EVAPCO AT ATLAS User manual

Bulletin ATLAS20RIG

Rigging and

Assembly Instructions

AT ATLAS

Induced Draft, Modular Counterow Cooling Towers

EVAPCO products are manufactured worldwide

EVAPCO, Inc. — World Headquarters & Research/Development Center

P.O. Box 1300 • Westminster, MD 21158 USA

Asia/Pacic

Europe

EVAPCO-BLCT Dry Cooling, Inc.

1011 US Highway 22 West

Bridgewater, NJ 08807 USA

1-908-379-2665 p

EVAPCO-BLCT Dry Cooling, Inc.

Littleton, CO 80127 USA

1-908-379-2665 p

EVAPCO Power México S. de R.L. de C.V.

Calle Iglesia No. 2, Torre E

Tizapan San Ángel, Del. Álvaro Obregón

Ciudad de México, D.F. México 01090

+52 (55) 8421-9260 p

Refrigeration Vessels &

Systems Corporation

A wholly owned subsidiary of EVAPCO, Inc.

Bryan, TX USA

979-778-0095 p

EvapTech, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

Edwardsville, KS USA

913-322-5165 p

Tower Components, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

Ramseur, NC USA

336-824-2102 p

EVAPCO Alcoil, Inc.

A wholly owned subsidiary of EVAPCO, Inc.

York, PA USA

717-347-7500 p

EVAPCO Europe BVBA

European Headquarters

Heersterveldweg 19

Industrieterrein Oost

3700 Tongeren, Belgium

(32) 12-395029 p | (32) 12-238527 f

EVAPCO Europe, S.r.l.

Milan, Italy

(39) 02-939-9041 p

EVAPCO Europe, S.r.l.

Sondrio, Italy

EVAPCO Europe GmbH

Meerbusch, Germany

(49) 2159 6956 18 p

EVAPCO Air Solutions

A wholly owned subsidiary of EVAPCO, Inc.

Aabybro, Denmark

(45) 9824 4999 p

EVAPCO Air Solutions GmbH

Garbsen, Germany

(49) 5137 93875-0 p

Evap Egypt Engineering Industries Co.

A licensed manufacturer of EVAPCO, Inc.

Nasr City, Cairo, Egypt

2 02 24022866 /2 02 24044997 p

EVAPCO Middle East DMCC

Dubai, United Arab Emirates

+971 4 448 7242 p

EVAPCO S.A. (Pty.) Ltd.

A licensed manufacturer of EVAPCO, Inc.

Isando 1600, Republic of South Africa

(27) 11-392-6630 p

EVAPCO Asia/Pacic Headquarters

1159 Luoning Road

Baoshan Industrial Zone

Shanghai 200949, P.R. China

(86) 21-6687-7786 p | (86) 21-6687-7008 f

EVAPCO (Shanghai) Refrigeration Equipment Co., Ltd.

Baoshan Industrial Zone Shanghai, P.R. China

(86) 21-6687-7786 p

Beijing EVAPCO Refrigeration Equipment Co., Ltd.

Huairou District Beijing, P.R. China

010-6166-7238 p

EVAPCO Air Cooling Systems (Jiaxing) Company, Ltd.

Building 10, 1133 Taoyuan Road,

Jiaxing, Zhejiang, China

(86) 573 83119379 p

EVAPCO Australia (Pty.) Ltd.

Riverstone NSW 2765, Australia

(61) 2 9627-3322 p

EvapTech Asia Pacic Sdn. Bhd

A wholly owned subsidiary of EvapTech, Inc.

Puchong, Selangor, Malaysia

(60-3) 8070-7255 p

South America

EVAPCO Brasil

Equipamentos Industriais Ltda.

Al. Vênus, 151 – CEP: 13347-659

Indaiatuba –São Paulo – Brasil

(55+11) 5681-2000 p

Fan Technology Resources

Cruz das Almas – Indaiatuba

São Paulo, Brasil 13308-200

55 (11) 4025-1670 p

EVAPCO, Inc.

