EV Global Motors E-Bike 24V User manual

MANUAL

24V MODELS

SERVICE

E-Bike™

Service Manual

24V MODELS

EV Global Motors Company

10900 Wilshire Boulevard

Suite 310

Los Angeles, CA 90024

Tel: 310/208-7076

Fax: 310/208-2444

www.ebike.com

Copyright © 2000 EV Global Motors Company

Second Edition

September, 2000

LIT-82001-00-00

All rights reserved. No parts of this publication may be

reproduced or transmitted in any form or by any means

without the prior permission of EV Global Motors

Company.

Although every precaution has been taken to assure this

publication is complete and accurate, EV Global

assumes no liability for errors or omissions. All informa-

tion contained in this publication is based on the latest

information available at the time of publication and is sub-

ject to change without notice.

TABLE OF CONTENTS

Chapter One: General Information 1-1

Beep/LED Codes

Terms

Vehicle Identification Number

Key number

Model Code

How to Read the Model Code

Terms

Lubricants

Threadlock

Recommended Maintenance Schedule

Special Tools

Chapter Two: Specifications 2-1

Mechanical Specifications

Gear Ratios

Electrical Specifications

Torque Specifications

Performance Specifications

Frame Specifications

Chapter Three:Battery Pack 3-1

Charging the Batteries

Replacing the Batteries

Replacing the Charger

Battery Pack

Chapter Four: Handlebar and Controls 4-1

Handlebar Position

Handlebar Height Adjustment

Handlebar Replacement

Throttle Control-Housing

Accessory Control Housing

Headset

Chapter Five: Brakes 5-1

Brake Cable Replacement

Brake Lever

Brake Lever Free Play Adjustment

Brake Pad

Brake Pad Alignment

Caliper Arm

Disc Brake

Chapter Six: Shifter and Derailleur 6-1

Shifter

Shifter Cable

Derailleur

Chapter Seven: Chain and Crankset 7-1

Chain

Crank Arm

Chainring

Pedal

Bottom-Bracket Cartridge

Chapter Eight: Electrical 8-1

Connector Identification

Right Side Cover

Left Side Cover

Controller

Quick-Release Connector

Motor

Headlight

Taillight

Troubleshooting

Electrical Schematic

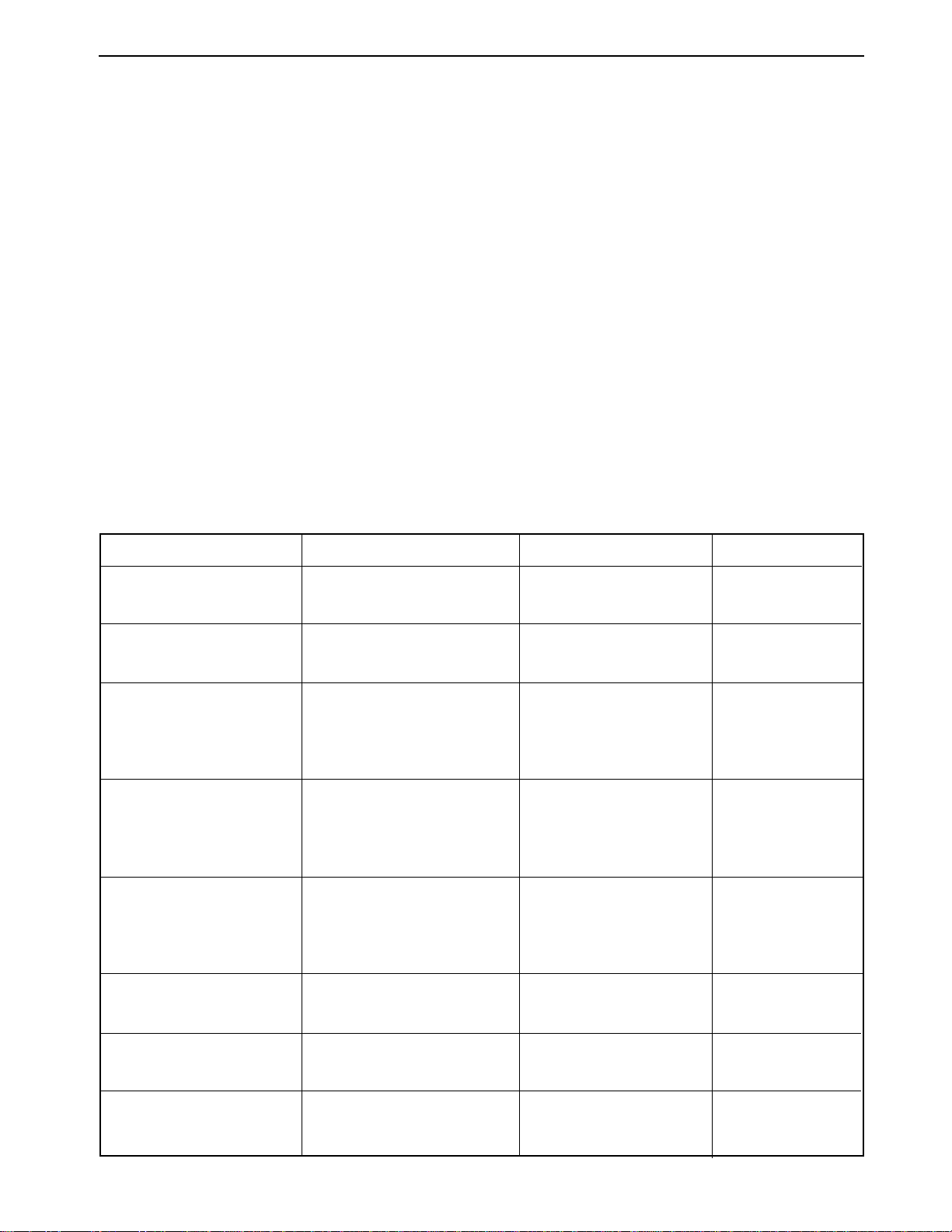

BEEP/LED CODES

The E-Bike™ beeps and flashes various codes to alert the rider to particular conditions. The fol-

lowing chart lists the codes and describes their various functions. Beep codes consist of a series of

long and short beeps, like Morse code.A long beep is represented by a dash (-).A short beep is rep-

resented by a dot (•).

Code Meaning Beep LEDs

OK The battery pack is - - - - •-

installed and properly

connected.

GO Sounds at power knob ON. - - •- - - The charge level

The system is on and LEDs cycle twice

ready to operate. in sequence.

