EVAPCO EAFWD Manual

for

LIFE

Operation and

Maintenance Instructions

For EVAPCO Air Cooled, Adiabatic and Spray

Fluid Coolers and Condensers

International Institute of

Ammonia Refrigeration

www.iiar.org

Member of

2

for

LIFE

Operation and Maintenance Instructions

Table of Contents

3 Introduction

3 Safety Precautions

4 Terminology

4 Receiving

4 Structural Steel Support

5 Rigging

5 Horizontally Mounted Flat Products (EAFWD/EAFCD)

6 Forkli Li

6 Crane Li

8 Required Liing Requirements – Flat EC Fan Models

9 Required Liing Requirements – Flat NEMA

Fan Models

10 V-Bank Style Products (EAVWD/EAVCD,

EAVWA/EAVCD and EAVWS/EAVCS)

10 Forkli Li

11 Crane Li

12 Required Liing Requirements – V Coil EC

Fan Models

13 Required Liing Requirements – V Coil NEMA

Fan Models

13 Initial Storage and/or Idle Period Recommendations

14 International Building Code Provisions

14 Initial and Seasonal Start-Up and Shut-Down

14 General

14 Initial and Seasonal Start-Up

15 Seasonal Shutdown

15 Dry, Adiabatic or Spray Fluid Coolers

15 Air Cooled, Adiabatic or Spray Condensers

15 Basic eco-Air Series Sequence of Operation

16 Maintenance Instructions

16 Cleaning Hydraulically

17 Cleaning with Compressed Air

17 Cleaning with Brushes

17 Cleaning the Fans

17 Adiabatic Pre-Cooling System – If Equipped

18 Operation (Adiabatic Pre-Cooling System)

18 Maintenance (Adiabatic Pre-Cooling System)

19 Spray System – If Equipped

19 Operation

19 Maintenance (Spray System)

20 Inlet Water (Adiabatic & Spray Systems)

20 Water Quality Guidelines (Adiabatic Pad Systems &

Adiabatic Spray Systems)

21 Maintenance Checklist

22 Fan System

22 Cold Weather Operation

22 Unit Layout

22 Freeze Protection

23 Troubleshooting

23 Replacement Parts

24 Replacement Part Drawings

24 eco-Air Flat NEMA Fans

24 eco-Air Flat EC Fans

25 eco-Air VCoil NEMA Fans

25 eco-Air VCoil EC Fans

26 eco-Air Adiabatic System Components

26 eco-Air Spray System Components

27 Notes

3

Introduction

Congratulations on the purchase of your EVAPCO air cooled unit. EVAPCO equipment is constructed of the highest quality materials and

designed to provide years of reliable service when properly maintained.

Thoroughly clean road salt, dirt and debris from unit immediately aer delivery. Residue le on product surfaces can cause damage that is

not covered by any warranty. All new cooling equipment and associated piping should be pre-cleaned and flushed to remove grease, oil,

dirt, debris and other suspended solids prior to operation. Any pre-cleaning chemistry should be compatible with the cooling equipment’s

materials of construction. Alkaline formulations should be avoided for systems which include galvanized materials of construction.

Closed hydronic systems connected to a dry fluid cooler should be pre-cleaned and flushed to remove debris, grease, flash rust, oil, and

other suspended solids prior to operation. EVAPCO recommends the use of inhibitor chemistry or inhibited glycol to minimize corrosion

and scale during normal operation.

Air cooled equipment is oen remotely located and periodic maintenance checks are oen overlooked. It is important to establish a

regular maintenance program and be sure that the program is followed. This bulletin should be used as a guide to establish a program. A

clean and properly serviced unit will provide a long service life and operate at peak efficiency.

This bulletin includes recommended maintenance and maintenance intervals for unit start up, unit operation and unit shutdown. Please

note: the maintenance intervals are minimums. Maintenance should be performed more oen when operating conditions necessitate.

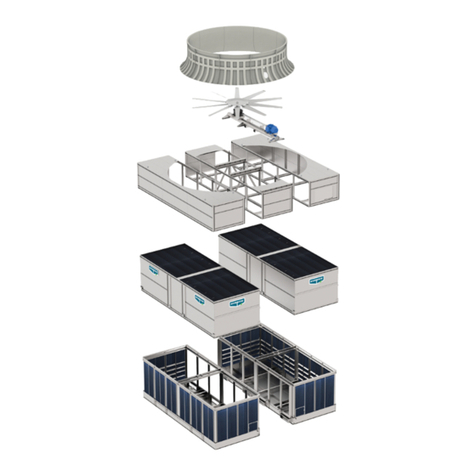

Become familiar with your air cooled equipment. Refer to the isometric drawings located on pages 21-23 for information on the arrange-

ment of components in your equipment.

If you should require any additional information about the installation, operation or maintenance of this equipment, contact your local

EVAPCO representative. You may also visit www.evapco.com or www.mrgoodtower.com for more information.

Safety Precautions

Qualified personnel should use proper care, procedures and tools when operating, maintaining or repairing this equipment in order to

prevent personal injury and/or property damage. The warnings listed below are to be used as guidelines only.

Never operate this equipment without fan screens and access panels properly secured and in place.

Each coil in this unit ships from the factory with a nitrogen charge on the coils. Verify that the nitrogen charge is

still applied before installing unit. Release pressure in each coil before installing heat transfer fluid piping.

An optional factory provided disconnect switch may be located on the unit for each fan motor associated with this

equipment. Before performing any type of service or inspection of the unit make certain that all power has been

disconnected and locked in the “OFF” position.

The top horizontal surface of any unit is not intended to be used as a working platform. No routine service work is

required from this area.

Closed hydronic systems connected to either a closed-circuit cooler or dry cooler should be pre-cleaned and

flushed to remove debris, grease, flash rust, oil, and other suspended solids prior to operation. EVAPCO recom-

mends the use of inhibitor chemistry or inhibited glycol to minimize corrosion and scale during normal operation

EVAPCO requires that all external piping and fittings be externally supported, the supplied connections are not

designed to support external piping or fitting weights. Additional weight to the connections or coil in any way

could cause damage to the unit not covered under warranty.

4

Terminology

Throughout this manual, the terms “Flat” and “V Coil” are used. Below is a list of EVAPCO eco-Air Dry Fluid Cooler and Air Cooled

Condenser product offerings and associated terminology.

eco-Air Series equipment includes the following product models:

<Flat Air Cooled

• EAFWD - Dry Fluid Cooler

• EAFCD - Air Cooled Condenser

<V Coil Air Cooled

• EAVWD - Dry Fluid Cooler

• EAVCD - Air Cooled Condenser

Receiving

Carefully inspect all units upon arrival to assure that no damage has occurred during shipment. This includes searching for dirt and debris

caused by shipping, as well as inspecting all components and accessories for physical damage. If any units have been damaged during

transit, immediately notify the carrier and file a claim with that carrier.