World Headquarters

P.O. Box 1300

Westminster, MD 21158 USA

410-756-2600 p | 410-756-6450 f

EVAPCO East

5151 Allendale Lane

Taneytown, MD 21787 USA

410-756-2600 p | 410-756-6450 f

EVAPCO East

Key Building

Taneytown, MD USA

410-756-2600 p

EVAPCO Midwest

Greenup, IL USA

217-923-3431 p

EVAPCO West

Madera, CA USA

559-673-2207 p

EVAPCO Iowa

Lake View, IA USA

712-657-3223 p

EVAPCO Iowa

Sales & Engineering

Medford, MN USA

507-446-8005 p

EVAPCO Newton

Newton, IL USA

618-783-3433 p

EVAPCOLD

Greenup, IL USA

217-923-3431 p

North America

EVAPCO...SPECiAliStS in HEAt trAnSfEr PrOduCtS And SErViCES.

Visit EVAPCO’s Website at: evapco.com

AT ATLAS Induced Draft Counterow Cooling Towers

2

Table of Contents

Introduction............................................................................................3

Shipping ..............................................................................................3

Nomenclature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Structural Steel Support .................................................................................4

Rigging Basin Sections ..................................................................................5

Joining Bottom Sections .................................................................................5

Application of Sealer Tape to Basin Sections ................................................................7

Rigging Casing Sections .................................................................................8

Assembly of the Casing Sections to the Basin Sections .......................................................8

Assembly of Bottom Inlet Piping .........................................................................10

Application of Sealer Tape to Casing Sections ..............................................................11

Rigging Fan Sections...................................................................................12

Assembly of the Fan Sections to the Casing Sections........................................................13

Rigging Fan Sections on Multicell Units ...................................................................14

Fan Sealing ...........................................................................................15

Extended Lifts.........................................................................................15

Floating Shaft Installation & Alignment ....................................................................16

Fan Assembly Instructions ..............................................................................17

Rigging Drive Assembly ................................................................................18

Fan Cylinder Assembly .................................................................................19

Fan Cylinder Rigging ...................................................................................20

Fan Cylinder Sealing ...................................................................................21

External Platform and Vertical Ladder Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

AT ATLAS Induced Draft Counterow Cooling Towers

3

Introduction

Thank you for purchasing your EVAPCO AT ATLAS, counterow, induced draft cooling tower. This manual provides instructions and

recommendations to safely and correctly install all AT ATLAS cooling towers. It is recommended that all instructions provided in this

manual are reviewed prior to rigging and assembly. If at any point specic circumstances not covered by this manual arise please

contact your local EVAPCO representative for assistance.

Proper care must be taken by all parties involved in handling and assembling the equipment to ensure that safe and

thorough installation practices are implemented to prevent damage or injury to the equipment, persons and environment

involved.

Shipping

Unless otherwise noted in the factory submittal, all EVAPCO AT ATLAS towers ship in seven (7) sections per cell plus the drive

system, fan and fan cylinder. Any special shipping congurations will be listed in the factory submittal. Please contact your local

EVAPCO representative for more information on alternate shipping congurations.

Nomenclature

AT 124-4N30-EV

Produc

t

Ty

pe

# of

Cells

Unit

Width

Layers of

Fill Media

Horsepower

Designator

Unit LengthFill

Ty

pe

Product Type

AT – Indicates an Advanced Technology (AT) tower.

# of Cells

Determined by the number of inlet connections, can be 1 or 2 cells.

Unit Width

The total width of the unit, in feet, all cells included.

Layers of Fill Media

Determined by the number of 1 foot tall ll layers. Can be 4 or 5.

Horsepower Designator

Determined by the horsepower per fan motor. Available from N = 40 HP to T = 150 HP.

Unit Length

The total length of the unit, in feet, all cells included.

Fill Type

Indicated the style of heat transfer media in the tower.

AT ATLAS Induced Draft Counterow Cooling Towers

4

Structural Steel Support

As standard, three structural “I” beams running the length of the unit are required for support of each cell. These beams should

be located underneath the outer anges of the unit (See Figure 1 and 1a). Transverse steel arrangements are also available (see

Figures 1b and 1c). Mounting holes 3/4” (19mm) in diameter are located in the bottom anges of the unit for bolting to the structural

steel (See steel support print in unit submittal for exact bolt hole location). Bolt the bottom sections to the steel support before

rigging the top sections.

Beams should be sized in accordance with accepted structural practices. Maximum deection of the beam under the unit to be

1/360th of the unit length, not to exceed 1/2” (13mm). Deection may be calculated by using 55% of the operating weight of the unit

as a uniform load on each beam (See certied print in unit submittal for operating weight).

The supporting “I” beams should be level before setting the unit. Do not level the unit by shimming between the bottom anges and

the beams as this will not provide proper and continuous longitudinal support. Support beams and anchor bolts are to be furnished

by others.

