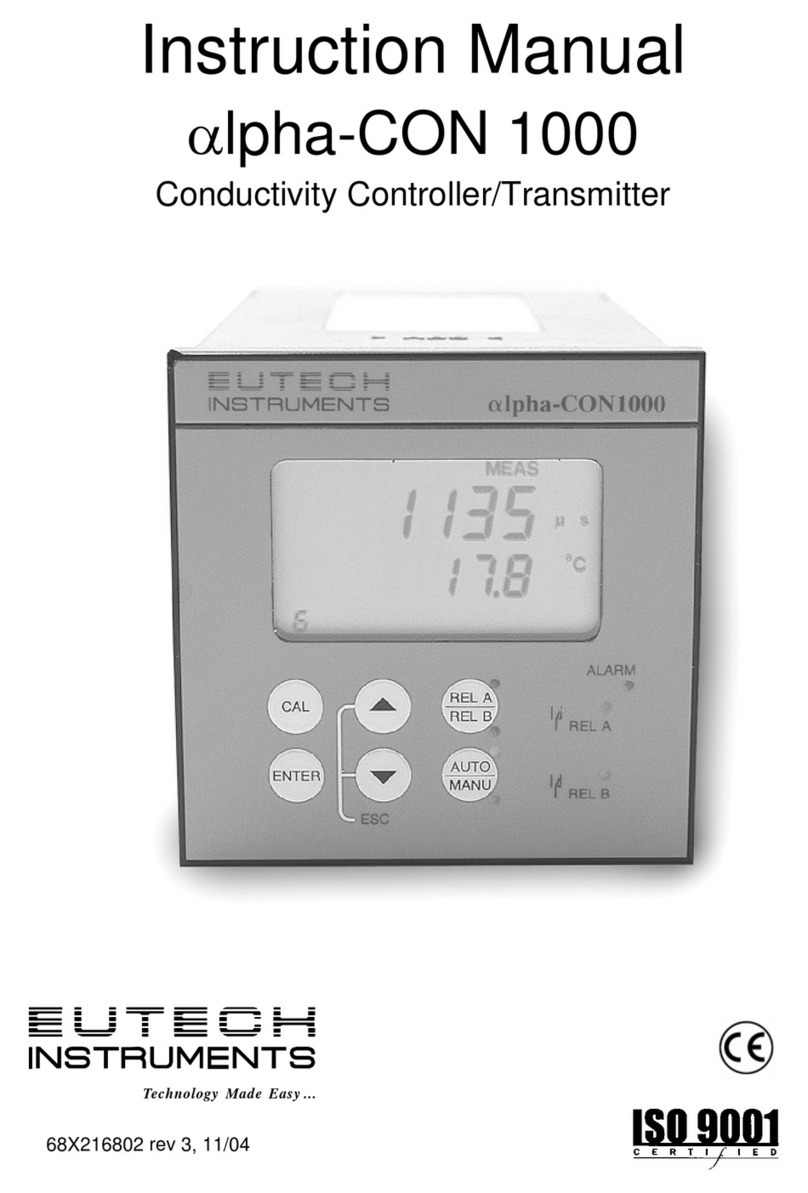

2.5 Display & Keypad................................................................................................................. 10

2.5.1 Display Overview......................................................................................................... 10

2.5.2 Key Functions.............................................................................................................. 11

3. Operation .............................................................................................................13

3.1 Measurement mode ............................................................................................................. 13

3.2 Menu Overview .................................................................................................................... 14

4. Calibration Mode .................................................................................................15

4.1 About Calibration.................................................................................................................. 15

4.2 Calibration............................................................................................................................ 16

5. Setup Mode..........................................................................................................19

5.1 Enter Setup mode ................................................................................................................19

5.2 Temperature Coefficient Settings......................................................................................... 20

5.3 Temperature Settings........................................................................................................... 21

5.4 Relay 1/Relay 2 Settings...................................................................................................... 23

5.5 Controller Settings................................................................................................................ 25

5.6 Measuring Range Settings................................................................................................... 27

5.7 Configuration Settings..........................................................................................................28

5.8 Viewing Electrode Properties............................................................................................... 30

6. Technical Specifications.....................................................................................31

7. List of Accessories .............................................................................................33

8. Troubleshooting..................................................................................................34

9. General Information ............................................................................................35

9.1 Warranty............................................................................................................................... 35

9.2 Return of Goods................................................................................................................... 35

9.3 Guidelines for Returning Unit for Repair.............................................................................. 35

10. Appendices.......................................................................................................36

10.1 Appendix 2 Conductivity of various aqueous solutions....................................................... 36

10.2 Appendix 2 Graphical Representation of the Function of Hysteresis ................................. 37

info@GlobalScientificSupply.com

www.GlobalScientificSupply.com

GLOBAL SCIENTIFIC SUPPLY

The Laboratory Supply Company!