Pedal assist The system requests •- - •

pedal assist. Sounds

when on a steep hill

or when the motor has

overheated.

Over heat 1 The motor is - - - ••••

overheated. Followed by the pedal

The system will disable the assist code (•- - •)

motor within 3-5 every 8 seconds

seconds.

Over heat 2 Sounds at power knob ON - - - - •-

if the motor has been

disabled.

System refusal An error has been - •- - -

detected.The system

will not operate.

Battery state of Indicates the battery Green = 100-60%

charge state of charge within 3 Yellow = 60-20%

seconds of power knob ON. Red = 20-0%

Low battery The system will shut •- ••- - - Charge level

LEDs

down within 3 to 5

cycle continuous

ly

seconds. in sequence.

1-1

Chapter One

GENERAL

INFORMATION

KEY NUMBER

The 4-digit key number is stamped on the

upper portion of the key shaft.

MODEL CODE

HOW TO READ THE MODEL CODE

ModelYear 99 B1 24 C V 00 BK

Product Line

& Category Power System Model Brake Type Battery Type Color

B1 = Bicycle, 24 = 24 Volts Base = B V=V-brake 00=Lead-Acid ML=Metallic Blue

Conventional Comfort = C D=Disk brake CR = Metallic Cranberry Red

Touring = T BK = Black

RD = Rally Red

1-2

Model code Model prefix Year Description Color 1 Color 2 Color 3

B1 Bicycles

99-B124BV00-BK,RD 1B1 1999 Base Black (BK) Rally Red (RD) NA

99-B124CV00-BK,RD 2B1 1999 Comfort Black (BK) Rally Red (RD) NA

99-B124TV00-ML,CR 2B1 1999 Touring Metallic Metallic NA

Blue (ML) Cranberry (CR)

TERMS

Left and Right

Most of the time, left and right in this man-

ual refer to the rider’s point of view when seat-

ed on the E-Bike™ and facing forward. The

one exception to this rule involves the brake

calipers. Left and right on the calipers refers to

a technician’s point of view when standing in

front of the E-Bike™ and looking directly at the

front brake caliper or when standing behind the

E-Bike™ and looking directly at the rear brake

caliper.

NOTE, CAUTION and WARNING

The terms NOTE, CAUTION and WARN-

ING have specific meaning in this manual. A

NOTE provides additional information to make

a procedure easier or clearer.

A CAUTION emphasizes precautions that

must be taken to avoid damage to your tools or

to the E-Bike™.

A WARNING alerts you to a situation where

negligence could lead to injury or death. Take

WARNINGS seriously. Failure to heed a

WARNING could result in serious personal

injury or death.

VEHICLE IDENTIFICATION NUMBER

The 17-digit vehicle identification number

(VIN) is printed on a label that is affixed to

the inside face of the right frame seat stay.

This label also contains the gross-vehicle

weight rating and recommended tire inflation

pressure.

LUBRICANTS

Grease

The bearings and other mechanical com-

ponents in the E-Bike™ operate at relatively

low temperatures so most automotive greases

are inappropriate for use on the E-Bike™.

Always use grease made specifically for a

bicycle, such as grease from Bullshot,

Campagnolo, Finish Line, Pedros, Phil Wood,

and Shimano.

OilAlways use oils made specifically for bicy-

cle use. Bicycle oils need to be thin enough to

penetrate tight places, they should be durable

so they can withstand exposure to the ele-

ments, and they must resist the accumulation

of dirt.

Suitable oils for the E-bike include Alsop,

Bullshot, Campagnolo, Finish Line, Lube Wax,

Phil Wood Tenacous Oil, Pedros, Superlube,

and Triflow.

Motor oil, WD40, 3-in-1 Oil, sewing

machine oil, gun oil, and other common oils

are not suitable and should not be used.

In general, applying oil from a drip applica-

promote over-lubrication, which leads to

excessive accumulation of dirt. Apply oil spar-

ingly. Apply enough oil to do the job, but not so

much that it starts to drip from the component.

After applying any oil, wipe off the excess.

THREADLOCK

A threadlocking compound should be used

on most fasteners on the E-Bike™.

Threadlocking compound prevents loosening

caused by vibration and helps seal out mois-

ture.

Loctite 242 (blue) or equivalent is recom-

mended for threadlocking applications. Loctite

242 is a medium-strength threadlocking com-

pound that permits disassembly with common

hand tools.

Before applying Loctite to threads, clean

the thread surface of oil, grease, and other

residue. Apply a small amount of Loctite.

Excess compound could work its way down

the threads and bond parts together. The

torque chart in Chapter Two includes Loctite

recommendations for particular fasteners.

1-3

RECOMMENDED MAINTENANCE SCHEDULE

Component or Condition Inspect before every ride Inspect every 5 to 10 rides*

Brake pad adjustment X

Wheel quick release adjustment X

Tire pressure X

Tire wear/damage X

Head/tail/brake light operation X

Mirror position X

Controls and display X

Seat post quick release adjustment X

Brake pad wear X

Brake cable tension/wear XX

Spoke tension X

Wheel true X

Hub bearings adjustment X

Hub bearing lubrication X

Chain lubrication X

Derailleur adjustment X

Reflectors X

Battery and charger X

Headset adjustment X

Bottom bracket adjustment X

Tighten all bolts, nuts, and mounting X

hardware

* Depending upon length of ride and riding conditions. Inspect more frequently when riding in dusty or wet

conditions.