Please refer to the unit submittal for detailed, project specic steel support arrangement.

24’

48’

30’

30’

Figure 1 - Standard Longitudinal Steel Support Arrangement

for 24’ x 30’ ATLAS

Figure 1b - Standard Transverse Steel Support Arrangement

for 24’ x 30’ ATLAS

Figure 1a - Standard Longitudinal Steel Support Arrange-

ment for 48’ x 30’ ATLAS

Figure 1c - Standard Transverse Steel Support Arrangement

for 48’ x 30’ ATLAS

AT ATLAS Induced Draft Counterow Cooling Towers

5

Rigging Basin Sections

Lifting devices are located along the inside edges of the bottom section for lifting and nal positioning purposes as shown in Figure 2.

The hook of the crane must be a minimum dimension of 26’ above the top of the basin section to prevent undue strain on the lifting

devices. If applicable, see “Extended Lifts” on page 15 for proper arrangement.

Bolt the bottom sections to the steel support before rigging the top sections.

Figure 2 - Rigging Unit Bottom Section - 1 Basin

26' (7.9m)

Joining Bottom Sections

Each 24’ x 30’ ATLAS basin is composed of two (2) 12’ x 30’ sections, connected by three (3) ume boxes for equalization.

In addition to the equalizer umes, these units are provided with horizontal drip channels and vertical splash guards to keep water

from splashing out from between the cells.

The equalizer ume boxes are shipped loose for eld assembly. It is important to connect the equalizer umes to balance the water

level in the basins for proper pump suction operation. The procedures that follow should be performed in sequence.

ATLAS Flume Box Installation Instructions:

1. Rig one of the bottom sections of the cooling tower. Bolt to steel support.

2. One face of the ume box is provided with 3/8” (10mm) welded bolts. Clean the mating ume opening on the rigged bottom

section and apply a layer of sealer tape on this surface, centered between the hole centers and the outside edge. Remove

paper backing strip from sealer tape.

3. Align the bolt holes in the rigged bottom section with the welded 3/8” (10mm) bolts on the ume box.

4. Install 3/8” (10mm) nuts and washers on every bolt around the ume opening and tighten.

AT ATLAS Induced Draft Counterow Cooling Towers

6

5. Repeat steps 2-4 for all 3 ume boxes.

6. Rig the second basin adjacent to the equalizer ume on the steel support as shown in Figure 3.

7. Clean the mating surfaces of the ume box and the surface of the ume opening on the adjacent section. Apply sealer tape to

the anged ume opening on the adjacent section.

8. Align the bolt holes in the ume box and ume opening with drift pins (by others) while drawing the second bottom section

against the ume box.

9. Install 3/8” (10mm) bolts, nuts, and washers in every hole around the ume opening and tighten.

10. Bolt the second bottom section to the steel support.

Drip Channel and Splash Guard Installation Instructions (this may be completed after the unit is completely rigged):

1. Remove the 1/4” (6mm) hardware which holds the drip channel retaining clips to the side panel. Place the drip channel over

the adjoining basin section anges. Turn around the retaining clips and install them using the same hardware.

2. Apply a single layer of sealer tape to the mating ange of the drip channels (see Figure 3a). Fasten drip channels together

end-to-end by driving a self-tapping 5/16” (8mm) screw through the section end with the larger hole into the mating end with

the smaller hole. Stainless steel units will use 5/16” (8mm) stainless steel nuts and bolts.

3. Add sealer tape to bottom of vertical splash guard. Place the vertical splash guard in the bend of the vertical supports. On

galvanized units, attach the vertical splash guard using 5/16” (8mm) self-tapping screws. On stainless steel units, attach the

vertical splash guards using 5/16” (8mm) stainless steel nuts and bolts. (See Figure 3)

4. Once the bottom of the vertical splash guard has been attached to the drip channel, place the ller cap channel in the upper

anges of the basin as shown in Figure 3. Attach to vertical splash guards using 5/16” (8mm) tappers (for galvanized units) or

stainless steel nuts and bolts (for stainless steel units).

Filler Cap Channel to be installed after the casing sections are rigged.