The coils on all EVAPCO eco-Air series coolers and condensers are shipped from the factory with a low-pressure nitrogen charge.

Maintain the nitrogen charge until connecting the unit to the system piping.

To confirm this nitrogen charge, quickly open then close the valve located on the coil header and listen or feel for escaping nitrogen. A

coil without the factory nitrogen charge may be an indication of damage during shipment. In this case, the coil should be pressure tested

with dry nitrogen gas to assure that it is leak free prior to installation. Please notify your EVAPCO representative before installing any unit

that has lost the factory nitrogen charge during shipment.

Structural Steel Support

Two structural “I” beams running the length of the unit are required for supporting the eco-Air series units. These beams should be

located underneath the outer flanges of the unit as shown in Figure 1. See Table 1 for Steel Support Dimensions.

Mounting holes, 3/4” in diameter, are provided for bolting the unit to the structural steel. Refer to the recommended structural steel

support drawing and certified print for exact bolt hole location.

Beams should be sized in accordance with accepted structural practices. Maximum deflection of the beam under the unit should be

1/360 of the unit length, not to exceed 1/2”.

The supporting “I” beams should be level before setting the unit in place. Do not level the unit by shimming between it and the beams as

this will not provide proper longitudinal support.

Support beams and anchor bolts are to be provided by others.

<V Coil Adiabatic

• EAVWA - Adiabatic Fluid Cooler

• EAVCA - Adiabatic Air Cooled Condenser

<V Coil Spray

• EAVWS - Spray Fluid Cooler

• EAVCS - Spray Air Cooled Condenser

5

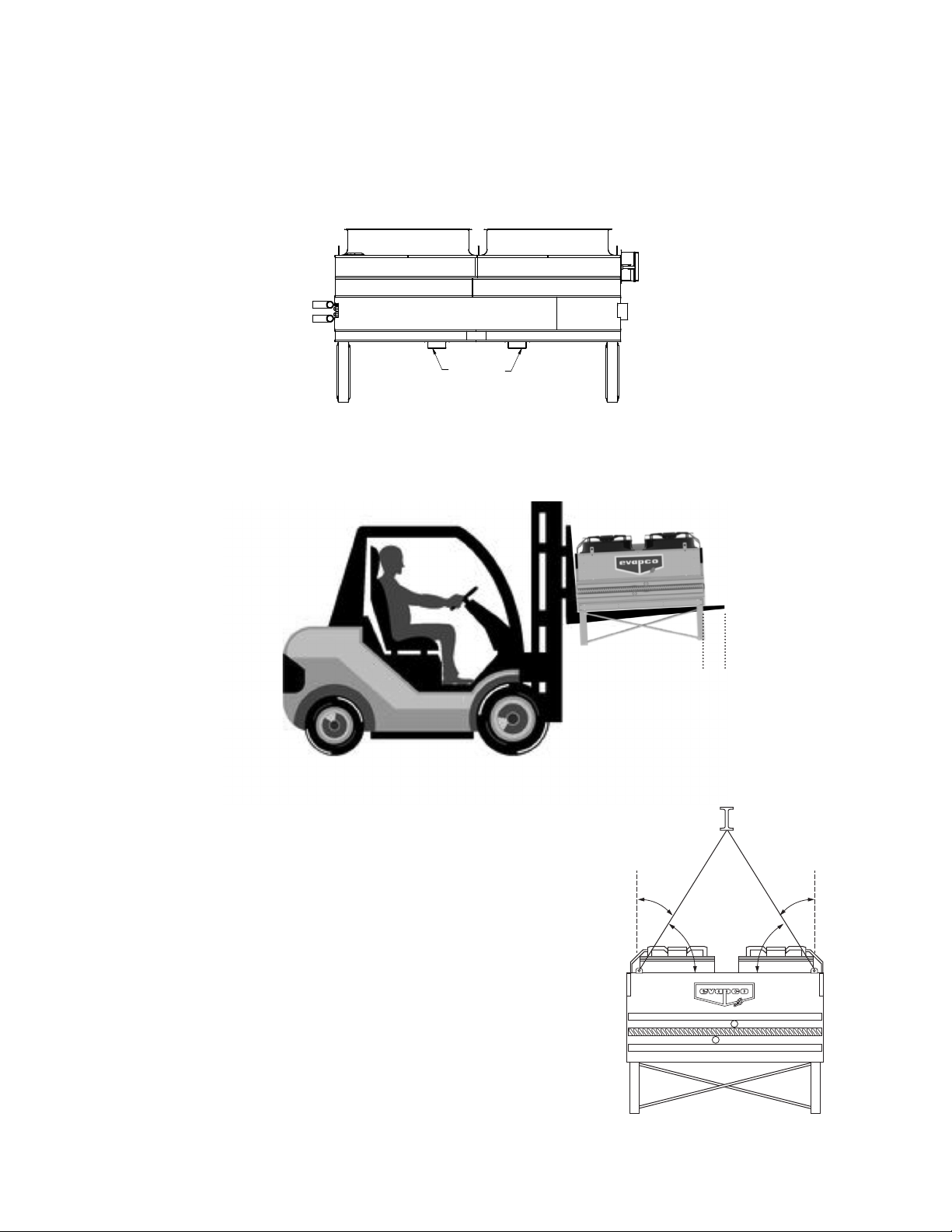

Rigging

All eco-Air Series air cooled units covered in this manual are designed to be removed from the truck via crane. Smaller units that are less

than 27 feet in length also have provisions for removal from the truck via forkli. These units can be installed onto the structural steel in the

same manner as removed from the truck.

Ensure that the crane operator and/or the truck driver li the unit securely. Always consider the weight of the unit with regard to crane or

forkli.

Tubes, return bends, coil connections and headers are never to be used for liing.

Remove any packaging material and verify that no damage has occurred. Slightly bent fins can be repaired easily using a fin comb or

needle nose pliers.

Damaged tubes are only to be repaired by a qualified welder. If the damaged tubes cannot be repaired by your welder contact your local

EVAPCO representative to arrange for inspection and/or repairs.

Flat Coil Configuration Products (EAFWD/EAFCD):

Flat coil units are typically shipped with legs attached. However there could be instances when flat coil units are strapped to a wooden

pallet or enclosed in an open slatted or fully enclosed crate. To avoid handling damage, EVAPCO recommends that the product is off-

loaded from the vehicle while still attached to its pallet or in its crate if provided.

When flat units are shipped crated with the legs removed, the legs will need to be attached before placing the unit on the structural steel.