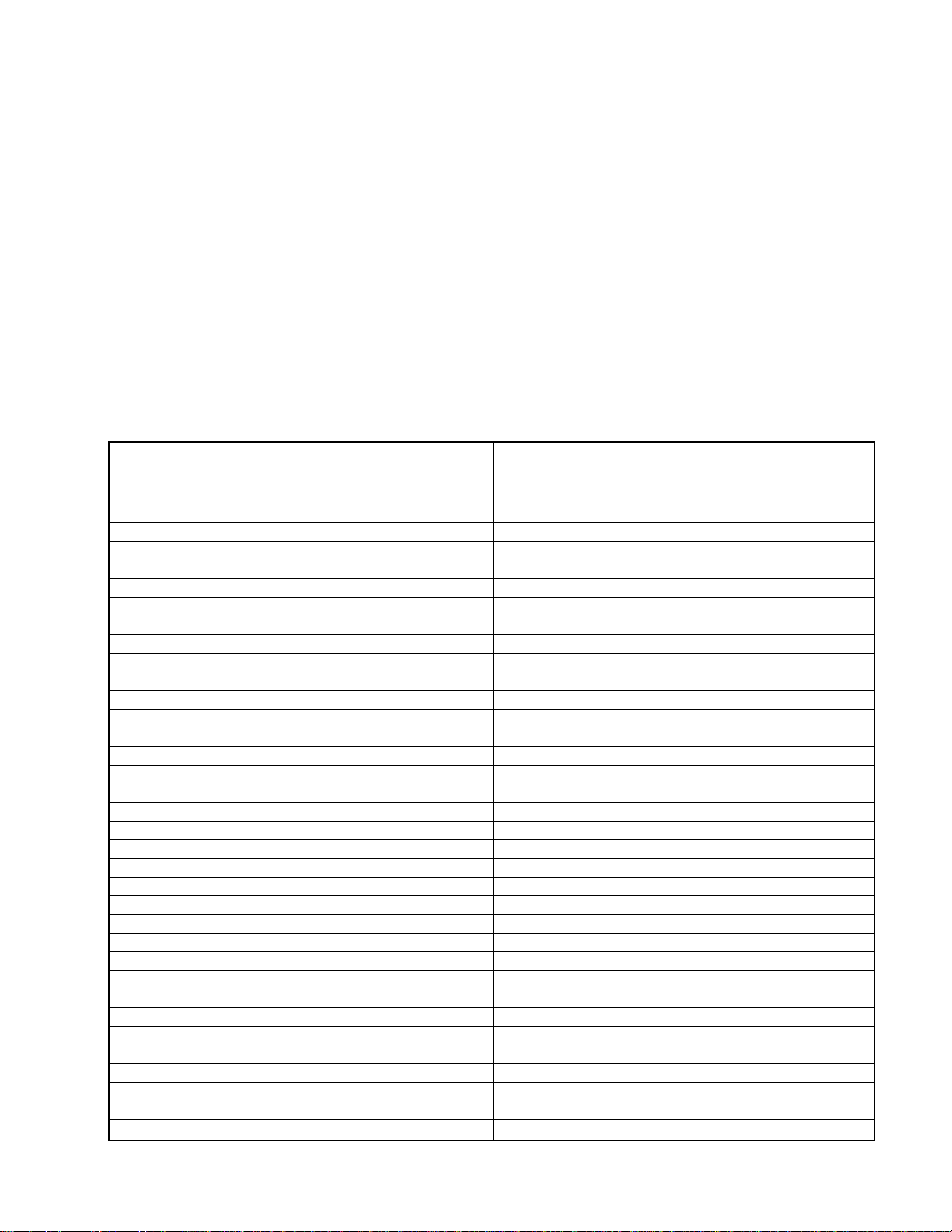

SPECIAL TOOLS

The following special tools are needed for servicing the E-Bike™.

Tool Part number

Hex wrench set: 4mm, 5mm, 6mm Park AWS-1

Hex wrench set Park AWS-11C

Hex wrench set: 2mm, 5mm, 3mm Park AWS-3

Fourth hand cable stretcher Park BT-2

Chain checker Park CC-2C

Chain breaker (screw type) Park CT-3

Crank wrench Park CCW-14R

Cable and housing cutter Park CN-4C

Gearclean brush Park GSC-1

32mm & 36mm head wrench Park HCW-15

Pedal wrench Park PW-3

Spoke wrench (black) Park SW-0

Spoke wrench (red) Park SW-2

Tire lever set Park TL-1C

Freewheel tool Park Tool FR-1

Bottom-bracket-cartridge tool Park Tool BBT-2

1-4

Table 1: Mechanical Specifications

Component Specification

Headset

Stack height 33 mm (1.30 in.)

Dimensions 25.4 mm x 34 mm x 30 mm w/seal

Fork

Type PU Allen key adjustable

Steerer tube 1-1/8 in.

Travel 65 mm

Stem 1

Std. model 17 degrees, 110 mm extension

C & T models 40 degrees, 110 mm extension

Stem 2 28.6 mm x 25.4 mm x 150 mm with quill

Handlebar

Std model

Rise 30 mm, 10 degrees

Width 620 mm

Handle 200 mm

Seat post

Std model 300 mm x 30.0 mm O.D.

Seat post spacer 100 mm x 30.1 mm ID x 34.9 mm O.D.

Seat post, suspension

C & T models 350 mm x 27.2 mm O.D.

Seat post spacer 100 mm x 27.3 I.D. x 34.9 mm O.D.

Tires

Std & C models 26 x 1.95 in., black

T model 26 x 1.95 in., Skinwall black

Rims 26 x 1.5 in., 14G x 36H, double wall

Spokes

Front 266 mm, 14G stainless with brass nipples

Rear 216 mm & 219 mm, 14G stainless with brass nipples

Bottom bracket (B/B) 127 mm cartridge

Freewheel 14-28 T, 7-speed

Chainring 33 T

Chainring clearance 16~17 mm (0.63~0.67 in.)

Crankarm 170 mm (6.7 in.)