FILLER CAP

CHANNEL

VERTICAL SPLASH

CHANNEL

EQUALIZER

FLUME BOX

DRIP CHANNEL

VERTICAL SPLASH

CHANNEL

SIDE PANEL

EQUALIZER

FLUME BOX

SEALER TAPE

DRIP CHANNEL

VERTICAL

SPLASH

GUARD

RETAINING

CLIP

Figure 3 - Joining Bottom Sections

AT ATLAS Induced Draft Counterow Cooling Towers

7

Figure 3a - Drip Channel and Vertical Splash Guard Installation

DRIP CHANNEL

SECTION

5/16"

HARDWARE

SEALER

TAPE

DRIP

CHANNEL

RETAINING

CLIP

SIDE PANEL

TAPPERS (GALVANIZED)

OR STAINLESS STEEL

BOLTS (STAINLESS)

DRILLING IS

REQUIRED

IN THE FIELD

FOR THESE

HOLES

Figure 4 - Sealer Tape on Flange of Basin Section

1LAYER OF SEALER TAPE

CENTERED OVER THE

MOUNTING HOLES

1LAYER OF SEALER TAPE

CENTERED OVER THE

MOUNTING HOLES

END SIDE

Application of Sealer Tape to Basin Sections

Once the basin sections have been set on the support steel and all fasteners are installed, the top anges should be wiped down

to remove any dirt or moisture. Apply one layer of sealer tape along the 12’ and 30’ sides, centered over the mounting hole (see

Figure 4).

The sealer tape should overlap on the corners as shown in Figure 4. Do not splice the sealer tape along the 12’ long end anges.

Sealer tape will need to be spliced and overlapped on the 30’ sides.

Always remove the paper backing from the sealer tape.

AT ATLAS Induced Draft Counterow Cooling Towers

8

Rigging Casing Sections

Lifting ears are provided in the corners of the casing sections and along the length (4 total lifting ears per side) for lifting and nal

positioning. The hook of the crane must be a minimum dimension 26’ above the casing sections to prevent undue strain on the

lifting ears.

Assembly of the Casing Sections to the Basin Sections

Before securing the casing sections to the basin sections, remove any loose parts shipped in the basin.

Wipe the anges on the bottom of the casing sections. Units are also provided with match markings on each section (i.e. A1 of

basin section should match up with A1 of casing section).

Lower the casing section to within several inches of the basin section making sure the two sections do not touch and the sealer

tape is not disturbed. Lower the casing section the rest of the way and fasten all four corners. See Table 1 for recommended

hardware. Make use of drift pins to simplify the nal positioning process (see Drift Pin explanation below).

Install the remaining fasteners, working from the corners towards the center. Fasteners must be installed in every hole in the anges.

Use of Drift Pins for Final Positioning

Drift pins are tools used to align holes in the anges of the casing and basin sections of the unit prior to nal fastening. They are

occasionally used in the positioning of the basin section as well.

Once the sealer tape is applied and the casing section is hovering over the basin section, a drift pin should be driven into each of

the corner bolt holes. Using drift pins in the corners (at minimum) is meant to restrict the sideways motion of the casing section

relative to the basin section.

A drift pin should be used in intermediate bolt holes in the rigging seams as needed to maintain alignment.

Figure 5 - Rigging a Unit Casing Section

H

26' (7.9m)

AT ATLAS Induced Draft Counterow Cooling Towers

9

Figure 6 - Assembling Casing and Basin Sections

Notes:

The side anges located in between cells can be accessed from inside the unit.

Bolts can be driven upward through the mating anges if access is restricted.

All rigging hardware is provided by EVAPCO. Drift pins are by others. The recommended drift pin is 3/16” punch size with

10” overall length.

Units Hardware Sizes

All ATLAS Units 3/8” (10mm) Nuts, Bolts & Washers (Galvanized or Stainless)

Table 1 - Hardware Sizes

AT ATLAS Induced Draft Counterow Cooling Towers

10

Assembly of Bottom Inlet Piping

On the ATLAS tower, the inlet connection is located on the bottom as standard. Internal piping is provided that allows the process

water to make its way to the hot water distribution system. Please follow the below steps to complete eld installation of the bottom

inlet after the unit is rigged.

1. On the ATLAS tower, the inlet connection is located on the bottom as standard.

2. Locate the bottom inlet assembly components, namely the riser pipes, two exible reinforced pipe connectors per basin, four

pipe clamps per basin and the lower pipe anged spool. These components are fastened securely in the unit’s basin prior to

shipment.

2a. Remove shipping strap under pipe.

3. Align the riser pipe assembly with the upper pipe section in the bottom of the casing section. Loosen the pipe clamp and slip

the pipe connector up over the upper pipe section.