Below is a drawing showing proper attachment of the legs to the unit.

eco-Air Series Supporting Steel Dimensions

V Models Dry & Spray Unit

Base Width (W)

Adiabatic Unit

Base Width (W)

4’ Wide 4’ 2” 5’ 10”

7’ Wide 7’ 2-1/2” 8’ 9-1/2”

8’ Wide 7’ 3-3/4” 9’ 3/4”

F Models Base Width (W) –

6’ Wide 5’ 7-5/16” –

7’ Wide 6’ 11-1/8” –

8’ Wide 7’ 7” –

Length (L)

Base Width (W)

Length (L)

Base Width (W)

Length as shown on “unit length range

(L)” on unit certified drawing

LEG PLENUM

CHANNEL

FLAT

WASHER M12 BOLT

NUT

Figure 1 – Supporting Steel Diagram

Figure 2 – Flat Unit Leg Attachement

Table 1 – Structural Steel Support Dimensions

6

Forkli Li:

Ensure that the forkli truck is large enough to handle the size and weight of the product required to be off-loaded. Unit weights can

be found on the unit certified drawing. Units with a length less than 27 feet are provided with standard EVAPCO steel forkli channels

positioned under the unit. Forkli channels will be identified by a label on the unit. If labels and forkli channels are not present, STOP!,

the unit will need to be rigged via a crane. Forkli channels are only provided on units that are capable of being rigged via forkli. Larger

units will need to be lied via a crane or else unit and coil damage may occur.

Below is a diagram representing the location of the forkli channels on flat units.

The forks must be long enough to protrude at least 12 inches (30 cm) beyond the width of the product.

Under no circumstances, even if forkli channels are fitted, should ‘short forks’ be

used as this will result in damage to the unit casing and/or coil of the unit. Ensure

that the weight is evenly distributed before attempting to li the product. Follow

industry standard forkli recommendations and guidelines.

Crane Li:

Ensure that the crane operator uses adequate straps, chains, spreader bars etc.,

to safely and securely handle the weight of the product. The minimum angles

for liing by crane, when viewed from the unit end, must NEVER be less than a

60°angle from horizontal as shown in Figure 5. When viewed from the side of the

unit the liing angle must always be perpendicular to the unit; any angle could

cause damage to the unit and coil.

To achieve a minimum 60° angle, the chains attached to the liing device must

be a minimum dimension “H” above the unit casing to prevent undue strain on

the liing ears. See Table 2 for the minimum “H” dimension. These liing devices

should not be used for extended lis or where any hazard exists unless safety slings

are employed under the unit.

FORKLIFT

CHANNELS

Figure 3– Flat Coil Forkli Channel Locations

12”

(30 cm)

Figure 4 – Flat Coil Units Forkli Liing Requirements

Figure 5 – Minimum Crane Liing Angles

30°

MAX.

30°

MAX.

60°

MIN.

60°

MIN.

7

Carefully and securely attach chains to unit liing ears based on the below information. Liing ears are provided on the top of the fan

sections for liing the unit into final position. The unit will only be supplied with the liing ears required, THEREFORE USE ALL LIFTING

EARS THAT ARE PROVIDED. The liing ear requirements vary depending on incremental fin length, or distance between tube sheets

and liing ears, therefore you will need to refer to the unit model number to accurately determine which of the below details describes

your unit.

The 6th digit aer the first hyphen in the model number depicts incremental fin length. For example in the model number:

EAVCD-15S2ZKxxxxx-xxxxxxxxxx the Kdepicts the incremental fin length. Possible incremental fin length characters are B, K, and I. This

can be further broken down by the type of fans.

Below is a table for a quick reference guide, showing which unit type applies to which liing ear requirement figure.

H

Figure 6 – Rigging Beam Height Requirements

Unit Width Minimum Height (H)

Dimension (.)

5’ (1.8m) 3.5

7’ (2.2m) 5.0

8’ (2.4m) 5.0

Table 2 – Minimum “H” Dimensions

Table 3 – Liing Ear Requirement Reference

Incremental Fin Length Designator Incremental Fin Length Fan Type Figure Number

B 5’ 9” (1755mm) EC N/A

NEMA 9

K 6’ 4” (1950mm) EC 7

NEMA N/A

I 7’ 8” (2340mm) EC 8

NEMA 10

8

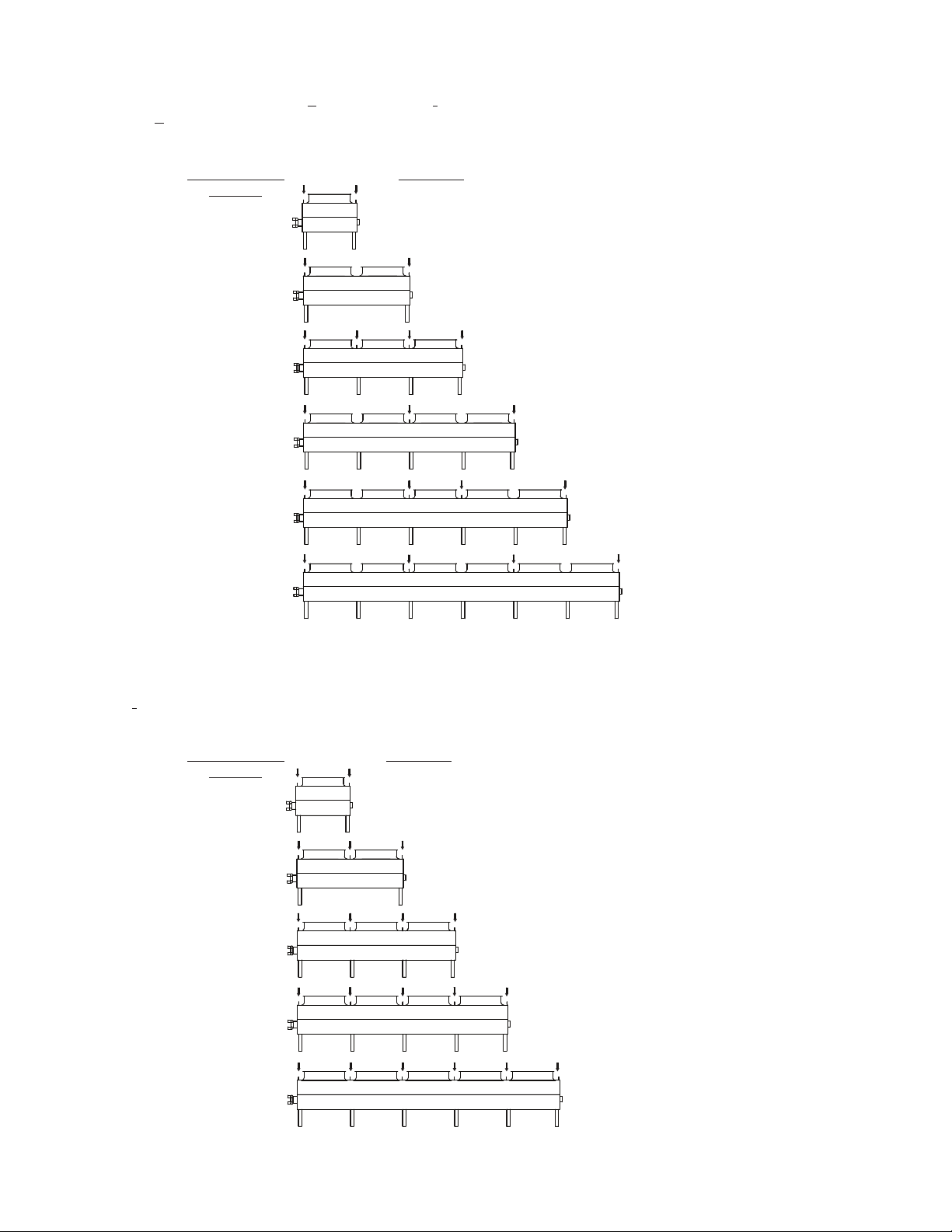

Required Liing Requirements – Flat EC Fan Models

Units with EC Fans will have either a K(6’ 4” [1950mm]), or I(7’ 8” [2340mm]) incremental fin length designator.