Chain 1/2 x 3/32 x 110 L

2-1

Chapter Two

SPECIFICATIONS

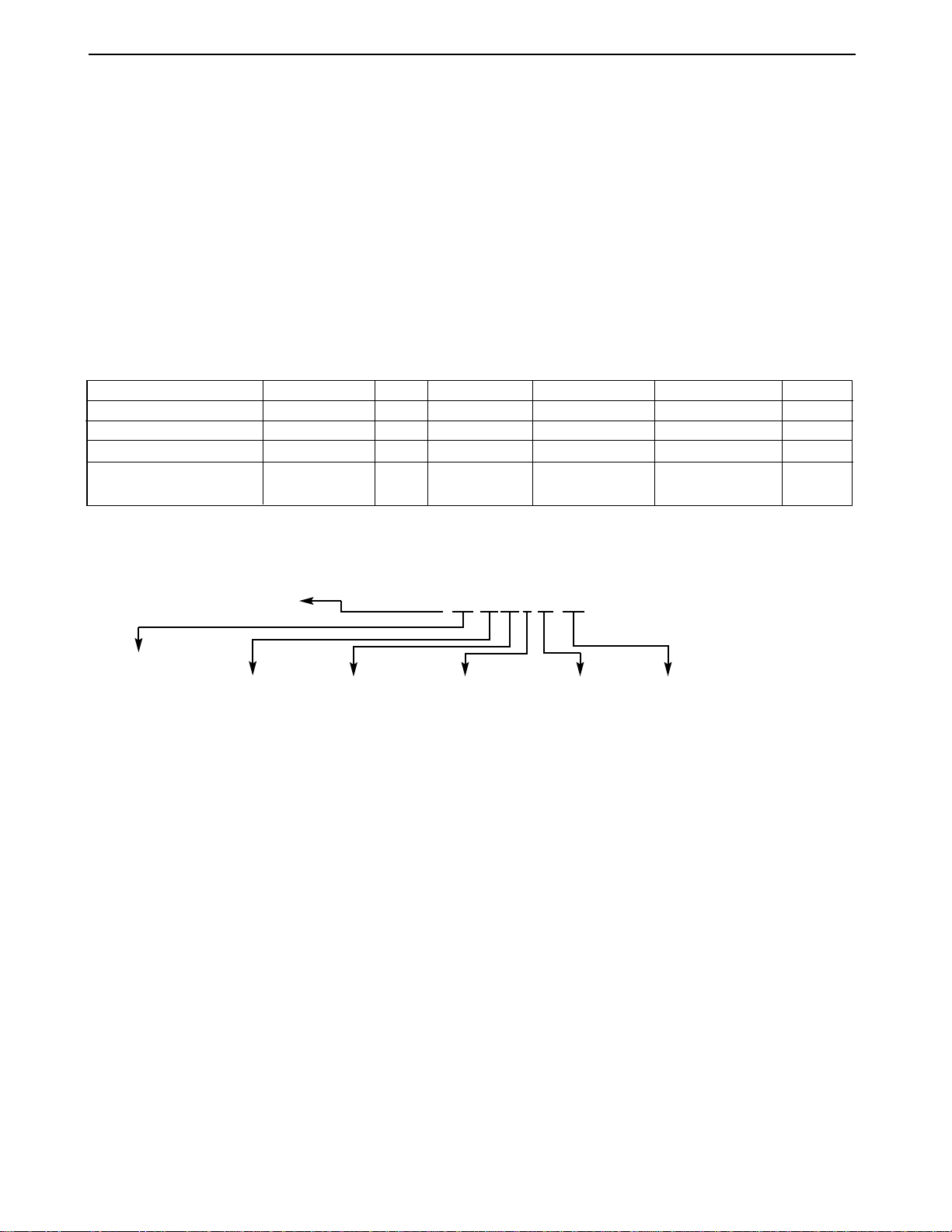

Table 2: Gear Ratios

Chainring Freewheel Gear Inches Ratio

33T 14T 61.3 0.42 (14/33)

33T 16T 53.6 0.48 (16/33)

33T 18T 47.7 0.55 (18/33)

33T 20T 42.9 0.61 (20/33)

33T 22T 39.0 0.67 (22/33)

33T 24T 35.8 0.73 (24/33)

33T 28T 30.6 0.85 (28/33)

Table 3: Electrical Specifications

Component Specification

Battery (WP12-12) 2 in series

Type Deep discharge, sealed AGM lead-acid

Capacity 12 volts, 12 amp hours.

Charger

Input 115 VAC, 60/50 Hz, 2 amps

Output 24 VDC, 3 amps

Charger cord

Length 1.2 m (4 ft.)

Wire 18 AWG, 2-wire with ground

Chapter Two

2-2

Table 4:Torque Specifications

Item kg-cm in.-lb. ft.-lb. Special Instructions

Handlebar-binder bolt 140~200 - 10~15 Apply Loctite

Handlebar-arm clamp bolts 140~200 - 10~15 Apply Loctite

Stem-binder bolt (stem-2 quill bolt) 180~250 - 13~18

Headset locknut 40~50 34.7~43.4

Accessory control clamp bolt 30~40 26.5~34.7 -

Throttle-control clamp bolt 30~40 26.5~34.7 -

Controller mounting screw 15 13.0 -

Brake-lever clamp bolt 30~40 26.5~34.7 -

Brake-caliper pinch bolt 140~200 - 10~15 Apply Loctite

Brake-pad nut 63.6~85.2 53~71 -

Caliper pivot bolt 85.2~106.8 71~89 - Apply Loctite

Left-side-cover mounting screws 10 8.6 - Apply Loctite

Right-side-cover mounting screws 10 8.6 - Apply Loctite

Battery-terminal-block mounting screw 10 8.3 -

Battery compartment mounting screw 10 8.3 -

Battery pack handle 15 13.0 -

Battery cover screw 20~30 17.4~26.5 Apply Loctite

Charger-board mounting screw 10 8.6 -

Derailleur mounting bolt 84 70 -

Derailleur pinch-mechanism nut 42 36.5 -

Shifter clamp bolt 30~40 26.5~34.7 -

Mirror-mounting screw 30~40 26.5~34.7 -

Chain guard screws 15 13.0 - Apply Loctite

Left bottom-bracket cover screws 20~30 17.4~26.5 - Apply Loctite

Crank-arm mounting bolt 200~250 - 14.4~18.1 Apply grease to the bolt

threads

Pedal 30~50 26.5~43.4 - Apply grease to the stud

threads

Bottom-bracket cartridge adapter ring 300~400 - 21.7~28.9 Apply grease to the threads

Chainring bolt 350~450 - 25~32 Apply oil to the bolt threads

Motor torque arm 15 13.0 - Apply Loctite

Headlight mount 15 13.0 -

Taillight mounting nut 20 17.4

Horn mounting nut 15 13.0 -

Cord access cover 5 4.2 -

Frame mounted connector 10 8.6 - Apply Loctite

Front fender 15 13.0 -

Rear fender 15 13.0 -

SPECIFICATIONS 2-3

Table 5: Performance Specifications*

Item Specification

Top speed 13.5-14.0 mph

Range (E mode, flat, no wind) 18-20 miles

Maximum gradeability 11% grade, 6 mph

Acceleration 0-10 mph in 5.3 seconds

*200-pound rider with tires inflated to 60 psi.

Frame Specifications

Frame Size (Center to top)

419 cm (16.5 in.)

Wheel Base 1062.3 mm (41.8 in.)

RC 431.5 mm

(17.0 in.)

72˚

Head Tube

163 mm (6.4 in.)

2-4

CHARGING THE BATTERIES

The E-Bike™ includes a charger that is an

integral part of the battery pack. Batteries can

be charged when the battery pack is on-board

the E-bike™ or when the battery pack is

removed for remote charging.