4. Tighten all pipe clamps (4 per basin: 2 on the upper). A ratchet wrench is recommended (See Figure 7).

5. Repeat this process for each riser pipe.

6. After tower is fully installed, insert the lower pipe anged spool with gaskets between anges, as shown in Figure 8. Use

hardware noted in Table 2

Figure 8 - Installation of Bottom Inlet Piping

UPPER PIPE

CONNECTOR AND

PIPE CLAMPS

LOWER PIPE

FLANGED SPOOL GASKET

Units Hardware Sizes

All ATLAS Units 7/8” (22mm) Nuts, Bolts & Washers (Galvanized or Stainless)

Table 2 - Hardware Sizes

RATCHET

WRENCH

UPPER PIPE

Figure 7 - Casing Bottom Inlet Piping

AT ATLAS Induced Draft Counterow Cooling Towers

11

Figure 9 - Fan to Casing Section Sealing

A

DETAIL A

TWO OVERLAPPING LAYERS OF SEALER TAPE

ON FLANGES BETWEEN CASING SECTIONS

FOR CENTER FAN SECTION SEALING

ONE LAYER OF SEALER TAPE

CENTERED OVER THE MOUNTING HOLES

APPLY CAULK INSIDE TO FAN

SECTION TOP AND END SEAMS

AFTER RIGGING

Application of Sealer Tape to Casing Sections

Once the casing sections have been rigged to the basin sections and all fasteners are installed, the top anges should be wiped

down to remove any dirt or moisture. Apply one layer of sealer tape, centered over the mounting holes (see Figure 9). On the

anges between casing sections, apply two strips of sealer tape, one partially overlapping the other on the entire length of the

anges. Apply sealer tape to the entire perimeter of the casing sections. Do not splice the sealer tape along the 12’ long end

anges. Sealer tape will need to be spliced and overlapped on the 30’ sides.

Always remove the paper backing from the sealer tape.

AT ATLAS Induced Draft Counterow Cooling Towers

12

Figure 10B - Rigging of End Fan Module

Figure 10A - Rigging of Middle Fan Module

26' (7.9m)

26' (7.9m)

Rigging Fan Sections

Each ATLAS unit has 3 fan sections: left, right and middle. On the middle section, lifting ears are provided for lifting and nal

positioning. For the left and right sections, “U” bolts are provided. The hook of the crane must be a minimum of 26’ above the lifting

device to prevent undue strain on the lifting ears and “U” bolts. See Figures 10A and 10B for the middle section and end sections,

respectively.

AT ATLAS Induced Draft Counterow Cooling Towers

13

Assembly of the Fan Sections to the Casing Sections

The fan sections rigging should begin with an end fan module, followed by the middle fan module and nally followed by the last

end fan module.

Drift pins should be used to align the fan section with the casing section. The installer will need to attach the fan section end

panels to the casing section end panels and the fan section side panels to the casing section side panels with 3/8” hardware.

Units are provided with match markings on each section to assist with arrangement (i.e. A1 of casing section should match up with

A1 of fan section).

Figure 11 - Assembling Fan and Casing Sections

AT ATLAS Induced Draft Counterow Cooling Towers

14

Figure 12 - Fan and Casing Rigging - Multicell

Rigging Fan Sections on Multicell Units

In multicell installations, placing multiple towers side-by-side will limit access between cells and make rigging more difcult.

Therefore multicell rigging channels will come attached to the inside of the casing and fan section panels, as shown in Figure 12.

Once the sections are mounted, the anges of the rigging channels must be bolted from inside the unit. Use hardware noted in

Table 3. The fasteners in the rigging channels are in addition to the fasteners required around the perimeter of the fan section.

CASING RIGGING CHANNEL

FAN SECTION RIGGING CHANNEL

DETAIL A

SEE DETAIL A

Units Hardware Sizes

All ATLAS Units 3/8” (10mm) Nuts, Bolts & Washers (Galvanized or Stainless)

Table 3 - Hardware Sizes

AT ATLAS Induced Draft Counterow Cooling Towers

15

Extended Lifts

Important: The lifting devices and “U” bolts should be used for nal positioning only and for lifting where no danger

exists. If they are used for extended lifts, safety slings should be provided under the sections.

Safety slings and skids must be removed before nal positioning of the unit.