Below are the Kunit liing requirements.

The arrows shown on the unit drawings below indicate (2) liing ears per arrow.

Below are I(7’ 8” [2340mm]) incremental fin length units rigging requirements:

The arrows shown on the unit drawings below indicate (2) liing ears per arrow.

Number of fans

in length

1

2

3

4

5

6

Number of fans

in length

1

2

3

4

5

Unit length

Unit length

6’ 8-1/4”

7’ 11-1/2”

13’ 0”

15’ 7-5/8”

19’ 5-3/4”

23’ 3-3/4”

25’ 10-1/2”

30’ 11-7/8”

38’ 8”

32’ 3-1/4”

38’ 8”

Figure 7 – Liing Ear Requirements for 6’ 4” Incremental Fin Length

Figure 8 – Liing Ear Requirements for 7’ 8” Incremental Fin Length

9

Required Liing Requirements – Flat NEMA Fan Models

Units with NEMA Fans will have either a B(5’ 9” [1755mm]) or I(7’ 8” [2340mm]) incremental fin length designator.

Below are the Bunit liing requirements.

The arrows shown on the unit drawings below indicate (2) liing ears per arrow.

Below are I(7’ 8” [2340mm]) incremental fin length units rigging requirements:

The arrows shown on the unit drawings below indicate (2) liing ears per arrow.

Number of fans

in length

1

2

3

4

5

6

Number of fans

in length

1

2

3

4

5

Unit length

Unit length

6’ 1/2”

7’ 11-1/2”

11 9-5/8”

15’ 7-5/8”

17’ 6-3/4”

23’ 3-3/4”

23’ 3-3/4”

30’ 11-7/8”

38’ 8”

29’ 7/8”

34’ 9”

Figure 9 – Liing Ear Requirements for 6’ 4” Incremental Fin Length

Figure 10 – Liing Ear Requirements for 7’ 8” Incremental Fin Length

10

V Coil Configuration Products (EAVWD/EAVCD, EAVWA/EAVCD and EAVWS/EAVCS)

EVAPCO eco-Air V Coil units utilize a skidless design allowing for ease of installation and transportation.

Forkli Li:

Ensure that the forkli truck is large enough to handle the size and weight of the product required to be off-loaded. Unit Weights can be

found on the unit certifed drawing.

Units with a length less than 27 feet are provided with standard EVAPCO steel forkli channels positioned under the unit. Forkli channels

will be identified by a label on the unit. If labels and forkli channels are not present, STOP!, the unit will need to be rigged via a crane.

Forkli channels are provided on all units that are capable of being rigged via forkli. Larger units will need to be lied via a crane or unit

and coil damage may occur.

Below is a diagram representing the location of the forkli channels on V Coil units.

The forks must be long enough to protrude at least 12 inches (30 cm) beyond the width of the product.

Under no circumstances, even using forkli channels, should ‘short forks’ be used as this will result in damage to either the unit casing or

coil of the unit.

Ensure that the weight is evenly distributed before attempting to li the product. Follow industry standard forkli recommendations and

guidelines.

FORKLIFT

CHANNELS

Figure 11 – V Coil Forkli Channel Locations

Figure 12 – V Coil Unit Forkli Liing Requirements

12”

(30 cm)

11

Crane Li:

Ensure that the crane operator uses adequate liing straps, chains, spreader bars etc.,

to safely and securely handle the weight of the product. The minimum angles for liing

by crane when viewed from the unit end, must NEVER be less than a 60° angle from

horizontal as shown in Fig 13. When viewed from the side of the unit the liing angle must

always be perpendicular to the unit; any angle could cause damage to the unit and coil.

To achieve a minimum 60° angle, the chains attached to the liing device must be a

minimum dimension “H” above the unit casing to prevent undue strain on the liing ears.

See Table 4 for the minimum “H” dimension. These liing devices should not be used for

extended lis or where any hazard exists unless safety slings are employed under the unit.

Carefully and securely attach chains to unit liing ears based on the below information. Liing ears are provided on the top of the fan

sections for liing the unit into final position. Unit will only be supplied with the liing ears required, THEREFORE USE ALL LIFTING

EARS THAT ARE PROVIDED. The liing ear requirements vary depending on incremental fin length, or distance between tube sheets

and liing ears, therefore you will need to refer to the unit model number to accurately determine which of the below details describes

your unit.

The 6th digit aer the first hyphen in the model number depicts incremental fin length. For example in the model number:

EAVCD-15S2ZKxxxxx-xxxxxxxxxx the Kdepicts the incremental fin length. Possible incremental fin length characters are A, J, B, K, and

I. This can be further broken down by the type of fans.

Below is a table for a quick reference guide, showing which unit type applies to which liing ear requirement figure.

30°

MAX.

30°

MAX.

60°

MIN.

Figure 14 – Rigging Beam Height Requirements

Table 4 – Minimum “H” Dimensions

Table 5 – Liing Ear Requirement Reference

H

Unit Width Minimum Height (H)

Dimension (.)

4’ (1.2m) 2.5

7’ (2.2m) 5.0

8’ (2.4m) 5.0

Incremental Fin Length Designator Incremental Fin Length Fan Type Figure Number

A 3’ 10” (1170mm) EC 15

J 4’ 3” (1300mm) EC 15

B 5’ 9” (1755mm) NEMA 16

K 6’ 4” (1950mm) NEMA 16

I 7’ 8” (2340mm) NEMA 17

Figure 13 – Minimum Crane

Liing Requirements

12

Required Liing Requirements – V Coil EC Fan Models

Units with EC fan assemblies will have either an A(3’ 10” [1170mm]) or J(4’ 3” [1300mm]) incremental fin length designator.

Below are the liing requirements for these units.

The arrows shown on the unit drawings below indicate (2) liing ears per arrow.

