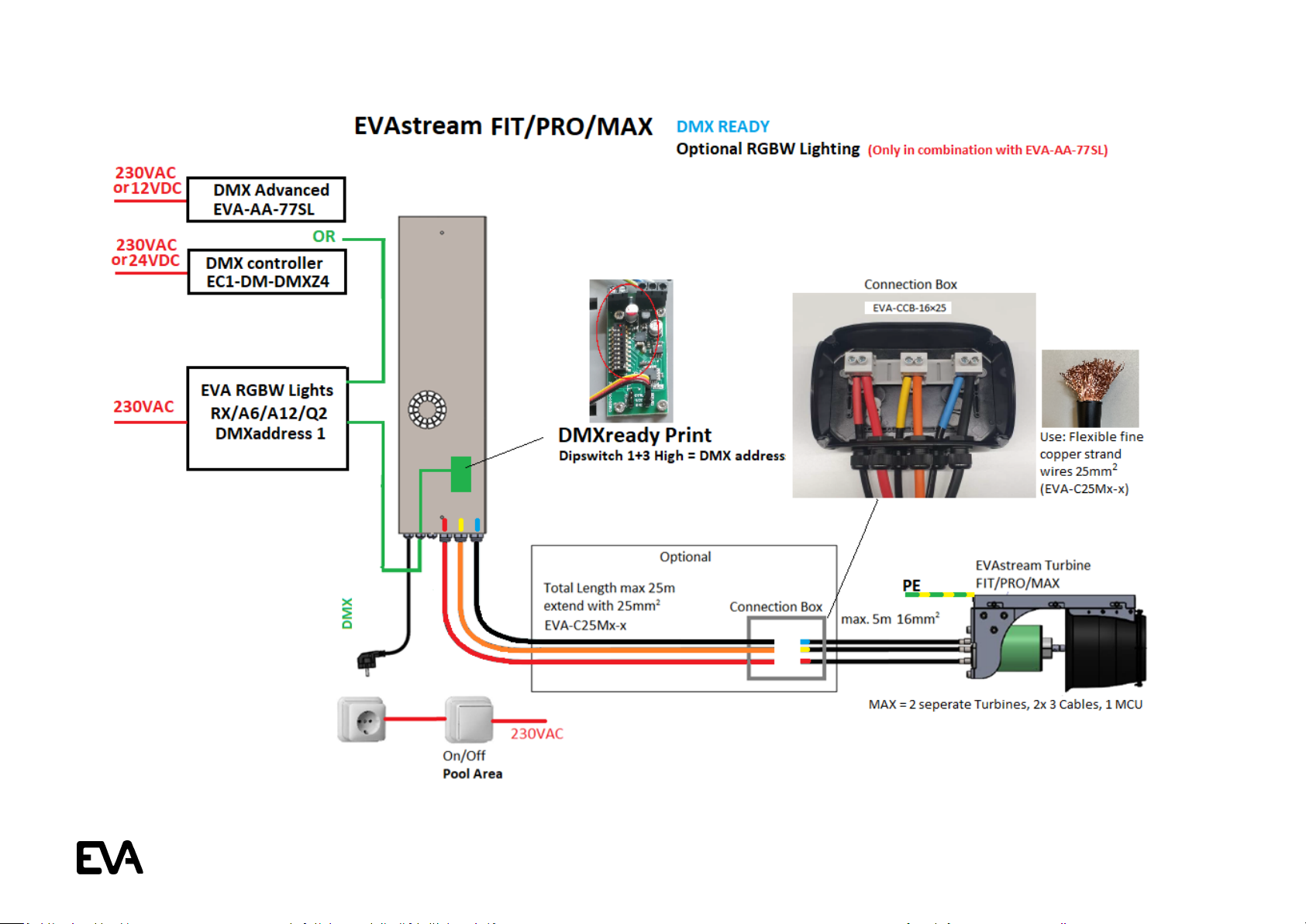

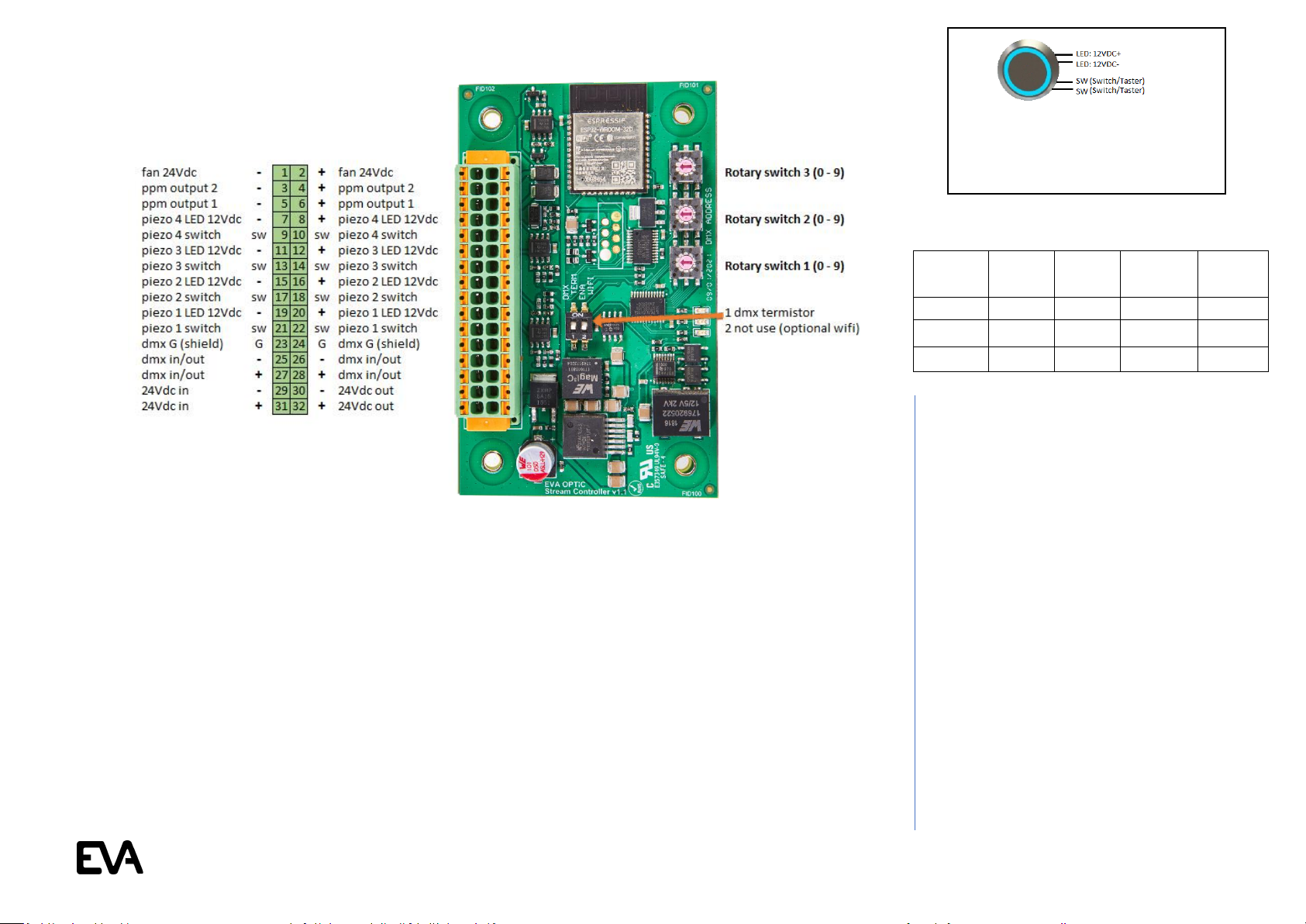

Slave mode: External master (DMX

Advanced Controller) control*

Rotary = dmx address 1-511

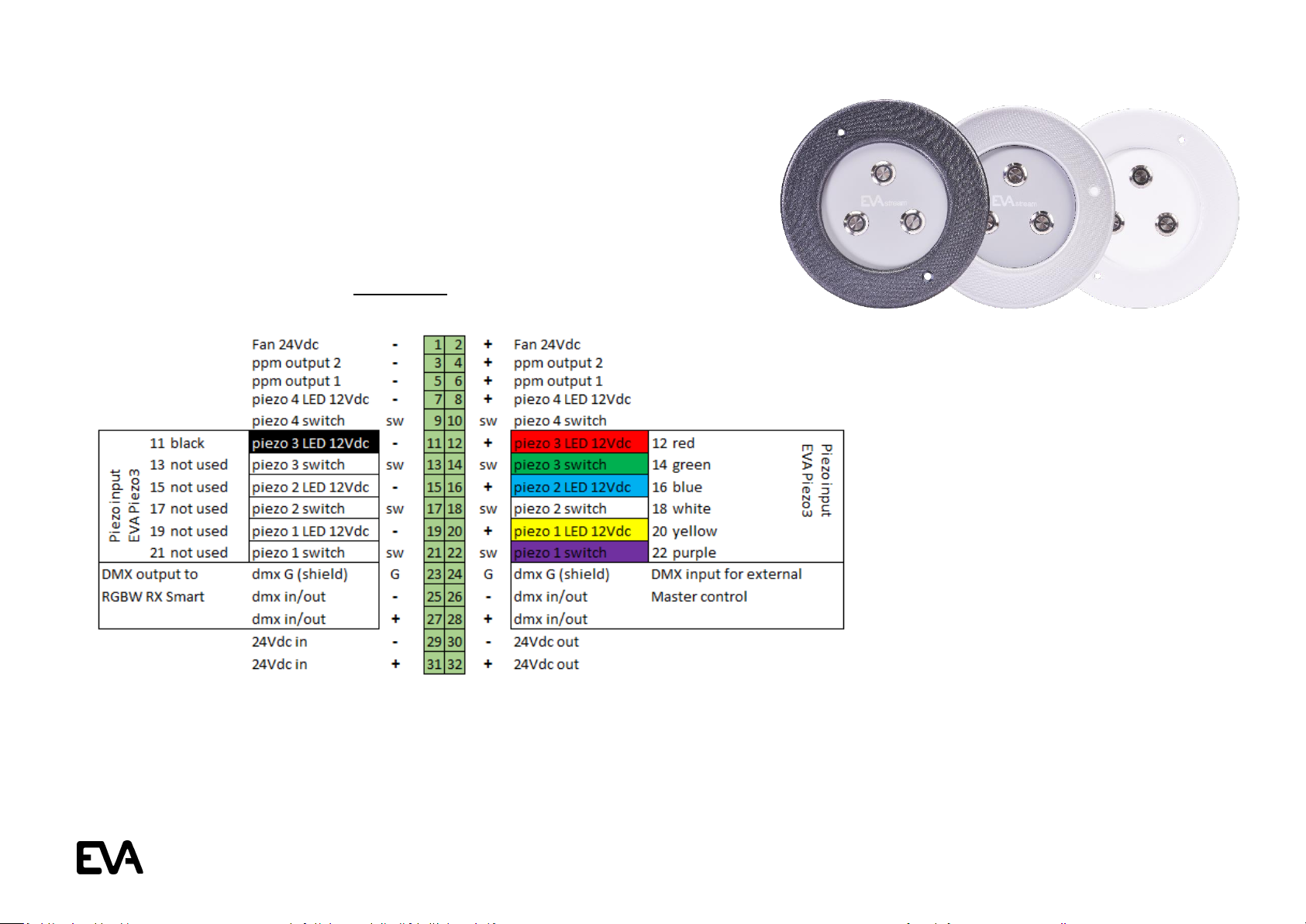

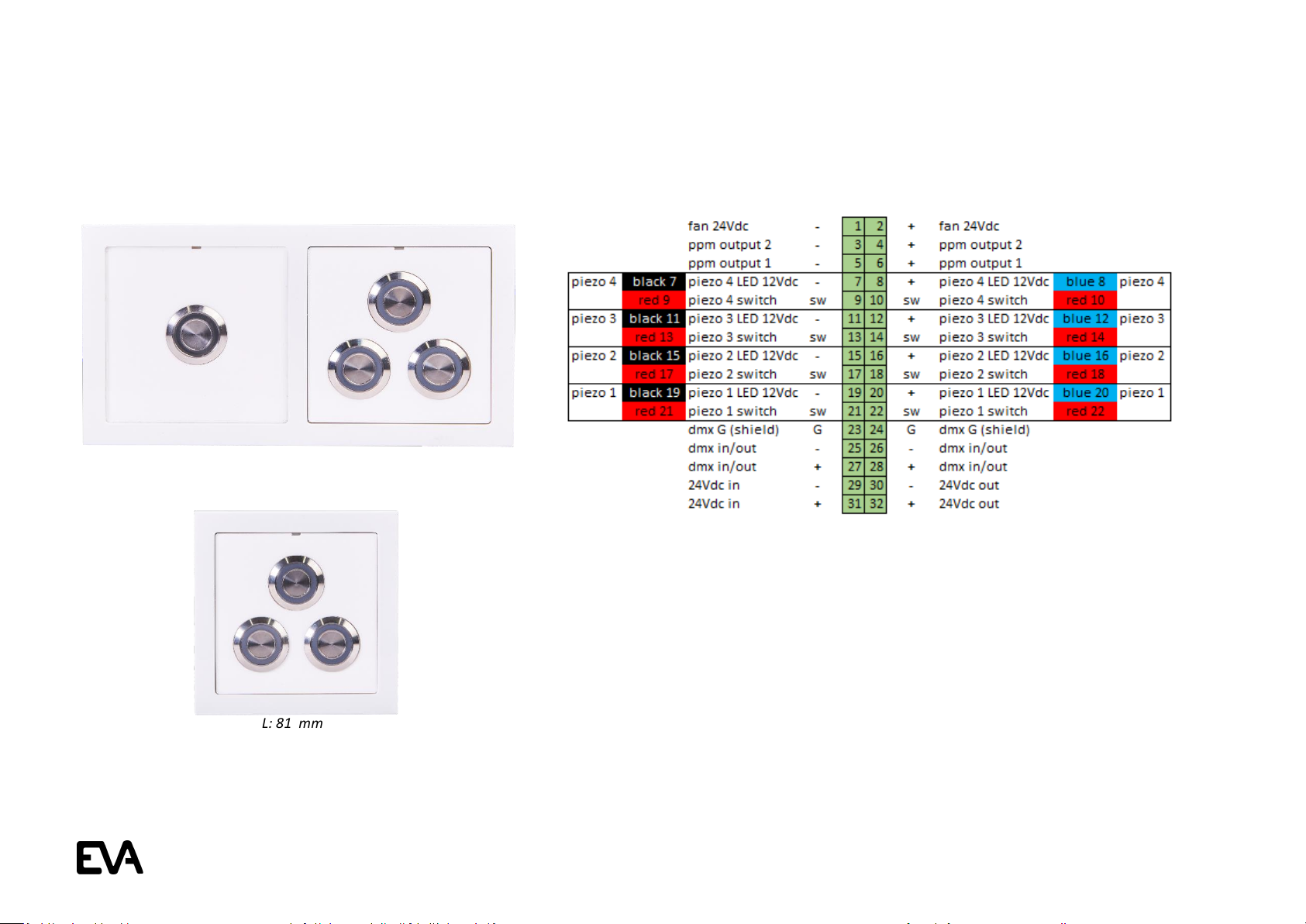

PPM output 1-2 to EVAstream motor control

Piezo 1 + 3 is pauze

Piezo 1 = speed +

Piezo 3 = speed -

Piezo 2 = on/off funtion

When no start/stop switch in pool, place a bridge

over sw/sw (piezo 2)

When using an EVA DMX controller as master,