The preferred method for extended lifts is to use slings under the unit, as shown in Figure 14 below. Spreader bars should always

be used between the cables at the top of the section to prevent damage to the upper anges.

Figure 14 - Extended Lifts

SAFETY SLING

26' (7.9m)

SAFETY SLING

26' (7.9m)

Fan Sealing

After rigging, apply caulk to the top and end seams of the fan sections (Figure 13). This must be done from the inside of the unit.

APPLY CAULK TO FAN

SECTION TOP AND END

SEAMS AFTER RIGGING

Figure 13 - Fan Section Sealing

AT ATLAS Induced Draft Counterow Cooling Towers

16

5. Check angular and axial misalignment between the drive shaft and both the motor and gear drive couplings.

6. Check angular misalignment with a dial indicator on gear drive side.

7. Attach the dial indicator support to the drive shaft and position the indicator tip to read off the opposite side ange.

8. With the dial indicator set to zero, rotate the shaft 360° and record the indicator readings at 90° increments.

9. The range between minimum and maximum values should be less than 0.010” (0.25mm). If alignment is out of tolerance, add

shims (not exceeding 1/4”).

10. When the angular alignment is within the acceptable ranges as mentioned in step 9, securely tighten all gear drive hardware.

11. Repeat steps 6 through 10 on the motor side of the drive shaft.

12. Check axial misalignment with a tape measure or dial caliper. Refer to Table 5 for axial alignment gap limits.

Angular Misalignment Axial Misalignment

Table 4 - Torque Requirements for Floating Shaft Assemblies

Shaft Model Torque Requirement

LRR 350 400 in-lbs (33 ft-lb 45 Nm)

LRR 375 400 in-lbs (33 ft-lb 45 Nm)

LRR 450 145 in-lbs (12 ft-lb 16 Nm)

LRA 485 240 in-lbs (20 ft-lb 27 Nm)

Floating Shaft Installation & Alignment

The fan motor and gear reducer will ship mounted to the mechanical equipment support. The system will be prealigned in the

factory, however alignment should be veried prior to rigging the mechanical equipment support to the fan section.

The steps for alignment of the oating shaft are:

1. Mount the drive shaft with the exible element assembly on the gear drive input shaft using the supplied 3/8” (10mm)

hardware. All bolts, lock washers and nuts are supplied with the drive shaft kit.

2. Insert steel bushings into the composite exible elements on the motor side.

3. Mount the drive shaft with the exible element assembly on the motor output shaft using the supplied 3/8” (10mm) hardware.

All bolts, lock washers and nuts are supplied with the drive shaft kit.

4. Torque requirements for the bolts are listed in Table 4 (these values are dependent upon the shaft model). Use a torque

wrench to properly torque all drive shaft bolts.

Table 5 - Axial Alignment Gap Limits

Shaft Model Axial Alignment Gap Limits

LRR 350 0.42-0.44 in. (10.7mm-11.2mm)

LRR 375 0.53-0.55 in. (13.5mm-14.0mm)

LRR 450 0.42-0.44 in. (10.7mm-11.2mm)

LRA 485 0.58-0.62 in. (14.9mm-15.9mm)

AT ATLAS Induced Draft Counterow Cooling Towers

17

Fan Assembly Instructions

Once the gear drive has been aligned the fan should be assembled onto the mechanical equipment assembly. This simplies

assembly by completing it at ground level and reducing the number of lifts required.

Hudson Fan:

Please see “Tuf-Lite® III Fans 4000KW Series Hub Installation Manual” and Figure 15.

H

LOCKING COLLAR

BUSHING

FAN BLADE

TOP OF GEAR BEARING

GEAR SHAFT

HUB

Figure 15 - Hudson Fan Mounting

Table 7 -Moore Fan Hub Distance

Table 6 -Hudson Fan Hub Distance

Gear Drive “H”

1008 8.5”

1110 7”

1311 6”

Gear Drive “H”

1008 7”

1110 6”

1311 5”

Figure 16 - Moore Fan Mounting

Moore Fan (Class 10000):

Please see “Moore Fans Class 10000 Fans Owners Manual” and Figure 16.

H

TOP OF GEAR BEARING

LOCKING COLLAR

BUSHING

GEAR SHAFT

HUB

GEAR DRIVE H

1008 7”

6”

5”

1110

1311

The relevant, above-mentioned manuals will be sent along with the tower.

