EVAPCO PMC-E User manual

Rigging

Assembly

Instructions

&

PMC–E

FORCED DRAFT,

EVAPORATIVE

CONDENSERS

BULLETIN 125D

2

PMC-E FORCED DRAFT EVAPORATIVE CONDENSERS

Table of Contents

Method of Shipment . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Storage. . . . . . . . . . .. . . . . .. . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

General . . .. . .. . . . . . . . . . . . .. . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . .4

International Building Code Provisions .. . . . . . . .. . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . .4

Structural Steel Support. . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . .4-5

Rigging the Basin/Fan Section —Standard Lift . . . . . . . . .. . . . . . . . . . . . . . .. . .. . . . . . . . . . . . . . .5-6

Rigging the Basin/Fan Section —Extended Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Applying Sealer Tape . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Rigging the Coil Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7-8

Assembly of the Coil Section to the Basin/Fan Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Optional Straight-Sided Hood Section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

Rigging Hardware Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Field Assembly of External Service Platform and Ladder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Final Assembly and Startup Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

The PMC SERIES FORCED DRAFT EVAPORATIVE CONDENSERS should be

rigged and assembled using the instructions and recommendations

outlined in this bulletin.

All personnel should review these procedures, as well as the latest industry-approved

Installation practices, prior to rigging and assembly. The information in this bulletin is

for informational purposes only. These instructions do not purport to cover all variations

and possible contingencies in connection with installation. Additionally, the procedures

described therein are subject to change without prior notice, due to EVAPCO, Inc.’s

ongoing research and development.

EVAPCO, Inc. makes no representations or warranties with respect to these instructions

or the products described herein. Nor shall EVAPCO, Inc. be responsible for any loss or

damage (direct, indirect, consequential, or other) during installation or handling of

equipment after shipment.

For a full description of EVAPCO’s liability policy, please visit www.evapcoasia.com to access our

Terms and Conditions.

3

PMC-E FORCED DRAFT EVAPORATIVE CONDENSERS

TECHNOLOGY FOR THE FUTURE, AVAILABLE TODAY

Visit EVAPCO’s Website at: http://www.evapcoasia.com

EVAPCO Asia/Pacific

1159 Luoning Rd, Baoshan Industrial Zone, Shanghai, China 200949

PHONE: (86) 21-6687-7786 ∙ FAX: (86) 21-6687-7008 ∙ E-MAIL: marketing@evapcochina.com

FOR EVPCO AUTHORIZED

PARTS AND SERVICE,

CONTACT YOUR

LOCAL EVAPCO

REPRESENTATIVE

OR THE LOCAL

SERVICE CENTER

4

PMC-E FORCED DRAFT EVAPORATIVE CONDENSERS

Method of Shipment

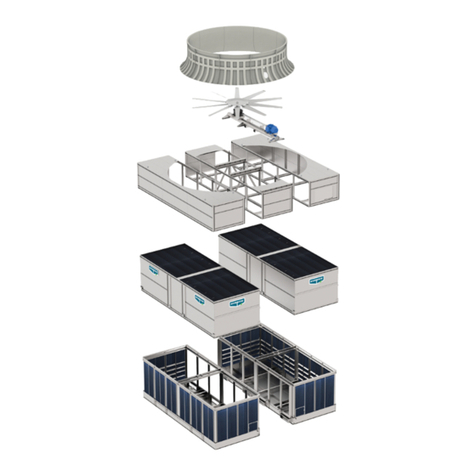

Forced draft units are shipped either fully assembled (small units) or with the coil section(s) separate

from the basin/fan section(s). These sections have mating flanges and will join together in a

waterproof joint when sealed and bolted together as described in the following instructions.

Miscellaneous items, such as sealer, self-tapping screws and any other required materials, are

packaged and placed inside the pan for shipment.

NOTE: All casing sections are factory inspected prior to shipment to verify proper fit for rigging.

Please take extra care to handle and rig each section per the instructions of this manual to

avoid possible distortion and poor casing alignment. It is advisable to check each section upon

receipt and during each lift to ensure that the factory alignment has not been altered. Should

the field inspection indicate the section alignment (“square”) has been altered, please contact

the factory or your local EVAPCO representative for additional instructions to obtain proper

section fit.