use DMX start address 5

*Combining a DMX Advanced Controller with

Piezo is only possible with a Piezo Ready Motor

Control Unit (Art.no: EVA-SP-xxx-MCU-PIEZO)

Master mode: piezo control

DMX in/out goes to EVAstream/UWL (underwater lighting) DMX input

Piezo/switch 4 = stop (reset) outside pool

Rotary (dmx) address 518 = 1 x piezo (1) control in 10% steps + (0, 30, 40, 50, 60, 70, 80, 90, 100)

When no start/stop switch in pool, place a bridge over sw/sw (piezo 2)

Rotary (dmx) address 601 = 2 x piezo (1+3) piezo 1 = speed +, piezo 3 = speed -, piezo 1+3 = on/standby. In standby piezo 3 = off

Rotary (dmx) address 901 = 3 x piezo (1+2+3) piezo 1 = speed +, piezo 2 = on/standby, piezo 3 = speed -. In standby piezo 3 = off

Rotary (dmx) address 931 = 3 x piezo (1+2+3). Step 1 = select user (piezo 1 or 2 or 3). Step 2 = select training

(piezo 1 or 2 or 3 --> make selection within 5 seconds otherwise step 2 is skipped, automatic proceeding to step 3)

* In training mode (step 2) piezo 1 = speed +, piezo 2 = standby, piezo 3 = speed -. In standy piezo 3 = off

* In stap 3 (stap 2 skipped) piezo 1 = speed +, piezo 2 = standby, piezo 3 = speed -. In standby piezo 3 = off

When using rotary (dmx) address 901/931, connect underwater lighting (UWL) to DMX in/out. Control UWL, see below:

UWL control: piezo 1+3 = switch colour, piezo 1+2 = light intensity -, piezo 2+3 = light intensity +

DMX start address (UWL and EVAstream) in master mode: UWL= dmx channel 1, EVAstream= dmx channel 5