AT ATLAS Induced Draft Counterow Cooling Towers

18

Units Hardware Sizes

All ATLAS Units 1/2” (13mm) Nuts, Bolts & Washers (Galvanized or Stainless)

Table 8 - Hardware Sizes

Rigging Drive Assembly

Once the gear drive has been aligned and the fan assembled onto the gear output shaft, the entire assembly should be lifted

onto the fan section (Figure 17). The hook of the crane must be a minimum of 17’ above the lifting ears. See Table 8 for hardware

required to attach the drive assembly to the fan deck. Be sure to position the lifting cables between fan blades so as not to damage

the fan during the lift.

17'-0" (5.2m)

Figure 17 - Rigging Drive System

AT ATLAS Induced Draft Counterow Cooling Towers

19

Figure 18 - Fan Cylinder Assembly

Fan Cylinder Assembly

The fan cylinder will ship in 10 sections for assembly and installation in the eld. Each section will be joined with a ange as shown

in Figure 18. Fan cylinder assembly should be performed on the ground with one person holding the sections up until the assembly

is able to stand alone. See Table 9 below for hardware required to assemble the fan cylinder.

Lifting devices to be installed in between cylinder sections during assembly. Remove lifting device after installing fan cylinder if the

tower has a Super Low Sound Fan.

Flanges should be cleaned prior to assembly. Each cylinder should have 5 lifting devices total, installed in every other cylinder

panel seam.

ASSEMBLE CYLINDER PANELS USING

PROVIDED 3/8" HARDWARE

(SEE DETAIL A)

A

DETAIL A

(TYPICAL)

*ASSEMBLE CYLINDER PANELS

WITH LIFTING DEVICE SANDWICHED

BETWEEN EVERY OTHER PANEL

3/8" NYLOCK NUT

3/8" FENDER WASHER

3/8" FENDER WASHER

3/8" DIA X 1 3/4" BOLT

*REMOVE LIFTER AFTER INSTALLING CYLINDER

Units Hardware Sizes

All ATLAS Units 3/8” (10mm) Nuts, Bolts & Washers

Table 9 - Hardware Sizes

AT ATLAS Induced Draft Counterow Cooling Towers

20

Fan Cylinder Rigging

Lower cylinder carefully around fan and drive shaft using the provided lifting ears. The hook of the crane must be a minimum of

17’ above the lifting ears. Make sure fan assembly is centered within the cylinder before attaching to fan section. Measure the

clearance between each fan tip and the cylinder with a tape measure, making sure it is 7/8” (22mm) or less.

Fasten to fan deck using hardware in Table 10. Holes are to be drilled through the cylinder and fan deck in the eld from outside

the tower.

17'-0" (5.2m)

Figure 19 - Fan Cylinder Rigging

Units Hardware Sizes

All ATLAS Units 3/8” (10mm) Nuts, Bolts & Washers (Galvanized or Stainless)

Table 10 - Hardware Sizes

Table of contents

Other EVAPCO Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Gage Bilt

Gage Bilt GB924 Original instructions

ABB

ABB HT611531 Operation manual

Siemens

Siemens SIMATIC ET 200M operating instructions

Muller

Muller HUDRO-GUARD 100 Series Operating instructions manual

Belimo

Belimo LM24A-MOD Technical data sheet

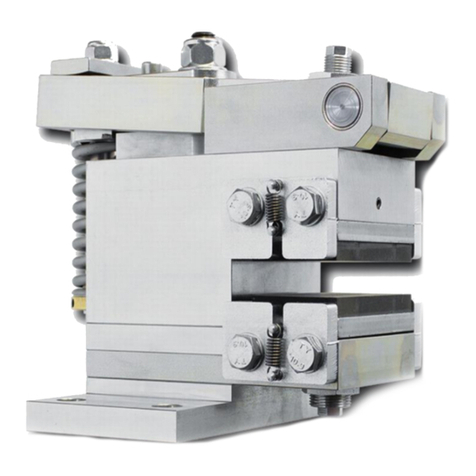

SMW Autoblok

SMW Autoblok Mario Pinto LT Use and maintenance instructions

Metz Connect

Metz Connect OpDAT REG K Series Mounting Note

Trane Technologies

Trane Technologies WIR10523 Installer's guide

Dedoes

Dedoes Alliance manual

RINGSPANN

RINGSPANN Brake EV 018 Installation and operating instructions

Green Eco Pro

Green Eco Pro GEP200M-300L instruction manual

Enduro

Enduro EM304 user manual