To assure maximum battery life, always

fully recharge the battery after each ride. If the

E-Bike™ will not be used for more than one

week, remove the battery pack from the E-

Bike™ and store it in a cool, dry place. The

controller uses a small amount of power when-

ever the battery pack is installed in the E-

Bike™. Consequently, the batteries slowly dis-

charge whenever the battery pack is in place,

even if the power knob is OFF.To prevent total

battery discharge during extended periods of

non-use, remove the battery pack and store it

in a cool, dry place. A stored battery should be

recharged at least every three months to help

maintain performance and quality.

On-board Charging

1. Be sure the power knob is turned OFF.

2. Turn the battery-compartment latches

clockwise, and open the door.

3. Retrieve the charging cord from the com-

partment above the bottom bracket.

4. Plug the female end of the charging cord

into the receptacle on the battery

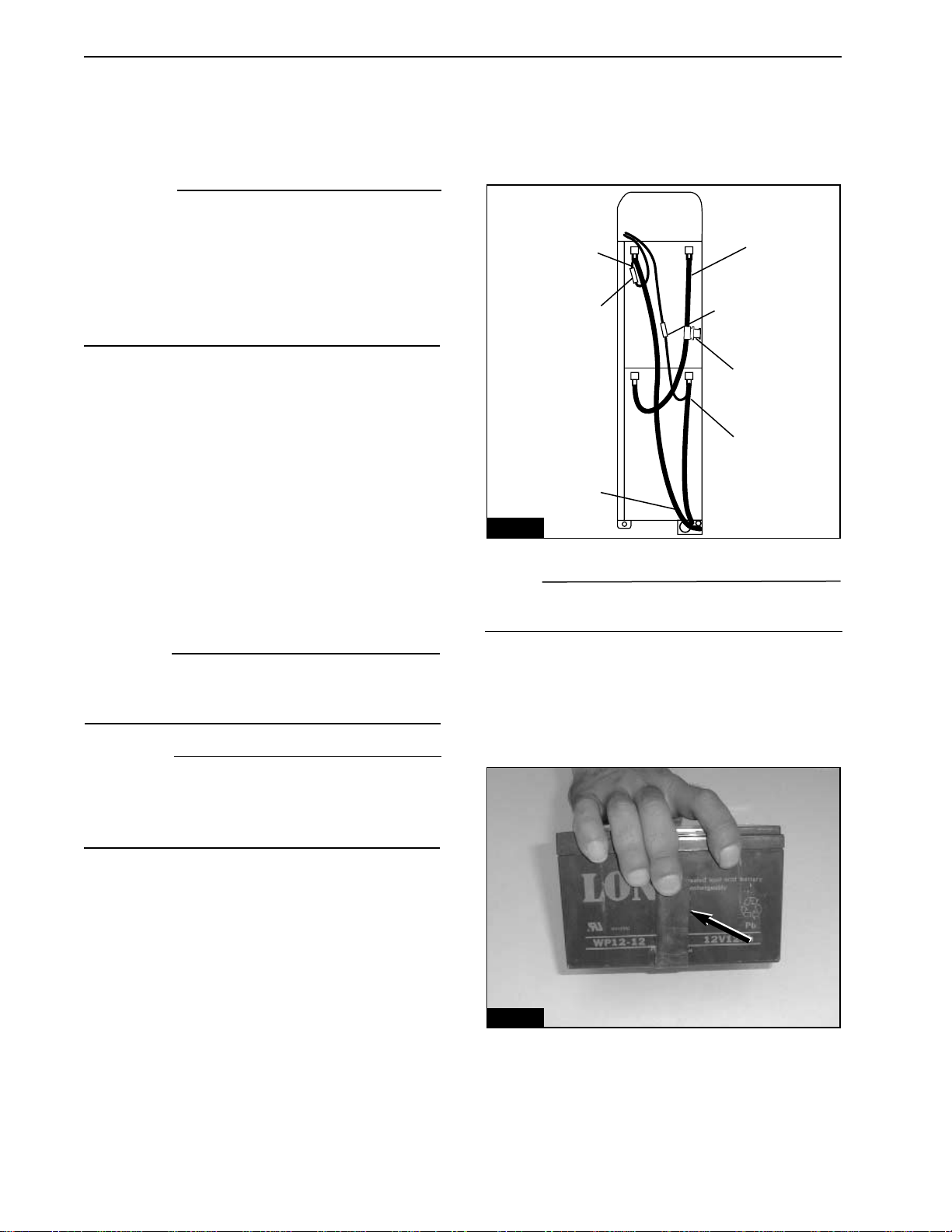

charger.(Figure 1)

FIG.1

Chapter Three

BATTERY PACK

3-1

WARNING

The charger is equipped with a cooling fan. If

the cooling fan does not operate when the

charging cord is plugged in and the red LED is

on, unplug the charger from the electrical out-

let immediately. Determine why the fan is not

operating before charging the battery pack.

Replace the charger if necessary.

5. Plug the male end of the charging cord into

a standard 110V/60 cycle electrical outlet.The

red LED on the charger and the cooling fan will

automatically turn on. The LED switches to

green and the cooling fan turns off when the

battery pack is fully charged.

Remote Charging

1. Remove the battery pack from the E-Bike™.

2. Set the battery pack on its side so the bat-

tery-pack cover faces up and the handle is to

the side.

FIG.3

Chapter Three

3. Retrieve the charging cord from the com-

partment above the bottom bracket.

4. Plug the female end of the charging cord

into the receptacle on the battery charger.

WARNING

The charger is equipped with a cooling fan. If

the cooling fan does not operate when the

charging cord is plugged in and the red LED is

on, unplug the charger from the electrical out-

let immediately. Determine why the fan is not

operating before charging the battery pack.

Replace the charger if necessary.

5. Plug the male end of the charging cord into

a standard 110V/60 cycle electrical outlet.The

red LED on the charger and the cooling fan will

automatically turn on. The LED switches to

green and the cooling fan turns off when the

battery pack is fully charged.

REPLACING THE BATTERIES

The battery pack contains two sealed lead-

acid batteries that are connected in series.The

following procedure describes how to remove

and replace the two batteries.

CAUTION

Always replace both batteries as a set. Do not

mix old batteries with new batteries, and do not

mix different brands of batteries.

WARNING

Never use a battery that is cracked or broken.

Battery acid is highly corrosive and can cause

severe burns if it comes in contact with your

eyes or skin.