Number of fans

in length

1

2

3

4

5

6

7

8

9

10

Unit length

4’ 10-3/8”

5’ 3-3/8”

8’ 8-3/8”

9’ 6-5/8”

12’ 6-1/2”

13’ 9-3/4”

16’ 4-1/2”

18’ 0”

20’ 2-5/8”

22’ 4-1/8”

24’ 5/8”

26’ 7-3/8”

27’ 10-3/4”

30’ 10-1/2”

31’ 8-3/4”

35’ 1-3/4”

35’ 6-7/8”

39’ 4-7/8”

39’ 4-7/8”

Figure 15 – Liing Ear Requirement for 3’ 10” and 4’ 3” Incremental Fin Lengths

13

Required Liing Requirements – V Coil NEMA Fan Models

Units with NEMA Fans will have either a B(5’ 9” [1755mm]), K(6’ 4” [1950mm]), or I(7’ 8” [2340mm]) incremental fin length designator.

The arrows shown on the unit drawings below indicate (2) liing ears per arrow.

Number

of fans

in length

1

2

3

4

5

6

Number

of fans

in length

1

2

3

4

5

Unit length Unit length

6’ 9-3/8”

7’ 5” 8’ 8-3/8”

12’ 6-1/2”

13’ 9-7/8” 16’ 4-1/2”

18’ 3-1/2”

20’ 2-5/8” 24’ 5/8”

24’ 5/8”

26’ 7-3/8”

31’ 8-3/4”

29’ 9-3/4”

33’ 1/8”

39’ 4-7/8”

35’ 6-7/8”

39’ 4-7/8”

Below are the Band Kunit liing requirements. Below are Iunit liing requirements.

Figure 16 – Liing Ear Requirement for 5’ 9”

and 6’ 4” Incremental Fin Lengths Figure 17 – Liing Ear Requirement

for 7’ 8” Incremental Fin Lengths

Initial Storage and/or Idle Period Recommendations

If the unit will remain inactive for an extended period of time prior to installation it is recommended that the following be performed in

addition to all component manufacturers recommended maintenance instructions.

• The fans must be turned by hand at least once every three months. This can be accomplished by tagging and locking out the unit’s

disconnect, grasping the fan assembly and rotating it several turns.

• If unit remains inactive longer than one month, insulation test motor windings semi-annually.

• See motor manufacturer maintenance and long term storage instructions for more detailed instructions.

• Thoroughly clean road salt, dirt and debris from unit immediately aer delivery. Residue le on product surfaces can cause

damage that is not covered by any warranty.

14

International Building Code Provisions

The International Building Code (IBC) is a comprehensive set of regulations addressing the structural design and installation requirements

for building systems – including HVAC and industrial refrigeration equipment. The code provisions require that the cooling equipment

and all other components permanently installed on a structure must meet the same seismic design criteria as the building.

All items attached to EVAPCO eco-Air Series coolers and condensers must be independently reviewed and isolated to meet applicable

wind and seismic loads. This includes piping, ductwork, conduit, and electrical connections. These items must be attached to the

EVAPCO unit so as not to transmit additional loads to the equipment as a result of seismic or wind forces. EVAPCO requires that all

external piping and fittings be externally supported, the supplied connections are not designed to support external piping or fitting loads.

Additional forces to the connections or coil in any way could cause damage to the unit not covered under warranty.

Initial and Seasonal Start-Up and Shut-Down

General

1. Verify that the overall installation reflects the requirements of the installation guidelines found in EVAPCO Bulletin #320. –

Equipment Layout Manual available at www.evapco.com.

2. Verify all safety interlocks work properly.

3. Examine wiring for loose connections or other obvious damage (quarterly).

4. For units supplied with an EVAPCO controls system see the Controls Operating Manual for motor and controls startup. For units

not supplied with controls see motor manufacturer’s and controls manufacturer’s start up recommendations.

5. If the unit is going to remain inactive for an extended period of time, follow all manufacturer’s fan motor for long term storage.

Properly ventilated plastic sheets or tarps can be used to protect a unit during storage. See your local EVAPCO representative for

additional information on unit storage.

BEFORE BEGINNING ANY MAINTENANCE, BE CERTAIN THAT THE POWER IS TURNED OFF AND THE UNIT IS

PROPERLY LOCKED AND TAGGED OUT!

Initial and Seasonal Start-Up

1. Clean and remove any debris, such as leaves and dirt from the coil face, adiabatic pads (if equipped), and fan screens. Flush the

adiabatic pads to remove any sediment or dirt.

2. If equipped, the factory set flow setter devices on the adiabatic system piping may need to be adjusted to maintain equal

distribution of water flow on both sides of the unit.

3. Fins can be brushed clean with a so bristle brush or pressurized water, not aimed at an angle, but directly onto the fins to clean

accumulated deposits. A fin comb or needle nose pliers can be used to straighten any fins that have become bent. Fins that had

been damaged and straightened with a fin comb may not look like new but will function normally if air spaces remain open.

4. Turn the fan(s) by hand to ensure it turns freely without obstructions.

5. Visually inspect the fan blades. Blade clearance should be approximately 1/4” from tip of blade to the fan cowl.

6. For fluid coolers only, fill the heat exchanger coil with the specified heat transfer fluid and purge air from the system before

pressurizing, using factory supplied coil vents.

NOTE: Dry fluid coolers should only be used on sealed, pressurized systems. Continual aeration of the heat transfer fluid in an

open system can cause corrosion inside the tubes of the cooler leading to premature failure.

For fluid coolers or condensers with optional controls, see EVAPCO Controls Operating Manual for proper start up procedure.

15

Aer the unit has been energized, check the following:

1. Verify fans are rotating in proper direction based on arrow sticker affixed to fan housing.

2. Measure voltage and current on all three power leads of fan motors. The current should not exceed the motor nameplate full load

amp rating.

3. Start the EVAPCO Air Pre-Cooling System if equipped. For Adiabatic units, check for proper pad wetting. For spray units, check to

ensure all nozzles are free from debris and have a uniform spray pattern. If the adiabatic or spray system is not operating correctly,

consult the troubleshooting guide in this manual.

Seasonal Shutdown

Steps should be taken to ensure that when the equipment is shut down for prolonged periods, the unit is managed in the correct fashion.

Dry, Adiabatic or Spray Fluid Coolers

1. Ensure the process is shut down and the system temperature has reached safe shut down condition.

2. If unit is equipped with an adiabatic or spray system ensure that all valves are open and system is completely drained.

3. Switch off the fans and power to the unit.

4. Close the isolating valves by others, if equipped.

5. If the cooler will be subjected to sub-zero temperatures and is not filled with a suitable antifreeze, open the air vent and drain

connection(s) and drain the heat transfer fluid. Applying a positive pressure to the air vent connection(s) will help ensure that there is no

heat transfer fluid retention, which could lead to frost damage.

Air Cooled, Adiabatic or Spray Condensers

1. Ensure that the refrigeration load is removed.

2. If unit is equipped with an adiabatic or spray system ensure that all valves are open and system is completely drained.

3. Switch off the fans and power to the product.

Basic eco-Air Series Sequence of Operation

NOTE: For units with an EVAPCO Controls system refer to the EVAPCO Controls Operating Manual for detailed sequence of

operation.