Storage

Do not place tarps or other coverings over the top of the units if the units are to be stored before

installation. Excessive heat can build up if the units are covered causing possible damage to the PVC

eliminators. For extended storage beyond six months rotate the fan and fan motor shaft(s) monthly.

Also, the fan shaft bearings should be purged and regreased prior to startup.

General

For extended lifts, or where hazards may exist, it is recommended that safety slings and spreaders be

employed for safety. Refer to the extended lift information in this bulletin.

International Building Code Provisions

The International Building Code (IBC) is a comprehensive set of regulations addressing the structural

design and installation requirements for building systems–including HVAC and industrial

refrigeration equipment. Since June 2008, all 50 states plus Washington, D.C. have adopted the

International Building Code. The code provisions require that evaporative cooling equipment and all

other components permanently installed on a structure must meet the same seismic design criteria

as the building. The PMC-E condensers are compliant with the latest IBC codes.

All items attached to the EVAPCO PMC-E evaporative condenser must be independently reviewed

and isolated to meet applicable wind and seismic loads. This includes piping, ductwork, conduit, and

electrical connections. These items must be flexibly attached to the EVAPCO unit so as not to

transmit additional loads to the equipment as a result of seismic or wind forces.

Structural Steel Support

Two structural I-beams running the length of the unit are required for supporting the unit. These

beams should be located underneath the outer flanges of the unit as shown in Figure 1. See Table 1

for steel support dimensions.

Mounting holes, 3/4”(19mm) in diameter, are located in the bottom flange for bolting to the struc-

tural steel. Refer to the recommended structural steel support drawing and certified print for exact

bolt hole location. Bolt the basin/fan section to the steel support before rigging the coil section.

Beams should be sized in accordance with accepted structural practices. Maximum deflection of the

beam under the unit should be 1/360 of the unit length, not to exceed 1/2”(13mm). Deflection may

be calculated by using 55% of the operating weight as a uniform load on each beam (see certified

print for operating weight).

5

PMC-E FORCED DRAFT EVAPORATIVE CONDENSERS

The supporting I-beams should be level to within 1.5mm in 1m before setting the unit. Do not level

the unit by shimming between the bottom flange and the beams as this will not provide proper

longitudinal support.

NOTE: Consult the latest version of the IBC code for required steel support layout and structural

design.

Table 1 –Steel Support Dimensions

Box Size (m) A (mm) B (mm)

1.5m Wide Models

1.5 x 3.6 3648 1930

1.5 x 5.4 5490 1930

3m Wide Models A (mm) B (mm)

3 x 3.6 3651 2991

3 x 5.4 5490 2991

3 x 7.2 7337 2991

3 x 11 11024 2991

3.6m Wide Models A (mm) B (mm)

3.6 x 3.6 3651 3616

3.6 x 5.4 5490 3616

3.6 x 6 6102 3616

3.6 x 7.2 7337 3616

3.6 x 11 11024 3616

3.6 x 12.2 12243 3616

Plan View

End Elevation

Figure 1 –Structural Steel Support

(See Table 2 for model numbers corresponding to box size)

Rigging the Basin/Fan Section —Standard Lift

U-bolts or similar lifting points are located in the basin/fan section for lifting and final positioning

purposes as shown below in Figures 2 and 3. Units with lengths up to 6m have 4 total lift points.

Units with lengths over 6m long units have either 6 or 8 lift points. See Table 2 for the minimum

“H” dimensions for rigging the basin/fan assembly. Always use safety slings for extended lifts or

where any hazard exits. See the “Extended Lifts” section in this bulletin.

NOTE: Use all of the U-bolts or lift points provided for lifting.

LIFTING

U-BOLTS

LIFTING

U-BOLTS

Figure 2 –Basin/Fan Section (up to 6m Long) Figure 3 –Basin/Fan Section (Over 6m Long)

Table of contents

Other EVAPCO Industrial Equipment manuals