Removal

1. Remove the battery pack from the E-Bike™.

2. Remove the two cover screws from the bat-

tery pack, and remove the cover.

3. Disconnect and remove the blue intercon-

nect wire that connects the two batteries to

each other in series.Note the fuse on the inter-

connect cable (Figure 2).

4. Disconnect the battery-pack leads (black

and red) from the spade connectors on each

battery.

3-2

FIG. 2

Black

Black

Interconnect Wire

(Blue)

Red

Fuse

Bullet Connector Bullet Connector

5. Invert the battery case.Tap the case against

the bench or floor to dislodge the batteries

from the battery pack.

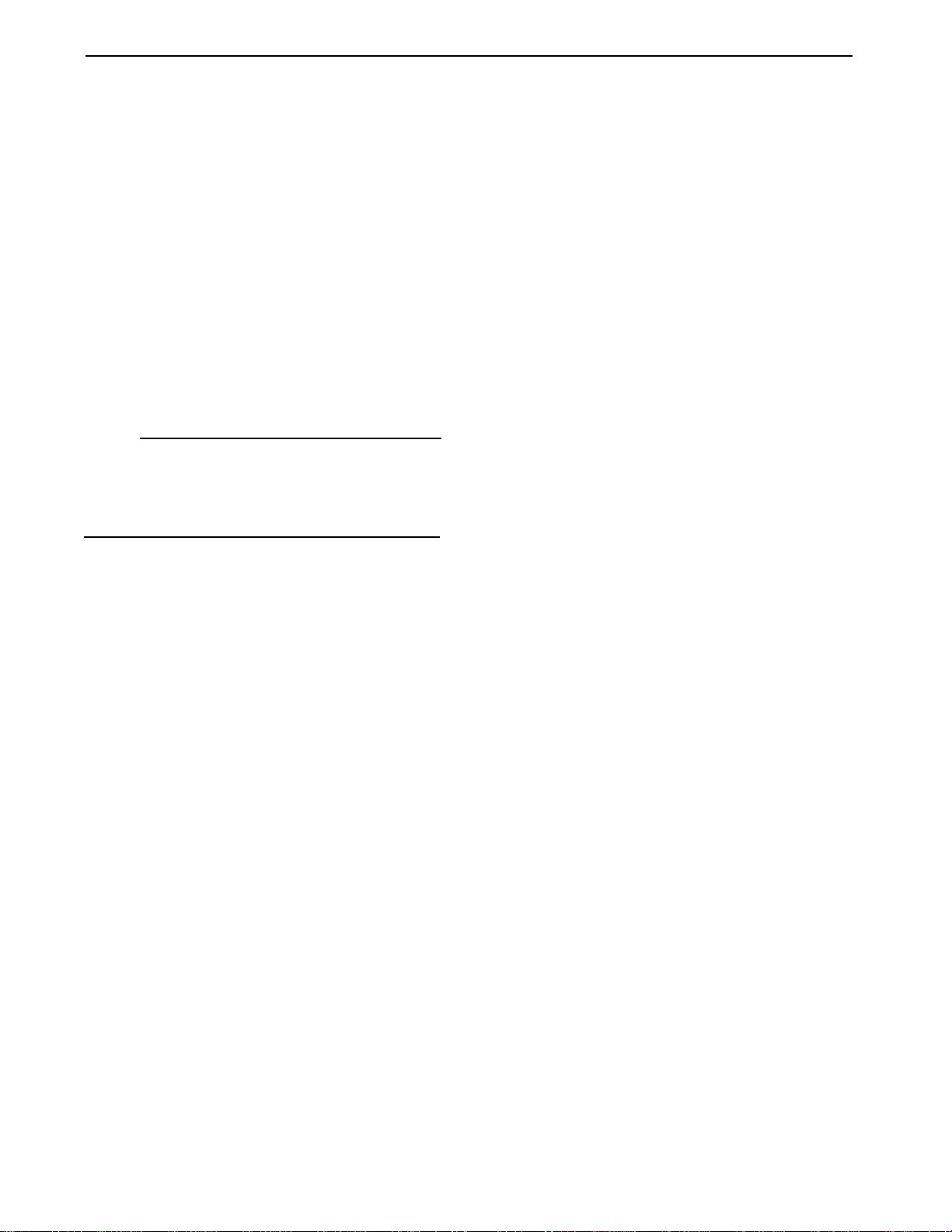

6. Remove each battery and its damper strap

(Figure 3).

NOTE

Contact your state or local agency for informa-

tion on proper battery disposal.

7. Properly dispose of the old batteries.

Installation

1. Wrap the damper strap around the first bat-

tery (Figure 3).

2. Set the battery into the compartment so the

end with the spade connectors faces the

charger. Press the battery into the compart-

ment until it bottoms.

Installation

1. Be sure the insulator (B, Figure 6) is in

place in the battery pack.

2. If removed, install the spacer (A, Figure 6)

onto each mounting stud in the battery pack.

3. Set the charger board into place on the

mounting studs.Secure the board in place with

the charger-board mounting screws and wash-

er (Figure 5).

4. Secure the board to the bracket with the

mounting screw (B, Figure 4).

5. Plug the connectors from the cover into

their mates in the charger board.

6. Fit the cover in place over the charger

board. Be sure the two charger wires are not

pinched under the cover.

7. Secure the cover in place with the three

charger-cover screws (A, Figure 4).

8. Reinstall the batteries and the battery-pack

cover.

3. Repeat for the second battery.

4. Inspect the fuse on the blue interconnect

wire. Replace the fuse as necessary.

5. Connect the blue interconnect wire to the

upper battery’s positive terminal and to the

lower battery’s negative terminal.

6. Connect the red lead from the battery pack

to the positive terminal on the lower battery.

7. Connect the black lead from the battery

pack to the negative terminal on the upper bat-

tery.

8. Fit the cover onto the battery pack. Be sure

no wire is pinched beneath the cover.

9. Apply Loctite 242 (blue) to the threads of

the two cover screws, and secure the cover in

place.

REPLACING THE CHARGER

Removal

WARNING

Make sure the charger is not plugged in during

service.

1. Remove the batteries from the battery pack.

2. Remove the three charger-cover screws

that secure the cover to the vent (A, Figure 4).

3. Lift the cover from the charger, and discon-

nect the three electrical connectors from the

charger board.

4. Remove the screw that secures the charg-

er board to the bracket (B, Figure 4).