System Off / No Load

The unit’s fans are off. Adiabatic or spray systems should be off, if equipped.

System/Condensing Temperature Rises

The fans turn on. For a variable speed controller, the fans are turned on to minimum speed, all fans maintaining the same speed. If the

system temperature continues to rise, then the fan speed is increased as required, up to full speed.

If temperatures continues to rise and an adiabatic or spray system is equipped then the water solenoid valve should open and completely wet

adiabatic pads, or spray water from nozzles. Fan speeds are increased and decreased as needed aer adiabatic or spray system is initiated.

NOTE: If the adiabatic or spray unit is equipped with the 2-stage operation accessory, 2 solenoid valves are provided, and the

pre-cooling systems are actuated in 2 stages to reduce overall water consumption.

System/Condensing Temperature Stabilizes

Control the leaving fluid temperature (fluid coolers) or condensing temperature (condensers) by modulating the fan speeds with equipped

controls system.

System/Condensing Temperature Drops

Decrease the fan speed, as required. If equipped, shut off adiabatic or spray system and continue to modulate fan speed.

16

System Off / No Load

The system fans turns off. The adiabatic or spray system should not be used as a means of capacity control, and should not be cycled

frequently. Excessive cycling can lead to scale build-up on the pads or coils (in case of spray).

NOTE: MINIMUM CONTROL POINT FOR PROCESS FLUID SHOULD NEVER BE LOWER THAN 6º F ABOVE PROCESS

FLUID FREEZING TEMPERATURE.

Maintenance Instructions

It is essential to understand that fouled or dirty fins reduce heat transfer.

1. Aer operation for a month, check for fouling of the fins. Inspect with a light between the fins to observe the accumulations of dirt

and dust.

2. Dry dust can normally be removed by compressed air, a so brush, or by a suitable industrial vacuum cleaner. Sweep along the fins

and under no circumstances across the fins.

3. Moist or sticky blemishes or grease should be removed by means of hot water or steam jet cleaning appliances (against the air

direction).

4. Keep the jet of the cleaning appliance at an angle of no more than 15° from vertical position, to avoid bending the fin edges.

Cleaning Hydraulically

When cleaning the coil hydraulically, EVAPCO recommends using water only. If cleaning

products are used ensure that they are compatible with the unit materials of construction.

When cleaning with water under pressure, use a power washing device designed for a

maximum of 600psig or less.

Always clean in the vertical direction. Never across the fins, as this will damage the fins. And

always from the top down to avoid the water spray entering the fans (this can short circuit

the fan motors).

For oily or otherwise difficult to remove dirt, it is possible to add a chemical cleaning agent

to the water used in the power washer. Ensure that the cleaning agent is compatible with the

materials used in the unit and that it is an environmentally friendly agent.

List of recommended cleaning solutions are shown in Table 6 below.

Figure 18 – Always Clean Fins in

Vertical Direction

STAINLESS STEEL/ALUMINUM COILS

Trade Name Manufacturer

CL-122 NALCO

CL-127 NALCO

LMC-44 LW Chemical

SoilSolv DuChem

FS Process Cleaner Zep

Formula 940 Zep

Table 6 – Acceptable Cleaning Solutions

17

Adiabatic Pre-Cooling System – If Equipped

Adiabatic air pre-cooling systems are supplied with many dry fluid coolers and air cooled condensers to enhance the performance of the

unit. The below figure shows the major components of the adiabatic water system.

ADIABATIC

WATER SYSTEM

ADIABATIC

PADS

COIL

SLOPED

DRAIN

CHANNEL

A

B

B

DETAIL A

FLOW SETTER

DEVICE

SOLENOID

VALVE

HAND

VALVE

DISTRIBUTION

PIPE

WATER PRESSURE

REGULATOR

WYE STRAINER

DISTRIBUTION

PADS

DISTRIBUTION

PADS

DETAIL B

DISTRIBUTION

TRAY

DISTRIBUTION

PIPE

Figure 19 – Adiabatic Air Pre-Cooling System Components

Cleaning with Compressed Air

When cleaning with compressed air, use a compressor designed for a maximum of 1,000psig or less. For the purpose of removing dirt

and debris, please ensure that the air stream is COMPLETELY VERTICAL to the fins as the compressed air stream can damage the fins.

Cleaning with Brushes

Dry dust and some dirt can be removed with brushes, possibly in conjunction with compressed air or an industrial vacuum cleaner.

However, ensure that so brushes are used and when possible all cleaning should be from the top down. ALWAYS brush along the fins.

NEVER across the fins, as this will damage the fins.

Cleaning the Fans

ALWAYS ensure that the power to fans has been locked and tagged out prior to cleaning and ensure that the fans cannot be accidentally

started during maintenance.

It is recommended to clean the fans either by means of brushes or with compressed air. When cleaning with compressed air, use a

compressor designed for a maximum discharge air pressure of 125psig or less.

18

Operation (Adiabatic Pre-Cooling System)

All connecting piping to the unit MUST be externally supported. The piping on the unit is not designed to bear additional piping weight.

EVAPCO recommends visually inspecting adiabatic pads and the distribution system regularly during operation and before seasonal

startup. When in operation the pads should be completely wetted (there will be a noticeable color difference). If portions of the pad are

not wetted, inspect the water distribution system for clogs.

Allow the pads to completely dry once every 24 hours with the fans running.

A water pressure regulator (WPR) is located at the end of each unit as shown in Figure 19. The WPR must be set to 50psig using the

provided pressure gauge located between the discharge of the WPR and the inlet of the hand shut off valve.

The water distribution system comes preset from the factory with the correct water flow rate to ensure minimal but even water distribution.

When the adiabatic system is in operation and the flow setters are set correctly a small amount of water will be present in the sloped drain

channel. If it becomes necessary to adjust the water flow rate, adjust the percentage closed of the flow setter devices using a

philips screw driver until only a small amount of water is in the sloped drain channel but ensuring that the adiabatic pads are

completely wetted.

Note that on longer units there are two flow setter devices on each side of the unit and the flow setter percentage closed settings are

different for each. The flow setter device that supplies the longest portion of the unit is designed to be as open as possible.

Maintenance (Adiabatic Pre-Cooling System)

Rinse the adiabatic pads to remove loose sediment or dirt. If further cleaning is required use only a mild and environmentally responsible

cleaning agent that is compatible with the unit and pads materials of construction.

To remove the adiabatic pads use the following instructions. Installation is the reverse of removal.

1. Remove the bolts on the top of the distribution system cover. This allows the distribution cover to be repositioned revealing the

water distribution tray, and the distribution pad.

2. Carefully remove the distribution pad, which is the 2” tall pad positioned between the distribution tray and the large vertical

adiabatic pads.

3. Li the large vertical adiabatic pad to clear the lower support (at the bottom) and remove. It is reccommended to start with the

center pad per module. This will allow for the pads adjacent to the tube sheets to clear metal brackets attached to the tube sheets.