5. Remove the three charger-board mounting

screws (Figure 5), and remove the charger

board. Do not lose the spacer (A, Figure 6)

from each mounting stud.

FIG.4

FIG. 6

FIG. 5

3-3

A

A

A

AA

A

B

B

BATTERY PACK

Removal

1. Turn the power knob OFF.

2. Open the battery compartment door.

3. Release the gate latch, and open the bat-

tery gate.

4. Use the handle to pull the battery pack from

the compartment. Be sure to support the bot-

tom of the battery pack with your free hand.

Installation

1. Set the lower end of the battery pack into

the battery compartment, and tilt the battery

into place.

NOTE

The E-Bike™ beeps the OK (_ _ _ _•_) when-

ever the battery pack is reinstalled and good

contact exists between the battery pack and

terminal block in the E-Bike™.

2. Close the gate over the battery, and secure

the gate latch.

3. Close the battery compartment door, and

turn the latches counterclockwise.

BATTERY PACK TEST

Charger operation test

1.Plug the female end of the charging cord into

the port on the charger.

2. Plug the male end into a 110-volt outlet.

3.Watch the battery charger LED and perform

the indicated procedure.

a. If the battery charger LED does not illu-

minate, the charger is faulty and should

be replaced. Unplug the charging cord,

and check the battery voltage (before

charging) as described below.

b. If the battery charger LED turns to

red and the cooling fan is not operating,

the charger is faulty and should be

replaced. Unplug the charger, and

check the battery voltage (before charg

ing) as described below.

c. If the battery charger LED turns red and

the cooling fan operates, perform the

charger output test described below.

d. If the battery charger LED turns green,

perform the charger output test

described below.

Charger Output Test

1. Remove the cover from the battery pack.

2. Connect a voltmeter’s positive (+) test probe

to the positive (+) battery terminal, and con-

nect the voltmeter’s negative (-) test probe to

the battery negative terminal as shown in

Figure 7. Note the reading on the voltmeter.

3. With the voltmeter still connected as

described in step 2, plug the charger into a

110-volt outlet. Note the reading on the volt-

meter.

4. Compare the two readings.

a. If the reading is higher when the charger

is plugged in, the charger is operating

properly. Perform the battery voltage

test (before charging).

b. If the two readings are the same, the

charger has failed and should be

replaced.

Battery Voltage Test, Before Charging

1. Let the battery stand for one hour.

2. Remove the cover from the battery pack.

3. Connect a voltmeter’s positive (+) test probe

to the positive (+) battery terminal, and con-

nect the voltmeter’s negative (-) test probe to

the battery negative terminal as shown in

Figure 7.

4. Note the reading on the voltmeter.

5. If the reading is less than 12 volts, the bat-

tery is faulty and should be replaced.

3-4

Battery Voltage Test, After Charging

NOTE

The charger must be operational for this test to

be valid.Perform the charger output test before

performing this test.

1. Charge the battery as described in this

chapter.

2. Unplug the charger, and let the battery

stand for one hour.

3. Remove the cover from the battery pack.

4. Connect a voltmeter’s positive (+) test

probe to the positive (+) battery terminal, and

connect the voltmeter’s negative (-) test probe

to the battery negative terminal as shown in

Figure 7.

5. Note the reading on the voltmeter.

6.The reading should be 12.5 volts or greater.

If the reading is less than 12.5 volts, the bat-

tery is faulty and should be replaced.

3-5

FIG. 7

HANDLEBAR POSITION

NOTE

The handlebar may be adjusted to suit the

rider’s preference. The following procedure

describes how to set the handlebar to the stock

position.

1. Loosen the handlebar-binder bolts (A,

Figure 1).

2. Position the handlebar so the ends point

down slightly.The handlebar grips should form

a 10-20˚ angle with a line that parallels the

floor. See Figure 2.

3.Be sure the knurled portion of the handlebar

is centered within the handlebar binder.

4. Tighten the handlebar-binder bolts to the

torque specification in Table 4.

HANDLEBAR HEIGHT ADJUSTMENT

1. Loosen the stem-binder bolt three or four

turns counterclockwise (A, Figure 3).If the bolt

rises from the steering stem, strike the bolt with

a plastic mallet to force the stem wedge down.

FIG.1

FIG. 2

FIG. 3

4-1

Chapter Four

HANDLEBAR

and CONTROLS

A

BA

B

C

B

A10~20˚

CAUTION

The "Minimum Insert" mark on the handlebar

stem must not sit above the top of the headset.

2. Raise or lower the stem within the head

tube until the handlebar is at the desired

height.

3. Rotate the handlebar from side to side, and

align the handlebar with the wheel or fork

dropouts.

4. Tighten the stem-binder bolt to the torque

specification in Table 4.

HANDLEBAR REPLACEMENT

Removal

1. Note how the brake cables, shifter cable,

and electrical wires are routed around the

headlight. They will have to be rerouted along

the same path during installation.

2. Remove the following components from the

right handlebar:

a.The handlebar grip.

b. The brake-lever housing

c.The throttle control and throttle stop.

3. Remove the following from the left handlebar:

a.The mirror.

b. The handlebar grip

c.The shifter.

d.The brake-lever housing.

e.The accessory control.

4. Remove the two handlebar-binder bolts (A,

Figure 1).

5. Remove the handlebar clamp (B, Figure 1)

and the handlebar.

Installation

1. Fit the handlebar into place in the binder on

the handlebar arm.Be sure the knurled portion

of the handlebar is centered in the binder.

2. Fit the handlebar clamp into place around

the handlebar.

3. Apply Loctite 242 (blue) to the threads of

the handlebar-binder bolts, and install the bolts

finger tight.

4. Position the handlebar as described in this

chapter, and tighten the handlebar-binder bolts

to the torque specification in Table 4.

5. Install the throttle control as described in

this chapter.

6. Install the accessory control as described

in this chapter.

THROTTLE CONTROL (RIGHT SIDE)

Removal

1. Remove the battery from the battery com-

partment.

2. Remove the right side cover from the E-

Bike™.

3. Pull the cable inlet cover around the head

tube, and remove the cable inlet cover from the

left side cover.

4. Disconnect the throttle control connector (F,

Figure 4) from the controller board. Note how

the throttle control wire is routed through the

frame. The new wire will have to be rerouted

along the same path.

5. Pull the wire so the connector passes

through the frame and emerges at the cable

inlet in the left side cover (Figure 5).

C

LM

N

Yellow

DEF

J

I

H

G

K

Behind controller connectors AB

Horn board

Controller board

Red

Black

FIG. 4

FIG. 5

Chapter Four

4-2

Behind controller connectors

Horn board

Controller board

6. Twist and remove the right handlebar grip

from the handlebar.

7. Disconnect the front brake cable from the

S-hook (C, Figure 1).Note how the front brake

cable is routed around the headlight. It will

have to be routed along the same path during

assembly.

8. Loosen the right-brake-lever clamp bolt,

and slide the brake lever body from the right

handlebar. Guide the front brake cable around

the headlight as you remove the brake lever.

9. Lay the brake lever over the frame top tube

so it is out of the way. Do not severely bend or

kink the cable.

10. Loosen the set bolt on the throttle control.

11. Slide the throttle control and throttle stop

off the handlebar. Pull its wire free of the head-

light bracket.

Installation

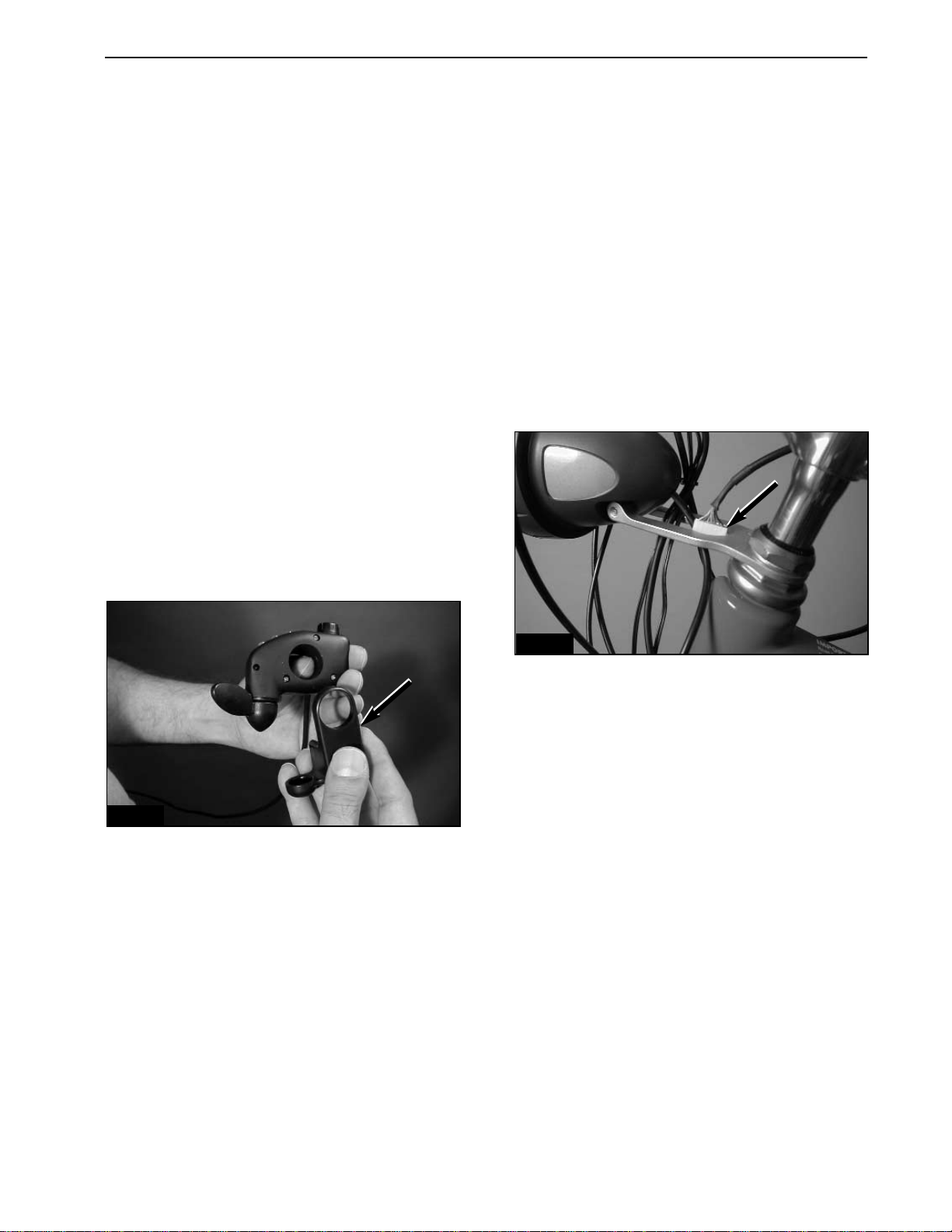

1. Fit the throttle stop onto the bottom of the

throttle control (Figure 6).

2.Slide the throttle control and the throttle stop

onto the right handlebar.

3. Feed the connector end of the throttle con-

trol wire through the cutout in the headlight

bracket (Figure 7).

4. Feed the cable around the head tube,

through the cable inlet in the left side cover,

and plug the connector into position (F, Figure

4) on the controller panel.

5. Slide the right-brake-lever body onto the

right handlebar. Guide the front brake cable

around the headlight as you install the brake

lever body.

6. Finger tighten the clamp bolt to hold brake

body in place. Use the S-hook to secure the

front brake cable to the shifter cable (C, Figure 1).

7. Twist the right handlebar grip onto the han-

dlebar until the grip is flush with the end of the

handlebar.

8. Slide the brake lever body against the han-

dlebar grip. Position the brake lever as

described in Chapter Five, and torque the

clamp bolt to the specification in Table 4.

9. Slide the throttle control/throttle stop

assembly against the brake lever. Rotate the

throttle control so the LEDs point to the rider’s

eyes.Tighten the clamp bolt so there is enough

friction to hold it in place. Do not over tighten

the clamp bolt.

10. Reinstall the right side cover.

ACCESSORY CONTROL (LEFT SIDE)

Removal

1. Remove the battery from the battery com-

partment.

2. Remove the right side cover from the E-

Bike™.

3. Pull the cable inlet cover around the head

tube, and remove the cable inlet cover from the

left side cover.

4. Disconnect the accessory control connec-

tor (E, Figure 4) from the controller board.

Note how the accessory control wire is routed

through the frame.The new wire will have to be

rerouted along the same path.

5. Pull the wire so the connector passes

through the frame and emerges at cable inlet

in the left side cover (Figure 5).

FIG. 6

FIG. 7

HANDLEBAR and CONTROLS 4-3

This manual suits for next models

1

Table of contents