4. Installation is reverse of removal.

Ensure the sloped drain channel and outlet connection are free of debris that would impede water flow by removing the adiabatic pads

and then removing the slotted sloped drain channel cover.

The pad material is a bonded cellulose UV Reistant material. Refer to local codes and ordinances for disposal methods.

Remove and clean the Wye strainer annually to prevent the build up of debris and decreased water flow rate to the adiabatic pads.

19

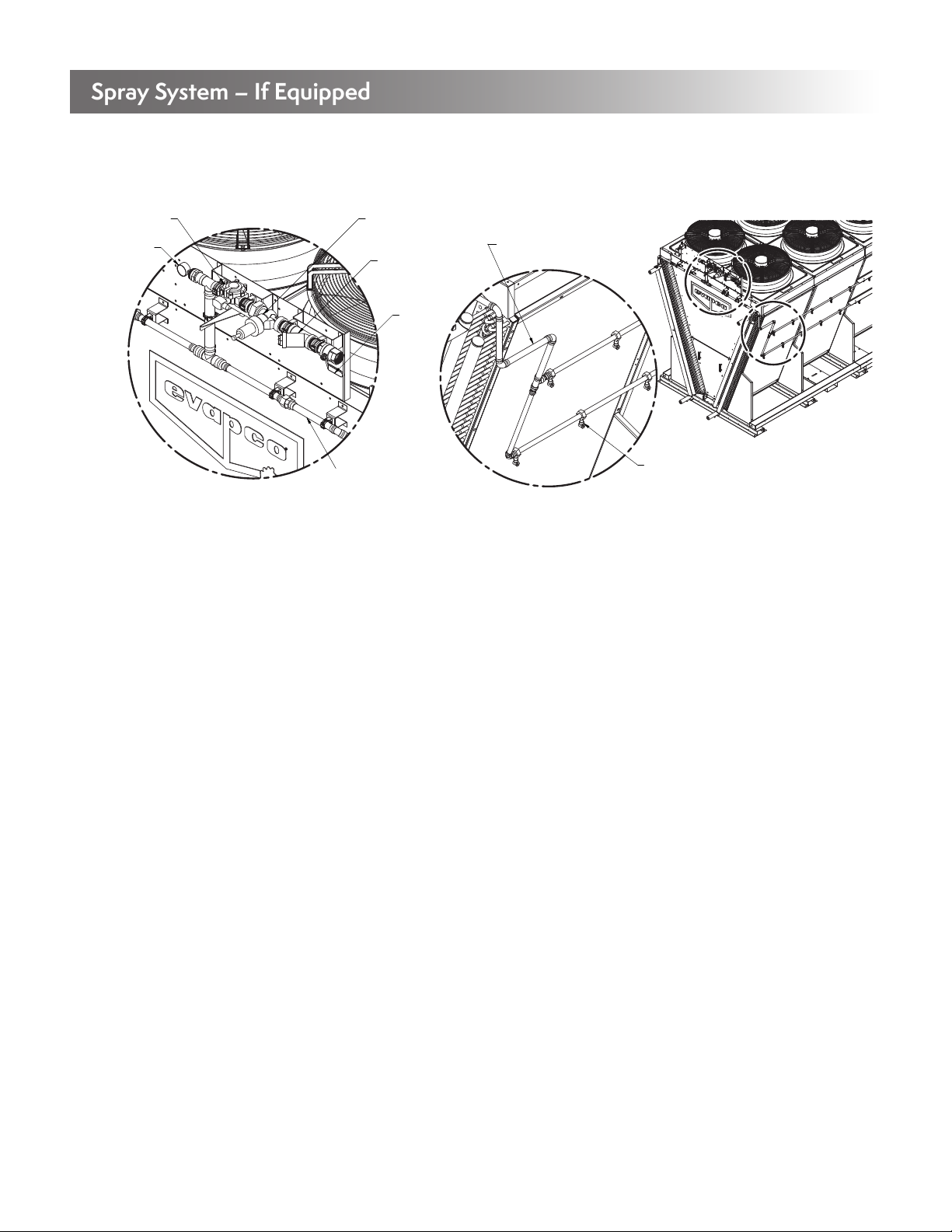

Spray System – If Equipped

Spray systems are supplied with many dry fluid coolers and air-cooled condensers to enhance the performance of the unit. The below

figure shows the major components of the spray system.

A

B

DETAIL A

WYE STRAINER

HAND

VALVE

SOLENOID

VALVE

WATER PRESSURE

REGULATOR

PRESSURE

GAUGE

DISTRIBUTION

PIPE DETAIL B

DISTRIBUTION

PIPE

SPRAY

NOZZLE

Figure 20 – Spray System Components

Operation (Spray System)

All connecting piping to the unit MUST be externally supported. The piping on the unit is not designed to bear additional piping weight.

EVAPCO recommends visually inspecting spray system regularly during operation and before seasonal startup. When in operation the

spray nozzles should be spraying outwards and evenly. If any nozzle isn’t operating correctly, inspect the water distribution system for clogs.

A water pressure regulator (WPR) is located at the end of each unit as shown in Figure 20. For units equipped with spray systems, the

discharge water pressure must be set once the unit is installed in the field. Refer to the technical data sheet in the factory submittal for the

WPR setting required for the submitted design conditions. The provided pressure gauge located at the discharge of the solenoid valve

can be used to validate WPR setting.There are no flow setters on the spray system. Inlet water pressure set correctly on the WPR and a

clean water distribution system will ensure proper operation of the spray system.

NOTE: In addition to the outlined water chemistry guidelines, EVAPCO recommends that dry fluid coolers and air-cooled

condensers equipped with Spray systems limit spray operation to peak ambient and load conditions, about 200 hours a year,

to help limit scale build-up, corrosion and to extend the life of the coil.

Maintenance (Spray System)

Clean the finned coils using the recommendations outlined under “Cleaning Hydraulically.”

Remove the spray nozzles, inspect for debris and clean as necessary.

Remove and clean the Wye strainer annually to prevent the build up of debris and decreased water flow rate to the spray system.

Inlet Water (Adiabatic & Spray Systems)

The water supply temperature and presure are typically around +50°F and +50 psig, respectively for standard city water main lines. The

adiabatic & spray systems require a minimum water pressure of 50 psig at the inlet connection.The adiabatic system piping (see Figures

19 & 20) includes a water pressure regulator to enable the use of high pressure supply water, up to 140 psig, to be connected. The inlet

connection is the highest point on the EVAPCO adiabatic and spray pre-cooling systems, allowing for free drainage of water, aer the

soleniod valve, upon system shutoff. Please refer to the Freeze Protection section of this O&M for more information on protecting the

adiabatic and spray water piping.

Normal municipal and ground water supplies are suitable for use with the adiabatic & spray systems. If other water sources, cleaning

agents, or treatments are to be used, ensure that they are compatible with all of the eco-Air product line materials of construction

including PVC, copper, brass, bonded cellulose, galvanized steel and 304L stainless steel.

20

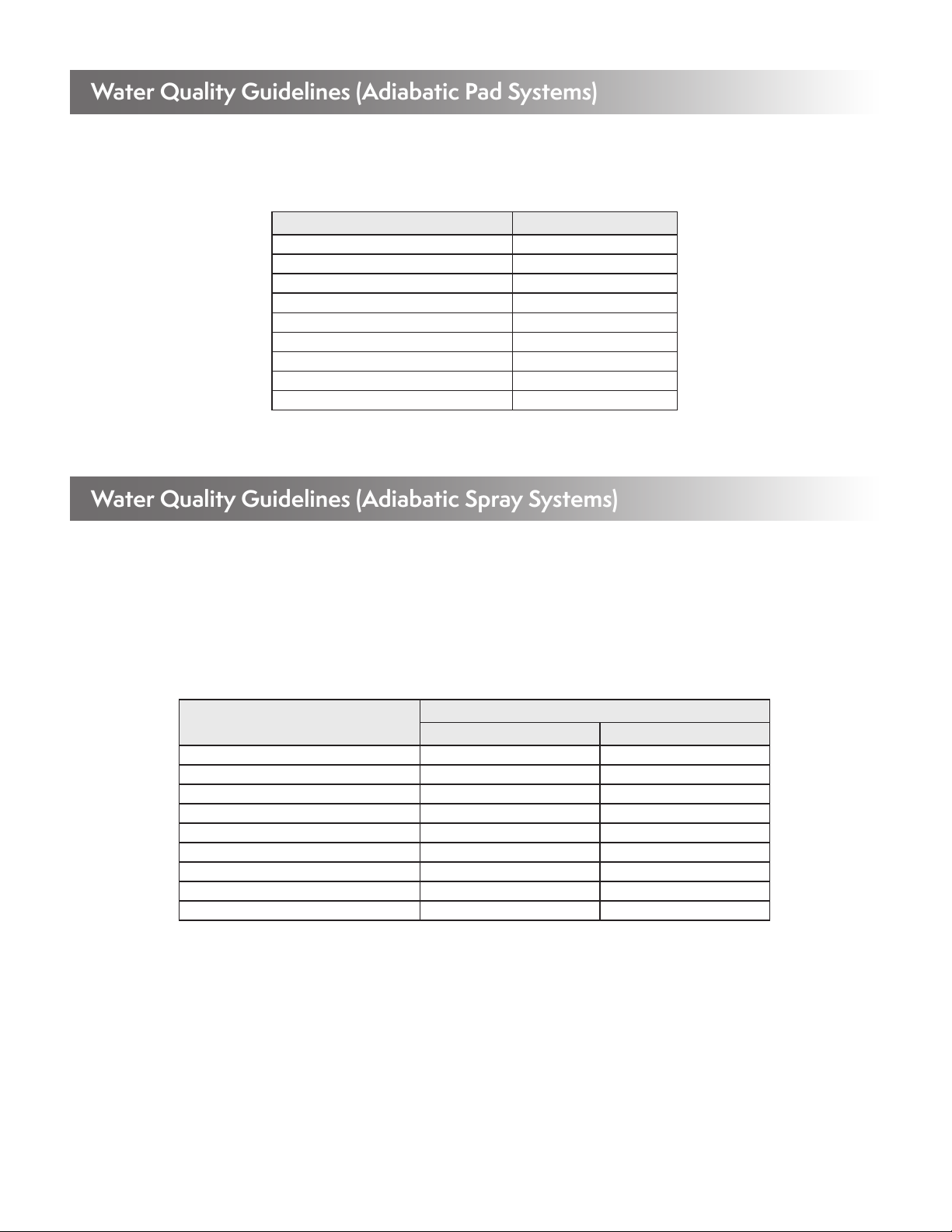

Water Quality Guidelines (Adiabatic Pad Systems)

EVAPCO recommends the below outlined water chemistry guidelines applicable to ADIABATIC PAD air pre-cooling systems for dry

fluid coolers and air-cooled condensers. The water quality guidelines shown below apply to the water which is dripped over the pads.

These guidelines are recommended to extend pad life and limit scale build up on the pads.

Property Adiabatic Spray System

Scenario 1 Scenario 2

pH 6.0 - 8.5 6.0 - 8.5

Conductivity (mhos/cm) <1,500 <1,000

Alkalinity as CaCO3(ppm) <250 <200

Calcium Hardness as CaCO3(ppm) <350 <250

Alkalinity + Calcium <550 <400

Chloride as Cl (ppm) <175 <150

Sulfate (ppm) <225 <200

Chloride + Sulfate <350 <300

Silica as SiO2 (ppm) <150 <150

Property Adiabatic Pads

pH 6.0 - 9.0

Conductivity (mhos/cm) <1,500

Alkalinity as CaCO3(ppm) <250

Calcium Hardness as CaCO3(ppm) <300

Alkalinity + Calcium <500

Chloride as Cl (ppm) <250

Sulfate (ppm) <250

Chloride + Sulfate <400

Silica as SiO2 (ppm) <150

Table 7 – Recommended Water Chemistry Guidelines for Inlet Water to Adiabatic Pad Systems

Table 8 – Recommended Water Chemistry Guidelines for Inlet Water to Adiabatic Spray Systems

Water Quality Guidelines (Adiabatic Spray Systems)

EVAPCO recommends the below outlined water chemistry guidelines applicable to ADIABATIC SPRAY air pre-cooling systems for dry

fluid coolers and air-cooled condensers. The water quality guidelines shown below apply to the water which passes thru the adiabatic

spray system. Although the adiabatic spray nozzles spray water away from the coils, the coils and structure of the unit will get wet when

the spray system is on. Thus, the water quality guidelines shown below are recommended to limit scale build-up and corrosion on the

finned tube bundles.

In addition to the water quality guidelines shown below, EVAPCO recommends designing the system for a maximum of 200 hours of

spray operation per year to help limit the possibility for scale build-up and corrosion.

*Scenario 1 applies when the entering Process Fluid or Superheated Refrigerant temperature is equal to or less than 120F.

*Scenario 2 applies when the entering Process Fluid or Superheated Refrigerant temperature is above 120F.

*For Process Fluid and Superheated Refrigerant temperatures in excess of 212F, please consult with Evapco.

“Process Fluid” or “Superheated Refrigerant” is the fluid that is circulated and cooled inside the coils. The water chemistry guidelines

outlined for Scenario 2 are more stringent than Scenario 1 because entering process fluid or refrigerant temperatures above 120°F can

accelerate the rate of scale formation and corrosion on the finned coil bundles when the Spray System is operational.

If the water chemistry guidelines are not followed or if the spray system is run for prolonged periods of time (>200 hours per

year) or cycled excessively, excessive scale buildup is possible and is not covered under unit warranty.

This manual suits for next models

7

Table of contents

Other EVAPCO Industrial Equipment manuals